Preparation and emission performance of tungsten-osmium mixed matrix dispenser cathode by microwave sintering

-

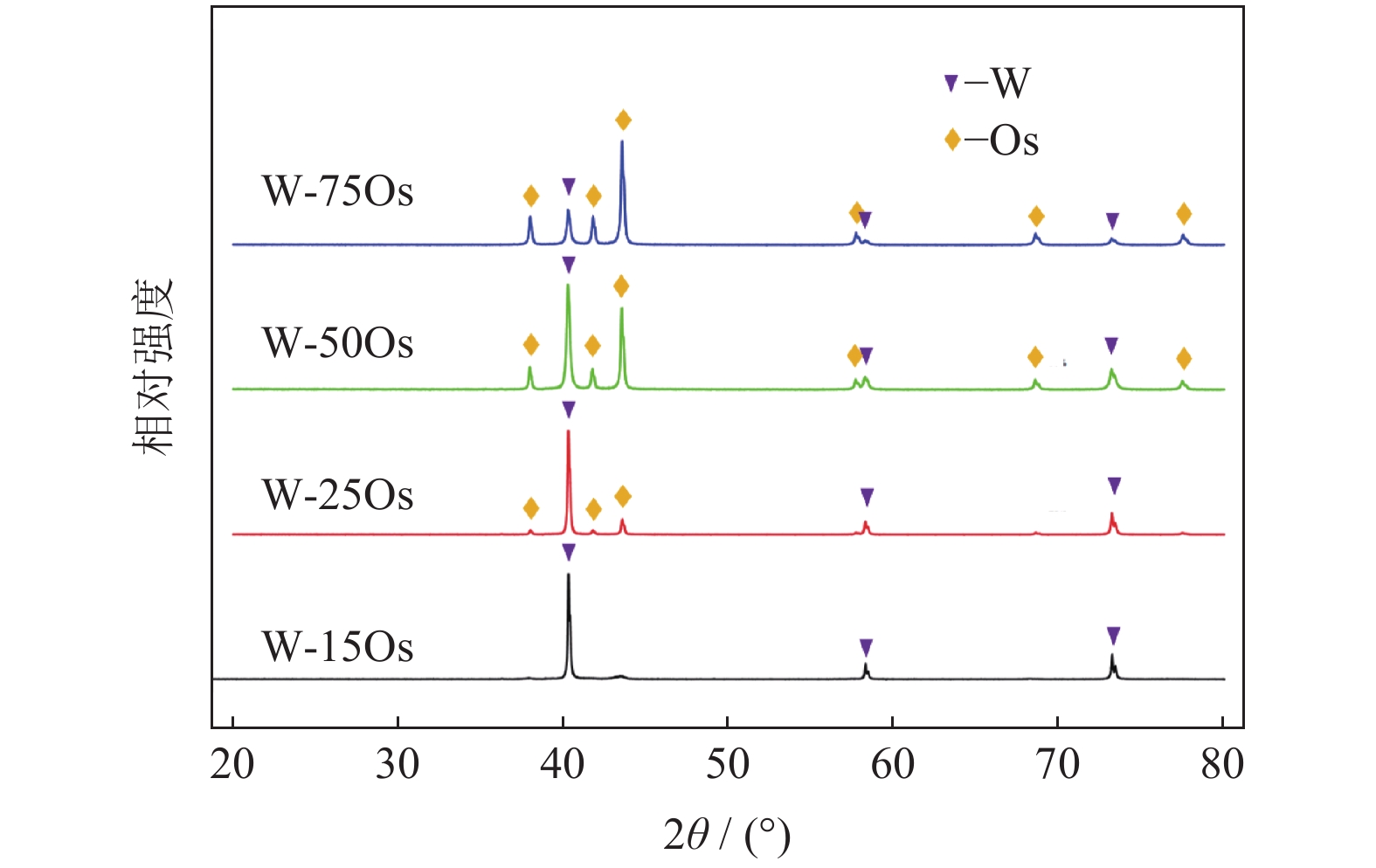

摘要: 采用固–液混合法制备出不同锇(Os)含量(原子数分数)的亚微米级钨锇混合粉体,通过微波烧结获得了孔道结构均匀的钨锇混合基扩散型阴极。电子发射测试结果表明,元素Os的加入使浸渍型钨基阴极的发射性能有明显提高。对比不同锇含量的混合基阴极,发现W–25Os阴极(Os原子数分数为25%)具有相对较低的逸出功和较高的发射电流密度,其在1100 ℃时脉冲发射电流密度为42.86 A·cm−2,斜率为1.40,发射电流密度是同等工作条件下传统钡钨阴极的1.7倍,达到了覆膜M型阴极的电子发射水平。W–25Os混合基阴极的有效逸出功最低为1.93 eV,有利于活性自由钡(Ba)的生成,表层元素摩尔比Ba:(W+Os)为0.83:1.00,比传统钡钨阴极中Ba:W(约为0.50:1.00)摩尔比有了明显提高。Abstract: Submicron tungsten-osmium mixed powders with the different content of Os (atomic number fraction) were prepared by solid‒liquid mixing method. The tungsten-osmium mixed matrix disperser cathodes with the uniform pore structure were obtained by microwave sintering. The electron emission testing results show that, the addition of Os obviously improves the emission performance of the impregnated tungsten-based dispenser cathode. The W–25Os cathode (Os atomic number fraction is 25%) exhibits the relatively low work function and high emission current density. At 1100 ℃, the pulse emission current density of the W–25Os cathode is 42.86 A·cm−2 with the emission slope of 1.40, which is 1.7 times of the conventional barium-tungsten dispenser cathodes under the same working conditions and up to the electron emission level of M-type cathodes. The W–25Os cathode shows the low effective work function as 1.93 eV, which is conducive to the generation of active free barium source. The molar ratio of surface elements Ba:(W+Os) is 0.83:1.00, which is significantly higher than that of the traditional barium tungsten cathode (about 0.50:1.00).

-

Key words:

- microwave sintering /

- mixed-matrix cathode /

- osmium /

- electron emission /

- work function

-

图 2 原始Os粉、氢气还原W粉末及W–Os混合粉末的扫描电子显微形貌:(a)原始Os粉;(b)氢气还原W粉;(c)W–15Os;(d)W–25Os;(e)W–50Os;(f)W–75Os

Figure 2. SEM images of the original Os powders, the hydrogen reduced W powders, and the W–Os mixed powders: (a) original Os powders; (b) hydrogen reduced W powders; (c) W–15Os; (d) W–25Os; (e) W–50Os; (f) W–75Os

图 3 原始Os粉、氢气还原W粉末和W–Os混合粉末的粒度分布曲线:(a)原始Os粉;(b)氢气还原W粉;(c)W–15Os;(d)W–25Os;(e)W–50Os;(f)W–75Os

Figure 3. Particle size distribution curves of the original Os powders, the hydrogen reduced W powders, and the W–Os mixed powders: (a) original Os powders; (b) hydrogen reduced W powders; (c) W–15Os; (d) W–25Os; (e) W–50Os; (f) W–75Os

表 1 W–Os混合基阴极与Ba‒W阴极逸出功

Table 1. Work functions of the W–Os mixed matrix dispenser cathodes and the barium impregnated tungsten cathodes

阴极编号 功函数 / eV W–15Os 1.97 W–25Os 1.93 W–50Os 1.96 W–75Os 1.94 Ba–W 2.03 -

[1] Zhang Z T. Development trend and future of microwave vacuum electron devices. Vac Electron, 2019(3): 1张兆镗. 真空微波电子器件的发展态势与前途. 真空电子技术, 2019(3): 1 [2] Ding Y G, Liu P K, Zhang Z C, et al. The state art and development of vacuum electronics and microwave vacuum electron devices. J Microwaves, 2010, 26(Suppl 1): 397丁耀根, 刘濮鲲, 张兆传, 等. 真空电子学和微波真空电子器件的发展和技术现状. 微波学报, 2010, 26(增刊 1): 397 [3] Yang M, Liu C, Zheng X. A study on the application of high power and high frequency microwave vacuum devices in radar detection system. Mod Radar, 2017, 39(4): 83杨明, 刘超, 郑新. 大功率、高频段电真空器件在雷达技术领域的应用分析. 现代雷达, 2017, 39(4): 83 [4] McChesney R W. Lee de Forest and the fatherhood of radio. J Am Hist, 1994, 81(1): 310 [5] Gao J Y, Yang Y F, Zhang X K, et al. A review on recent progress of thermionic cathode. Tungsten, 2020, 2(3): 289 doi: 10.1007/s42864-020-00059-1 [6] Longo R T, Adler E A, Falce L R. Dispenser cathode life prediction model // International Electron Devices Meeting. San Francisco, 1984: 318 [7] Cheng C, Yu Z Q. Evaporation of osmium-coated dispenser cathode. Vac Electron, 2014(4): 5程诚, 于志强. 覆锇阴极的蒸发. 真空电子技术, 2014(4): 5 [8] Zalm P, Van Stratum A J A. Osmium dispenser cathodes. Philips Tech Rev, 1966, 27(3-4): 69 [9] Brion D, Tonnerre J C, Shroff A. Electron emission and surface composition of osmium and osmium-tungsten coated dispenser cathodes. Appl Surf Sci, 1985, 20: 429 doi: 10.1016/0378-5963(85)90166-7 [10] Green M C. The M-type cathode—no longer magic? // 1980 International Electron Devices Meeting. Washington, 1980: 471 [11] Ares Fang C S, Maloney C E. Surface studies of Os/Re/W alloy-coated impregnated tungsten cathodes. J Vac Sci Technol A, 1990, 8(3): 2329 doi: 10.1116/1.576758 [12] Makarov A P, Kultashev O K. A work model for barium dispenser cathodes with the surface covered by metal Os, Ir or Os (Ir) W alloy layer. Appl Surf Sci, 1997, 111: 56 doi: 10.1016/S0169-4332(96)00764-7 [13] Goldwater D L, Danforth W E. Thorium dispenser cathodes. J Franklin Inst, 1956, 262(3): 229 [14] Isagawa S, Higuchi T, Kobayashi K, et al. Application of M-type cathodes to high-power cw klystrons. Appl Surf Sci, 1999, 146(1): 89 [15] Jenkins R O. A review of thermionic cathodes. Vacuum, 1969, 19(8): 353 doi: 10.1016/S0042-207X(69)80077-1 [16] Zhang H L, Liu Y W, Zhang M C, et al. Emission and surface characteristic of ternary alloy Ir/Re/W-coated impregnated tungsten cathodes. Appl Surf Sci, 2005, 251(1-4): 130 doi: 10.1016/j.apsusc.2005.03.162 [17] Zhang H W, Wu H X, He Z C. Emission performance studies of novel tri-mixed barium-tungsten cathode. Chin J Electron Dev, 2007, 30(1): 57张红卫, 吴华夏, 贺兆昌. 新型三元混合基钡钨阴极的发射性能研究. 电子器件, 2007, 30(1): 57 [18] Zhang H W, Wu H X, He Z C. Emission performance studies of novel dual mixed barium-tungsten cathode. Chin J Electron Dev, 2006, 29(2): 308张红卫, 吴华夏, 贺兆昌. 新型二元混合基钡钨阴极的发射性能研究. 电子器件, 2006, 29(2): 308 [19] Lai C, Wang J S, Zhou F, et al. Preparation and surface characteristics of Re3W matrix scandate cathode: An experimental and theoretical study. Appl Surf Sci, 2018, 440: 763 doi: 10.1016/j.apsusc.2018.01.169 [20] Lai C, Wang J S, Zhou F, et al. Thermal electron emission properties of novel W–Re mixed matrix cathodes. Rare Met Mater Eng, 2016, 45(7): 1871赖陈, 王金淑, 周帆, 等. 新型钨铼混合基阴极的热电子发射性能. 稀有金属材料与工程, 2016, 45(7): 1871 [21] Liu W, Li J H, Wang J S, et al. Preparation of scandium dispenser cathode by microwave sintering and it’ s electron emission property. Rare Met Mater Eng, 2020, 49(5): 1766刘伟, 李俊辉, 王金淑, 等. 微波烧结法制备含钪扩散阴极及其发射性能研究. 稀有金属材料与工程, 2020, 49(5): 1766 [22] Roy R, Agrawal D, Cheng J P, et al. Full sintering of powdered-metal bodies in a microwave field. Nature, 1999, 399: 668 doi: 10.1038/21390 [23] Chhillar P, Agrawal D, Adair J H. Sintering of molybdenum metal powder using microwave energy. Powder Metall, 2008, 51(2): 182 doi: 10.1179/174329007X178001 [24] Liu W, Li S L, Zhou F, et al. Process and kinetic analysis of osmium prepared by microwave sintering. Powder Metall Technol, 2021, 39(5): 394刘伟, 李世磊, 周帆, 等. 微波烧结锇的工艺研究及动力学分析. 粉末冶金技术, 2021, 39(5): 394 [25] Yin S Y, Ren F, Lu Z P, et al. Study on electron emission phenomenon of the surface micro area of coated impregnated dispenser cathode. J Electron Inf Technol, 2018, 40(10): 2535阴生毅, 任峰, 卢志鹏, 等. 覆膜浸渍扩散阴极表面微区电子发射像研究. 电子与信息学报, 2018, 40(10): 2535 -

下载:

下载: