Interfacial microstructure and properties of steel bonded cemented carbide/Q235 steel by vacuum fusion

-

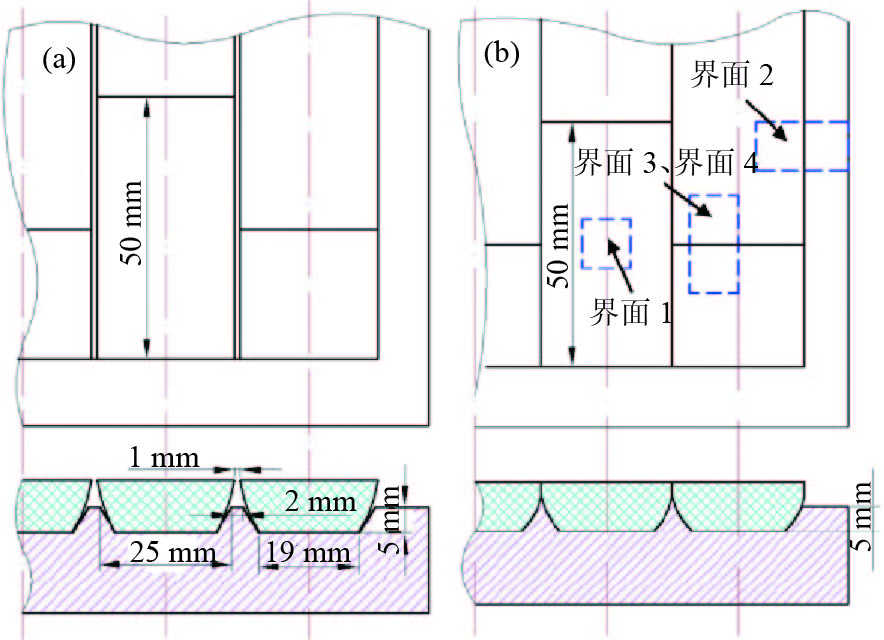

摘要: 采用真空熔结工艺制备了TiC钢结硬质合金/Q235钢复合板,研究了复合板界面显微组织和力学性能。结果表明:钢结硬质合金与Q235钢基体之间形成了一定宽度的互溶区,互溶区宽度主要取决于熔结温度和熔结时间。Mn、Ni、Mo元素由钢结硬质合金经互溶区向基体中扩散,Fe元素由基体通过互溶区向钢结硬质合金扩散。互溶区是材料显微组织、化学成分及显微硬度变化的过渡区。复合板界面剪切强度为176~245 MPa,表明钢结硬质合金与Q235钢基体之间形成冶金结合。Abstract: The composite plates of TiC-based steel bonded cemented carbides and Q235 steels were prepared by vacuum fusion. The interfacial microstructure and mechanical properties of the composite plates were investigated. The results show that, there is a certain width mutual dissolution zone between the steel bonded cemented carbides and Q235 steel matrix, and the width of the mutual dissolution zone depends on the fusion temperature and fusion time. Mn, Ni, and Mo elements diffuse from the steel bonded cemented carbides to the matrix through the mutual dissolution zone, and Fe element diffuses from the matrix to the steel bonded cemented carbides through the mutual dissolution zone. The mutual dissolution zone is the transition zone of microstructure, chemical composition, and microhardness. The shear strength of the composite plate interface is 176~245 MPa, indicating that the metallurgical bonding between the steel bonded cemented carbides and Q235 steels matrix is formed.

-

表 1 钢结硬质合金化学成分(质量分数)

Table 1. Chemical composition of the steel bonded cemented carbides

% TiC C Mn Ni Mo Fe 50~58 0.8~2.1 8~10 1~3 0.6~3.0 余量 元素 A B C D E F Fe 52.3046 65.7974 75.0251 90.9639 93.7813 97.4950 Ti 34.4689 25.1755 16.0481 1.2048 0 0 C 9.6192 4.9147 4.8144 3.0121 2.8084 2.4048 Mn 1.7034 2.7081 3.3099 4.0543 2.7585 0 Ni 0.9018 0.7021 0.6018 0.5786 0.5014 0 Mo 1.0020 0.7021 0.2006 0.1864 0.1503 0.1002 -

[1] Zhu Y C. Microstructure and Mechanism of Interface Layer of Composite Casting Wear-Resiting Thin Plate Based on Liquid-Semisolid Bimetal Process [Dissertation]. Harbin: Harbin Institute of Technology, 2017朱永长. 液/半固态双金属铸造复合耐磨薄板界面层组织及形成机制[学位论文]. 哈尔滨: 哈尔滨工业大学, 2017 [2] Ma H, Luo J. Preparation and high temperature oxidation properties of TiC−NiCrCoMo steel bonded cemented carbides. Powder Metall Technol, 2021, 39(2): 147马会, 罗骥. TiC‒NiCrCoMo钢结硬质合金的制备与高温氧化性能. 粉末冶金技术, 2021, 39(2): 147 [3] Fan X P, Fan W. Research status and development tendency of steel bonded carbide. Foundry Technol, 2017, 38(3): 507范兴平, 范维. 钢结硬质合金研究现状与发展趋势. 铸造技术, 2017, 38(3): 507 [4] Fan A P, Xiao P A, Li C K, et al. Research situation of TiC-based steel bonded carbide. Powder Metall Technol, 2013, 31(4): 298范安平, 肖平安, 李晨坤, 等. TiC基钢结硬质合金的研究现状. 粉末冶金技术, 2013, 31(4): 298 [5] Gong H L. The Research of Technology on Torch Brazing Steel Bond Hard Alloy TM60 and Steel [Dissertation]. Zhengzhou: Zhengzhou University, 2013宫红亮. 钢结硬质合金TM60与钢火焰钎焊工艺的研究[学位论文]. 郑州: 郑州大学, 2013 [6] Hou S Z, Bao C G, Han J D, et al. Abrasive wear behavior of steel bonded carbide/medium Cr steel composite. Mater Prot, 2019, 52(4): 20侯书增, 鲍崇高, 韩建东, 等. 钢结硬质合金/中铬钢复合材料的磨料磨损性能. 材料保护, 2019, 52(4): 20 [7] Hou S Z, Bao C G, Han J D, et al. Wear behavior of medium Cr steel matrix composite localized reinforced by steel bonded carbide. Hot Working Technol, 2020, 49(22): 80侯书增, 鲍崇高, 韩建东, 等. 钢结硬质合金局域化增强中铬钢基复合材料的磨损性能. 热加工工艺, 2020, 49(22): 80 [8] Wu Z X. Practical Technology of Vacuum Fusion of Surface Engineering. Beijing: Metallurgical Industry Press, 2016吴仲行. 真空熔结表面工程实用技术. 北京: 冶金工业出版社, 2016 [9] Ma Z, Tao Y, Li H Y, et al. Process of vacuum fusion technology. Hot Working Technol, 2012, 41(18): 4马壮, 陶莹, 李海玉, 等. 真空熔结工艺研究进展. 热加工工艺, 2012, 41(18): 4 [10] Dong G, Yan B, Li X, et al. Process in preparation methods of TiC reinforced Fe-based coating. Surf Technol, 2009, 38(1): 4董刚, 严彪, 李翔, 等. TiC增强铁基熔覆层制备方法的研究进展. 表面技术, 2009, 38(1): 4 [11] Wang Z. Study on the Preparation and Properties of CrMo Steel Bonded Titanium Carbide [Dissertation]. Beijing: University of Science and Technology Beijing, 2017王志. TiC‒CrMo钢钢结硬质合金的制备与性能研究[学位论文]. 北京: 北京科技大学, 2017 [12] Guo Y J, Guo D, Zhou T T, et al. Effect of dwelling time on microstructure and property of cemented carbide/steel joint fabricated by partial transient liquid phase bonding. Mater Mech Eng, 2018, 42(8): 7郭亚杰, 郭栋, 周婷婷, 等. 保温时间对部分瞬间液相连接硬质合金/钢接头组织与性能的影响. 机械工程材料, 2018, 42(8): 7 [13] Hasan M, Zhao J, Huang Z, et al. Effects of holding time on the sintering of cemented tungsten carbide powder and bonding with high-strength steel wire. J Mater Eng Perform, 2019, 28(3): 4074 [14] Aramian A, Sadeghian Z, Wan D, et al. Microstructure and texture evolution during the manufacturing of in situ TiC‒NiCr cermet through selective laser melting process. Mater Charact, 2021, 178: 111289 doi: 10.1016/j.matchar.2021.111289 [15] Li Y X, Zhang X S, Zhu Z T, et al. Effect of element Ni diffusion on microstructure and mechanical properties of brazed joints of cemented carbide and steel. Rare Met Mater Eng, 2017, 46(4): 1120李远星, 张晓山, 朱宗涛, 等. Ni元素扩散行为对硬质合金/钢钎焊接头微观组织及力学性能的影响. 稀有金属材料与工程, 2017, 46(4): 1120 [16] Cai X, Xu Y, Liu M, et al. Characterization of iron-based surface multilayer-structured tungsten carbide composite layers by EBSD and FIB/TEM. Surf Coat Technol, 2020, 403: 126365 doi: 10.1016/j.surfcoat.2020.126365 [17] Zhao J Y, Sun Y F. Study on interface and structure of TiC steel bonded carbide and multicomponent low alloy steel by cast-sintering technique. Foundry, 2013, 62(5): 420赵靖宇, 孙玉福. 铸造烧结TiC钢结硬质合金/多元低合金钢复合界面及组织的研究. 铸造, 2013, 62(5): 420 [18] Li S W, Shi J M, Xiong J T, et al. Microstructural characteristics and mechanical properties of WC‒Co/steel joints diffusion bonded utilizing Ni interlayer. Ceram Int, 2021, 47(4): 4446 doi: 10.1016/j.ceramint.2020.09.157 [19] Guo B X, Dong Y, Wang Y, et al. Microstructure and properties of solid-liquid compound interface of 42CrMo steel/Al‒Si alloy. Spec Cast Nonferrous Alloys, 2022, 42(1): 93郭冰鑫, 董渊, 王宇, 等. 42CrMo钢/Al‒Si合金固-液复合界面结构及组织性能. 特种铸造及有色合金, 2022, 42(1): 93 -

下载:

下载: