Microstructure and mechanical properties of diffusion alloyed steel composites reinforced by ceramic particles

-

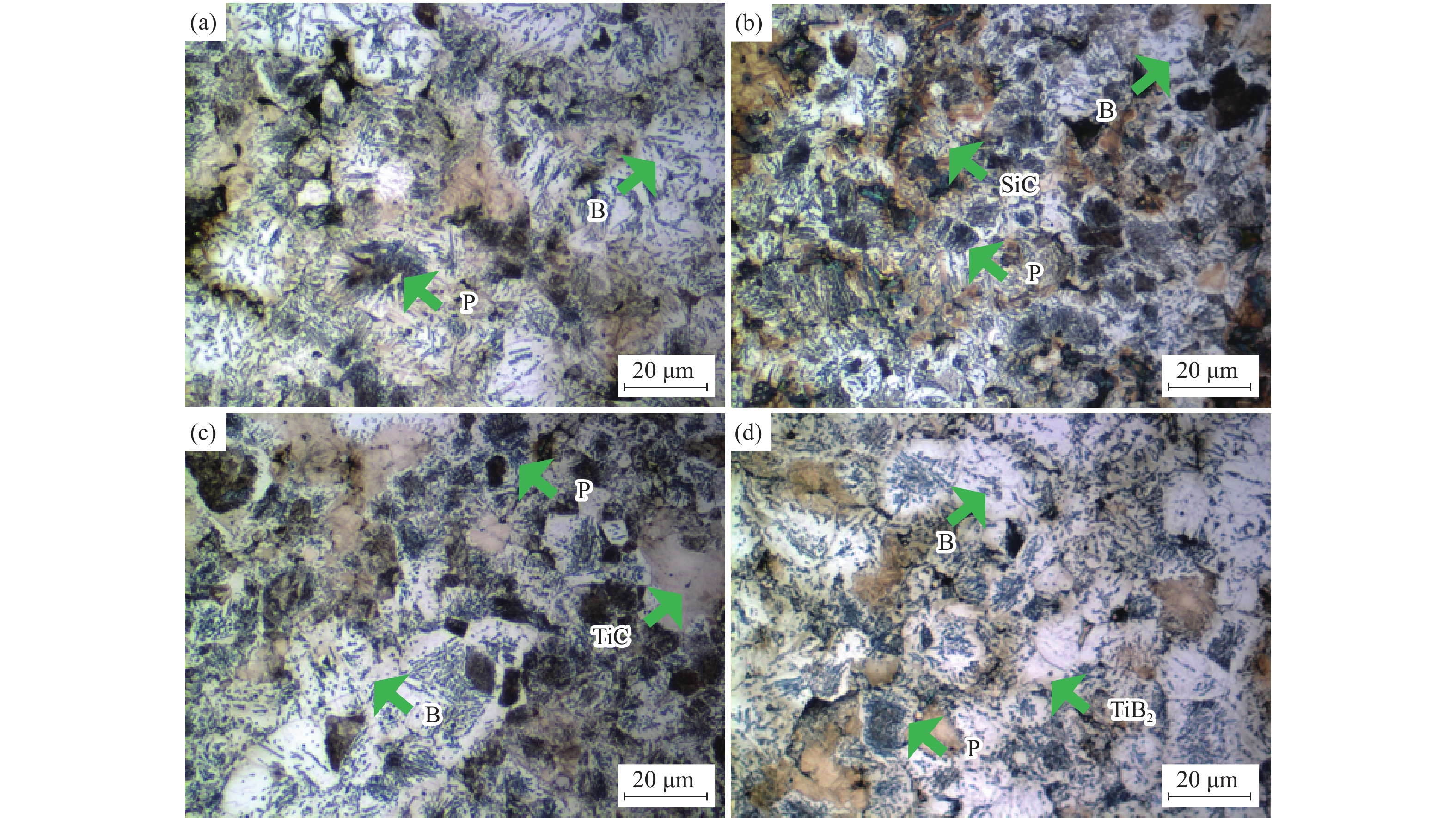

摘要: 采用传统粉末冶金工艺制备了陶瓷颗粒增强Fe‒0.5Mo‒1.75Ni‒1.5Cu‒0.7C扩散合金化钢复合材料,选用的陶瓷颗粒为SiC、TiC和TiB2。采用光学显微镜和扫描电子显微镜观察了烧结材料微观结构,并对烧结材料的硬度、强度和摩擦磨损性能进行了测试。结果表明,由于SiC和TiB2与基体的化学相容性好,陶瓷颗粒与基体界面结合良好;由于TiC颗粒具有极高的化学稳定性,TiC颗粒与基体界面结合情况不理想。随着陶瓷相含量(质量分数)的增加,添加SiC和TiC的烧结试样相对密度降低;添加TiB2的烧结试样相对密度先增加后降低,当添加TiB2质量分数为0.9%时达到最大值。随着陶瓷含量增加,添加SiC和TiB2烧结试样的硬度增大,当陶瓷相质量分数超过1.2%时,硬度增加缓慢;添加TiC烧结试样的硬度先增加后降低,当添加TiC质量分数为0.9%时达到最大值。随着陶瓷相含量增加,添加SiC和TiC烧结试样的强度降低,少量添加SiC对强度没有明显损害;添加TiB2烧结试样的强度先增加后降低,当添加TiB2质量分数为0.6%时达到最大值(971.7MPa),比基体提高了14.1%以上。添加陶瓷相对烧结钢性能的积极影响依次是TiB2、SiC和TiC。

-

关键词:

- 颗粒增强 /

- 扩散合金化钢复合材料 /

- 微观结构 /

- 力学性能

Abstract: The ceramic particle reinforced Fe‒0.5Mo‒1.75Ni‒1.5Cu‒0.7C diffusion alloyed steel composites were prepared by the conventional powder metallurgy techniques, using SiC, TiC, and TiB2 as the reinforced ceramic particles, respectively. The microstructures of the sintered specimens were observed by the optical microscope and scanning electron microscope, and the hardness, tensile strength, and friction-wear performance were tested systematically. In the results, the interface bonding between the matrix and the ceramic particles is perfect due to the excellent chemical compatibility of SiC and TiB2 with the matrix; the interface bonding between the matrix and TiC particles is inferior because of the high chemical stability. The relative density of the sintered specimens reinforced by SiC and TiC decreases monotonously with the increase of the ceramic phase mass fraction; while the relative density of the sintered specimens reinforced by TiB2 increases firstly and then decreases with the increase of TiB2 mass fraction, and the relative density reaches the maximum value when the TiB2 mass fraction is 0.9%. The hardness of the sintered specimens reinforced by SiC and TiB2 increases monotonously with the increase of the ceramic phase mass fraction, and the increased rate becomes gently when the ceramic particle mass fraction exceeds 1.2%; the hardness of the sintered specimens reinforced by TiC increases firstly and then decreases with the increase of TiC mass fraction and reaches the maximum value when the TiC mass fraction is 0.9%. The tensile strength of the sintered specimens reinforced by SiC and TiC decreases monotonously with the increase of the ceramic particle mass fraction, a small amount of SiC addition has no visible impairment on the tensile strength; the tensile strength of the sintered specimens reinforced by TiB2 increases firstly and then decreases and reaches the maximum value of 971.7 MPa when the TiB2 mass fraction is 0.6%, which increases by over 14.1% compared with the martrix. The positive effect of the ceramic particles on the performance of the sintered specimens is TiB2, SiC, TiC in turn. -

表 1 LAP100.29D1扩散型合金钢粉化学成分(质量分数)

Table 1. Chemical composition of the LAP100.29D1 diffusion alloyed steel powders

% C Si Mn P S Ni Mo Cu HL 0.010 0.020 0.120 0.005 0.005 1.750 0.500 1.500 0.150 表 2 陶瓷颗粒增强扩散合金钢成分组成(质量分数)

Table 2. Composition of the ceramic particle reinforced diffusion alloyed steels

% 陶瓷颗粒(SiC、TiC、TiB2) C 润滑剂 LAP100.29D1 0、0.3、0.6、0.9、1.2、1.5 0.7 0.7 余量 表 3 陶瓷颗粒增强扩散合金化钢摩擦磨损减重(质量分数)

Table 3. Weight lost of the ceramic particles reinforced diffusion alloyed steels

% 增强颗粒 磨损量 / mg 不添加增强颗粒 5.9±0.18 SiC(0.9%) 4.0±0.16 TiB2(0.9%) 3.6±0.11 -

[1] Ye X, Tu H J, Qiu Z W, et al. Effect of WC content on pore morphology and properties of Fe‒1.5Cu‒1.8Ni‒0.5Mo‒1C powder metallurgy composites. Hot Working Technol, 2019, 48(22): 89叶璇, 涂华锦, 邱志文, 等. WC含量对Fe‒1.5Cu‒1.8Ni‒0.5Mo‒1C粉末冶金复合材料的孔隙形貌与性能的影响. 热加工工艺, 2019, 48(22): 89 [2] Ru J J, He H. Preparation methods and research progress of ceramic particle reinforced metal matrix composites. Technol Innov Appl, 2019, 19(2): 116 doi: 10.3969/j.issn.2095-2945.2019.02.048汝娟坚, 贺函. 陶瓷颗粒增强金属基复合材料的制备方法及研究进展. 科技创新与应用, 2019, 19(2): 116 doi: 10.3969/j.issn.2095-2945.2019.02.048 [3] Pang Y D. Preparation and Properties of TiC/NbC Ceramic Reinforced Fe Matrix Composites [Dissertation]. Baotou: Inner Mongolia University of Science and Technology, 2020庞雅丹. TiC/NbC陶瓷颗粒增强Fe基复合材料的制备及工艺研究[学位论文]. 包头: 内蒙古科技大学, 2020 [4] Cao J X, Jin J F, Cao J H, et al. Wear resistance of iron matrix composites reinforced by mixed-type particles. J Mater Eng, 2017, 45(8): 62 doi: 10.11868/j.issn.1001-4381.2015.001136曹建新, 金剑锋, 曹敬袆, 等. 不同类型颗粒混合增强铁基复合材料的磨损性能. 材料工程, 2017, 45(8): 62 doi: 10.11868/j.issn.1001-4381.2015.001136 [5] Zhuang W B, Han M M, Liu J F, et al. Research progress of ceramic particle reinforced iron matrix composites. Hot Working Technol, 2018, 47(4): 40 doi: 10.14158/j.cnki.1001-3814.2018.04.009庄伟斌, 韩明明, 刘敬福, 等. 陶瓷颗粒增强铁基复合材料的研究进展. 热加工工艺, 2018, 47(4): 40 doi: 10.14158/j.cnki.1001-3814.2018.04.009 [6] Tan A S. Research on Mechanical and Tribological Properties of Aluminium Matrix Composites Reinforced with Hybrid SiC Microparticles and TiB2 Nanoparticles [Dissertation]. Changsha: Hunan University, 2017谭傲霜. SiC/TiB2颗粒颗粒混杂增强铝基复合材料力学及摩擦磨损性能研究[学位论文]. 长沙: 湖南大学, 2017 [7] Deirmina F, Pellizzari M. Production and characterization of a tool steel-PSZ composite by mechanical alloying and spark plasma sintering. J Alloys Compd, 2017, 709: 742 doi: 10.1016/j.jallcom.2017.03.203 [8] Guan D D. Preparation and Properties of Ceramic Particle Reinforced 316L Stainless Steel Matrix Composites by Powder Metallurgy [Dissertation]. Beijing: Beijing University of Science and Technology, 2018管丹丹. 粉末冶金法制备陶瓷颗粒增强316L不锈钢基复合材料及其性能[学位论文]. 北京: 北京科技大学, 2018 [9] Kumar A, Banerjee M K, Pandel U. Development of a novel MWCNT reinforced iron matrix nanocomposite through powder metallurgy route. Powder Technol, 2018, 331: 41 doi: 10.1016/j.powtec.2018.03.009 [10] Han M M, Liu J F, Zhuang W B, et al. Study on thermal fatigue properties of SiCp/Fe composites. Hot Working Technol, 2019, 48(16): 89韩明明, 刘敬福, 庄伟彬, 等. SiCp/Fe复合材料的热疲劳性能研究. 热加工工艺, 2019, 48(16): 89 [11] Zhong X Y, Zhen M H, Qiu Y, et al. Electroless copper plating on α-SiC powder and its effect on the properties of α-SiC/Fe composites. Surf Technol, 2018, 47(3): 244 doi: 10.16490/j.cnki.issn.1001-3660.2018.03.039种详远, 甄明晖, 仇溢, 等. α-SiC粉体化学镀铜及其对铁基复合材料性能的影响. 表面技术, 2018, 47(3): 244 doi: 10.16490/j.cnki.issn.1001-3660.2018.03.039 [12] Gao Q C, Dai Q F, Wang B B, et al. Effect of Ni-coated SiC particles on mechanical properties of SiC(Ni)/Fe composite. Adv Ceram, 2017, 38(2): 108 doi: 10.16253/j.cnki.37-1226/tq.2016.11.003高前程, 代巧飞, 王彬彬, 等. Ni包裹SiC对SiC(Ni)/Fe复合材料性能的影响. 现代技术陶瓷, 2017, 38(2): 108 doi: 10.16253/j.cnki.37-1226/tq.2016.11.003 [13] Guo Y B. Study on Mechanical Properties and Dry Friction and Wear Behavior of TiB2 Particle Reinforced Iron Matrix Composites [Dissertation]. Chengdu: Southwest Jiaotong University, 2018郭远博. 硼化钛颗粒增强铁基复合材料的力学性能及干摩擦磨损行为研究[学位论文]. 成都: 西南交通大学, 2018 [14] Fan S Z, Zhong L S, Cheng S L, et al. Research status of in-situ titanium carbide particle reinforced steel matrix composite. Hot Working Technol, 2015, 44(10): 16 doi: 10.14158/j.cnki.1001-3814.2015.10.004樊少忠, 钟黎声, 程仕李, 等. 原位制备碳化钛颗粒增强钢铁基复合材料研究现状. 热加工工艺, 2015, 44(10): 16 doi: 10.14158/j.cnki.1001-3814.2015.10.004 [15] Tang W M, Zheng Z X, Ding H F, et al. A study of solid state reaction between silicon carbide and iron. Mater Chem Phys, 2002, 74(3): 258 doi: 10.1016/S0254-0584(01)00480-1 [16] He Q Q, Li P M, Yuan Y, et al. Microstructure and mechanical properties of ceramic particle reinforced powder metallurgy Fe‒2Cu‒0.6C composites. Powder Metall Technol, 2019, 37(1): 11何勤求, 李普明, 袁勇, 等. 陶瓷颗粒增强粉末冶金Fe‒2Cu‒0.6C复合材料的微观结构和力学性能. 粉末冶金技术, 2019, 37(1): 11 -

下载:

下载: