Effect of electrochemical polishing on surface quality and corrosion resistance of Ti6Al4V crowns fabricated by selective laser melting

-

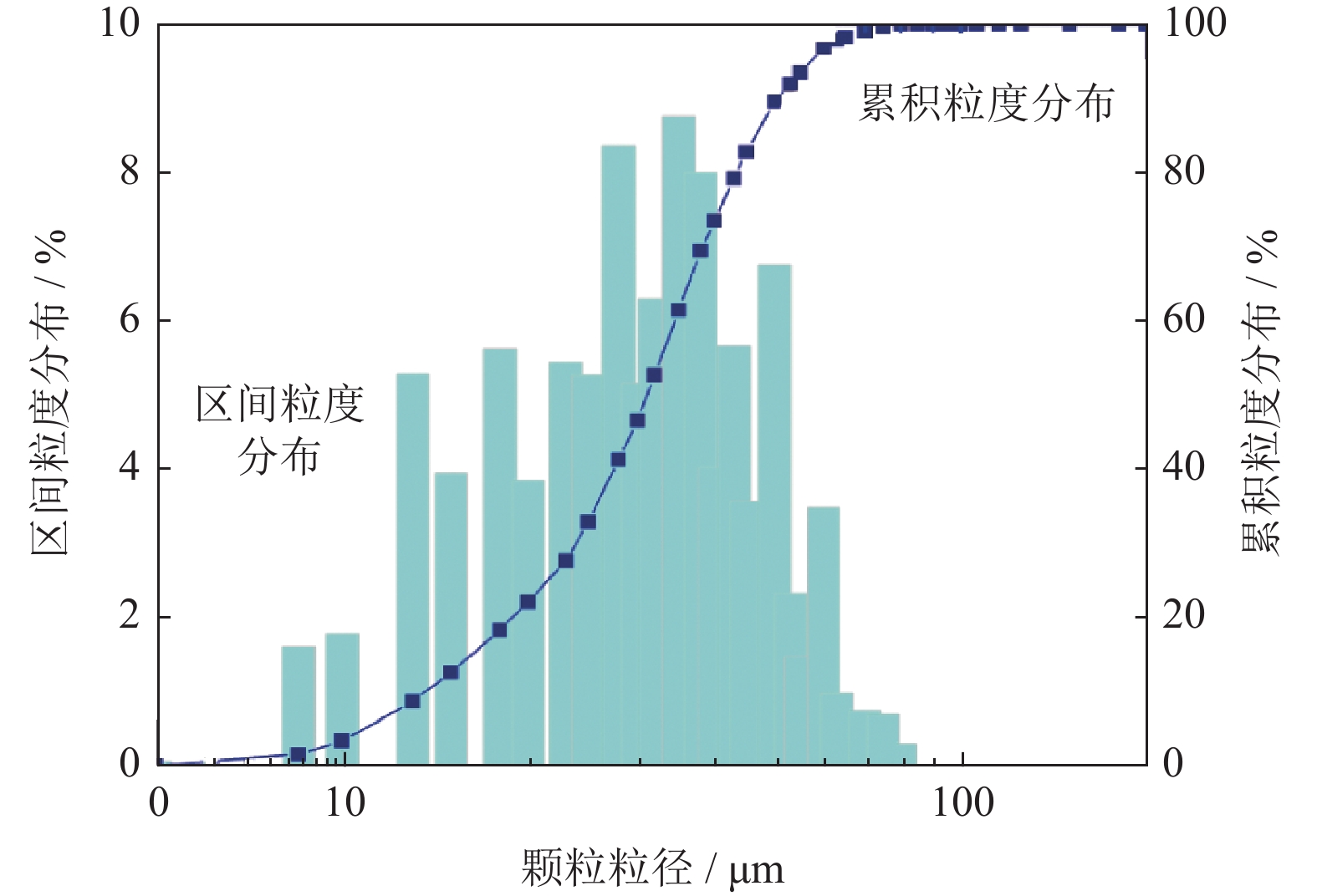

摘要: 研究了电化学抛光过程中电解液比例、电压、电解时间等参数对选区激光熔化成形Ti6Al4V牙冠表面质量及耐蚀性能的影响。结果表明,选区激光熔化成形的Ti6Al4V牙冠表面粗糙度较大,有明显的熔池边界及台阶,试样表面粘结大量粉末颗粒,初始粗糙度高达30 μm。在体积比1:8的高氯酸和醋酸电解液中进行电化学抛光,当电压较小(10 V)时,只能去除表面粘附的粉末颗粒,抛光效果不明显;当抛光电压较高(50 V)或高氯酸和醋酸比例较大时,表面抛光过度,导致局部凹凸不平,粗糙度明显上升。在30 V电压下抛光30 min后,表面质量较好,表面粗糙度约为1 μm,达到使用要求。经抛光处理后的Ti6Al4V牙冠表面的耐蚀性能大大提升,相比于未进行表面处理的牙冠,其耐蚀性能提高近一个数量级。Abstract: The effects of electrolyte ratio, voltage, and polishing time on the surface quality and corrosion resistance of the Ti6Al4V crowns fabricated by selective laser melting were analyzed in this paper. The results show that, the surface roughness of the Ti6Al4V crowns is large, and there are a large number of powder particles on the sample surface. At the same time, the undulating molten pool boundary and steps can be observed and the initial roughness is about 30 μm. For the electrochemical polishing performed with the volume ratio of perchloric acid and acetic acid as 1:8, when the voltage is low (10 V), the adhered powder particles are removed, the surface roughness changes little, the polishing effect is not obvious. Meanwhile, when the voltage is high (50 V) or the volume ratio of perchloric acid and acetic acid is high, the surface is locally uneven, the surface roughness increases, the polishing effect is excessive. The surface quality of the Ti6Al4V crowns is significantly optimized by polishing in the electrolyte with the volume ratio of perchloric acid and acetic acid as 1:8 at 30 V for 30 min, the surface roughness is about 1 μm after polishing, satisfying the requirements for application. The corrosion resistance of the Ti6Al4V crowns after electrochemical polishing is greatly improved, which is nearly an order of magnitude compared with the crowns without the surface treatment.

-

Key words:

- selective laser melting /

- titanium alloys /

- crown /

- electrochemical polishing /

- roughness /

- corrosion resistance

-

图 8 选区激光熔化成形Ti6Al4V牙冠电化学抛光处理前后宏观形貌(a),失重率与抛光时间关系(b)和表面线粗糙度与抛光时间关系(c)

Figure 8. Macroscopic morphology of the Ti6Al4V crowns fabricated by selective laser melting before and after electrochemical polishing (a), the weight loss rate with polishing time (b), and the surface roughness with polishing time (c)

表 1 选区激光熔化成形Ti6Al4V的最优打印工艺参数

Table 1. Optimal printing parameters for the selective laser melted Ti6Al4V

激光功率 / W 扫描速度 / (mm·s−1) 扫描间距 / μm 铺粉层厚 / μm 粉末尺寸 / μm 扫描策略 / (°) 280 1200 140 30 15~53 67 -

[1] Bose S, Ke D, Sahasrabudhe H, et al. Additive manufacturing of biomaterials. Prog Mater Sci, 2018, 93: 45 doi: 10.1016/j.pmatsci.2017.08.003 [2] Li Y J, Li X P, Zhang L C, et al. Processing and properties of topologically optimised biomedical Ti−24Nb−4Zr−8Sn scaffolds manufactured by selective laser melting. Mater Sci Eng A, 2015, 642: 268 doi: 10.1016/j.msea.2015.06.088 [3] Zhang L C, Klemm D, Eckert J, et al. Manufacture by selective laser melting and mechanical behavior of a biomedical Ti−24Nb−4Zr−8Sn alloy. Scr Mater, 2011, 65: 21 doi: 10.1016/j.scriptamat.2011.03.024 [4] Hanada S, Masahashi N, Semboshi S, et al. Low Young's modulus of cold groove-rolled β Ti–Nb–Sn alloys for orthopedic applications. Mat Sci Eng A, 2021, 802: 140645 doi: 10.1016/j.msea.2020.140645 [5] Zhang G X, Liu S F, Yang X, et al. Research progress in preparation of biological implant materials by additive manufacturing technology. Powder Metall Technol, 2019, 37(4): 312 doi: 10.19591/j.cnki.cn11-1974/tf.2019.04.012张光曦, 刘世锋, 杨鑫, 等. 增材制造技术制备生物植入材料的研究进展. 粉末冶金技术, 2019, 37(4): 312 doi: 10.19591/j.cnki.cn11-1974/tf.2019.04.012 [6] Liu Y J, Li S J, Wang H L, et al. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater, 2016, 113: 56 doi: 10.1016/j.actamat.2016.04.029 [7] Ren H S, Tian X J, Liu D, et al. Microstructural evolution and mechanical properties of laser melting deposited Ti−6.5Al−3.5Mo−1.5Zr−0.3Si titanium alloy. Trans Nonferrous Met Soc China, 2015, 25: 1856 [8] Campoli G, Borleffs M S, Yavari S A, et al. Mechanical properties of open-cell metallic biomaterials manufactured using additive manufacturing. Mater Des, 2013, 49: 957 doi: 10.1016/j.matdes.2013.01.071 [9] Wang X, Xu S, Zhou S, et al. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials, 2016, 83: 127 doi: 10.1016/j.biomaterials.2016.01.012 [10] Wu Q C, Ji Z, Jia C C, et al. Research progress of titanium and titanium alloy human implant materials. Powder Metall Technol, 2019, 37(3): 225 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.011武秋池, 纪箴, 贾成厂, 等. 钛及钛合金人体植入材料研究进展. 粉末冶金技术, 2019, 37(3): 225 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.011 [11] Debroy T, Wei H L, Zuback J S, et al. Additive manufacturing of metallic components—process, structure and properties. Prog Mater Sci, 2018, 92: 112 doi: 10.1016/j.pmatsci.2017.10.001 [12] Pang Y, Cao Y, Chu Y, et al. Additive manufacturing of batteries. Adv Funct Mater, 2020, 30(1): 1906244 doi: 10.1002/adfm.201906244 [13] Singh A, Kapil S, Das M. A comprehensive review of the methods and mechanisms for powder feedstock handling in directed energy deposition. Addit Manuf, 2020: 101 [14] Wang H M. Laser additive manufacturing of high performance large metal components: some basic material problems. Acta Aeronaut Astronaut Sin, 2014, 35(10): 2690王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题. 航空学报, 2014, 35(10): 2690 [15] Huang S H, Liu P, Mokasdar A, et al. Additive manufacturing and its societal impact: a literature review. Int J Adv Manuf Technol, 2013, 67(5): 1191 [16] Singh S, Ramakrishna S, Singh R. Material issues in additive manufacturing: A review. J Manuf Process, 2017, 25: 185 doi: 10.1016/j.jmapro.2016.11.006 [17] Sun Y Y, Gulizia S, Oh C H, et al. The influence of as-built surface conditions on mechanical properties of Ti−6Al−4V additively manufactured by selective electron beam melting. JOM, 2016, 68(3): 791 doi: 10.1007/s11837-015-1768-y [18] Wang D, Liu Y, Yang Y, et al. Theoretical and experimental study on surface roughness of 316L stainless steel metal parts obtained through selective laser melting. Rapid Prototyp J, 2016, 22(4): 706 doi: 10.1108/RPJ-06-2015-0078 [19] Calignano F, Manfredi D, Ambrosio E P, et al. Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int J Adv Manuf Technol, 2013, 67(9-12): 2743 doi: 10.1007/s00170-012-4688-9 [20] Gu D D, Shen Y F, Balling phenomena in direct laser sintering of stainless steel powder: Metallurgical mechanisms and control methods. Mater Des, 2009, 30(8): 2903 [21] Qiu C L, Panwisawas C, Ward M, et al. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater, 2015, 96: 72 doi: 10.1016/j.actamat.2015.06.004 [22] Maleki E, Bagherifard S, Bandini M, et al. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit Manuf, 2021, 37: 101619 [23] Pyka G, Burakowski A, Kerckhofs G, et al. Surface modification of Ti6Al4V open porous structures produced by additive manufacturing. Adv Eng Mater, 2012, 14(6): 363 doi: 10.1002/adem.201100344 [24] Bose S, Robertson S F, Bandyopadhyay A. Surface modification of biomaterials and biomedical devices using additive manufacturing. Acta Biomater, 2018, 66: 6 doi: 10.1016/j.actbio.2017.11.003 -

下载:

下载: