Microstructure and properties of 316L/430 duplex stainless steels processed by selective laser melting

-

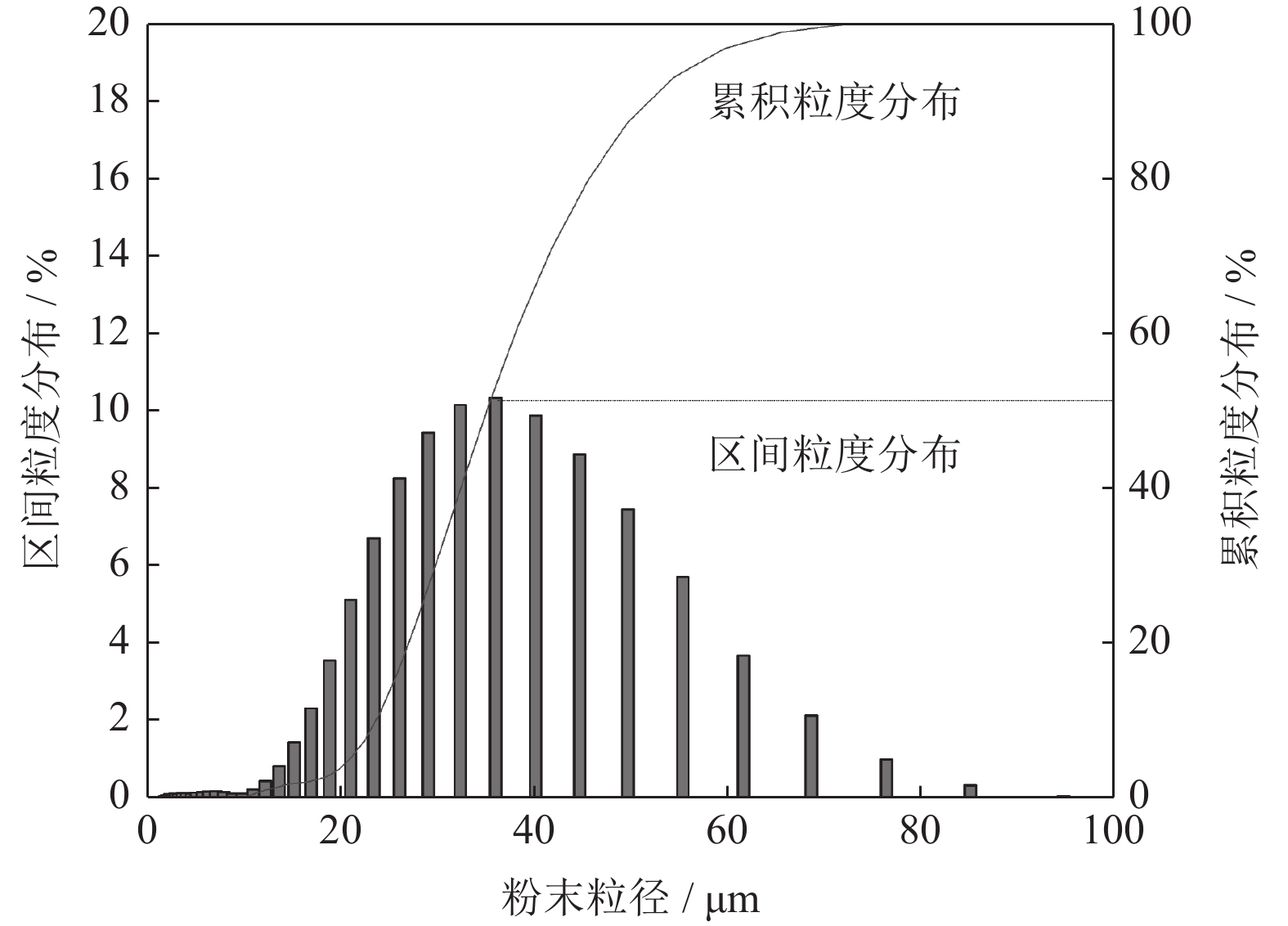

摘要: 以气雾化316L和430混合粉末为原料,采用选区激光熔化工艺制备了316L/430双相不锈钢。利用光学显微镜、电子材料试验机、电化学工作站研究了选区激光熔化双相不锈钢固溶处理前后的显微组织、力学性能和耐腐蚀性能。结果表明:当固溶温度为1250 ℃时,铁素体与奥氏体两相面积比为45.7:54.3,此时试样的力学性能较好,抗拉强度830 MPa,屈服强度340 MPa,硬度HV 356,断后伸长率25%;当固溶温度为1150 ℃时,试样的耐腐蚀性能较好,自腐蚀电流密度为3.196×10−6 A·cm−2,点蚀电位为−0.118 V。Abstract: The 316L/430 duplex stainless steels were prepared by selective laser melting in this study, using 316L and 430 mixed powders prepared by gas atomization as the raw materials. The microstructure, mechanical properties, and corrosion resistance of the 316L/430 duplex stainless steels before and after solution treatment were examined by optical microscope, electronic material testing machine, and electrochemical workstation. The results indicate that, as the solution temperature is 1250 ℃, the 316L/430 duplex stainless steels specimens show the better comprehensive mechanical properties, the tensile strength, yield strength, elongation, and microhardness are 830 MPa, 340 MPa, 25%, and HV 356, respectively, and the area ratio of ferrite to austenite is 45.7:54.3. When the solution temperature is 1150 ℃, the specimens have the better corrosion resistance, the self-corrosion current density and pitting potential are 3.196×10‒6 A/cm2 and −0.118 V, respectively.

-

表 1 双相不锈钢粉末的化学成分(质量分数)

Table 1. Chemical composition of the 316L/430 duplex stainless steel powders

% Cr Ni Mn Mo C Si Fe 17.00 6.00 1.50 1.25 0.06 0.50 余量 表 2 打印态和固溶态试样铁素体与奥氏体两相面积比

Table 2. Area ratio of ferrite and austenite for the printing state and the solution treatment specimens

试样 α:γ(面积比) DY 99.0:1.0 950GR 13.5:86.5 1000GR 14.6:85.4 1050GR 13.7:86.3 1100GR 12.0:88.0 1150GR 23.9:76.1 1200GR 31.2:68.8 1250GR 45.7:54.3 1300GR 60.4:39.6 1350GR 80.7:19.3 表 3 不同工艺试样力学性能比较

Table 3. Mechanical properties of the specimens prepared by the different processes

材料 抗拉强度 / MPa 屈服强度 / MPa 硬度,HV 断后伸长率 / % MIM–316L ≥517 ≥172 ≥120 ≥50 SLM–316L–1050GR[14] 673 420 — 48 MIM–316L:430–1250GR[15] 756 — — — 3RE60 ≥590 ≥390 ≤300 ≥20 50A–DY 924±5 843±4 335±6 22±1.0 50A–1150GR 994±18 444±6 320±4 16±1.5 50A–1250GR 830±14 340±6 356±7 25±3.0 50A–1350GR 598±8 375±56 253±13 21±3.0 表 4 双相不锈钢固溶处理前后电化学试验结果

Table 4. Parameters of the 50A specimens before and after solution treatment in the potentio-dynamic polarization curves

试样 E / VSCE I / A Ep / VSCE DY −0.402 6.983×10−6 −0.595 1150GR −0.433 3.196×10−6 −0.118 1250GR −0.460 6.145×10−6 −0.195 1350GR −0.463 7.896×10−6 −0.221 -

[1] Chail G, Kangas P. Super and hyper duplex stainless steels: structures, properties and applications. Procedia Struct Integr, 2016, 2: 1755 doi: 10.1016/j.prostr.2016.06.221 [2] Martín F, García C, Blanco Y, et al. Influence of sinter-cooling rate on the mechanical properties of powder metallurgy austenitic, ferritic, and duplex stainless steels sintered in vacuum. Mater Sci Eng A, 2015, 642: 360 doi: 10.1016/j.msea.2015.06.097 [3] Davidson K P, Singamneni S B. Magnetic characterization of selective laser-melted S32750 duplex stainless steel. JOM, 2017, 69(3): 569 doi: 10.1007/s11837-016-2193-6 [4] Davidson K P, Singamneni S B. Selective laser melting of duplex stainless steel powders: An investigation. Mater Manuf Processes, 2016, 31(12): 1543 doi: 10.1080/10426914.2015.1090605 [5] Davidson K P, Singamneni S B. Metallographic evaluation of duplex stainless steel powders processed by selective laser melting. Rapid Prototyp J, 2017, 23(6): 1146 doi: 10.1108/RPJ-04-2016-0053 [6] Hengsbach F, Koppa P, Duschik K, et al. Duplex stainless steel fabricated by selective laser melting-microstructural and mechanical properties. Mater Des, 2017, 133: 136 doi: 10.1016/j.matdes.2017.07.046 [7] Saeidi K, Kevetkova L, Lofaj F, et al. Novel ferritic stainless steel formed by laser melting from duplex stainless steel powder with advanced mechanical properties and high ductility. Mater Sci Eng A, 2016, 665: 59 doi: 10.1016/j.msea.2016.04.027 [8] Shang F, Chen X Q, Zhang P, et al. Novel ferritic stainless steel with advanced mechanical properties and significant magnetic responses processed by selective laser melting. Mater Trans, 2019, 60(6): 1096 doi: 10.2320/matertrans.M2018374 [9] Shang F, Chen X Q, Wang Z Y, et al. The microstructure, mechanical properties, and corrosion resistance of UNS S32707 hyper-duplex stainless steel processed by selective laser melting. Metals, 2019, 9(9): 1012 doi: 10.3390/met9091012 [10] Sotomayor M E, Cervera A, Varez A, et al. Duplex stainless steel self-ligating orthodontic brackets by micro-powder injection moulding. Int J Eng Res, 2016, 2(4): 184 [11] Sotomayor M E, Kloe R D, Levenfeld B, et al. Microstructural study of duplex stainless steels obtained by powder injection molding. J Alloys Compd, 2014, 589(4): 314 [12] Shulga A V. A comparative study of the mechanical properties and the behavior of carbon and boron in stainless steel cladding tubes fabricated by PM HIP and traditional technologies. J Nucl Mater, 2013, 434(1-3): 133 doi: 10.1016/j.jnucmat.2012.11.008 [13] Yang T, Zheng J M, Liu X G, et al. Influence of sintering temperature on microstructure and properties of 420 stainless steel PM sintered body. Powder Metall Technol, 2016, 34(5): 373 doi: 10.3969/j.issn.1001-3784.2016.05.010杨霆, 郑军妹, 刘晓刚, 等. 烧结温度对420不锈钢组织和性能的影响. 粉末冶金技术, 2016, 34(5): 373 doi: 10.3969/j.issn.1001-3784.2016.05.010 [14] Zhang R Q, Fan L, Zhou B G, et al. Microstructure and properties of selective laser melted 316L stainless steel in different directions. Heat Treat Met, 2020, 45(9): 161 doi: 10.13251/j.issn.0254-6051.2020.09.030张仁奇, 樊磊, 周宝刚, 等. 选区激光熔化316L不锈钢的各向组织与性能. 金属热处理, 2020, 45(9): 161 doi: 10.13251/j.issn.0254-6051.2020.09.030 [15] Sotomayor M E, Levenfeld B, Varez A. Powder injection moulding of premixed ferritic and austenitic stainless steel powders. Mater Sci Eng A, 2011, 528(9): 3480 doi: 10.1016/j.msea.2011.01.038 -

下载:

下载: