| [1] |

Wolfgang H. Materials for Nuclear Plants. 2nd Ed. Transl by Shanghai Nuclear Engineering Research and Design Institute. Shanghai: Shanghai Science and Technology Press, 2017沃尔夫冈. 核电厂材料. 2版. 上海核工程研究设计院译. 上海: 上海科学技术出版社, 2017

|

| [2] |

Yang J, Yang Z C, Xu L J, et al. Review of 2017 nuclear energy technology hotspots. Sci Technol Rev, 2018, 36(1): 31杨军, 杨章灿, 徐乐瑾, 等. 2017年核能科技热点回眸. 科技导报, 2018, 36(1): 31

|

| [3] |

Busby J T, Leonard K J. Space fission reactor structural materials: Choices past, present, and future. JOM, 2007, 59(4): 20 doi: 10.1007/s11837-007-0049-9

|

| [4] |

Jaffee R I, Sims C T, Harwood J J. The effect of rhenium on the fabric ability and ductility of molybdenum and tungsten // 3rd Plansee Seminar. Vienna, 1959: 664

|

| [5] |

Wadsworth J, Nith T G, Stephens J J. Dilute Mo−Re alloys—A critical evaluation of their comparative mechanical properties. Scr Metall, 1986, 20(5): 637 doi: 10.1016/0036-9748(86)90481-3

|

| [6] |

Tyumentsev A N, Levitskii A D, Freze N I, et al. Temperature characteristics of the mechanical properties and of the dislocation structure of molybdenum-rhenium alloys. Sov Phys J, 1975, 18(12): 1668 doi: 10.1007/BF00892783

|

| [7] |

Busby J T, Ohriner E K, Snead L L, et al. Molybdenum-rhenium alloys for spacecraft reactor applications // Proceedings of the Space Nuclear Conference 2005. California, 2005: 1184

|

| [8] |

Dong D, Huang H T, Xiong N, et al. Application of molybdenum and molybdenum alloy in nuclear reactor. China Molybdenum Ind, 2018, 42(4): 6 doi: 10.13384/j.cnki.cmi.1006-2602.2018.04.002董帝, 黄洪涛, 熊宁, 等. 钼及钼合金在核反应堆中的应用. 中国钼业, 2018, 42(4): 6 doi: 10.13384/j.cnki.cmi.1006-2602.2018.04.002

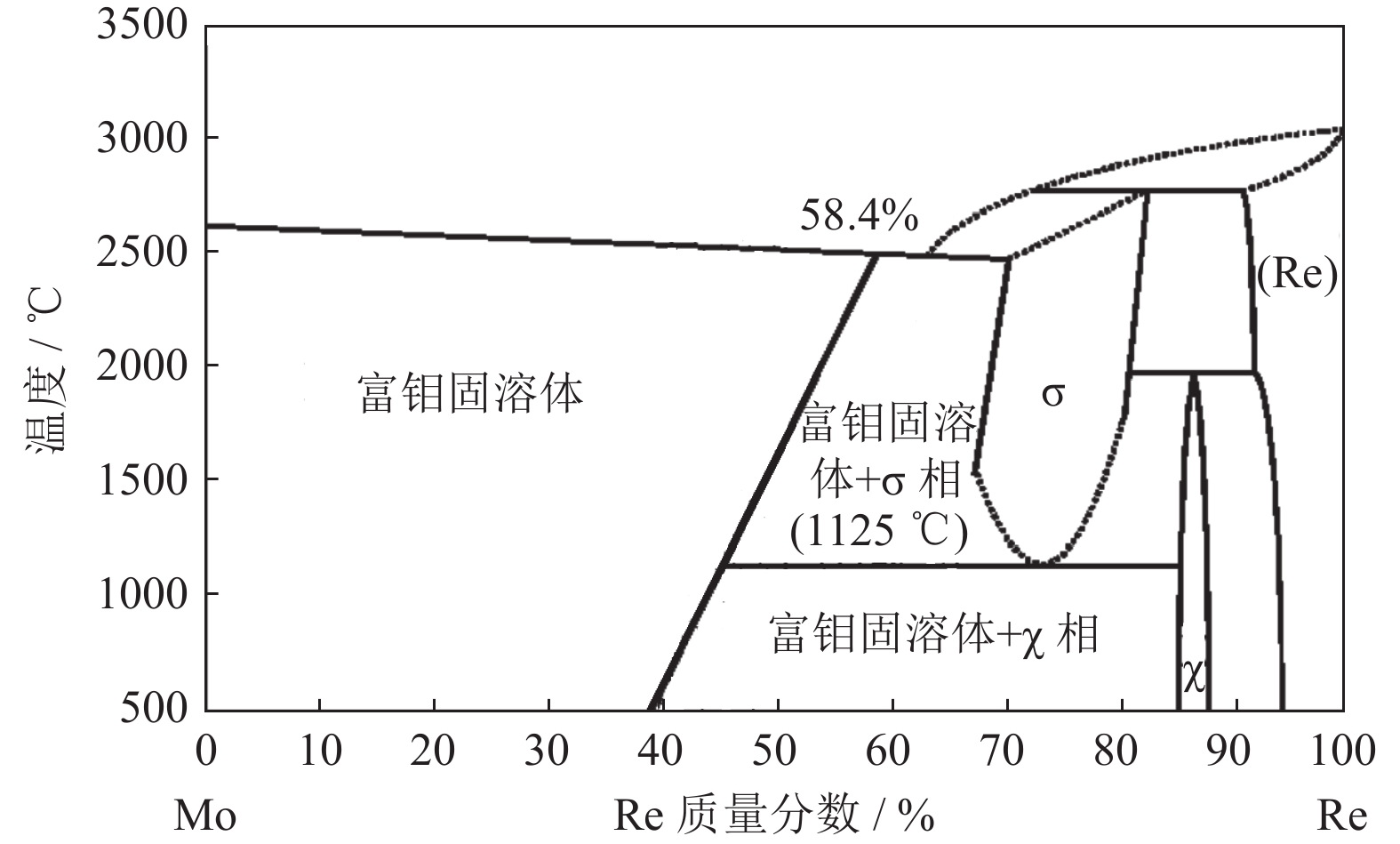

|

| [9] |

Chen C, Wang M P, Tan W, et al. Study on preparation of molybdenum−rhenium alloys by powder metallurgy methods. Mater Rev, 2008, 22(5): 74 doi: 10.3321/j.issn:1005-023X.2008.05.018陈畅, 汪明朴, 谭望, 等. 粉末冶金方法制备钼铼合金的研究. 材料导报, 2008, 22(5): 74 doi: 10.3321/j.issn:1005-023X.2008.05.018

|

| [10] |

Zinkle S J, Ott L J, Ingersoll D T, et al. Overview of materials technologies for space nuclear power and propulsion // Proceedings of Space Technology and Applications International Forum. Albuquerque, 2002: 1063

|

| [11] |

Ashcroft J. Documentation of naval reactors papers and presentations for the space technology and international forum (STAIF) 2006 [J/OL]. UNT Digital Library Online (2006-04-10) [2022-07-01]. https://digital.library.unt.edu/ark:/67531/metadc892374/

|

| [12] |

Jahshan S N, Borkowski J A. A modular gas-cooled cermet reactor system for planetary base power. Symp Space Nucl Power Propul, 1993(1): 641

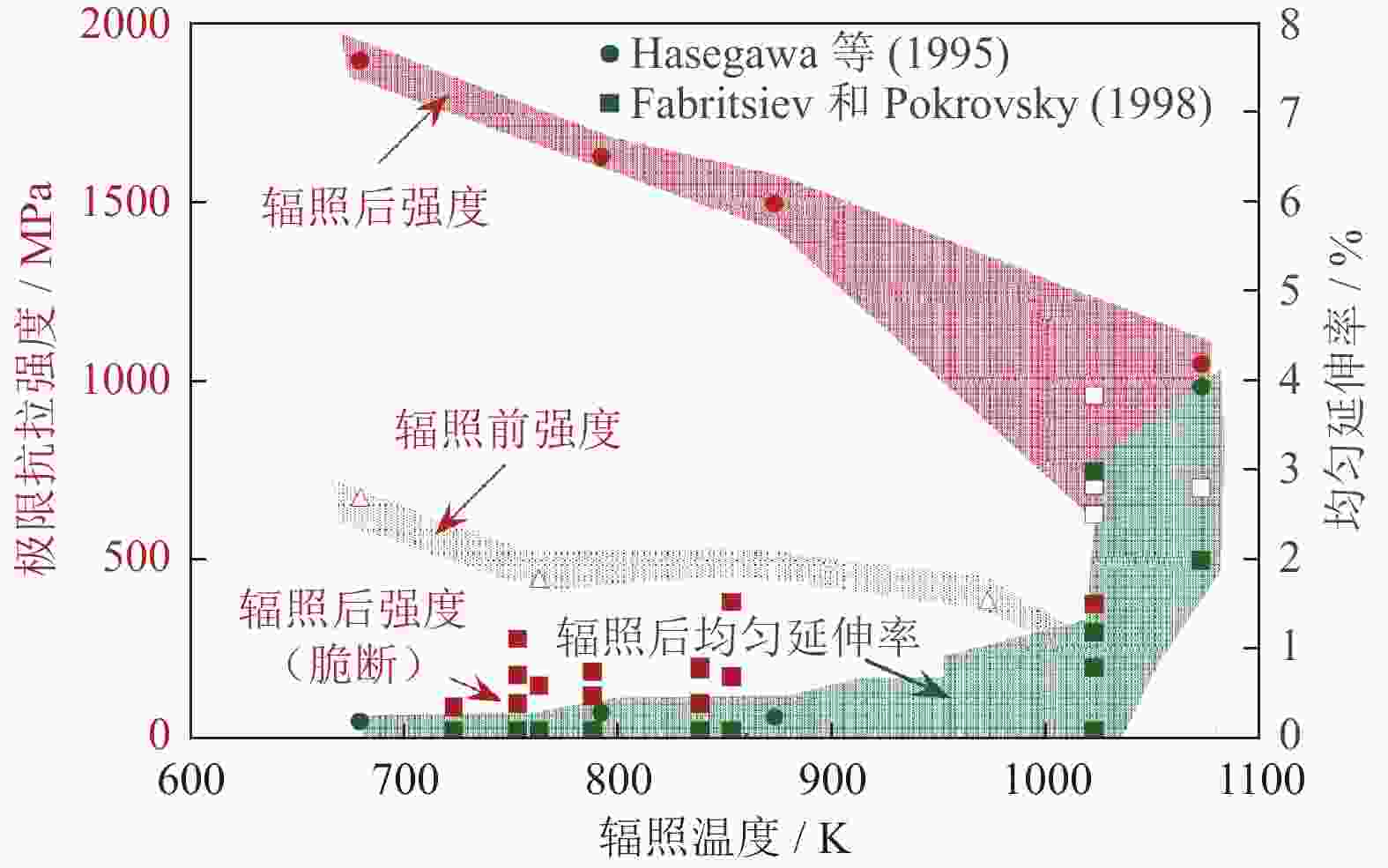

|

| [13] |

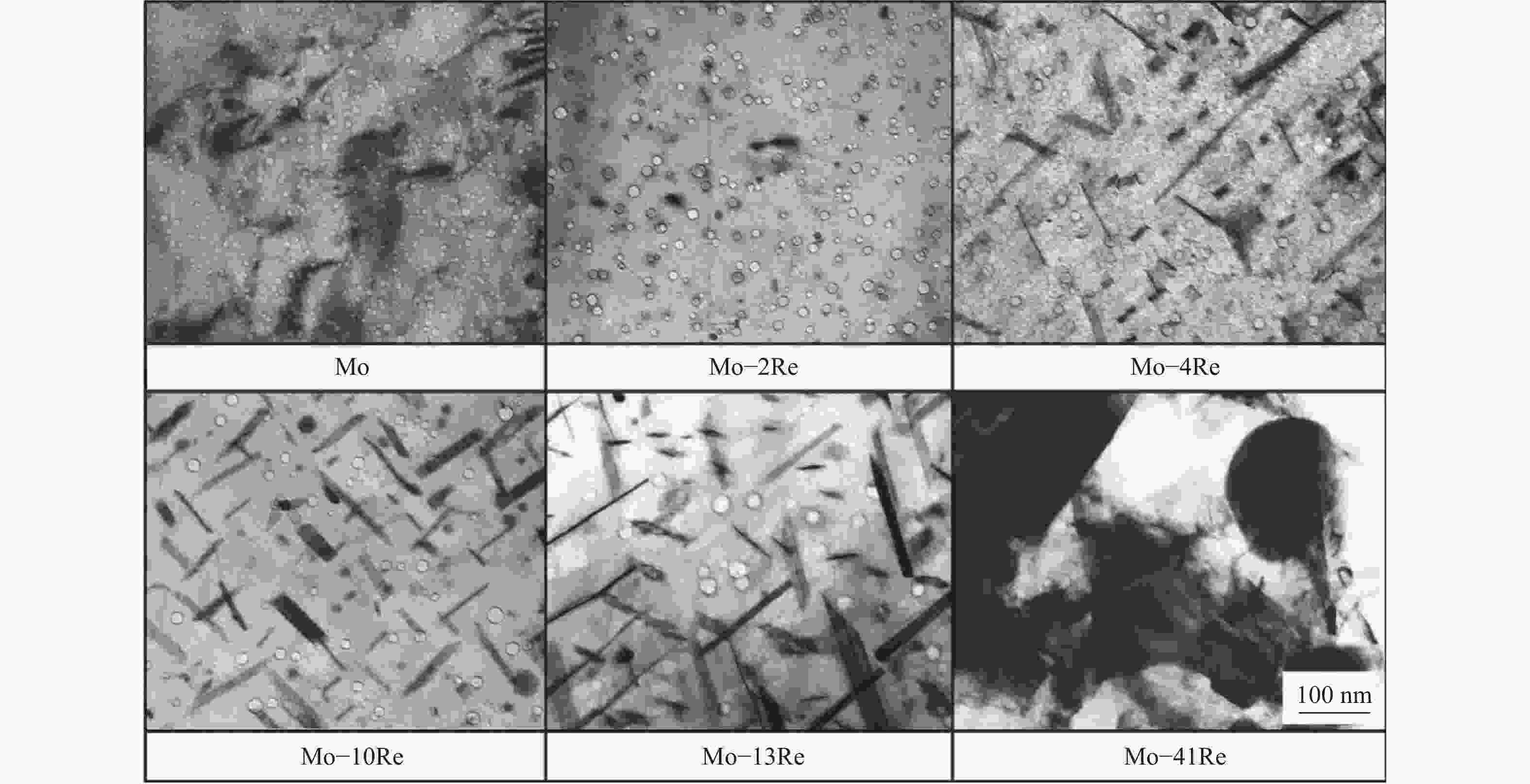

Kambe M, Tsunoda H, Mishima K, et al. Rapid-L operator-free fast reactor concept without any control rods. Nucl Technol, 2003, 143(1): 11 doi: 10.13182/NT03-A3394

|

| [14] |

Liu R Z, An G, Yang Q L, et al. Microstructures and mechanical properties of Mo−Re−La alloy. Powder Metall Technol, 2018, 36(6): 30 doi: 10.19591/j.cnki.cn11-1974/tf.2018.06.005刘仁智, 安耿, 杨秦莉, 等. 钼−铼−镧合金微观组织及力学性能研究. 粉末冶金技术, 2018, 36(6): 30 doi: 10.19591/j.cnki.cn11-1974/tf.2018.06.005

|

| [15] |

Mueller A J, Bianco R, Buckman R W. Evaluation of oxide dispersion strengthened (ODS) molybdenum and molybdenum–rhenium alloys. Int J Refract Met Hard Mater, 1999, 18(4-5): 205

|

| [16] |

Tyumentsev A N, Manako V V, Korotaev A D. Influence of the temperature and structural state on the systematic features of plastic deformation in Mo−Re-based alloys. Russ Phys J, 1994, 37(12): 1193 doi: 10.1007/BF00569803

|

| [17] |

Liu S, Cao Y, Shu J B. Study of mechanical behavior of low rhenium molybdenum alloys. Rare Met Cemented Carb, 1999(3): 33刘沙, 曹昱, 舒金波. 低铼钼合金力学性能的研究. 稀有金属与硬质合金, 1999(3): 33

|

| [18] |

Osadnik M, Wrona A, Lis M, et al. Plasma-sprayed Mo−Re coatings for glass industry applications. Surf Coat Technol, 2017, 318: 349 doi: 10.1016/j.surfcoat.2017.01.056

|

| [19] |

Mitchell D, Todd L, Jim D, et al. Powder Materials: Current Research and Industrial Practices III. Chicago: John Wiley & Sons Press, 2014

|

| [20] |

Cheetham A K. Low-temperature preparation of refractory alloys. Nature, 1980, 288: 469 doi: 10.1038/288469a0

|

| [21] |

Liu S, Zhang C Z, Zhao L Z, et al. Study on mixing method of molybdenum−rhenium powder. Rare Met Mater Eng, 1985(5): 33刘沙, 张传忠, 赵连仲, 等. 钼−铼粉末混合方法的研究. 稀有金属材料与工程, 1985(5): 33

|

| [22] |

Garin J L, Mannheim R L. Manufacturing of Mo−25Re and Mo−50Re alloys by means of powder sintering at medium temperatures. Adv Manuf Processes, 1998, 13(5): 731 doi: 10.1080/10426919808935295

|

| [23] |

Osadnik M, Staszewski M, Czepelak M. Phase transformations in Mo−Re alloys produced by pressure sintering. Solid State Phenom, 2010, 163: 191 doi: 10.4028/www.scientific.net/SSP.163.191

|

| [24] |

Mannheim R L, Garin J L. Structural identification of phases in Mo–Re alloys within the range from 5 to 95% Re. J Mater Process Technol, 2003, 143-144: 533 doi: 10.1016/S0924-0136(03)00342-X

|

| [25] |

Carlen J C, Bryskin B D. Cold-forming mechanisms and work-hardening rate for rhenium. Int J Refract Met Hard Mater, 1992, 11(6): 343 doi: 10.1016/0263-4368(92)90088-J

|

| [26] |

Mannheim R L, Garin J L. Strain hardening of rhenium and two typical molybdenum−rhenium alloys manufactured by powder sintering. Z Metallkd, 2000, 91: 848

|

| [27] |

Feli V M, Li J H. Extrusion method of Mo−Re alloy pipe. Tungsten Molybdenum Mater, 1997(2): 6Feli V M, 李俊怀. 钼−铼合金管的挤压方法. 钨钼材料, 1997(2): 6

|

| [28] |

Lü Z, Xing Y H. Study on the Mo−Re alloy sheet. China Molybdenum Ind, 1992(1): 18吕忠, 邢英华. 钼铼合金板材研究. 中国钼业, 1992(1): 18

|

| [29] |

Zhang J L, Li Z K, Fu J, et al. The effect of cross rolling and annealing on the deep drawability of Mo−Re alloys foil. China Molybdenum Ind, 2009(3): 37 doi: 10.3969/j.issn.1006-2602.2009.03.010张军良, 李中奎, 付洁, 等. 交叉轧制及退火对钼铼合金箔材深冲性能的影响. 中国钼业, 2009(3): 37 doi: 10.3969/j.issn.1006-2602.2009.03.010

|

| [30] |

Morito F. Effect of heat treatment on mechanical behavior of electron beam welded sintered molybdenum. J Nucl Mater, 1989, 165(2): 142 doi: 10.1016/0022-3115(89)90242-0

|

| [31] |

Morito F. Characteristics of EB-weldable molybdenum and Mo−Re alloys. JOM, 1993, 45(6): 54 doi: 10.1007/BF03223314

|

| [32] |

Wu L, Xia C Z, Liu P. Research status of molybdenum rhenium alloy welding technology. Weld Join, 2017(2): 4 doi: 10.3969/j.issn.1001-1382.2017.02.003吴磊, 夏春智, 刘鹏. 钼铼合金焊接技术研究现状. 焊接, 2017(2): 4 doi: 10.3969/j.issn.1001-1382.2017.02.003

|

| [33] |

Zhang L L, Zhang L J, Long J, et al. Effects of titanium on grain boundary strength in molybdenum laser weld bead and formation and strengthening mechanisms of brazing layer. Mater Des, 2019(1): 22

|

| [34] |

Felix V M, Wells D A. Friction Welding Molybdenum−Rhenium Alloy: US Patent, US5261592A. 1993-11-16

|

| [35] |

Fabritsiev S A, Gosudarenkova V A, Potapova V A, et al. Effects of neutron irradiation on physical and mechanical properties of Mo−Re alloys. J Nucl Mater, 1992(2): 426

|

| [36] |

Evans J H. Radiation-induced shrinkage of voids in molybdenum and TZM. Nature, 1979, 278: 728 doi: 10.1038/278728a0

|

| [37] |

Nemoto Y, Hasegawa A, Satou M, et al. Microstructural development and radiation hardening of neutron irradiated Mo–Re alloys. J Nucl Mater, 2004, 324(1): 63

|

| [38] |

Busby J T, Leonard K J, Zinkle S J. Radiation-damage in molybdenum–rhenium alloys for space reactor applications. J Nucl Mater, 2007, 366(3): 388 doi: 10.1016/j.jnucmat.2007.03.028

|

| [39] |

Hasegawa A, Ueda K, Satou M, et al. Neutron irradiation embrittlement of molybdenum rhenium alloys and their improvement by heat treatment. J Nucl Mater, 1998, 258(4): 902

|

| [40] |

Cockeram B V, Smith R W, Hashimoto N, et al. The swelling, microstructure, and hardening of wrought LCAC, TZM, and ODS molybdenum following neutron irradiation. J Nucl Mater, 2011, 418(1-3): 121 doi: 10.1016/j.jnucmat.2011.05.055

|

| [41] |

King J C, El-Genk M S. Review of refractory materials for alkali metal thermal-to-electric conversion cells. J Propul Power, 2012, 17(3): 547

|

| [42] |

Devan J H, Litman A P, Distefano J R, et al. Lithium and potassium corrosion studies with refractory metals. Alk Met, 1967(3): 12

|

| [43] |

Katsuta H, Furukawa K. Air contamination effects on the compatibility of liquid lithium with molybdenum; TZM, niobium, stainless steels, nickel and hastelloy N in stainless-steel vessels at 600 ℃. J Nucl Mater, 1977, 71(1): 95 doi: 10.1016/0022-3115(77)90192-1

|

| [44] |

Distefano J R. Review of alkali metal and refractory alloy compatibility for Rankine cycle applications. J Mater Eng, 1989, 11(3): 215 doi: 10.1007/BF02834839

|

| [45] |

Saito J I, Morinaga M, Kano S, et al. Corrosion behavior of Mo–Re based alloys in liquid Li. J Nucl Mater, 1999, 264(1-2): 206 doi: 10.1016/S0022-3115(98)00459-0

|

| [46] |

Carlen J C, Bryskin B D. Rhenium—A unique rare metal. Adv Manuf Processes, 2007, 9(6): 1087

|

| [47] |

Zhu Z J, Yang W, Shi J J, et al. A preliminary study of oxidation behavior of Mo−50Re alloy at different temperature using positron annihilation lifetime spectroscopy. Defect Diffus Forum, 2016(373): 134

|

| [48] |

Distefano J R, Chitwood L D. Oxidation of Mo−Re at reduced oxygen pressures // Proceedings of Space Technology and Applications International Forum. Albuquerque, 2001: 1076

|

| [49] |

Wilkes K E, Williams R K, Moore J P, et al. Thermophysical properties of Mo−47.5wt.% Re alloy // The 26th International Thermal Conductivity Conference (ITCC) and The 14th International Thermal Expansion Symposium (ITES). Massachusetts, 2001: 179

|

下载:

下载: