-

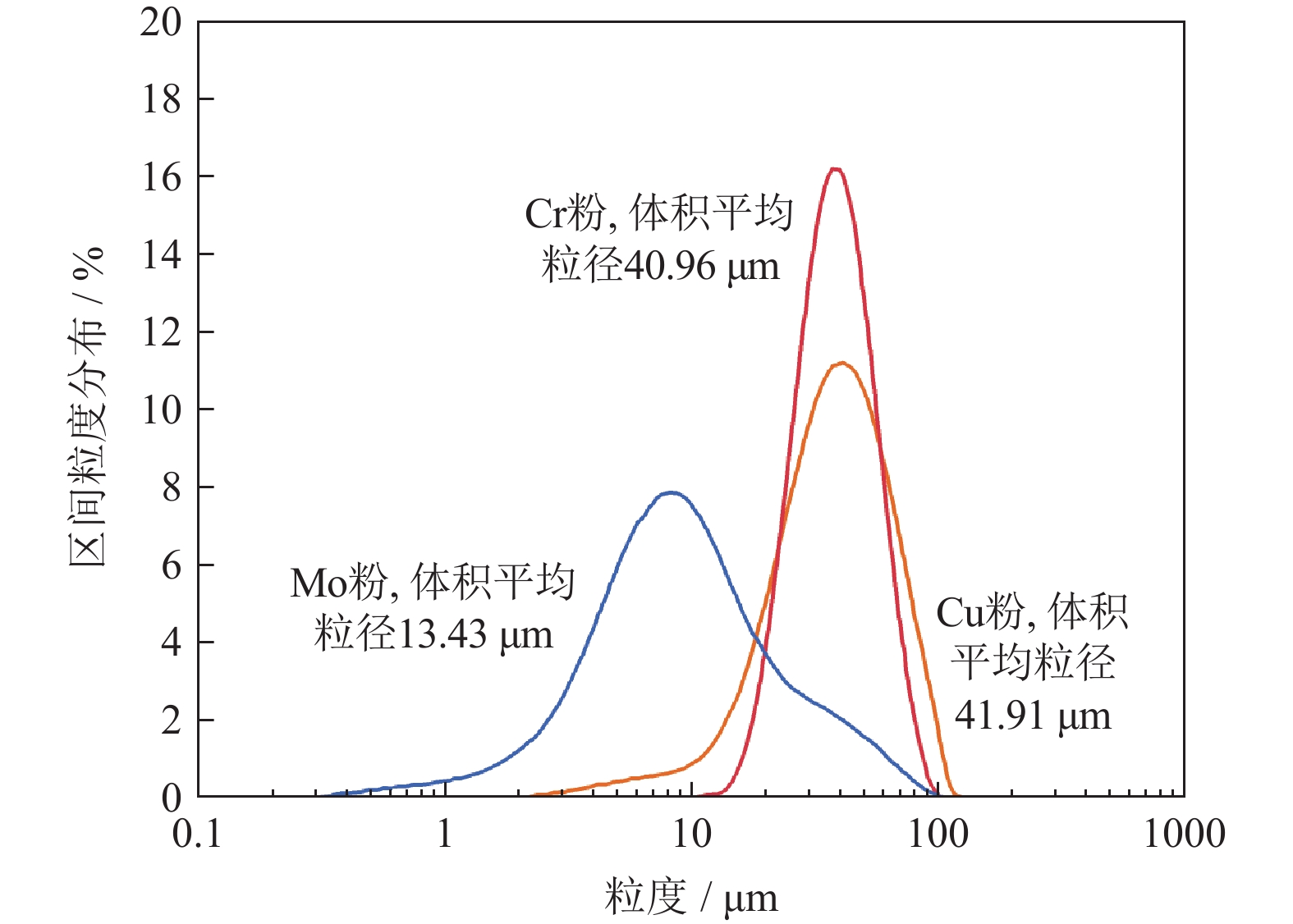

摘要: 通过机械混合和机械合金化工艺制备Cu–9.3Cr–9.3Mo(质量分数)粉末,并利用热等静压压制Cu–Cr–Mo合金。采用X射线衍射和激光粒度分析等方法表征了粉末物相、组织分布和粒度;通过对相对密度、硬度、电导率等性能检测和微观组织观察分析了合金性能。结果表明,机械合金化过程可诱导Cu–Cr–Mo过饱和固溶体形成,合金的晶格畸变程度提高,晶粒尺寸和粉末颗粒尺寸减小,制备的合金块材硬度高,相对密度和电导率理想,综合性能优异。

-

关键词:

- Cu–Cr–Mo合金 /

- 机械混合 /

- 机械合金化 /

- 过饱和固溶体 /

- 热等静压

Abstract: The Cu–9.3Cr–9.3Mo (mass fraction) powders were prepared by mechanical mixing and mechanical alloying, respectively, and the Cu–Cr–Mo alloys were pressed by hot isostatic pressing. The phase composition, organizational structure, and particle size of the powders were characterized by X-ray diffraction and laser particle size analysis. The relative density, hardness, conductivity, and microstructure of the alloys were measured. The results show that, the mechanical alloying process can induce the formation of Cu–Cr–Mo supersaturated solid solution, improve the degree of lattice distortion, and reduce the grain size and powder particle size. The prepared alloy blocks by mechanical alloying have the high hardness, ideal relative density, and electrical conductivity, showing the excellent comprehensive properties. -

表 1 Cu–Cr–Mo合金块材理论密度和相对密度

Table 1. Solid density and relative density of the Cu–Cr–Mo alloy blocks

块材类型 理论密度 / (g·cm−3) 相对密度 / % 机械混合块材 8.86 96.8±0.2 机械合金化块材 8.86 95.5±0.3 表 2 Cu–Cr–Mo合金块材性能

Table 2. Properties of the Cu–Cr–Mo alloy blocks

块材类型 硬度,HV0.3 电导率 / (%IACS) 机械混合块材 149.0±2.4 56.1±0.8 机械合金化块材 362.9±6.7 24.8±0.8 表 3 图5中不同测试点能谱分析

Table 3. EDS analysis of the different points in Fig.5

测试点 元素质量分数 / % Cu Cr Mo 1 3.51 96.33 0.16 2 98.21 1.46 0.34 3 14.50 4.73 80.77 4 42.55 30.27 27.18 5 84.38 7.32 8.31 -

[1] Jiang Y X, Lou H F, Xie H F, et al. Development status and prospects of advanced copper alloy materials. Strat Study CAE, 2020, 22(5): 84 doi: 10.15302/J-SSCAE-2020.05.015姜业欣, 娄花芬, 解浩峰, 等. 先进铜合金材料发展现状与展望. 中国工程科学, 2020, 22(5): 84 doi: 10.15302/J-SSCAE-2020.05.015 [2] Li L J, Yu F Y, Li R G, et al. Research status and development trend of high-performance copper alloys. Spec Cast Nonferrous Alloys, 2021, 41(3): 293李龙健, 于凤云, 李仁庚, 等. 高性能铜合金研究现状及发展趋势. 特种铸造及有色合金, 2021, 41(3): 293 [3] Zhao H T, Liu C. Effect of aging time on the microstructure and hardness of Cu–4.5Ti alloy by surface mechanical polishing. Powder Metall Technol, 2020, 38(2): 92赵海涛, 刘超. 时效时间对表面机械研磨处理Cu–4. 5Ti合金组织和硬度的影响. 粉末冶金技术, 2020, 38(2): 92 [4] Zeng Z F, Zhou B T, Xiong X W, et al. Research progress of SiCp/Cu composite. Powder Metall Technol, 2021, 39(2): 184曾昭锋, 周波涛, 熊宣雯, 等. SiCp/Cu复合材料的研究进展. 粉末冶金技术, 2021, 39(2): 184 [5] Shi J L, Pei J, Zhang B P, et al. Progress in the preparation of thermoelectric materials by mechanical alloying combined with spark plasma sintering. Powder Metall Technol, 2021, 39(1): 4石建磊, 裴俊, 张波萍, 等. 机械合金化结合放电等离子烧结技术制备热电材料的研究进展. 粉末冶金技术, 2021, 39(1): 4 [6] Lei R S, Chen G R, Xu S Q, et al. Preparation of nanocrystalline supersaturated solid solution by severe plastic deformation: a review. Mater Rev, 2017, 31(21): 130雷若姗, 陈广润, 徐时清, 等. 大塑性变形工艺制备纳米晶过饱和固溶体的研究进展. 材料导报, 2017, 31(21): 130 [7] Xi S Q, Zheng X X, Zheng L D, et al. High hardness conductive Cu–Cr–Mo alloy prepared by mechanical alloying // The 13th National Typical Parts Heat Treatment Academic and Technical Exchange Conference and the 10th National Heat Treatment Society Physical Metallurgy Academic Exchange Conference Proceedings. Yichun, 2015: 41席生岐, 郑晓雪, 郑良栋, 等. 机械合金化制备高硬度导电Cu–Cr–Mo合金 // 第十三届全国典型零件热处理学术及技术交流会暨第十届全国热处理学会物理冶金学术交流会论文集. 伊春, 2015: 41 [8] Kumar A, Pradhan S K, Jayasankar K, et al. Structural investigations of nanocrystalline Cu–Cr–Mo alloy prepared by high-energy ball milling. J Electron Mater, 2017, 46(2): 1339 doi: 10.1007/s11664-016-5125-x [9] Xi S, Zuo K, Li X, et al. Study on the solid solubility extension of Mo in Cu by mechanical alloying Cu with amorphous Cr (Mo). Acta Mater, 2008, 56(20): 6050 doi: 10.1016/j.actamat.2008.08.013 [10] Aguilar C, Guzmán D, Castro F, et al. Fabrication of nanocrystalline alloys Cu–Cr–Mo super satured solid solution by mechanical alloying. Mater Chem Phys, 2014, 146(3): 493 doi: 10.1016/j.matchemphys.2014.03.060 [11] Patra A, Karak S K, Pal S. Effects of mechanical alloying on solid solubility. Adv Eng Forum, 2016, 15: 17 doi: 10.4028/www.scientific.net/AEF.15.17 [12] Sun C, Hai X, Xi S, et al. New insights of solid-state alloying and amorphous-nanocrystalline cyclic phase transitions during Cr-40wt.% Mo powder milling. J Alloys Compd, 2018, 731: 667 doi: 10.1016/j.jallcom.2017.10.083 [13] Bai X B, Wang H T, Yao H L, et al. Microstructure evolution of Fe–Al alloy powder during mechanical alloying. Heat Treat Met, 2018, 43(12): 31白小波, 王洪涛, 姚海龙, 等. 机械合金化过程中Fe–Al合金粉末的组织演变. 金属热处理, 2018, 43(12): 31 [14] Hu J H, Shang H S, Cheng C, et al. Theory and process development of metal powder press forming. Hot Work Technol, 2012, 41(20): 45胡建华, 尚会森, 程呈, 等. 金属粉末压制成形理论与工艺进展. 热加工工艺, 2012, 41(20): 45 [15] Wang D B. Research on the Preparation and Performance of Advanced Wear-Resistant Copper Matrix Composites [Dissertation]. Hefei: Hefei University of Technology, 2008王德宝. 高性能耐磨铜基复合材料的制备与性能研究[学位论文]. 合肥: 合肥工业大学, 2008 [16] Li Y Y, Ni K Y, Zhu F W. Study on TiC particle-reinforced Cu matrix composites. Powder Metall Technol, 2018, 36(2): 106李月英, 倪慨宇, 祝夫文. TiC颗粒增强铜基复合材料的研究. 粉末冶金技术, 2018, 36(2): 106 [17] Adhikari K R. Electrical conductivity: Classical electron and quantum mechanical approaches. Himalayan Phys, 2014, 5: 31 [18] Fei W D. Solid State Physics. 3rd Ed. Harbin: Harbin Institute of Technology Press, 2020费维栋. 固体物理(第3版). 哈尔滨: 哈尔滨工业大学出版社, 2020 [19] Liu P, Zhang X Q, Wu X J, et al. Preparation of Cu–Cr–Zr alloy by mechanical alloying and hot-pressing sintering. Hot Working Technol, 2012, 41(6): 14刘鹏, 张修庆, 武小记, 等. 机械合金化与热压烧结法制备Cu–Cr–Zr合金. 热加工工艺, 2012, 41(6): 14 -

下载:

下载: