Pressing the coarse-grained WC−10Co cemented carbide assisted by ultrasonic vibration

-

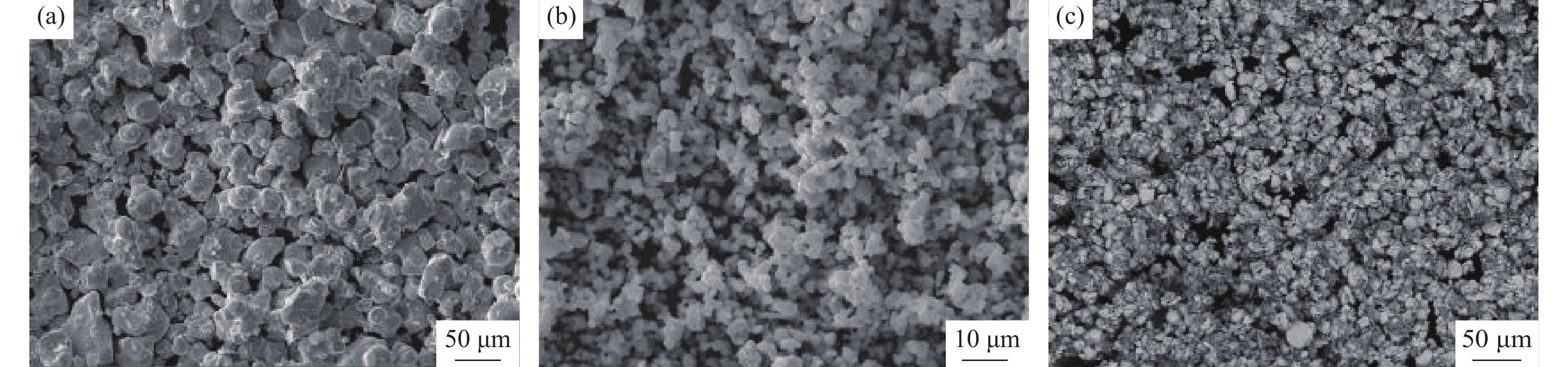

摘要: 为改善粗晶WC−10Co硬质合金在常规压制过程中粉末流动性差、颗粒大小分布不均匀以及合金力学性能差等问题,提出了一种纵向超声辅助压制的工艺方法,研究了压制力、高径比、预压超声时间以及超声振幅等因素对压坯密度、表面质量和合金力学性能的影响。结果表明,与常规压制相比,在超声振动作用下,粉末颗粒发生剧烈碰撞,颗粒间流动性增强,压制力在80~100 MPa之间,压力越大,密度增益越明显;减小高径比,增加预压超声时间,增大超声振幅,压坯密度提升显著;在超声振动作用下,压坯表面质量有所提升,压坯弹性后效下降0.16%;烧结后合金孔隙减少,晶粒大小分布均匀,粗大晶粒减少,在硬度和密度变化较小的情况下,断裂韧性提升了5.83%~16.10%,抗弯强度明显下降。Abstract: The suppression technology assisted by longitudinal ultrasonic vibration was proposed to solve the problems of poor powder fluidity, uneven particle size distribution, and poor mechanical properties for the coarse-grained WC−10Co cemented carbides. The effects of compression force, height-diameter ratio, ultrasonic time of preloading, and ultrasonic amplitude on the compact density, compact surface quality, and mechanical properties of the alloys were discussed. The results show that, compared with the conventional pressing, the powder particles have the violent collision under the effect of ultrasonic vibration, enhancing the fluidity between particles. The density increases with the pressing force increase from 80 to 100 MPa. The compact density increases significantly, when the height-diameter ratio reduces, the ultrasonic time of preloading increases, and the ultrasonic amplitude increases. At the same time, the surface quality of the compacts is improved, and the elastic aftereffect is decreased by 0.16%. The pores of the alloys are reduced, the grain size is evenly distributed, and the coarse grain is reduced after sintering. With the little change in hardness and density, the fracture toughness increases by 5.83%~16.10%, while the bending strength decreases obviously.

-

Key words:

- cemented carbides /

- ultrasonic vibration /

- fluidity /

- compact density /

- mechanical properties

-

表 1 原始粉末性能参数

Table 1. Performance parameters of the raw powders

原料 费氏粒度 / μm 质量分数 / % 松装密度 /

(g·cm−3)总碳 游离碳 氧 WC 9.6 6.11 0.01 0.01 5.7 Co 1.2 0.02 — 0.30 — 表 2 常规压制与超声压制WC−10Co硬质合金力学性能

Table 2. Mechanical properties of the WC−10Co cemented carbides by conventional pressing and ultrasonic pressing

试样 密度 / (g·cm−3) 硬度,HV20 断裂韧性 / (MPa·m2) 抗弯强度 / MPa 常规压制 14.58 1158 20.97 2544 14.57 1170 22.28 2556 14.57 1161 21.02 2420 超声压制 14.62 1163 23.67 2427 14.60 1156 23.58 2150 14.62 1159 24.34 2356 -

[1] Gao D Q, Liu X M, Feng H, et al. Study on microstructure evolution of ultra coarse-grained WC−8Co cemented carbide during cyclic compression. Chin J Stereol Image Anal, 2020, 25(2): 135高德强, 刘雪梅, 冯浩, 等. 超粗晶WC−8Co硬质合金循环压缩过程中组织演变的研究. 中国体视学与图像分析, 2020, 25(2): 135 [2] He R, Li B, Ou P, et al. Effects of ultrafine WC on the densification behavior and microstructural evolution of coarse-grained WC−5Co cemented carbides. Ceram Int, 2020, 46(8): 12852 doi: 10.1016/j.ceramint.2020.01.113 [3] Cao R J, Lin C G, Xie X C, et al. Microstructure and mechanical properties of WC−Co-based cemented carbide with bimodal WC grain size distribution. Rare Met, 2023, 42(8): 2809 doi: 10.1007/s12598-018-1025-y [4] Xu W, Chen Y B, Tang C R, et al. Preparation and formation mechanism of high performance cemented carbide with non-uniform structure. China Tungsten Ind, 2021, 36(1): 48 doi: 10.3969/j.issn.1009-0622.2021.01.008徐伟, 陈玉柏, 汤昌仁, 等. 高性能非均匀结构硬质合金的制备及其形成机理研究. 中国钨业, 2021, 36(1): 48 doi: 10.3969/j.issn.1009-0622.2021.01.008 [5] Ignatieva L N, Zverev G A, Adamenko N A, et al. Peculiarities of the structure of copper- and nickel-fluoropolymer composites fabricated by explosive pressing. J Fluorine Chem, 2015, 172: 68 doi: 10.1016/j.jfluchem.2015.02.002 [6] Asnaashari S, Ghambari M. Preparation and characterization of composite WC/Co through rapid omnidirectional compaction. J Alloys Compd, 2020, 859: 157764 [7] Cao S H, Huang B Y, Qu X H, et al. Densification mechanism of warm compaction and powder mixture designing rules. J Cent South Univ Technol, 2000, 7(1): 4 doi: 10.1007/s11771-000-0002-3 [8] Wang X, Qi Z, Chen W. Study on constitutive behavior of Ti−45Nb alloy under transversal ultrasonic vibration-assisted compression. Arch Civ Mech Eng, 2021, 21(1): 1 doi: 10.1007/s43452-020-00148-5 [9] Bagherzadeh S, Abrinia K, Han Q. Analysis of plastic deformation behavior of ultrafine-grained aluminum processed by the newly developed ultrasonic vibration enhanced ECAP: Simulation and experiments. J Manuf Processes, 2020, 50: 485 doi: 10.1016/j.jmapro.2020.01.010 [10] Du K, Huang J, Chen J, et al. Mechanical property and structure of polypropylene/aluminum alloy hybrid prepared via ultrasound-assisted hot-pressing technology. Materials, 2020, 13(1): 236 doi: 10.3390/ma13010236 [11] Lin J, Li J, Liu T, et al. Evaluation of friction reduction and frictionless stress in ultrasonic vibration forming process. J Mater Process Technol, 2021, 288(7): 116881 [12] Lv K, Yang K, Zhou B, et al. The densification and mechanical behaviors of large-diameter polymer-bonded explosives processed by ultrasonic-assisted powder compaction. Mater Des, 2021, 207: 109872 doi: 10.1016/j.matdes.2021.109872 [13] Zhao Y B, Ma L, Liu B, et al. Analysis of vibration filling density of pure iron powder based on discrete element method. Powder Metall Technol, 2020, 38(6): 429 doi: 10.19591/j.cnki.cn11-1974/tf.2019070006赵艳波, 马麟, 刘波, 等. 基于离散元法的纯铁粉振动填充密度分析. 粉末冶金技术, 2020, 38(6): 429 doi: 10.19591/j.cnki.cn11-1974/tf.2019070006 [14] Wang H L, Liu J, Lin L, et al. Analysis of relative density and force chain of powder with different particle size ratio based on discrete element method. Powder Metall Technol, 2021, 39(6): 490 doi: 10.19591/j.cnki.cn11-1974/tf.2019120014王海陆, 刘军, 林立, 等. 基于离散元的不同粒径配比粉末压制相对密度与力链分析. 粉末冶金技术, 2021, 39(6): 490 doi: 10.19591/j.cnki.cn11-1974/tf.2019120014 [15] Jiang Y, Li X D. Meso simulation analysis of powder pressing. J Gansu Sci, 2020, 32(5): 56 doi: 10.16468/j.cnki.issn1004-0366.2020.05.012蒋煜, 李旭东. 粉末压制成形的细观模拟分析. 甘肃科学学报, 2020, 32(5): 56 doi: 10.16468/j.cnki.issn1004-0366.2020.05.012 [16] Chen C X. Quality Control Principle of Cemented Carbide. Zhuzhou: Cemented Carbide Branch of China Tungsten Industry Association, 2007陈楚轩. 硬质合金质量控制原理. 株洲: 中国钨业协会硬质合金分会, 2007 [17] Sedaghat H, Xu W, Zhang L. Ultrasonic vibration-assisted metal forming: Constitutive modelling of acoustoplasticity and applications. J Mater Process Technol, 2019, 265: 122 doi: 10.1016/j.jmatprotec.2018.10.012 [18] Zhu J F, Zhang L, Xu T, et al. Parametric quantitative analysis of cemented carbide microstructure based on Image J software. Mater Sci Eng Powder Metall, 2015, 20(1): 26朱骥飞, 张立, 徐涛, 等. 基于Image J软件的硬质合金显微组织参数化定量分析. 粉末冶金材料科学与工程, 2015, 20(1): 26 [19] Feng Z, Cheng D F, Li M H, et al. Effect of carbon content on morphology of coarse WC powder and properties of WC−8% Co alloy. Cement Carb, 2021, 38(3): 171冯志, 程登峰, 黎明华, 等. 碳化配碳量对粗颗粒WC粉末形貌及WC−8%Co合金性能的影响. 硬质合金, 2021, 38(3): 171 -

下载:

下载: