-

摘要: 以45#钢和TC4钛合金为基体材料,采用等离子喷涂方法制备了钨(W)及钨合金涂层,并在不同烧蚀条件下进行了烧蚀实验,比较了涂层的抗烧蚀性能,探讨了涂层烧蚀破坏机理。结果表明:基体材料喷涂W涂层后,提高了抗烧蚀性能。烧蚀温度为2600 ℃时,烧蚀11 s,涂层存在氧化,基本无烧蚀现象;烧蚀温度为3400 ℃时,烧蚀6 s,涂层有了明显的烧蚀,存在基体熔化现象,说明热量传递到基体,导致基体温度超过了自身熔点。W+Al2O3和W+ZrO2复合涂层可减缓热量从涂层表面向基体的传递速率,提高了基体材料的抗烧蚀性能。W+Al2O3和W+ZrO2复合涂层测力曲线呈锯齿状下降,不抗冲刷,但涂层的抗烧蚀时间相对较长。Abstract: Tungsten (W) and tungsten alloy coatings were prepared by plasma spraying on 45# steel and TC4 titanium alloys. Ablation tests were carried out under the different ablation conditions. The ablation resistance of the coatings was compared, and the ablation failure mechanism of the coatings was discussed. The results show that, the ablation resistance of the base materials is improved by spraying W coatings. When the ablation temperature is 2600 ℃ for 11 s, the coatings are oxidized, and there is no ablation phenomenon. When the ablation temperature is 3400 ℃ for 6 s, the coatings have the obvious ablation, indicating that the heat is transferred to the matrix, resulting in the matrix temperature exceeding the own melting point. The W+Al2O3 and W+ZrO2 composite coatings slow down the heat transfer rate from the coating surface to the substrate, and improve the ablative resistance of the substrate materials. The dynamometer curves of W+Al2O3 and W+ZrO2 composite coatings show the zigzag decline and do not resist the erosion, but the coating ablative resistance time is relatively long.

-

Key words:

- plasma spraying /

- W coatings /

- composite coatings /

- ablation resistance properties

-

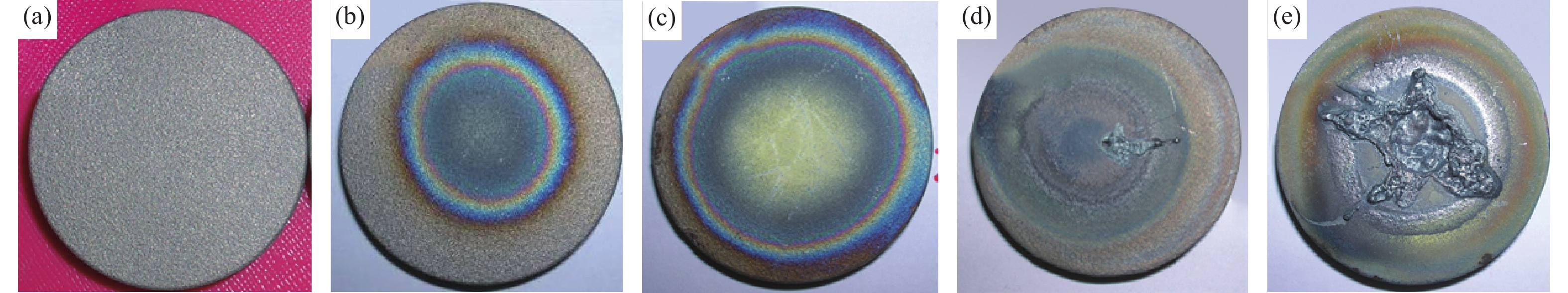

图 1 喷涂纯W涂层45#钢烧蚀后表面形貌:(a)未烧蚀;(b)2600 ℃、烧蚀6 s;(c)2600 ℃、烧蚀11 s;(d)3400 ℃、烧蚀3 s;(e)3400 ℃、烧蚀6 s

Figure 1. Surface morphology of the pure W-coated 45 # steels after ablation: (a) unablated; (b) ablated at 2600 ℃ for 6 s; (c) ablated at 2600 ℃ for 11 s; (d) ablated at 3400 ℃ for 3 s; (e) ablated at 3400 ℃ for 6 s

图 3 不同基体材料及涂层烧蚀表面形貌:(a)45#钢、W涂层;(b)45#钢、W+Al2O3涂层;(c)45#钢、W+ZrO2涂层;(d)钛合金、W+ZrO2涂层

Figure 3. Ablative surface morphology of the coatings on the different substrate materials: (a) 45# steels, W coatings; (b) 45# steels, W+Al2O3 coatings; (c) 45# steels, W+ZrO2 coatings; (d) Ti alloys, W+ZrO2 coatings

表 1 ZrO2粉末化学成分(质量分数)

Table 1. Chemical composition of the ZrO2 powders

% ZrO2 Y2O3 SiO2 Fe2O3 Al2O3 TiO2 92.25 7.48 <0.02 <0.02 <0.01 <0.01 表 2 Al2O3粉末化学成分(质量分数)

Table 2. Chemical composition of the Al2O3 powders

% Al2O3 Fe2O3 Na2O SiO2 99.00 0.07 0.18 0.14 表 3 等离子喷涂工艺参数

Table 3. Plasma spraying process parameters

材料 Ar流量 / (m3∙h‒1) He流量 / (m3∙h‒1) 电流 / A 送粉量 / (g∙min‒1) 功率 / kW 纯W涂层 2.83 1.13 780 49.8 28 W+ZrO2涂层 2.83 0.85 800 40.2 27 W+Al2O3涂层 2.83 0.85 750 34.8 25 -

[1] Ge Y C, Peng K, Yang L, et al. Coating tungsten on C/C–Cu composites surface by plasma spraying. Mater Sci Eng Powder Metall, 2010, 15(2): 136葛毅成, 彭可, 杨琳, 等. C/C–Cu复合材料表面等离子喷涂钨涂层. 粉末冶金材料科学与工程, 2010, 15(2): 136 [2] Liang M D, Yu J P, Zhang X, et al. Progress in ceramic materials for high temperature thermal barrier coatings. Therm Spray Technol, 2013, 5(2): 1梁明德, 于继平, 张鑫, 等. 高温热障涂层陶瓷层材料研究进展. 热喷涂技术, 2013, 5(2): 1 [3] Xu P, Song R G, Wang C. Research progress of atmospheric plasma sprayed zirconia thermal barrier. Hot Working Technol, 2011, 40(12): 114徐鹏, 宋仁国, 王超. 大气等离子喷涂氧化锆热障涂层研究进展. 热加工工艺, 2011, 40(12): 114 [4] Guo H B, Gong S K, Xu H B. Progress in thermal barrier coatings for advanced aeroengines. Mater China, 2009, 28(9-10): 18郭洪波, 宫声凯, 徐惠彬. 先进航空发动机热障涂层技术研究进展. 中国材料进展, 2009, 28(9-10): 18 [5] Guo H B, Gong S K, Xu H B. Research progress on new high/ultra-high temperature thermal barrier coatings and processing technologies. Acta Aeronaut Astronaut Sin, 2014, 35(10): 2722郭洪波, 宫声凯, 徐惠彬. 新型高温/超高温热障涂层及制备技术研究进展. 航空学报, 2014, 35(10): 2722 [6] Zhang X X, Lin C G, Cui S, et al. Research status of tungsten and its alloy coating. Acta Armament, 2013, 34(3): 365张雪辉, 林晨光, 崔舜, 等. 钨及其合金涂层的研究现状. 兵工学报, 2013, 34(3): 365 [7] Zhou X J, Zhao G, Tian J P. Design of a new type of Nb–W alloy and its high-temperature oxidation resistance coating uesd in the field of spacecraft engine. Chin J Space Sci, 2016, 36(1): 99 doi: 10.11728/cjss2016.01.099周小军, 赵刚, 田进鹏. 一种面向航天器发动机的新型铌钨合金制备及其抗氧化涂层设计. 空间科学学报, 2016, 36(1): 99 doi: 10.11728/cjss2016.01.099 [8] Zhao G, Zhou X J, Tian J P, et al. Coating accumulation on surface of Nb–W alloy used for aerospace engine. Heat Treat Met, 2015, 40(12): 161赵刚, 周小军, 田进鹏, 等. 航天发动机用铌钨合金表面涂层堆积. 金属热处理, 2015, 40(12): 161 [9] Zhang H. Friction and Wear Properties of Tungsten Alloy Coating Deposited on Gun Steel [Dissertation]. Shenyang: Shenyang Ligong University, 2021)张贺. 炮钢表面沉积钨合金涂层的摩擦磨损性能研究[学位论文]. 沈阳: 沈阳理工大学, 2021 [10] Liu J J, Li T H, Hao Z B, et al. Study on structure and performance of plasma-spraying tungsten coatings on carbon-carbon composites. Surf Technol, 2003, 32(3): 28刘建军, 李铁虎, 郝志彪, 等. 炭/炭复合材料表面等离子喷涂钨涂层结构与性能研究. 表面技术, 2003, 32(3): 28 [11] Tang Q, Wu J H, Yan C, et al. Effect of process parameters on properties of atmospheric plasma sprayed Al2O3 coating. Mater Protect, 2019, 52(4): 106唐强, 伍建华, 颜超, 等. 大气等离子喷涂工艺参数对Al2O3涂层性能的影响. 材料保护, 2019, 52(4): 106 [12] Xie J, Xie S, Quan Q R, et al. Metallography technology of plasma sprayed Al2O3 ceramic coating. Heat Treat Met, 2021, 46(4): 210解菁, 谢善, 全琼蕊, 等. 等离子喷涂Al2O3陶瓷涂层的显微组织检测技术. 金属热处理, 2021, 46(4): 210 [13] Zhang W. Progress on zirconia-based ceramics for thermal barrier coatings. Adv Aeronaut Sci Eng, 2018, 9(4): 464张巍. 氧化锆基陶瓷热障涂层的研究进展. 航空工程进展, 2018, 9(4): 464 [14] Sheng X C, Meng J, Yan B, et al. Preparation and oxidation behavior of Si–Ti–Hf high temperature anti-oxidation coatings on Ta–10W alloy. Powder Metall Ind, 2021, 31(2): 23盛晓晨, 孟佳, 严彪, 等. 钽钨合金Si–Ti–Hf高温抗氧化涂层的制备及性能研究. 粉末冶金工业, 2021, 31(2): 23 [15] Yang Y H, Li B Q, Liu W D, et al. Preparation and properties of anti-oxidation coatings of molybdenum-tungsten alloy. Rare Met Mater Eng, 2020, 49(6): 2089杨益航, 李保强, 刘文迪, 等. 钼钨合金抗氧化涂层的制备及性能. 稀有金属材料与工程, 2020, 49(6): 2089 [16] Zhang X F, Ge C C, Li Y J, et al. Experimental study of tungsten and tungsten alloy coating produced by cold gas dynamic spray and tungsten particles calculation and simulation. Acta Phys Sin, 2012, 61(2): 36张小锋, 葛昌纯, 李玉杰, 等. 冷动力喷涂法制备钨和钨合金涂层及其涂层的计算模拟. 物理学报, 2012, 61(2): 36 [17] Han X Y, Liu X L, Wu Z Z, et al. Research progress in refractory metal coatings. Mater Rep, 2020, 34(7): 13146韩雪莹, 刘新利, 吴壮志, 等. 含难熔金属涂层的研究进展. 材料导报, 2020, 34(7): 13146 [18] Chong F L. Spraying parameter optimization of plasma sprayed tungsten coating. Hot Working Technol, 2015, 44(14): 196种法力. 钨涂层等离子体喷涂参数优化分析. 热加工工艺, 2015, 44(14): 196 [19] Du J. Preparation of Tungsten Carbide Based Coatings and Performance of Their Slurry Erosion Resistance and Cavitation [Dissertation]. Yangzhou: Yangzhou University, 2020杜晋. 碳化钨基硬质合金涂层的制备及抗冲蚀与空蚀性能研究[学位论文]. 扬州: 扬州大学, 2020 [20] Fu Q Q, Tong Y P. Fractal character and fracture toughness of plasma sprayed yttria-stabilized zirconia coatings. Powder Metall Technol, 2021, 39(2): 122付倩倩, 通雁鹏. 等离子喷涂氧化钇稳定氧化锆涂层的分形特征与断裂韧性. 粉末冶金技术, 2021, 39(2): 122 [21] Fu Q Q, Tong Y P. Study on particle characteristics and microstructure of La2Ce2O7 coating by atmospheric plasma spraying based on the response surface method. Powder Metall Technol, 2020, 38(5): 332付倩倩, 通雁鹏. 基于曲面响应法的大气等离子喷涂La2Ce2O7涂层粒子特性与微观结构研究. 粉末冶金技术, 2020, 38(5): 332 [22] He M T, Meng H M, Wang Y C, et al. Research and development of advanced thermal barrier coating materials and preparation technology. Powder Metall Technol, 2019, 37(1): 62何明涛, 孟惠民, 王宇超, 等. 新型热障涂层材料及其制备技术的研究与发展. 粉末冶金技术, 2019, 37(1): 62 [23] Ji Z, Wang C Y, Xia Y, et al. The research of YSZ ceramic coating’ s preparation techniques on the surface of etching machine process chamber. Powder Metall Technol, 2015, 33(6): 460纪箴, 王聪瑜, 夏洋, 等. 氧化钇稳定氧化锆耐刻蚀涂层的研究现状. 粉末冶金技术, 2015, 33(6): 460 -

下载:

下载: