CoCrMoNbTi refractory high-entropy alloys prepared by mechanical alloying combined with laser cladding

-

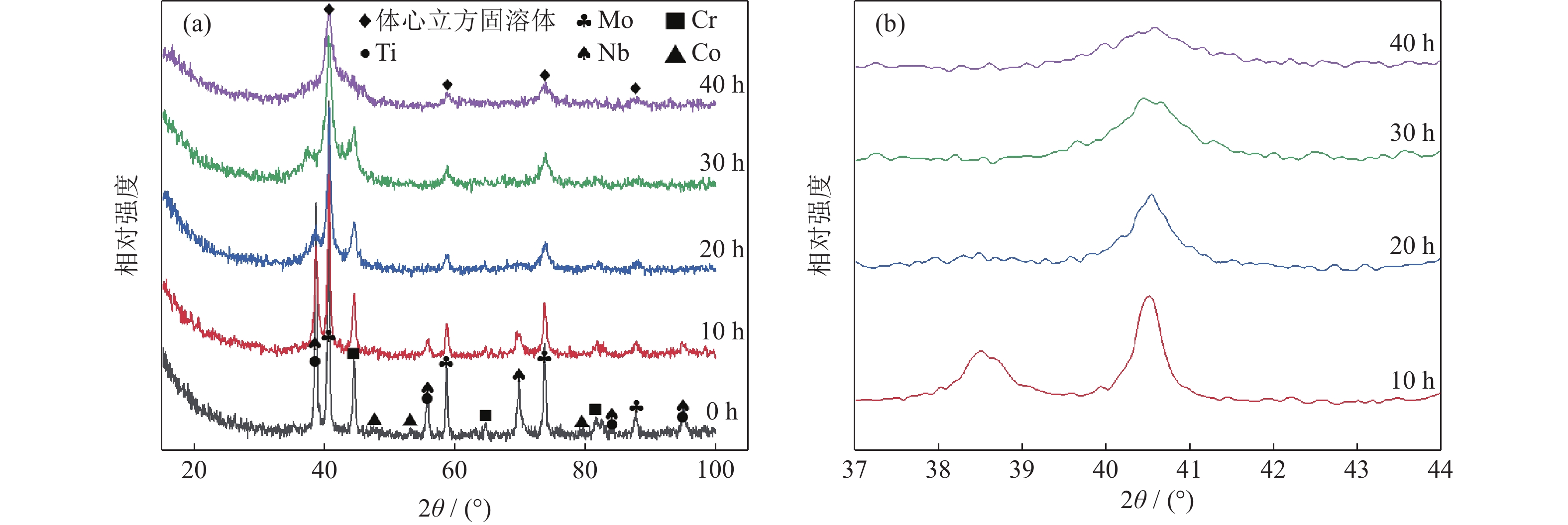

摘要: 采用机械合金化方法制备CoCrMoNbTi难熔高熵合金粉末,并通过激光熔覆技术成功制备出CoCrMoNbTi高熵合金涂层。研究了球磨时间对合金粉末组织形貌的影响,并利用X射线衍射仪、扫描电子显微镜和能谱仪等分析了高熵合金粉末和涂层的微观结构。结果表明,随着球磨时间的增加,单质金属的衍射峰按其熔点由低到高陆续消失。粉末微观形貌随球磨时间变化明显,粉末由原始状态被挤压成片状,片状粉末逐渐焊合在一起形成扁平状粉末颗粒。在球磨时间达到40 h时,粉末实现完全合金化,此时粉末形貌趋于球形且得到了极大的细化,粉末中各元素分布均匀,形成了稳定的单相体心立方固溶体结构。CoCrMoNbTi难熔高熵合金激光熔覆层成形质量良好,主要由体心立方固溶体和少量Cr2Nb、Co2Ti化合物组成,树枝晶组织细小致密。Abstract: CoCrMoNbTi refractory high-entropy alloy powders were prepared by mechanical alloying, and the CoCrMoNbTi high-entropy alloy coatings were successfully prepared by laser cladding technology. The influence of ball milling time on the phase composition and microstructure of the CoCrMoNbTi refractory high-entropy alloy powders and coatings were studied by X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy dispersive spectrum (EDS) analysis. The results show that, with the increase of milling time, the diffraction peak of the pure metal phase gradually disappears, which is mainly related to the melting point of the alloying element. In addition, the powder morphology changes significantly with the extension of milling time. The powders are extruded from the original state into the flake, and the flake powders are gradually welded together to form the flat powder particles. When the milling time reaches 40 h, the powders are completely alloyed, the powder shape tends to be spherical and greatly refined, and the elements in the powders are evenly distributed, forming a stable single-phase body-centered cubic solid solution structure. The CoCrMoNbTi refractory high entropy alloy coatings prepared by laser cladding technology have the good forming quality. The coatings are mainly composed of the body-centered cubic solid solution structure and a small amount of Cr2Nb and Co2Ti compounds, forming a fine and compact dendritic structure.

-

Key words:

- high-entropy alloys /

- mechanical alloying /

- ball milling time /

- microstructure /

- laser cladding

-

表 1 图3中不同位置的CoCrMoNbTi合金粉末能谱点扫描分析结果(原子分数)

Table 1. EDS point scanning analysis results at the different spots in Fig.3 of the CoCrMoNbTi alloy powders

% 元素 谱图1 谱图2 谱图3 Ti 17.65 18.46 19.17 Cr 19.44 22.99 19.72 Co 19.59 19.81 20.58 Nb 21.29 18.89 20.47 Mo 22.03 19.84 20.07 总量 100.00 100.00 100.00 -

[1] Han C J, Fang Q H, Shi Y S, et al. Recent advances on high-entropy alloys for 3D printing. Adv Mater, 2020, 32(26): e1903855 doi: 10.1002/adma.201903855 [2] Yang Y, He Q F. Lattice distortion in high-entropy alloys. Acta Metall Sinica, 2021, 57(4): 385杨勇, 赫全锋. 高熵合金中的晶格畸变. 金属学报, 2021, 57(4): 385 [3] Maresca F, Curtin W A. Theory of screw dislocation strengthening in random BCC alloys from dilute to "High-Entropy" alloys. Acta Mater, 2020, 182: 144 doi: 10.1016/j.actamat.2019.10.007 [4] Miao Z W, Zhu F W, Liu Q. Study on the microstructure and corrosion resistance of CoCrFeNiCuTi x high-entropy alloy. Powder Metall Technol, 2020, 38(1): 10苗振旺, 祝夫文, 刘琪. CoCrFeNiCuTi x 高熵合金的微观组织与耐腐蚀性能研究. 粉末冶金技术, 2020, 38(1): 10 [5] Senkov O N, Wilks G B, Miracle D B, et al. Refractory high-entropy alloys. Intermetallics, 2010, 18(9): 1758 doi: 10.1016/j.intermet.2010.05.014 [6] Senkov O N, Jensen J K, Pilchak A L, et al. Compositional variation effects on the microstructure and properties of a refractory high-entropy superalloy AlMo0.5NbTa0.5TiZr. Mater Des, 2018, 139: 498 [7] Nie X W, Cai M D, Cai S. Microstructure and mechanical properties of a novel refractory high entropy alloy HfMoScTaZr. Int J Refract Met Hard Mater, 2021, 98: 105568 doi: 10.1016/j.ijrmhm.2021.105568 [8] Huang Y, Wang Z, Xu Z, et al. Microstructure and properties of TiNbZrMo high entropy alloy coating. Mater Lett, 2021, 285: 129004 doi: 10.1016/j.matlet.2020.129004 [9] Li Q, Zhang H, Li D, et al. W x NbMoTa refractory high-entropy alloys fabricated by laser cladding deposition. Materials, 2019, 12(3): 533 doi: 10.3390/ma12030533 [10] Zhang G Y, Cha W S, Chen X L, et al. Application of mechanical ball milling technology in material preparation. Powder Metall Technol, 2018, 36(4): 315张桂银, 查五生, 陈秀丽, 等. 机械球磨技术在材料制备中的应用. 粉末冶金技术, 2018, 36(4): 315 [11] Prica C V, Neamtu B V, Marinca T F, et al. Synthesis of Invar 36 type alloys from elemental and prealloyed powders by mechanical alloying. Powder Metall, 2019, 62(3): 155 doi: 10.1080/00325899.2019.1625509 [12] Shivam V, Shadangi Y, Basu J, et al. Alloying behavior and thermal stability of mechanically alloyed nano AlCoCrFeNiTi high-entropy alloy. J Mater Res, 2019, 34(5): 787 doi: 10.1557/jmr.2019.5 [13] Yudanto S D, Dewi Y P, Imaduddin A, et al. Improvement in the crystallographic phase content and superconducting properties of mechanically alloyed MgB2. J Supercond Novel Magn, 2019, 32: 2829 doi: 10.1007/s10948-019-5061-0 [14] Shawon A K M A, Ur S C. Synthesis and thermoelectric property elucidation of mechanically alloyed and vacuum hot pressed single-phase AlSb. J Electron Mater, 2020, 49: 2762 doi: 10.1007/s11664-019-07726-1 [15] Qi P B, Liang X B, Tong Y G, et al. Effect of milling time on the preparation of NbMoTaW high entropy alloy powder by mechanical alloying. Rare Met Mater Eng, 2019, 48(8): 2623漆陪部, 梁秀兵, 仝永刚, 等. 球磨时间对机械合金化制备NbMoTaW高熵合金粉末的影响. 稀有金属材料与工程, 2019, 48(8): 2623 [16] Zhou Q, Wei S C, Yang S Z, et al. Preparation of FeCuNiSnCo powder by mechanical alloying and the research on physical properties of its matrix materials. Powder Metall Technol, 2019, 37(1): 30周强, 魏世超, 杨树忠, 等. 机械合金化FeCuNiSnCo粉末的制备及其胎体材料物理性能研究. 粉末冶金技术, 2019, 37(1): 30 [17] Chen C L, Suprianto. Microstructure and mechanical properties of AlCuNiFeCr high entropy alloy coatings by mechanical alloying. Surf Coat Technol, 2020, 386(1): 12443 [18] Zhu C, Li Z, Hong C, et al. Microstructure and mechanical properties of the TiZrNbMoTa refractory high-entropy alloy produced by mechanical alloying and spark plasma sintering. Int J Refract Met Hard Mater, 2020, 93: 105357 doi: 10.1016/j.ijrmhm.2020.105357 [19] Zhang M, Zhou X, Li J. Microstructure and mechanical properties of a refractory CoCrMoNbTi high-entropy alloy. J Mater Eng Perform, 2017, 26: 3657 doi: 10.1007/s11665-017-2799-z [20] Zhang M, Zhou X, Zhu W, et al. Influence of annealing on microstructure and mechanical properties of refractory CoCrMoNbTi0.4 high-entropy alloy. Metall Mater Trans A, 2018, 49: 1313 doi: 10.1007/s11661-018-4472-z [21] Peng H Y, Kang Z X, Li X Z, et al. Effects of milling time on the microstructure and properties of NbMoTaWVCr refractory high entropy alloy. Powder Metall Mater Sci Eng, 2020, 25(6): 513彭海燕, 康志新, 李小珍, 等. 球磨时间对NbMoTaWVCr难熔高熵合金组织与性能的影响. 粉末冶金材料科学与工程, 2020, 25(6): 513 [22] An X L, Liu Q B, Zheng B. Microstructure and properties of laser cladding high entropy alloy MoFeCrTiWAl x Si y coating. Infrared Laser Eng, 2014, 43(4): 1140安旭龙, 刘其斌, 郑波. 激光熔覆制备高熵合金MoFeCrTiWAl x Si y 涂层的组织与性能. 红外与激光工程, 2014, 43(4): 1140 -

下载:

下载: