Hot deformation behavior and ring rolling process of SiCp/Al composites used in aircraft manufacturing

-

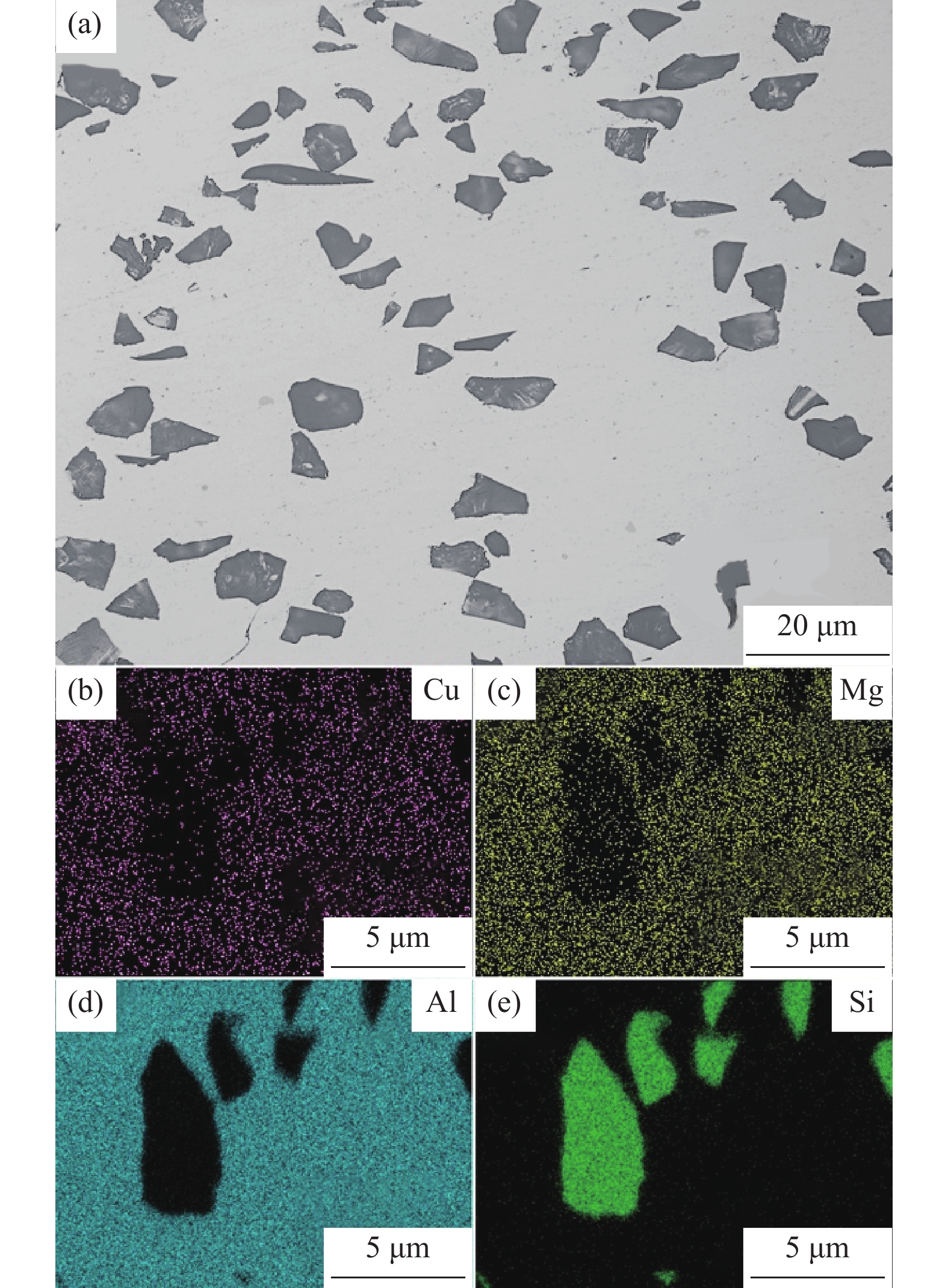

摘要: 为了研究航空用高强韧碳化硅颗粒增强铝基复合材料(SiCp/Al)的热变形行为,为环轧制备航空用大尺寸环件提供工艺依据,采用粉末冶金工艺制备了17%SiCp/Al复合材料(体积分数)。通过不同温度与不同变形速率的热压缩实验,获得了复合材料在不同热变形条件下的应力应变关系,并根据这一关系建立了复合材料的热加工图。研究结果表明,SiCp/Al复合材料随着变形量的增加,在低于440 ℃或高于490 ℃以及高于0.100 s‒1的变形速率下易发生失稳变形。SiCp/Al复合材料在变形温度与变形速率不适宜时,除了发生传统金属的失稳变形等工艺缺陷外,还会出现颗粒损伤引起的表面开裂,这种开裂无法通过机加工去除,应予以避免。最后,在热加工图的指导以及环轧实验验证下,给出了适宜SiCp/Al复合材料环轧成型的工艺参数,完成了外径达1200 mm的SiCp/Al复合材料环件制备。

-

关键词:

- 粉末冶金 /

- 颗粒增强铝基复合材料 /

- 热变形行为 /

- 环轧

Abstract: To study the thermal deformation behavior of high-strength and high-toughness SiC particle reinforced aluminum matrix composites (SiCp/Al) used in aircraft manufacturing and to provide the technical basis for the preparation of large size rings by ring rolling used for the aviation, the 17%SiCp/Al composites (volume fraction) were prepared by powder metallurgy process. The stress-strain relationships of the SiCp/Al composites under the different thermal deformation conditions were obtained through the thermal compression experiments at the different temperatures and deformation rates, and the thermal working diagram was established according to the relationship. In the results, with the increase of deformation, the SiCp/Al composites are prone to the instability deformation at the deformation temperature lower than 440 ℃ or higher than 490 ℃ and the deformation rates higher than 0.100 s‒1. When the deformation temperature and deformation rate of the SiCp/Al composite are not suitable, besides the traditional process defects such as the instability deformation but also the surface cracking caused by the particle damage may occur, which cannot be removed by machining and should be avoided. Finally, under the guidance of the hot working diagram and the verification of the ring rolling experiment, the process parameters suitable for the ring rolling of the SiCp/Al composite are given, and the circular workpieces prepared using the SiCp/Al composites with the outer diameter of 1200 mm are prepared. -

图 6 1#样件扩孔时发生多次开裂后的裂纹宏观形貌(a),1#样件裂纹附近微观组织(b),2#样件在环轧过程中发生失稳变形的宏观形貌(c)及3#样件完成环轧后宏观形貌(d)

Figure 6. Cracking macro appearance of 1# part (a), the microstructure near the cracks of 1# part (b), the macro appearance of 2# part after the buckling deformation during rolling (c), and the macro appearance of 3# part finished the ring rolling process (d)

表 1 Al‒Cu‒Mg合金化学成分(质量分数)

Table 1. Chemical composition of the Al‒Cu‒Mg alloys

% Cu Mg Al 4.8 2.0 93.2 表 2 SiCp/Al复合材料环轧工艺方案

Table 2. Processing parameter of ring rolling for the SiCp/Al composites

样件编号 变形速率 / s‒1 变形温度 / ℃ 单次变形量 1# 0.100 450 0.3 2# 0.010 480 0.1 3# 0.010 450 0.1 -

[1] Kumar S, Singh R, Hashmi M S J. Metal matrix composite: a methodological review. Adv Mater Process Technol, 2019, 6(1): 13 [2] Zhou L Y, Li X L, Zhong Q, et al. Research progress in preparation of ceramic particle reinforced aluminum matrix composites. Hot Working Technol, 2020, 49(18): 21 doi: 10.14158/j.cnki.1001-3814.20183200周立玉, 李秀兰, 钟强, 等. 陶瓷颗粒增强铝基复合材料制备工艺研究进展. 热加工工艺, 2020, 49(18): 21 doi: 10.14158/j.cnki.1001-3814.20183200 [3] Nardone V C, Prewo K M. On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr Metall, 1986, 20(1): 43 doi: 10.1016/0036-9748(86)90210-3 [4] Hou Y N, Yang K M, Liu Y, et al. Research progress on the effect of interfacial thermal mismatch on mechanical properties of metal matrix composites. Powder Metall Technol, https://doi.org/10.19591/j.cnki.cn11-1974/tf.2021030033侯雅男, 杨昆明, 刘悦, 等. 界面热失配对金属基复合材料力学性能的影响研究. 粉末冶金技术, https://doi.org/10.19591/j.cnki.cn11-1974/tf.2021030033 [5] Ashby M F, Johnson L. On the generation of dislocations at misfitting particles in a ductile matrix. Philos Mag A, 1969, 20(167): 1009 doi: 10.1080/14786436908228069 [6] Miller W S, Humphreys F J. Strengthening mechanisms in particulate metal matrix composites. Scr Metall Mater, 1991, 25(1): 33 doi: 10.1016/0956-716X(91)90349-6 [7] Yang Z, Fan J, Liu Y, et al. Effect of the particle size and matrix strength on strengthening and damage process of the particle reinforced metal matrix composites. Materials, 2021, 14(3): 675 doi: 10.3390/ma14030675 [8] Lewis C A, Withers P J. Weibull modelling of particle cracking in metal matrix composites. Acta Metall Mater, 1995, 43(10): 3685 doi: 10.1016/0956-7151(95)90152-3 [9] Chen J, Xiong N, Ge Q L, et al. Fabrication and properties of large size aluminum-based boron carbide composites by hot isostatic pressing. Powder Metall Technol, 2020, 38(2): 132 doi: 10.19591/j.cnki.cn11-1974/tf.2020.02.008陈锦, 熊宁, 葛启录, 等. 热等静压法制备大尺寸铝基碳化硼复合材料及性能研究. 粉末冶金技术, 2020, 38(2): 132 doi: 10.19591/j.cnki.cn11-1974/tf.2020.02.008 [10] Chegini M, Aboutalebi M R, Seyedein S H, et al. Study on hot deformation behavior of AISI 414 martensitic stainless steel using 3D processing map. J Manuf Process, 2020, 56: 916 doi: 10.1016/j.jmapro.2020.05.008 [11] Lin N, Huang N, Dong N, et al. Hot deformation behaviors in Ti−6Al−4V/(TiB+TiC) composites. Acta Metall Sinica, 2021, 34(12): 11 [12] Wang J, Li S, Ma H. Evolution of microstructure, texture, and mechanical properties of as-extruded ND/ZK60 composite during hot compression deformation. Metals, 2020, 10(9): 1191 doi: 10.3390/met10091191 [13] Meng Q, Bai C, Xu D. Flow behavior and processing map for hot deformation of ATI425 titanium alloy. J Mater Sci Technol, 2018, 34(4): 679 doi: 10.1016/j.jmst.2017.07.015 [14] Pang J A, Peng M Q, Hao S M. Study on hot deformation behavior and hot processing map of 40%SiCp/Al composites. Powder Metall Technol, https://doi.org/10.19591/j.cnki.cn11-1974/tf.2021080007庞晋安, 彭名卿 , 郝世明. 40%SiCp/Al复合材料的热变形行为及热加工图研究. 粉末冶金技术, https://doi.org/10.19591/j.cnki.cn11-1974/tf.2021080007 [15] Yang Q, Lei L, Fan X, et al. Microstructure evolution and processing map of Al–Cu–Li–Mg–Ag alloy. Mater Chem Phys, 2020, 254: 123256 doi: 10.1016/j.matchemphys.2020.123256 [16] Yang Z, Fan J Z, Liu Y Q, et al. Effect of combination variation of particle and matrix on the damage evolution and mechanical properties of particle reinforced metal matrix composites. Mater Sci Eng A, 2021, 806: 140804 doi: 10.1016/j.msea.2021.140804 [17] Williams J J, Flom Z, Amell A A, et al. Damage evolution in SiC particle reinforced Al alloy matrix composites by X-ray synchrotron tomography. Acta Mater, 2010, 58(18): 6194 doi: 10.1016/j.actamat.2010.07.039 -

下载:

下载: