Effect of rare earth Yb and Ce on high temperature oxidation resistance of TiAl alloys

-

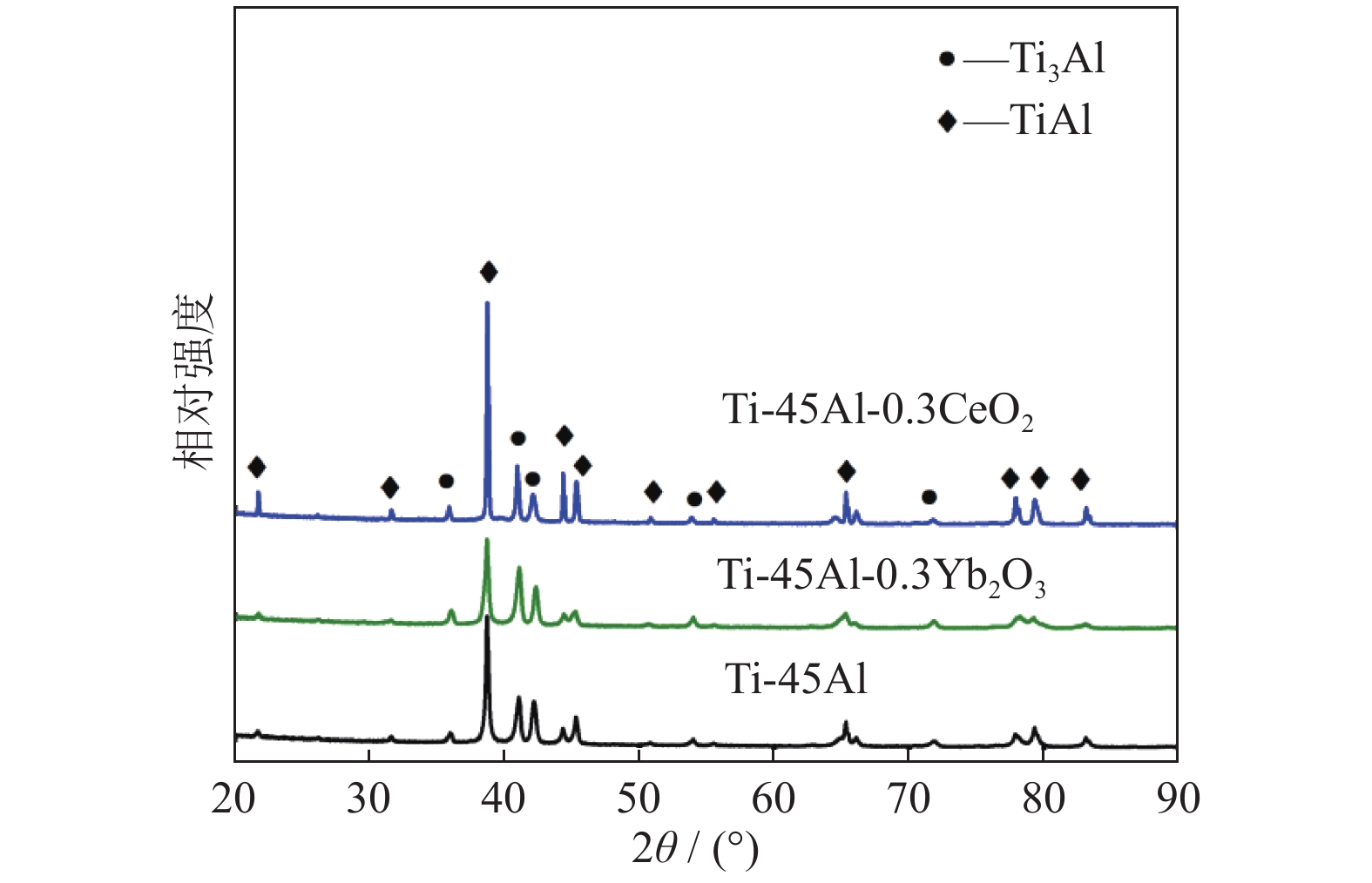

摘要: 采用放电等离子烧结制备添加微量稀土元素的钛铝合金,研究稀土元素Yb、Ce对钛铝合金高温抗氧化性能的影响。利用金相显微镜、扫描电子显微镜和X射线衍射仪分析钛铝合金的组织结构、微观形貌和物相组成,通过高温氧化实验分析合金的高温抗氧化性能。结果表明:经放电等离子烧结制备的钛铝合金的相对密度最高可达99%。800 ℃高温氧化后的氧化动力学曲线均近似遵循抛物线规律;经过100 h的高温氧化处理后,Ti‒45Al、Ti‒45Al‒0.3Yb2O3和Ti‒45Al‒0.3CeO2三种合金的质量增重分别为14.63 g·m‒2、7.02 g·m‒2、8.19 g·m‒2。添加稀土元素的钛铝合金的高温抗氧化性能明显得到改善,其中添加Yb的钛铝合金的高温抗氧化性能提高约1倍。钛铝合金的氧化产物均具有典型层状结构,最外层为TiO2,第二层为TiO2+Al2O3混合氧化物。Abstract: TiAl alloys added with the trace rare earth elements were prepared by spark plasma sintering (SPS). The effects of rare earth elements Yb and Ce on the high temperature oxidation resistance of TiAl alloys were investigated. The microstructure, morphology, and phase composition of TiAl alloys were analyzed by metallographic microscope, scanning electron microscope, and X-ray diffraction. The high temperature oxidation resistance of the alloys was studied by high temperature oxidation experiment. The results show that the relative density of TiAl alloys prepared by SPS is up to 99%. The oxidation kinetics curves of 800 ℃ high temperature oxidation approximately follow the parabolic rule. After the high temperature oxidation at 800 ℃ for 10 h, the mass gain of Ti‒45Al, Ti‒45Al‒0.3Yb2O3, and Ti‒45Al‒0.3CeO2 are 14.63 g·m‒2, 7.02 g·m‒2, and 8.19 g·m‒2, respectively. The high temperature oxidation resistance of the TiAl alloys with the rare earth elements addition is obviously improved, and the high temperature oxidation resistance of Ti‒45Al‒0.3Yb2O3 is increased by about 1 time compared with that of Ti‒45Al. The oxidation products of TiAl alloys have the typical layered structure, the outermost layer is TiO2, and the second layer is TiO2+Al2O3 mixed oxide.

-

图 3 钛铝合金电子背散射衍射形貌和晶粒分布:(a)Ti‒45Al EBSD;(b)Ti‒45Al‒0.3Yb2O3 EBSD;(c)Ti‒45Al‒0.3CeO2 EBSD;(d)Ti‒45Al晶粒分布;(e)Ti‒45Al‒0.3Yb2O3晶粒分布;(f)Ti‒45Al‒0.3CeO2晶粒分布

Figure 3. EBSD and grain size distribution of TiAl alloys: (a) Ti‒45Al EBSD; (b) Ti‒45Al‒0.3Yb2O3 EBSD; (c) Ti‒45Al‒0.3CeO2 EBSD; (d) Ti‒45Al grain size distribution; (e) Ti‒45Al‒0.3Yb2O3 grain size distribution; (f) Ti‒45Al‒0.3CeO2 grain size distribution

表 1 实验制备试样的化学成分(原子数分数)及相对密度

Table 1. Chemical compositions (atomic fraction) and relative density of the samples

% 试样编号 化学成分 相对密度 1# Ti–45Al 98.2 2# Ti–45Al–0.3Yb2O3 99.5 3# Ti–45Al–0.3CeO2 93.4 -

[1] Fang H Z, Chen R R, Liu Y L, et al. Effects of niobium on phase composition and improving mechanical properties in TiAl alloy reinforced by Ti2AlC. Intermetallics, 2019, 115: 106630 doi: 10.1016/j.intermet.2019.106630 [2] Zhua L, Li J S, Tang B, et al. Microstructure evolution and mechanical properties of diffusion bonding high Nb containing TiAl alloy to Ti2AlNb alloy. Vacuum, 2019, 164: 140 doi: 10.1016/j.vacuum.2019.03.010 [3] Kim Y K, Youn S J, Kim S W, et al. High-temperature creep behavior of gamma Ti‒48Al‒2Cr‒2Nb alloy additively manufactured by electron beam melting. Mater Sci Eng, 2019, 763: 138138 doi: 10.1016/j.msea.2019.138138 [4] Cakmak E, Nandwana P, Shin D, et al. A comprehensive study on the fabrication and characterization of Ti‒48Al‒2Cr‒2Nb preforms manufactured using electron beam melting. Materialia, 2019, 6: 100284 doi: 10.1016/j.mtla.2019.100284 [5] Wang S J, Xu T, Liu M J, et al. Failure behavior and long-life design of thermal barrier coating: a review. Mater Res Appl, 2022, 16(1): 1 doi: 10.3969/j.issn.1673-9981.2022.01.003王斯佳, 徐彤, 刘梅军, 等. 热障涂层失效行为及长寿命设计研究现状. 材料研究与应用, 2022, 16(1): 1 doi: 10.3969/j.issn.1673-9981.2022.01.003 [6] Gao C P, Luo T G, Liu S L, et al. Debinding and sintering properties of titanium alloys prepared by powder injection molding. Powder Metall Technol, 2022, 39(5): 410高春萍, 罗铁钢, 刘胜林, 等. 粉末注射成形钛合金的脱脂和烧结性能. 粉末冶金技术, 2022, 39(5): 410 [7] Huang B, Li X, Xie X Q, et al. Effects of yttrium on the microstructure and high temperature oxidation behavior of Ti‒45Al‒6Nb alloys. Spec Cast Nonferrous Alloys, 2020, 40(8): 925黄波, 李轩, 谢小青, 等. Y对Ti‒45Al‒6Nb合金组织结构和高温氧化性能的影响. 特种铸造及有色合金, 2020, 40(8): 925 [8] Xie X Q, Li X, Lü W, et al. Effect of Co on microstructure and high temperature oxidation resistance of Ti45Al‒8Nb‒03Y alloy. J Mater Eng, 2022, 50(1): 101谢小青, 李轩, 吕威, 等. Co对Ti45Al‒8Nb‒0.3Y合金组织结构和高温抗氧化性能的影响. 材料工程, 2022, 50(1): 101 [9] Tian S W, He A R, Liu J H, et al. Oxidation resistance of TiAl alloy improved by hot-pack rolling and cyclic heat treatment. Mater Charact, 2021, 178: 111196 doi: 10.1016/j.matchar.2021.111196 [10] Zou Q, Guan Y, Li Y G, et al. Advances and perspectives of TiAl alloy and its composites, J Yanshan Univ, 2020, 44(2): 95邹芹, 关勇, 李艳国, 等. TiAl合金及其复合材料的研究进展与发展趋势. 燕山大学学报, 2020, 44(2): 95 [11] Dai J J, Zhu J Y, Chen C Z, et al. High temperature oxidation behavior and research status of modifications on improving high temperature oxidation resistance of titanium alloys and titanium aluminides: A review. J Alloys Compd, 2016, 685: 784 doi: 10.1016/j.jallcom.2016.06.212 [12] Chen L. Study on Microstructure Optimization and Creep Properties of TiAl Alloy Containing β Stable Element [Dissertation]. Beijing: University of Science and Technology Beijing, 2021陈林. 含β稳定元素TiAl合金组织优化及其蠕变性能研究[学位论文]. 北京: 北京科技大学, 2021 [13] Wang K K, Luo T G, Dong Y H, et al. Effect of Y2O3 on microstructure and mechanical properties of Ti‒6Al‒4V alloy, Powder Metall Ind, 2020, 30(4): 26王昆昆, 罗铁钢, 董应虎, 等. Y2O3对Ti‒6Al‒4V合金显微组织及力学性能的影响. 粉末冶金工业, 2020, 30(4): 26 [14] Zhao L L, Li G Y, Zhang L Q, et al. Influence of Y addition on the long time oxidation behaviors of high Nb containing TiAl alloys at 900 ℃. Intermetallics, 2010, 18: 1586 doi: 10.1016/j.intermet.2010.04.012 [15] Shi J L, Pei J, Zhang B P, et al. Research progress on processing of thermoelectric materials by mechanical alloying combined with spark plasma sintering. Powder Metall Technol, 2021, 39(1): 4 doi: 10.19591/j.cnki.cn11-1974/tf.2020120005石建磊, 裴俊, 张波萍, 等. 机械合金化结合放电等离子烧结技术制备热电材料的研究进展. 粉末冶金技术, 2021, 39(1): 4 doi: 10.19591/j.cnki.cn11-1974/tf.2020120005 [16] Shen D N, Wang C N, Gao P, et al. Ultrafine grained W‒Ti alloys prepared by spark plasma sintering. Powder Metall Technol, 2021, 39(2): 165 doi: 10.19591/j.cnki.cn11-1974/tf.2019110008沈丹妮, 王超宁, 高鹏, 等. 放电等离子烧结制备超细晶钨钛合金. 粉末冶金技术, 2021, 39(2): 165 doi: 10.19591/j.cnki.cn11-1974/tf.2019110008 [17] Zheng Z B, Wang S, Long J, et al. Effect of rare earth elements on high temperature oxidation behaviour of austenitic steel. Corros Sci, 2020, 164: 108359 doi: 10.1016/j.corsci.2019.108359 [18] Young D J. High Temperature Oxidation and Corrosion of Metals. Oxford: Elsevier Ltd. , 2008 [19] Wei L L, Zheng J H, Chen L Q, et al. High temperature oxidation behavior of ferritic stainless steel containing W and Ce. Corros Sci, 2018, 142: 79 doi: 10.1016/j.corsci.2018.07.017 [20] Zhou J, Effect of Nano-Y2O3 on High Temperature Properties and Heat Treatment Microstructure Transformation of Ti‒48Al‒2Cr‒2Nb Alloy [Dissertation]. Harbin: Harbin Institute of Technology, 2018周俊. 纳米Y2O3对Ti‒48Al‒2Cr‒2Nb合金高温性能及热处理组织转变的影响[学位论文]. 哈尔滨: 哈尔滨工业大学, 2018 -

下载:

下载: