Effects of Y2O3 on microstructure and mechanical properties of AlCoCrFeNi high-entropy alloy coatings

-

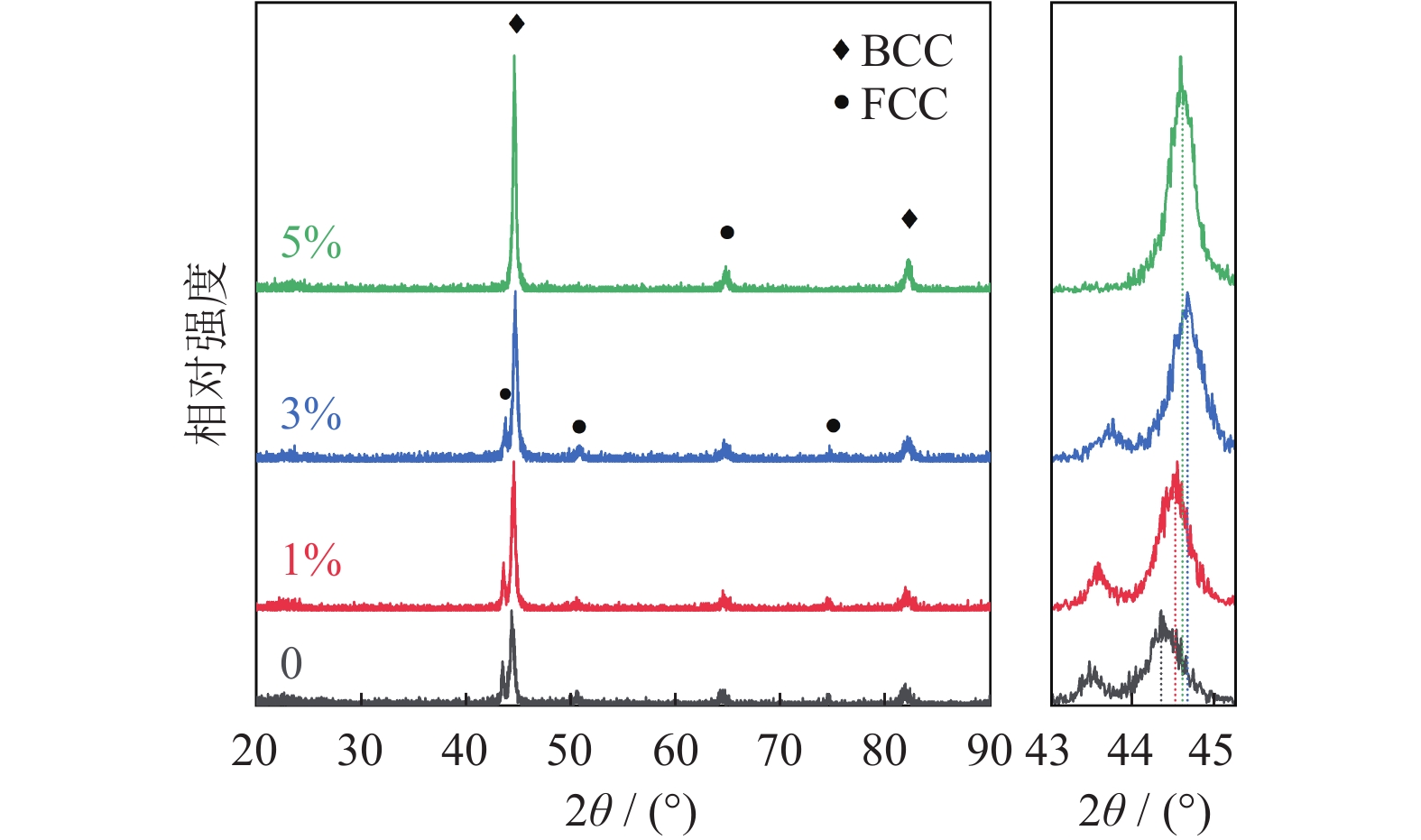

摘要: 利用激光熔覆技术在Q235钢基体表面分别制备出添加不同质量分数Y2O3的AlCoCrFeNi高熵合金涂层。采用X射线衍射仪、扫描电子显微镜、显微硬度计和摩擦磨损试验机对AlCoCrFeNi高熵合金涂层的微观组织、硬度及摩擦磨损性能进行了分析。结果表明:AlCoCrFeNi高熵合金涂层由面心立方结构(FCC)和体心立方结构(BCC)两相构成;随着Y2O3质量分数的提高,其体心立方结构相体积分数增加,而面心立方结构相的体积分数变化呈相反趋势。AlCoCrFeNi高熵合金涂层组织由等轴晶构成,加入Y2O3后,促进了熔池流动,使气孔逐渐消失,致密性提高,晶粒明显细化。添加质量分数5%Y2O3的涂层组织呈树枝晶状,形成弥散分布的YAl2和Y2O3相;涂层的显微硬度可达HV 350,约为AlCoCrFeNi高熵合金涂层硬度的2倍,强化效果明显。Y2O3的添加有利于促进涂层中体心立方相的形成和YAl2相的析出,能有效提高高熵合金涂层的硬度及耐磨性能。Abstract: AlCoCrFeNi high entropy alloy (HEA) coatings add by Y2O3 in the different mass fraction were prepared on Q235 steel matrix by laser cladding technology in this study, and the microstructure, hardness, and wear resistance of the AlCoCrFeNi high entropy alloy coatings were analyzed by X-ray diffractometer, scanning electron microscope, microhardness tester, and friction and wear tester. The results show that, the phase structure of AlCoCrFeNi HEAs coatings is composed of face-centered cubes (FCC) phase and body-centered cubes (BCC) phase. The volume fraction of BCC phase increases with the increase of Y2O3 mass fraction, while the FCC phase volume fraction shows the opposite trend. The microstructure of the AlCoCrFeNi high-entropy alloy coatings is composed of the equiaxed crystals, the addition of Y2O3 promotes the melt pool flow, makes the pores disappear gradually, improves the denseness, and makes the grains become fine. The addition of 5% Y2O3 (mass fraction) in the coatings results in the dendritic organization and the diffusely distributed YAl2 and Y2O3 phases, and the coating microhardness reaches up to HV 350, which is about twice than that of the AlCoCrFeNi high-entropy alloy coatings, showing the obvious strengthening effect. The addition of Y2O3 is beneficial to promote the formation of BCC phase and the precipitation of YAl2 phase in the coatings, which can effectively improve the hardness and wear resistance of the high entropy alloy coatings.

-

Key words:

- laser cladding /

- high entropy alloy /

- dual-phase structure /

- hardness /

- friction /

- wear

-

表 1 CoCrFeMnNi-xY2O3(x=0、1%、3%、5%)高熵合金涂层能谱分析结果

Table 1. EDS analysis results of the CoCrFeMnNi-xY2O3 (x=0, 1%, 3%, 5%) high-entropy alloy coatings

Y2O3质量分数,x / % 区域 Al Co Cr Fe Ni Y 0,图2(a) 1 11.48 17.84 14.82 41.76 14.10 0 2 8.64 18.68 14.48 44.35 13.85 0 1,图2(b) 1 9.36 14.70 15.31 49.76 10.67 0.20 2 7.85 14.54 17.14 48.79 11.48 0.20 3,图2(c) 1 11.09 14.37 14.12 48.75 11.39 0.27 2 9.30 14.75 14.78 48.25 12.67 0.25 5,图2(d) 1 9.64 15.56 14.32 48.24 11.46 0.77 2 8.55 16.16 13.71 48.97 11.89 0.73 -

[1] Sun S J, Tan Y Z, Lin H R, et al. Enhanced strength and ductility of bulk CoCrFeMnNi high entropy alloy having fully recrystallized ultrafine-grained structure. Mater Des, 2017, 133: 122 doi: 10.1016/j.matdes.2017.07.054 [2] Zhang X, Cui H Z, Wang M L, et al. Effect of Al content on microstructure and corrosion resistance of AlxCoCrFeNi high entropy alloys. Trans Mater Heat Treat, 2018, 39(12): 29张雪, 崔洪芝, 王明亮, 等. Al含量对AlxCoCrFeNi系高熵合金组织和耐蚀性能的影响. 材料热处理学报, 2018, 39(12): 29 [3] Ma M X, Zhu D C, Wang Z X, et al. Effect of Zr addition on microstructure and wear properties of CoCrCuFeMn high-entropy alloy. Adv Eng Sci, 2021, 53(6): 204马明星, 朱达川, 王志新, 等. Zr元素对CoCrCuFeMn高熵合金组织及耐磨性能的影响. 工程科学与技术, 2021, 53(6): 204 [4] Senkov O N, Jensen J K, Pilchak A L, et al. Compositional variation effects on the microstructure and properties of a refractory high-entropy superalloy AlMo0.5NbTa0. 5TiZr. Mate Des, 2017, 139: 498 [5] Zhang W, Liaw P K, Zhang Y. Science and technology in high-entropy alloys. Sci China Mate, 2018, 61(1): 2 doi: 10.1007/s40843-017-9195-8 [6] Li X F, Fu A, Cao Y K, et al. High-temperature mechanical properties and deformation behavior of carbides reinforced TiNbTaZrHf composite. J Alloys Compd, 2022, 894: 162414 doi: 10.1016/j.jallcom.2021.162414 [7] Das A K. Effect of rare earth oxide additive in coating deposited by laser cladding: A review. Mater Today Proc, 2022, 52: 1558 doi: 10.1016/j.matpr.2021.11.236 [8] Rogal L, Kalita D, Litynska-Dobrzynska L. CoCrFeMnNi high entropy alloy matrix nanocomposite with addition of Al2O3. Intermetallics, 2017, 86: 104 doi: 10.1016/j.intermet.2017.03.019 [9] Li X F, Yang X H, Yi D H, et al. Effects of NbC content on microstructural evolution and mechanical properties of laser cladded Fe50Mn30Co10Cr10-xNbC composite coatings. Intermetallics, 2021, 138: 107309 doi: 10.1016/j.intermet.2021.107309 [10] Jia B, Liu X J, Wang H, et al. Microstructure and mechanical properties of FeCoNiCr high-entropy alloy strengthened by nano-Y2O3 dispersion. Sci China Technol Sci, 2018, 61(2): 179 doi: 10.1007/s11431-017-9115-5 [11] Guo T M, Pu Y B, Zhang R H, et al. Influence of Y2O3 content on microstructure and properties of laser cladding 0.3C-18Cr alloy coating. Rare Met Mater Eng, 2019, 48(11): 3643郭铁明, 蒲亚博, 张瑞华, 等. Y2O3含量对激光熔覆0.3C-18Cr合金涂层组织和性能的影响. 稀有金属材料与工程, 2019, 48(11): 3643 [12] Wang C L, Gao Y, Zhang G Y. Effect of Y2O3 addition on interface structure and corrosion resistance of laser additive manufacturing on the surface of Al alloys. Rare Met Mater Eng, 2017, 46(3): 812王成磊, 高原, 张光耀. Y2O3对铝合金表面激光增材制造组织及耐蚀性影响. 稀有金属材料与工程, 2017, 46(3): 812 [13] Gu X, Jiang S, Cao F, et al. A β-solidifying TiAl alloy reinforced with ultra-fine Y-rich precipitates. Scr Mater, 2021, 192: 55 doi: 10.1016/j.scriptamat.2020.10.010 [14] Li X F, Feng X H, Liu B, et al. Influence of NbC particles on microstructure and mechanical properties of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. J Alloys Compd, 2019, 788: 485 doi: 10.1016/j.jallcom.2019.02.223 [15] Liu H, Sun S F, Zhang T, et al. Effect of Si addition on microstructure and wear behavior of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. Surf Coat Technol, 2021, 405: 126522 doi: 10.1016/j.surfcoat.2020.126522 [16] Miao X J, Xia S H, Wu M P, et al. Effect of adding CeO2 on properties of Al-Ti laser clad coating on aluminum alloy. Heat Treat Met, 2021, 46(9): 234缪小进, 夏思海, 武美萍, 等. 添加CeO2对铝合金表面激光熔覆铝钛熔覆层性能的影响. 金属热处理, 2021, 46(9): 234 -

下载:

下载: