-

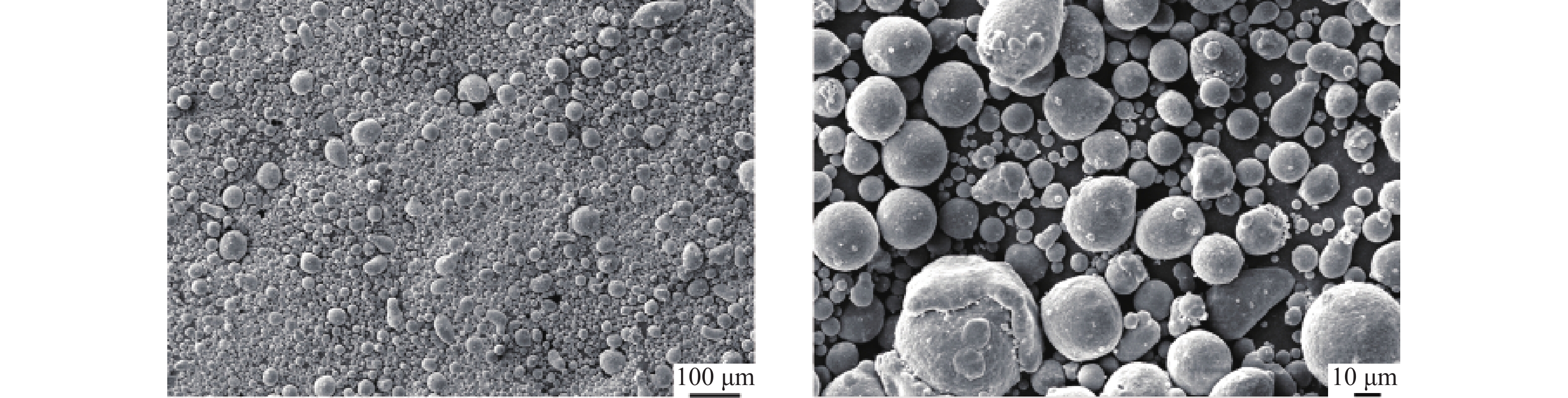

摘要: 采用粉末混合+热挤压和粉末混合+气雾化+热挤压两种工艺制备了Al–5Ti–1B合金杆,研究了两种工艺制备Al–5Ti–1B合金的显微组织,并进行了晶粒细化性能评定。结果表明:两种制备工艺均可以使TiB2粒子均匀分布,并抑制TiAl3相的长大。在7050铝合金熔体中分别添加质量分数为0.2%的两种工艺制备的Al–5Ti–1B合金,添加粉末混合+热挤压工艺制备的Al–5Ti–1B合金后,7050铝合金晶粒细化效果不明显,铝合金晶粒尺寸仍达1400 μm;添加粉末混合+气雾化+热挤压工艺制备的Al–5Ti–1B合金后,7050铝合金晶粒细化效果非常好,铝合金平均晶粒尺寸仅有176 μm。根据此实验现象,对Al–5Ti–1B合金晶粒细化双重形核机理提出新的解释。Abstract: Two kinds of Al–5Ti–1B alloys were prepared by powder mixing + hot extrusion and powder mixing + gas atomization + hot extrusion, respectively. The microstructures of the Al–5Ti–1B alloys prepared by two kinds of processes were studied, and the grain refinement properties were assessed. The results show that, the TiB2 particles can be uniformly distributed and the growth of TiAl3 phase can be inhibited by these two kinds of processes. The Al–5Ti–1B alloys with the mass fraction of 0.2% are added to the melt of 7050 aluminum alloys. The grain refinement effect of the Al–5Ti–1B alloys prepared by powder mixing + hot extrusion is not obvious, and the grain size of 7050 aluminum alloys is still up to 1400 μm. The grain refinement effect of the Al–5Ti–1B alloys prepared by powder mixing+ gas atomization + hot extrusion is very good, the average grain size of 7050 aluminum alloys is only 176 μm. According to this experimental phenomenon, a new explanation for the grain refinement and double nucleation mechanism of the Al–Ti–B alloys is proposed.

-

Key words:

- hot extrusion /

- grain refiner /

- Al–Ti–B alloys /

- powder metallurgy /

- refinement mechanism

-

表 1 Al–5Ti–2B合金样品的原材料和工艺路线

Table 1. Raw materials and the process route of the Al–5Ti–2B alloy samples

样品 原材料 工艺路线 1# Al粉,Ti粉,TiB2粉 混合–热挤压 2# Al粉,Ti粉,TiB2粉 混合–真空气雾化–热挤压 表 2 Al–5Ti–1B合金化学成分

Table 2. Chemical composition of the Al–5Ti–1B alloys

(×10−6) 样品 Ti B Zr Si Fe 1# 49716.3 9889.7 1261.8 959.5 966.9 2# 50716.3 10269.5 918.8 608.2 1480.4 -

[1] Ma S G, Xiong H, Wang Z T. Review and outlook of output of aluminum product and grain refiner requirement in the world. Light Alloy Fab Technol, 2011, 39(10): 1 doi: 10.3969/j.issn.1007-7235.2011.10.001马世光, 熊慧, 王祝堂. 回顾与展望全球铝产品产量及对晶粒细化剂的需求. 轻合金加工技术, 2011, 39(10): 1 doi: 10.3969/j.issn.1007-7235.2011.10.001 [2] Yan J M, Li P, Zuo X Q, et al. Research progress of Al–Ti–B grain refiner: mechanism analysis and second phases controlling. Mater Rep, 2020, 34(5): 152闫敬明, 黎平, 左孝青, 等. Al–Ti–B晶粒细化剂研究进展: 细化机理及第二相控制. 材料导报, 2020, 34(5): 152 [3] Zhong H Y, Yuan F S. Production method and development trend of the Al–Ti–B master alloy. Nonferrous Met Mater Eng, 2016, 37(5): 243钟海燕, 袁孚胜. Al–Ti–B中间合金生产方法及发展趋势. 有色金属材料与工程, 2016, 37(5): 243 [4] Chen Y J, Xu Q Y, Huang T Y. Development of research on grain refiners for aluminum alloys. Mater Rev, 2006, 20(12): 57 doi: 10.3321/j.issn:1005-023X.2006.12.016陈亚军, 许庆彦, 黄天佑. 铝合金晶粒细化剂研究进展. 材料导报, 2006, 20(12): 57 doi: 10.3321/j.issn:1005-023X.2006.12.016 [5] Li R X, Zhang W H, Zhang P, et al. Effect of electromagnetic stirring on the microstructure and refinement of Al–5Ti–B master alloy. Foundry, 2016, 65(1): 1 doi: 10.3969/j.issn.1001-4977.2016.01.001李润霞, 张文华, 张鹏, 等. 电磁搅拌对Al–5Ti–B中间合金组织及细化效果的影响. 铸造, 2016, 65(1): 1 doi: 10.3969/j.issn.1001-4977.2016.01.001 [6] Wang S C, Zheng K H, Qi W J, et al. Effect of electromagnetic stirring on microstructure and grain refining efficiency of Al–5Ti–1B grain refiner. Nonferrous Met Sci Eng, 2014, 5(1): 58王顺成, 郑开宏, 戚文军, 等. 电磁搅拌对Al–5Ti–1B的显微组织与晶粒细化能力的影响. 有色金属科学与工程, 2014, 5(1): 58 [7] Dong T S, Cui C X, Liu S J, et al. Study on the rapid solidification and refining mechanism of Al–Ti–B refiner. Rare Met Mater Eng, 2008, 37(1): 29 doi: 10.3321/j.issn:1002-185X.2008.01.007董天顺, 崔春翔, 刘双进, 等. Al–Ti–B细化剂的快速凝固及其细化机理研究. 稀有金属材料与工程, 2008, 37(1): 29 doi: 10.3321/j.issn:1002-185X.2008.01.007 [8] Ghadimi H, Hossein N S, Eghbali B. Enhanced grain refinement of cast aluminum alloy by thermal and mechanical treatment of Al–5Ti–B master alloy. Trans Nonferrous Met Soc China, 2013, 23: 1563 doi: 10.1016/S1003-6326(13)62631-X [9] Wang S C, Kang Y H, Zhou N, et al. Microstructure and grain refining performance of Al–5Ti–1B alloy prepared by powder compaction. Chin J Nonferrous Met, 2019, 29(8): 1583 doi: 10.1016/S1003-6326(19)65065-X王顺成, 康跃华, 周楠, 等. 粉末压制Al–5Ti–1B合金的显微组织与晶粒细化性能. 中国有色金属学报, 2019, 29(8): 1583 doi: 10.1016/S1003-6326(19)65065-X [10] Liu Y, You Q S, Zhu H M, et al. Preparation of new high hardness martensitic iron-based alloy powders by electrode induction gas atomization. Powder Metall Technol, 2021, 39(6): 537刘艳, 尤齐燊, 朱红梅, 等. 电极感应气雾化法制备新型高硬度马氏体铁基合金粉末. 粉末冶金技术, 2021, 39(6): 537 [11] Huang P Y. Theory of Power Metallurgy. 2nd Ed. Beijing: Metallurgical Industry Press, 2004黄培云. 粉末冶金原理. 2版. 北京: 冶金工业出版社, 2004 [12] Wang C Y, Chang Y, Zhang L H, et al. Effect of ZrO2 content on microstructure and properties of molybdenum alloys. Powder Metall Technol, 2021, 39(5): 429王承阳, 常洋, 张林海, 等. 氧化锆含量对钼合金组织和性能的影响. 粉末冶金技术, 2021, 39(5): 429 [13] Wu M M, Li L P, Gao X Q, et al. Research progress of molybdenum-based composites prepared by powder metallurgy technology. Powder Metall Technol, 2021, 39(5): 462吴明明, 李来平, 高选乔, 等. 粉末冶金技术制备钼基复合材料研究进展. 粉末冶金技术, 2021, 39(5): 462 [14] Gao Z S. Test method for grain refiners of aluminum alloys. Light Met, 1999(4): 52高泽生. 铝合金晶粒细化剂的试验方法(2). 轻金属, 1999(4): 52 [15] He S W, Liu Y, Guo S. Cooling rate calculation of non-equilibrium aluminum alloy powders prepared by gas atomization. Rare Met Mater Eng, 2009, 38(Suppl 1), 353 [16] Ministry of Industry and Information Technology, People’s Republic of China. YST 447.1-2011 Alloy Wires Used for the Grain Refiner for Aluminium and Aluminium Alloys — Part 1: Al–Ti–B Wires. Beijing: Standards Press of China, 2011中华人民共和国工业和信息化部. YST 447.1-2011铝及铝合金晶粒细化用合金线材, 第1部分: 铝–钛–硼合金线材. 北京: 中国标准出版社, 2011 [17] Qi W J, Wang S C, Chen X M, et al. Effective nucleation phase and grain refinement mechanism of Al–5Ti–1B master alloy. Chin J Rare Met, 2013, 37(2): 179 doi: 10.3969/j.issn.0258-7076.2013.02.002戚文军, 王顺成, 陈学敏, 等. Al–5Ti–1B合金的有效形核相与晶粒细化机制. 稀有金属, 2013, 37(2): 179 doi: 10.3969/j.issn.0258-7076.2013.02.002 [18] Fan Z, Wang Y, Zhang Y, et al. Grain refining mechanism in the Al/Al–Ti–B system. Acta Mater, 2015, 84: 292 doi: 10.1016/j.actamat.2014.10.055 [19] Limmaneevichitr C, Eidhed W. Fading mechanism of grain refinement of aluminum-silicon alloy with Al–Ti–B grain refiners. Mater Sci Eng, 2003, 349: 197 doi: 10.1016/S0921-5093(02)00751-7 [20] Xue X G, Gu J C, Yan Z W. Study progress and new trends for Al–Ti–B grain refining mechanism. Alum Fab, 2004(1): 43 doi: 10.3969/j.issn.1005-4898.2004.01.002薛希国, 谷吉存, 闫振武. 铝钛硼晶粒细化剂机理研究的进展及最新动向. 铝加工, 2004(1): 43 doi: 10.3969/j.issn.1005-4898.2004.01.002 -

下载:

下载: