Determination of oxygen mass fraction and distribution in aluminum nitride ceramics

-

摘要: 氮化铝陶瓷以其优异的导热性能成为集成电路、半导体及大功率器件的重要封装材料,然而杂质氧含量(质量分数)直接影响着氮化铝陶瓷的导热性能。准确测定氮化铝陶瓷内氧含量(质量分数)及其分布十分重要。在惰性熔融红外吸收法基础上,对氮化铝陶瓷中不同形式氧含量分析方法进行了研究。通过步进式升温模式对样品中的表面吸附氧、晶界氧和晶格氧的氧含量进行分开测定,探讨了坩埚、裕料的选择及测试过程对结果的影响,分析了石墨粉含量对晶界氧的释放作用,最终优化了升温程序、加粉顺序以及称样量。通过氮化铝陶瓷样品多次平行试验对测定方法的准确性进行了验证,实测晶界氧和晶格氧含量的相对标准偏差分别为4.5%、8.5%,能够满足相关科研要求。Abstract: Aluminum nitride ceramics have become the important packaging materials for integrated circuits, semiconductors, and high-power devices due to the excellent thermal conductivity. The oxygen impurities in aluminum nitride ceramics directly affect the thermal conductivity. Thus, it is important to accurately determine the oxygen content (mass fraction) and distribution in aluminum nitride ceramics. Based on the inert melting infrared absorption method, the analysis methods of oxygen mass fraction in different forms in the aluminum nitride ceramics were studied. The mass fraction of surface adsorption oxygen, grain boundary oxygen, and lattice oxygen in the nitride ceramics was measured separately by the stepped heating method. The influence of crucible and auxiliary material selection on the measurement process and test results was discussed. The effect of graphite powder content on the release of grain boundary oxygen was analyzed. Finally, the heating program, the order of adding powder, and weight were optimized. The measurement method accuracy was verified by the multiple parallel tests on the aluminum nitride ceramics. In the results, the relative standard deviations of the measured grain boundary oxygen and lattice oxygen content are 4.5% and 8.5%, respectively, meeting the requirements of the relevant scientific research.

-

Key words:

- aluminum nitride /

- oxygen distribution /

- inert melting /

- infrared absorption method

-

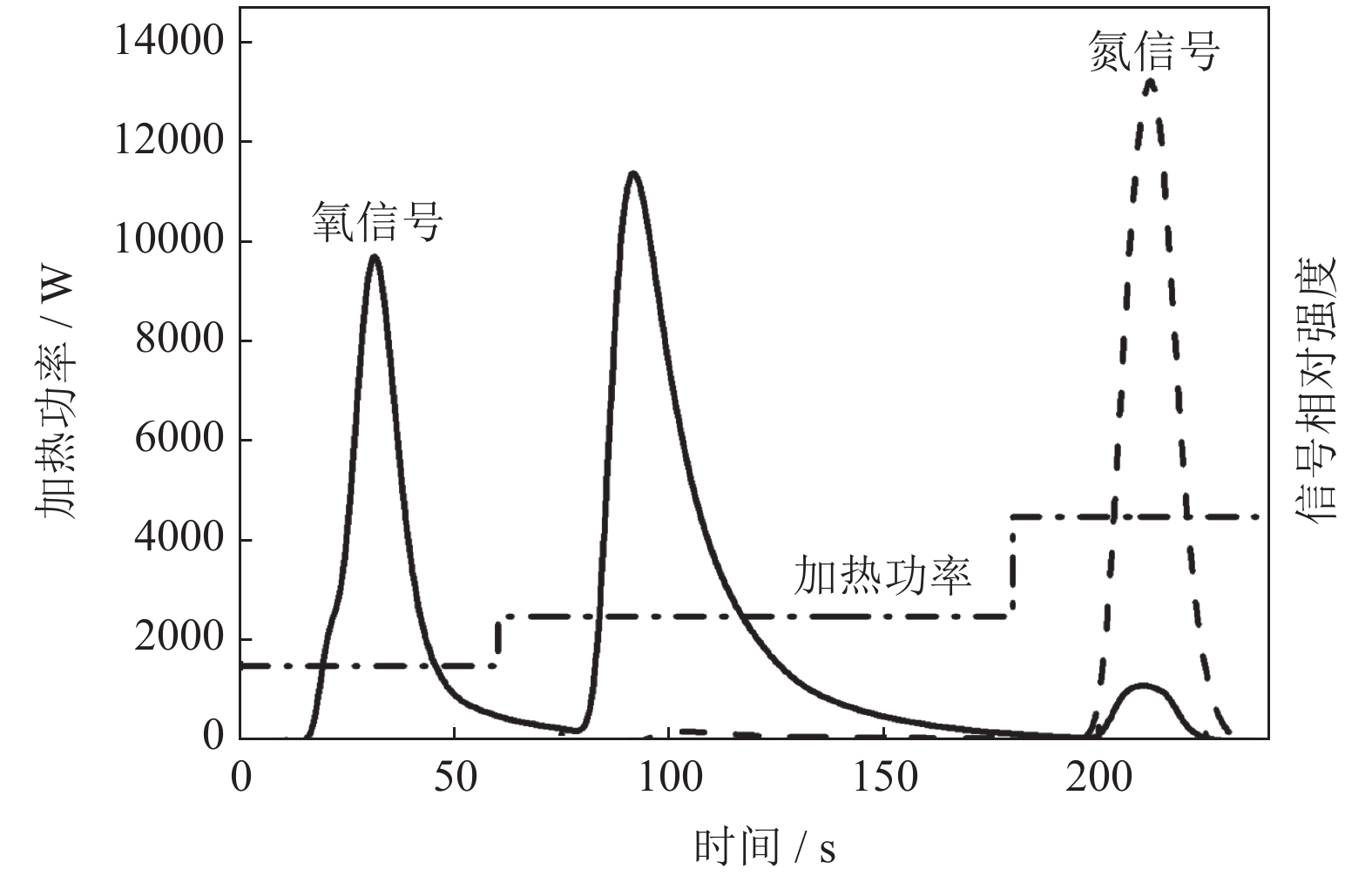

图 7 低晶格氧试样高温段氧氮释放曲线:(a)4000 W氧释放曲线;(b)4000 W氮释放曲线;(c)4500 W氧释放曲线;(d)4500 W氮释放曲线

Figure 7. Oxygen and nitrogen release curves of the low lattice oxygen samples at the high temperature: (a) oxygen release curve at 4000 W; (b) nitrogen release curve at 4000 W; (c) oxygen release curve at 4500 W; (d) nitrogen release curve at 4500 W

图 8 加入镍助熔剂时氧氮释放曲线:(a)步进式升温氧释放曲线;(b)步进式升温氮释放曲线;(c)斜率升温氧释放曲线;(d)斜率升温氮释放曲线

Figure 8. Oxygen and nitrogen release curve when adding nickel flux: (a) oxygen release curve with the step-up temperature rise; (b) nitrogen release curve with the step-up temperature rise; (c) oxygen release curve with the slope temperature rise; (d) nitrogen release curve with the slope temperature rise

表 1 实验所用设备及辅料信息

Table 1. Equipments and the auxiliary materials used in the experiments

名称 型号 制造商或品牌 分析仪 TCH600 美国LECO 分析软件 Version4.15 美国LECO 计算机 Optiplex 330 联想 稳压电源 CWY型10KVA交流 铁塔 电子天平 — 赛得利斯 外部冷却水 RW-5000F 泰州郁金香 助熔剂 镍篮(502-344) 美国LECO 助熔剂 铜屑(9T-1362) 美国WELL GROUP 助熔剂 锡屑(9T-1076) 美国WELL GROUP 助熔剂 锡片(761-739) 美国WELL GROUP 助熔剂 石墨粉(501-073) 美国LECO 试样 氮化铝粉末(粒度小于75 μm) 北京科技大学新材料技术研究院 表 2 石墨粉对氧氮质量分数的影响

Table 2. Influence of graphite powder on the mass fraction of oxygen and nitrogen

石墨粉量 / g 称样量 / g 石墨粉与称样量质量比 元素质量分数 / % 表面氧 晶界氧 晶格氧 氮 0.0905 0.0247 3.6 0.52194 0.51674 0.03472 26.4160 0.0372 0.0255 1.5 0.43488 0.58182 0.03909 25.3210 0.0314 0.0248 1.3 0.42869 0.52170 0.03550 31.0100 0.0285 0.0252 1.1 0.41158 0.56148 0.03914 31.6160 0.0214 0.0246 0.9 0.39485 0.41520 0.10998 30.2350 表 3 称样量对氧氮质量分数的影响

Table 3. Effect of weighing sample on the mass fraction of oxygen and nitrogen

称样量 / g 元素质量分数 / % 总氧 氮 晶格氧 0.0104 1.4102 34.5970 0.0457 0.0153 1.5647 34.2720 0.0657 0.0205 1.6099 32.5520 0.0735 0.0250 1.6388 32.9300 0.0767 0.0287 1.6234 33.2630 0.0721 0.0301 1.7011 30.5090 0.0835 0.0347 1.7782 27.8130 0.0894 表 4 氮化铝试样氧含量(质量分数)分布测定结果

Table 4. Measurement results of the oxygen content distribution (mass fraction) for the AlN samples

氧质量分数 / % 相对标准偏差,RSD / % 表面吸附氧 晶界氧 晶格氧 表面吸附氧 晶界氧 晶格氧 0.0404 0.6117 0.1369 86.0 4.5 8.5 0.0159 0.5965 0.1618 0.0133 0.6231 0.1291 0.0099 0.6591 0.1454 0.0030 0.5891 0.1484 平均值0.0165 平均值0.6159 平均值0.1443 -

[1] Chen L J, Xu X Y, Lei Y H, et al. A novel piezoelectric vibration sensor with aluminum nitride crystal at high temperature. J China Acad Electron Inf Technol, 2020, 15(12): 1212陈丽洁, 徐兴烨, 雷亚辉, 等. 新型氮化铝AlN晶体高温压电振动传感器. 中国电子科学研究院学报, 2020, 15(12): 1212 [2] Zhang Y Q, Yin S Y, Gao X Y, et al. Study on aluminum nitride microwave attenuation ceramics with high thermal conductivity. Rare Met Mater Eng, 2020, 49(2): 655张永清, 阴生毅, 高向阳, 等. 新型高热导率氮化铝基微波衰减陶瓷研究. 稀有金属材料与工程, 2020, 49(2): 655 [3] Zhang J B, Niu T, Cui K, et al. Technology of ENEPEG on AlN HTCC. Electron Mech Eng, 2020, 36(1): 42 doi: 10.19659/j.issn.1008-5300.2020.01.011张静波, 牛通, 崔凯, 等. 氮化铝多层共烧陶瓷基板的化学镀镍钯金技术. 电子机械工程, 2020, 36(1): 42 doi: 10.19659/j.issn.1008-5300.2020.01.011 [4] Sheng P F, Nie G L, Li Y H, et al. Research progress in shaping technology of AlN ceramics with high thermal conductivity. J Ceram, 2020, 41(6): 771 doi: 10.13957/j.cnki.tcxb.2020.06.001盛鹏飞, 聂光临, 黎业华, 等. 高导热氮化铝陶瓷成型技术的研究进展. 陶瓷学报, 2020, 41(6): 771 doi: 10.13957/j.cnki.tcxb.2020.06.001 [5] Nakano H, Watari K, Hayashi H, et al. Microstructural characterization of high-thermal-conductivity aluminum nitride ceramic. J Am Ceram Soc, 2002, 85(12): 3093 [6] Thomas A, Müller G. Determination of the concentration of oxygen dissolved in the AlN lattice by hot gas extraction from AlN ceramics. J Eur Ceram Soc, 1991, 8(1): 11 doi: 10.1016/0955-2219(91)90087-G [7] Zhu Y J, Li S J. Determination of surface oxygen on metal or ceramic powder by pulse-infrared method. Metall Anal, 1996, 16(4): 13 doi: 10.13228/j.issn.1000-7571.1996.04.004朱跃进, 李素娟. 脉冲红外法测定金属和陶瓷粉末表面氧的研究. 冶金分析, 1996, 16(4): 13 doi: 10.13228/j.issn.1000-7571.1996.04.004 [8] Jiang Y F. Determination of oxygen in WC‒Ni3Al by TCH600 oxygen nitrogen hydrogen analyzer. Nonferrous Met Abstr, 2016, 31(1): 182蒋亚芳. TCH600氧氮氢仪测定WC‒Ni3Al中氧量. 有色金属文摘, 2016, 31(1): 182 [9] Lin F, Yang Q Q, Wen Y M, et al. Simultaneous determination of oxygen and nitrogen in aluminum nitride by inert gas fusion infrared thermal conductivity // Award-Winning Proceedings of the 8th Metallurgical Annual Meeting of Beijing Metal Society. Beijing, 2014: 679蔺菲, 杨倩倩, 文元梅, 等. 惰气熔融红外热导法同时测定氮化铝中氧和氮 // 北京金属学会第八届冶金年会获奖论文集. 北京, 2014: 679 [10] Xie J, Zhu Y C, Zhang F J, et al. Influence of crucible on the analysis results of oxygen, nitrogen and hydrogen in superalloy. Metall Anal, 2018, 38(10): 7 doi: 10.13228/j.boyuan.issn1000-7571.010510谢君, 朱瑛才, 仉凤江, 等. 坩埚对高温合金中氧氮及氢分析结果的影响. 冶金分析, 2018, 38(10): 7 doi: 10.13228/j.boyuan.issn1000-7571.010510 [11] Zhang L, Na D, Yin Z H, et al. Determination of oxygen in lanthanum-cerium alloy by impulse fusion-infrared absorption method. Metall Anal, 2020, 40(6): 8 doi: 10.13228/j.boyuan.issn1000-7571.11047张琳, 那铎, 尹志华, 等. 脉冲熔融-红外吸收法测定镧铈合金中氧. 冶金分析, 2020, 40(6): 8 doi: 10.13228/j.boyuan.issn1000-7571.11047 [12] Li Y, Wang Q. Study on determination method of oxygen content in aluminum vanadium alloy. Chin J Anal Lab, 2010, 29(Suppl 1): 331 doi: 10.13595/j.cnki.issn1000-0720.2010.0445李岩, 王强. 铝钒合金中氧含量测定方法的研究. 分析试验室, 2010, 29(增刊 1): 331 doi: 10.13595/j.cnki.issn1000-0720.2010.0445 [13] Wu B, Liu X P. Determination of nitrogen in nitrided managanese by manual mode of nitrogen/oxygen analytical instrument. Angang Technol, 2007(1): 49 doi: 10.3969/j.issn.1006-4613.2007.01.014武斌, 刘小平. 氧氮分析仪手动模式测定氮化锰中的氮. 鞍钢技术, 2007(1): 49 doi: 10.3969/j.issn.1006-4613.2007.01.014 [14] Wang S W. Nitrogen content in steel was analyzed by oxygen and nitrogen meter. Shandong Chem Ind, 2020, 49(24): 106 doi: 10.3969/j.issn.1008-021X.2020.24.041王神武. 氧氮仪下进样检测钢中氮含量. 山东化工, 2020, 49(24): 106 doi: 10.3969/j.issn.1008-021X.2020.24.041 [15] Zhang Z R, Qin M L, Wu H Y, et al. Research progress and preparation method of aluminum nitride powder. Powder Metall Technol, 2021, 393(4): 373张智睿, 秦明礼, 吴昊阳, 等. 氮化铝粉末制备方法及研究进程. 粉末冶金技术, 2021, 393(4): 373 [16] Lan J, Ma S Q, Li Y K, et al. Progress in preparation and application of aluminum nitride powder. J Ceram, 2021, 42(1): 44 doi: 10.13957/j.cnki.tcxb.2021.01.004蓝键, 马思琪, 李邑柯, 等. 氮化铝粉末制备与应用研究进展. 陶瓷学报, 2021, 42(1): 44 doi: 10.13957/j.cnki.tcxb.2021.01.004 [17] Zhuang A C, Xiao H X, Zhang S. Progress and present situation of standard analysis techniques for oxygen and nitrogen in inorganic materials. Metall Anal, 2020, 40(8): 30 doi: 10.13228/j.boyuan.issn1000-7571.011057庄艾春, 肖红新, 张胜. 无机材料氧氮标准分析技术进展及现状. 冶金分析, 2020, 40(8): 30 doi: 10.13228/j.boyuan.issn1000-7571.011057 -

下载:

下载: