Effect of selective laser melting process on phase transition and tensile properties of NiTi shape memory alloys

-

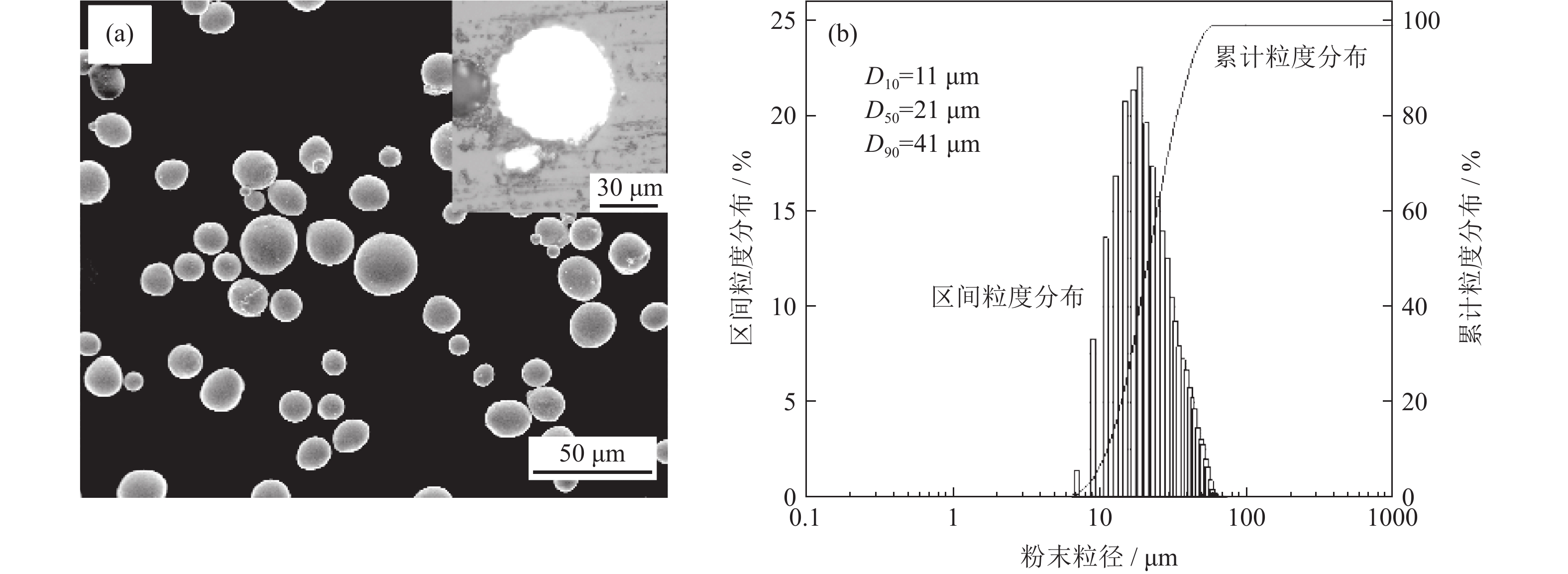

摘要: 采用选区激光熔化成形工艺制备了NiTi形状记忆合金,研究了不同工艺参数组合下激光能量密度对NiTi合金相变、显微组织、拉伸性能和形状记忆性能的影响。结果表明:激光能量密度在45~85 J·mm−3时,试样相对密度均在99.5%以上。随激光能量密度增大,试样中NiTi(B2)相含量有所减少,相变温度逐渐提高。在打印试样中均存在纳米Ti2Ni相,随激光能量密度增大,析出相从均匀点状分布变为半网状分布。激光能量密度为47.62 J·mm−3的试样具有最优综合性能,样品的抗拉强度为(783±3) MPa,断后伸长率为(13.9±0.2)%,室温循环拉伸20次经热回复后回复率可达100%,可回复应变为2.75%。Abstract: TiNi shape memory alloys were prepared by selective laser melting (SLM). The effects of laser energy density on the phase transformation, microstructure, tensile properties, and shape memory properties of the NiTi alloys under the different printing combinations of process parameters were studied. The results show that, when the laser energy density is between 45 J·mm‒3 to 85 J·mm−3, the relative density of the samples is above 99.5%. With the increase of laser energy density, the content of NiTi(B2) phase in the SLM-formed NiTi alloys decreases, and the phase transition temperature increases gradually. Nano Ti2Ni precipitates exist in all the printed samples. With the increase of laser energy density, the precipitates change from the uniform point distribution to the semi-reticular distribution. The SLM-formed samples at the laser energy density of 47.62 J·mm−3 show the best comprehensive performance as the tensile strength of (783±3) MPa, the elongation after fracture of (13.9±0.2)%, the recovery rate of 100%, and the recoverable strain of 2.75% after 20 times of cyclic tensile at room temperature.

-

Key words:

- selective laser melting /

- NiTi alloys /

- shape memory effect /

- phase transformation /

- tensile properties

-

图 7 1#试样透射电镜和高分辨率透射电镜形貌:(a)晶粒形貌;(b)位错网络;(c)Ti2Ni析出相分布;(d)Ti2Ni/NiTi(B2)界面的高分辨率透射电镜形貌及相应的快速傅立叶变换(fast fourier transform,FFT)图像

Figure 7. TEM images and HRTEM images of the 1# samples: (a) grain morphology; (b) dislocation network; (c) Ti2Ni precipitation phase distribution; (d) HRTEM image of Ti2Ni/NiTi (B2) interface and the corresponding FFT image

表 1 选区激光熔化制备NiTi合金工艺参数

Table 1. SLM process parameters of the NiTi alloys

实验编号 激光功率 / W 扫描速率 / (mm·s‒1) 粉末层厚 / μm 扫描间距 / μm 能量密度 / (J·mm‒3) 1# 80 700 30 80 47.62 2# 100 700 30 80 59.52 3# 80 500 30 80 66.67 4# 100 500 30 80 83.33 表 2 不同能量密度下制备SLMed-NiTi合金的临界应力、抗拉强度和断后伸长率

Table 2. Critical stress, tensile strength, and plasticity of the SLMed-NiTi alloys formed under the different energy densities

试样 临界应力 / MPa 抗拉强度 / MPa 断后伸长率 / % 1# 430±3 783±3 13.9±0.2 2# 377±2 675±4 11.4±0.3 3# 302±3 752±3 13.0±0.2 4# 144±4 579±5 11.9±0.2 -

[1] Buehler W J, Gilfrich J V, Wiley R C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J Appl Phys, 1963, 34(5): 1475 doi: 10.1063/1.1729603 [2] Otsuka K, Ren X B. Recent developments in the research of shape memory alloys. Intermetallics, 1999, 7(5): 511 doi: 10.1016/S0966-9795(98)00070-3 [3] Moghaddam N S, Skoracki R, Miller M, et al. Three dimensional printing of stiffness-tuned, nitinol skeletal fixation hardware with an example of mandibular segmental defect repair. Procedia CIRP, 2016, 49: 45 doi: 10.1016/j.procir.2015.07.027 [4] Speirs M, Wang X, Baelen S V, et al. On the transformation behavior of NiTi shape-memory alloy produced by SLM. Shap Mem Superelasticity, 2016, 2: 310 doi: 10.1007/s40830-016-0083-y [5] Jani J M, Leary M, Subic A, et al. A review of shape memory alloy research, applications and opportunities. Mater Des, 2014, 56: 1078 doi: 10.1016/j.matdes.2013.11.084 [6] Moghaddam N S, Jahadakbar A, Amerinatanzi A, et al. Recent advances in laser-based additive manufacturing // Laser-Based Additive Manufacturing of Metal Parts. Boca Raton, 2017: 1 [7] Elahinia M, Moghaddam N S, Andani M T, et al. Fabrication of NiTi through additive manufacturing: a review. Prog Mater Sci, 2016, 83: 630 doi: 10.1016/j.pmatsci.2016.08.001 [8] Hassan M R, Mehrpouya M, Dawood S. Review of the machining difficulties of nickel-titanium based shape memory alloys. Appl Mech Mater, 2014, 564: 533 doi: 10.4028/www.scientific.net/AMM.564.533 [9] Elahinia M H, Hashemi M, Tabesh M, et al. Manufacturing and processing of NiTi implants: a review. Prog Mater Sci, 2012, 57(5): 911 doi: 10.1016/j.pmatsci.2011.11.001 [10] Wu M H. Fabrication of nitinol materials and components. Mater Sci Forum, 2002, 394-395: 285 doi: 10.4028/www.scientific.net/MSF.394-395.285 [11] Haberland C, Elahinia M, Walker J M, et al. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater Struct, 2014, 23(10): 104002 doi: 10.1088/0964-1726/23/10/104002 [12] Jahadakbar A, Moghaddam N S, Amerinatanzi A, et al. Finite element simulation and additive manufacturing of stiffness-matched NiTi fixation hardware for mandibular reconstruction surgery. Bioengineering, 2016, 3(4): 36 doi: 10.3390/bioengineering3040036 [13] Amerinatanzi A, Moghaddam N S, Ibrahim H, et al. Evaluating a NiTi implant under realistic loads: a simulation study // Proceedings of the ASME 2016 Smart Materials, Adaptive Structures and Intelligent Systems. Stowe, 2016: 28 [14] Saedi S, Moghaddam N S, Amerinatanzi A, et al. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater, 2018, 144: 552 doi: 10.1016/j.actamat.2017.10.072 [15] Moghaddam N S, Saghaian S E, Amerinatanzi A, et al. Anisotropic tensile and actuation properties of NiTi fabricated with selective laser melting. Mater Sci Eng A, 2018, 724: 220 doi: 10.1016/j.msea.2018.03.072 [16] Dadbakhsh S, Speirs M, Kruth J P, et al. Influence of SLM on shape memory and compression behaviour of NiTi scaffolds. CIRP Ann, 2015, 64(1): 209 doi: 10.1016/j.cirp.2015.04.039 [17] Saedi S, Turabi A S, Andani M T, et al. The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J Alloys Compd, 2016, 677: 204 doi: 10.1016/j.jallcom.2016.03.161 [18] Bormann T, Müller B, Schinhammer M, et al. Microstructure of selective laser melted nickel-titanium. Mater Charact, 2014, 94: 189 doi: 10.1016/j.matchar.2014.05.017 [19] Dadbakhsh S, Vrancken B, Kruth J P, et al. Texture and anisotropy in selective laser melting of NiTi alloy. Mater Sci Eng A, 2016, 650: 225 doi: 10.1016/j.msea.2015.10.032 [20] Moghaddam N S, Saedi S, Amerinatanzi A, et al. Achieving superelasticity in additively manufactured NiTi in compression without post-process heat treatment. Sci Rep, 2019, 9(1): 41 doi: 10.1038/s41598-018-36641-4 [21] Andani M T, Saedi S, Turabi A S, et al. Mechanical and shape memory properties of porous Ni50.1Ti49.9 alloys manufactured by selective laser melting. J Mech Behav Biomed Mater, 2017, 68: 224 doi: 10.1016/j.jmbbm.2017.01.047 [22] Yang Y, Zhan J B, Li B, et al. Laser beam energy dependence of martensitic transformation in SLM fabricated NiTi shape memory alloy. Materialia, 2019, 6: 100305 doi: 10.1016/j.mtla.2019.100305 [23] Lu H Z, Yang C, Luo X, et al. Ultrahigh-performance TiNi shape memory alloy by 4D printing. Mater Sci Eng A, 2019, 763: 1381 [24] Lu H Z, Ma H W, Cai W S, et al. Stable tensile recovery strain induced by a Ni4Ti3 nanoprecipitate in a Ni50.4Ti49. 6 shape memory alloy fabricated via selective laser melting. Acta Mater, 2021, 219: 117261 doi: 10.1016/j.actamat.2021.117261 [25] Ren D C, Zhang H B, Liu Y J, et al. Microstructure and properties of equiatomic Ti–Ni alloy fabricated by selective laser melting. Mater Sci Eng A, 2020, 771(35): 138586 [26] Bimber Beth A, Hamilton R F, Keist J, et al. Anisotropic microstructure and superelasticity of additive manufactured NiTi alloy bulk builds using laser directed energy deposition. Mater Sci Eng A, 2016, 674: 125 doi: 10.1016/j.msea.2016.07.059 [27] Bagheri A, Mahtabi M J, Shamsaei N. Fatigue behavior and cyclic deformation of additive manufactured NiTi. J Mater Process Technol, 2018, 252: 440 doi: 10.1016/j.jmatprotec.2017.10.006 [28] Xiong Z W, Li Z H, Sun Z, et al. Selective laser melting of NiTi alloy with superior tensile property and shape memory effect. J Mater Sci Technol, 2019, 35(10): 2238 doi: 10.1016/j.jmst.2019.05.015 -

下载:

下载: