-

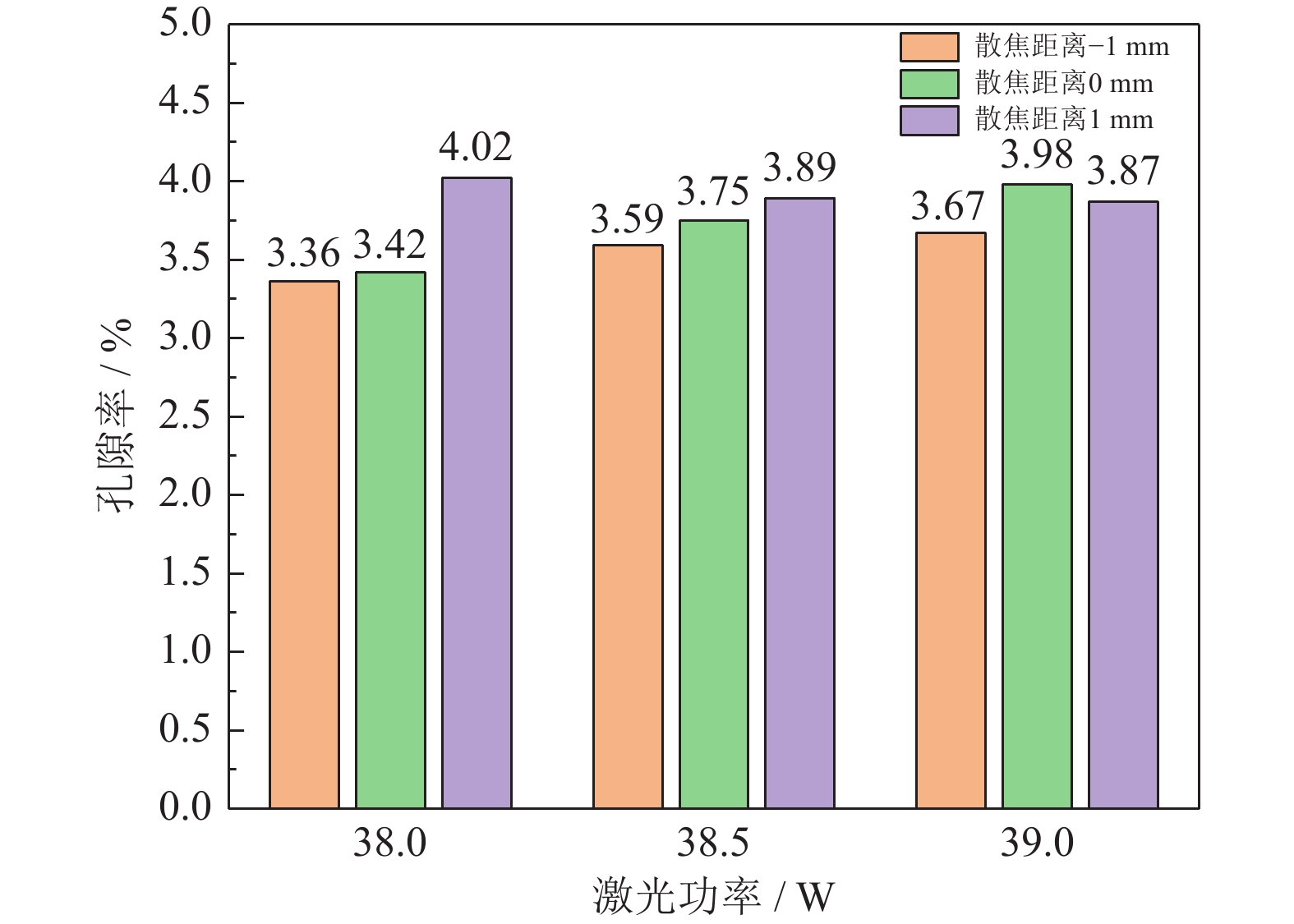

摘要: 选择性激光熔化技术具有一次成形、节省原材料、可成形任意复杂结构工件及性能优良等特点,是17–4PH不锈钢成形研究的新方向。本文综述了近几年选择性激光熔化制备17–4PH不锈钢研究现状,包括工艺参数对17–4PH不锈钢性能的影响,热处理和热等静压对17–4PH不锈钢力学性能的改善,不同成形方式和不同后处理17–4PH不锈钢的显微组织变化,以及在选择性激光熔化成形17–4PH不锈钢过程中出现的问题和发展趋势。Abstract: Selective laser melting technology (SLM) is a new direction in the forming research of the 17–4PH stainless steels because of the advantages of one-time forming, raw material saving, arbitrary complex structure workpiece forming, and excellent performance. The research status of the 17–4PH stainless steels prepared by SLM in recent years was reviewed in this paper, including the effect of process parameters on the properties of the 17–4PH stainless steels, the improvement on the mechanical properties of the 17–4PH stainless steels by heat treatment and hot isostatic pressing (HIP), the microstructure changes of the 17–4PH stainless steels treated by the different forming ways and the different post-treatments, and the problems and development trend of the 17–4PH stainless steels by SLM.

-

Key words:

- selective laser melting /

- stainless steels /

- process parameters /

- microstructure

-

图 10 选区激光熔化成形17–4PH不锈钢明场透射电子显微镜图(a)、选区电子衍射图(b)及富奥氏体缺陷和马氏体缺陷晶体学关系图(c)[27]

Figure 10. Bright field transmission electron microscope (a), the selected area diffraction pattern (b), and the crystallographic relationship between the austenite rich defects and the martensite defects (c) of the SLM formed 17–4PH stainless steels[27]

图 12 锻造和选择性激光熔化成形17–4PH不锈钢扫描电子显微形貌[30]:(a)具有完全马氏体组织的锻造试样;(b)选择性激光熔化样品熔池形态,柱状晶上有条纹;(c)典型的选择性激光熔化样品的熔池形态;(d)为图(c)所示区域的电子背散射衍射晶粒取向

Figure 12. SEM images of the 17–4PH stainless steels formed by forging and selective laser melting[30]: (a) as-received wrought samples with fully martensitic microstructure; (b) as-built SLM samples showing the melt pool morphology with striations on the colunar grains; (c) a typical melt pool in the as-built SLM samples; (d) an EBSD grain orientation map obtained from the area shown in Fig. 12(c)

表 1 17–4PH不锈钢化学成分(质量分数)

Table 1. Chemical composition of the 17–4PH stainless steels

% C Cu Ni Nb Cr Mn Si S P ≤0.07 3.00~5.00 3.00~5.00 0.15~0.45 15.00~17.50 ≤1.00 ≤1.00 ≤0.03 ≤0.04 -

[1] Murr L E, Martinez E, Hernandez J, et al. Microstructures and properties of 17–4PH stainless steel fabricated by selective laser melting. J Mater Res Technol, 2012, 1(3): 167 doi: 10.1016/S2238-7854(12)70029-7 [2] Chen B, Chen H F, Wang Z M. Present situation and development trend of 17–4PH stainless steel. J Shanghai Inst Technol Nat Sci, 2016, 16(1): 83陈贝, 陈惠芬, 王泽民. 17–4PH不锈钢的研究现状及发展趋势. 上海应用技术学院学报(自然科学版), 2016, 16(1): 83 [3] Yap C Y, Chua C K, Dong Z L, et al. Review of selective laser melting: Material and applications. Appl Phys Rev, 2015, 2(4): 1 [4] Averyanova M, Cicala E, Bertrand P, et al. Experimental design approach to optimize selective laser melting of martensitic 17–4PH powder: part I — single laser tracks and first layer. Rapid Prototyp J, 2012, 18(1): 28 doi: 10.1108/13552541211193476 [5] Gu X L, Shi J G, Liu P, et al. Study on selective laser melted 17–4PH alloy. Mech Eng, 2017(2): 69 doi: 10.3969/j.issn.1002-2333.2017.02.026顾小龙, 史金光, 刘平, 等. 选择性激光熔化17–4PH合金的成形研究. 机械工程师, 2017(2): 69 doi: 10.3969/j.issn.1002-2333.2017.02.026 [6] Ni X Q, Kong D C, Wen Y, et al. Influence factors and improvement methods on the porosity of 3D printing metal materials. Powder Metall Technol, 2019, 37(3): 163 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.001倪晓晴, 孔德成, 温莹, 等. 3D打印金属材料中孔隙率的影响因素和改善方法. 粉末冶金技术, 2019, 37(3): 163 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.001 [7] Zapico P, Gigabto S, Martinez-Pellitero S, et al. Influence of laser energy in the surface quality of parts manufactured by selective laser melting // Proceedings of the 29th International DAAAM Symposium. Zadar, 2018: 0279 [8] Hu Z H, Zhu H H, Zhang H, et al. Experimental investigation on selective laser melting of 17–4PH stainless steel. Opt Laser Technol, 2017, 87: 17 doi: 10.1016/j.optlastec.2016.07.012 [9] Wei F T, Xu G, Mao W D, et al. Research on the process optimization of selective laser melting and the mechanical properties of 18Ni300 die steel. Powder Metall Technol, 2019, 37(3): 214 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.009魏富涛, 许冠, 毛卫东, 等. 18Ni300模具钢激光选区熔化工艺优化及力学性能研究. 粉末冶金技术, 2019, 37(3): 214 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.009 [10] Makoana N W, Möller H, Burger H, et al. Evaluation of single tracks of 17–4PHsteel manufactured at different power densities and scanning speeds by selective laser melting. S Afr J Ind Eng, 2016, 27(3): 210 [11] Gu H, Gong H, Pal D, et al. Influences of energy density on porosity and microstructure of selective laser melted 17–4PH stainless steel // 2013 Solid Freeform Fabrication Symposium. Austin, 2013: 474 [12] Lee H J, Dao V H, Ma Y W, et al. Effects of process parameters on the high temperature strength of 17–4PH stainless steel produced by selective laser melting. J Mech Sci Technol, 2020, 34(8): 3261 doi: 10.1007/s12206-020-0718-y [13] Rashid R, Masood S H, Ruan D, et al. Effect of scan strategy on density and metallurgical properties of 17–4PH parts printed by selective laser melting (SLM). J Mater Process Technol, 2017, 249: 502 doi: 10.1016/j.jmatprotec.2017.06.023 [14] Giganto S, Zapico P, Castro-Sastre M Á, et al. Influence of the scanning strategy parameters upon the quality of the parts. Procedia Manuf, 2019, 41: 698 doi: 10.1016/j.promfg.2019.09.060 [15] Kudzal A, McWilliams B, Hofmeister C, et al. Effect of scan pattern on the microstructure and mechanical properties of powder bed fusion additive manufactured 17–4 stainless steel. Mater Des, 2017, 133: 205 doi: 10.1016/j.matdes.2017.07.047 [16] Ponnusamy P, Masood S H, Palanisamy S, et al. Characterization of 17–4PH alloy processed by selective laser melting. Mater Today, 2017, 4(8): 8498 [17] Yadollahi A, Shamsaei N, Thompson S M, et al. Mechanical and microstructural properties of selective laser melted 17–4PH stainless steel // International Mechanical Engineering Congress and Exposition. Houston, 2015: 52362 [18] Yadollahi A, Shamsaei N, Thompson S M, et al. Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17–4PH stainless steel. Int J Fatigue, 2017, 94: 218 doi: 10.1016/j.ijfatigue.2016.03.014 [19] Wang J, Zou H, Li C, et al. The effect of microstructural evolution on hardening behavior of type 17–4PH stainless steel in long-term aging at 350 ℃. Mater Charact, 2006, 57(4-5): 274 doi: 10.1016/j.matchar.2006.02.004 [20] Du D M, Wang Y, Bai X B. Effect of heat treatment on microstructure and property of 17–4PHstainless steel. Heat Treat Technol Equip, 2012, 33(1): 30 doi: 10.3969/j.issn.1673-4971.2012.01.008杜大明, 汪洋, 白小波. 热处理对17–4PH不锈钢组织和性能的影响. 热处理技术与装备, 2012, 33(1): 30 doi: 10.3969/j.issn.1673-4971.2012.01.008 [21] Riza S H, Ashok A M, Masood S H, et al. Sub-Zero temperature effect on impact properties of 17–4PH stainless steel processed by selective laser melting. Solid State Phenom, 2017, 266: 3 doi: 10.4028/www.scientific.net/SSP.266.3 [22] Alnajjar M, Christien F, Barnier V, et al. Influence of microstructure and manganese sulfides on corrosion resistance of selective laser melted 17–4PH stainless steel in acidic chloride medium. Corros Sci, 2020, 168: 108585 doi: 10.1016/j.corsci.2020.108585 [23] Mahmoudi M, Elwany A, Yadollahi A, et al. Mechanical properties and microstructural characterization of selective laser melted 17–4PH stainless steel. Rapid Prototyp J, 2017, 23(2): 280 doi: 10.1108/RPJ-12-2015-0192 [24] Shi Q, Qin F, Li K F, et al. Effect of hot isostatic pressing on the microstructure and mechanical properties of 17–4PH stainless steel parts fabricated by selective laser melting. Mater Sci Eng A, 2021, 810: 141035 doi: 10.1016/j.msea.2021.141035 [25] Guan Q F, Qiu D H, Li Y, et al. The formation behavior of aging precipitates on 17–4PH stainless steel. J Jilin Univ Eng Technol, 2011, 41(3): 654关庆丰, 邱冬华, 李艳, 等. 17–4PH不锈钢时效析出相的形成过程. 吉林大学学报(工学版), 2011, 41(3): 654 [26] Miao S S. Effect of aging treatment on microstructure and properties of 17–4PH stainless steel. J Henan Sci Technol, 2013(12): 70苗树森. 浅析时效处理对17–4PH不锈钢组织性能的影响. 河南科技, 2013(12): 70 [27] Facchini L, Vicente J N, Lonardelli I, et al. Metastable austenite in 17–4 precipitation-hardening stainless steel produced by selective laser melting. Adv Eng Mater, 2010, 12(3): 184 doi: 10.1002/adem.200900259 [28] Ponnusamy P, Sharma B, Masood S H, et al. A study of tensile behavior of SLM processed 17–4PH stainless steel. Mater Today, 2021, 45: 4531 [29] Alnajjar M, Christien F, Wolski K, et al. Evidence of austenite by-passing in a stainless steel obtained from laser melting additive manufacturing. Addit Manuf, 2019, 25: 187 [30] Sun Y, Hebert R J, Aindow M. Effect of heat treatments on microstructural evolution of additively manufactured and wrought 17–4PH stainless steel. Mater Des, 2018, 156: 429 doi: 10.1016/j.matdes.2018.07.015 [31] DebRoy T, Wei H L, Zuback J S, et al. Additive manufacturing of metallic components-process, structure and properties. Prog Mater Sci, 2018, 92: 112 doi: 10.1016/j.pmatsci.2017.10.001 [32] LeBrun T, Nakamoto T, Horikawa K, et al. Effect of retained austenite on subsequent thermal processing and resultant mechanical properties of selective laser melted 17–4 PH stainless steel. Mater Des, 2015, 81: 44 doi: 10.1016/j.matdes.2015.05.026 [33] Qin F, Shi Q, Liu X, et al. Effect of heat treatment on microstructure and mechanical properties of selective lasermelted 17–4PH stainless steel. Chin J Mater Res, 2021, 35(8): 606秦奉, 施麒, 刘辛, 等. 热处理对选区激光熔化17–4PH不锈钢力学性能的影响. 材料研究学报, 2021, 35(8): 606 -

下载:

下载: