Effect of powder characteristics on microstructure and properties of 30CrMnSiNi2A steels

-

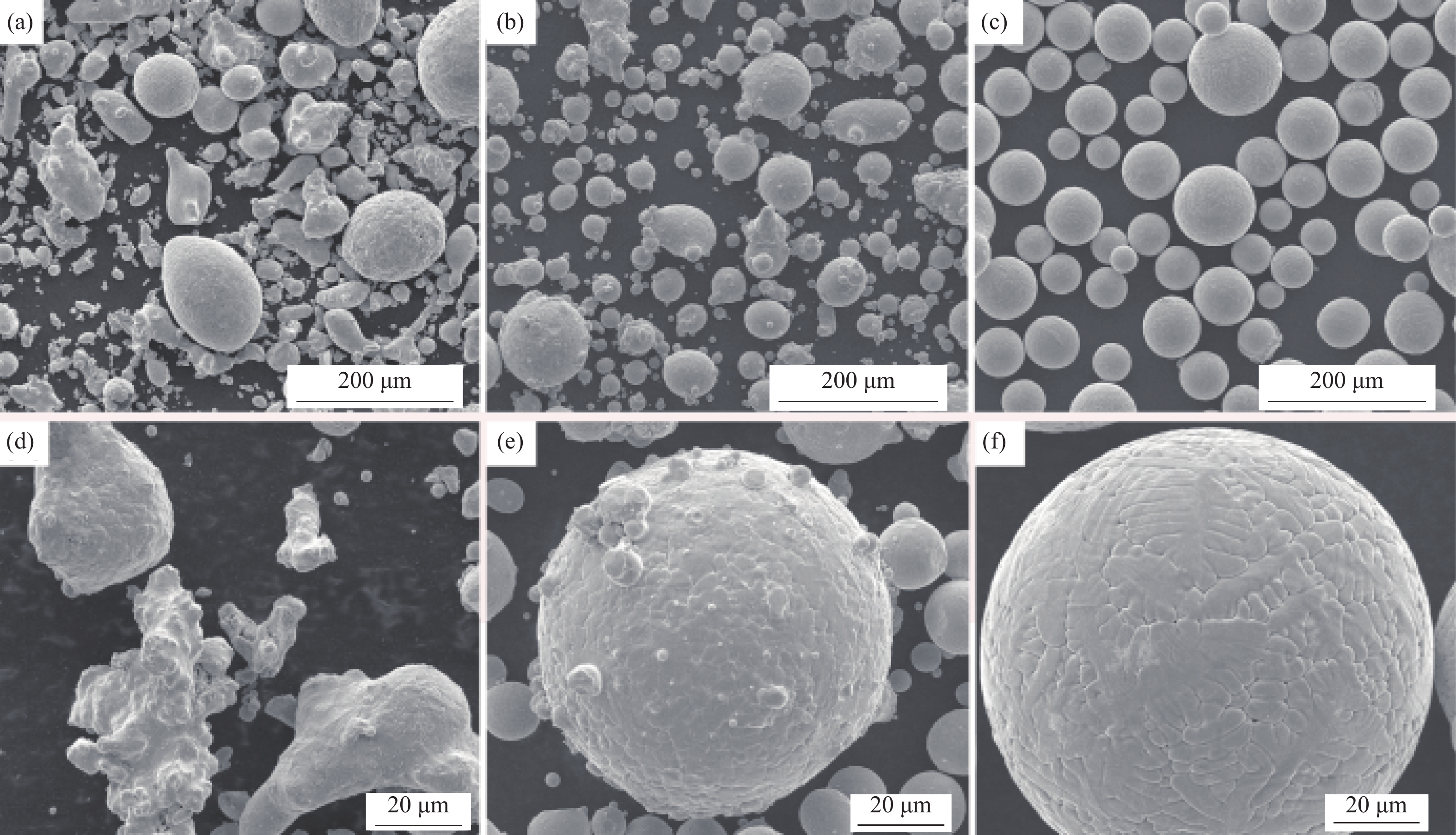

摘要: 采用水雾化(water atomization,WA)、气雾化(gas atomization,GA)和等离子旋转电极雾化(plasma rotating electrode process,PREP)方式制备30CrMnSiNi2A钢粉,对比分析了不同雾化粉末的特征及其烧结体的组织与性能。结果表明:不同雾化粉末的形貌、粒度分布、氧含量及流动性等特征均存在一定差异,其中水雾化和气雾化粉末中存在空心粉和卫星粉,等离子旋转电极雾化粉末无内部缺陷,具有优异流动性,且氧含量最低。三种雾化粉末的烧结样品组织均为粒状贝氏体,但呈现出不同的原始颗粒边界形貌,随粉末氧含量的降低,原始颗粒边界处夹杂物尺寸减小,成分由富Al氧化物变为富Al、Si氧化物。相比于水雾化和气雾化粉末,等离子旋转电极雾化粉末的烧结样品拉伸性能最优,其拉伸强度和伸长率分别为1310 MPa和11.5%,这得益于良好的粉末质量和低的氧含量。Abstract: The 30CrMnSiNi2A steel powders were prepared by water atomization (WA), gas atomization (GA), and plasma rotating electrode process (PREP) in this paper. The characteristics of the different atomized powders and the microstructure and properties of the sintered products were compared and analyzed. The results show that, the characteristics of the different atomized powders are different, such as morphology, particle size distribution, oxygen content, and fluidity. The hollow powders and satellite powders exist in the WA and GA powders. The PREP powders have no internal defects, showing the excellent fluidity and the lowest oxygen content. The microstructure of the sintered products using the three atomized powders is granular bainite, but the morphology of the prior particle boundary (PPB) is different. With the decrease of the powder oxygen content, the inclusion size at the PPBs decreases, and the composition changes from Al-rich oxide to Al-Si-rich oxide. Compared with WA and GA powders, the sintered product using PREP powders has the best tensile properties with the tensile strength and elongation of 1310 MPa and 11.5%, respectively, which benefit from the good powder quality and low oxygen content.

-

表 1 雾化钢粉化学成分(质量分数)

Table 1. Chemical Composition of the three atomized steel powders %

粉末 C O Si Mn Cr Ni Mo V Fe WA粉 0.25 0.426 0.98 1.13 1.28 1.76 0.31 0.11 余量 GA粉 0.25 0.037 1.09 1.15 1.13 1.74 0.28 0.11 余量 PREP粉 0.26 0.018 0.94 1.12 1.23 1.75 0.28 0.11 余量 表 2 3种雾化粉末的物理性质

Table 2. Physical properties of the atomized powders

粉末类型 流动性 / [s·(50 g)‒1] 松装密度 / (g·cm‒3) 振实密度 / (g·cm‒3) 粒度分布 / μm D10 D50 D90 WA粉末 46.50 3.42 4.50 8.15 30.2 103.0 GA粉末 23.60 4.46 4.95 8.81 34.7 99.2 PERP粉末 13.99 4.62 4.95 46.90 81.4 148.0 -

[1] Yuan S Q, Shen Z X, Zhou C H, et al. Microstructure and property of 30CrMnSiNi2A in different heat treatment. Mater Sci Technol, 2015, 23(2): 125 doi: 10.11951/j.issn.1005-0299.20150222袁书强, 沈正祥, 周春华, 等. 不同热处理条件下30CrMnSiNi2A钢的组织性能研究. 材料科学与工艺, 2015, 23(2): 125 doi: 10.11951/j.issn.1005-0299.20150222 [2] Yao C G, Meng S, Li X L, et al. Effect of powder oxygen content on mechanical properties and microstructure of FGH4169 alloy. Mater Sci Eng Powder Metall, 2017, 22(1): 33 doi: 10.3969/j.issn.1673-0224.2017.01.006姚草根, 孟烁, 李秀林, 等. 粉末氧含量对热等静压FGH4169合金力学性能与组织的影响. 粉末冶金材料科学与工程, 2017, 22(1): 33 doi: 10.3969/j.issn.1673-0224.2017.01.006 [3] Higashi M, Kanno N. Effect of initial powder particle size on the hot workability of powder metallurgy Ni-based superalloys. Mater Des, 2020, 194: 108926 doi: 10.1016/j.matdes.2020.108926 [4] Sreenu B, Sarkar R, Kumar S S S, et al. Microstructure and mechanical behaviour of an advanced powder metallurgy nickel base superalloy processed through hot isostatic pressing route for aerospace applications. Mater Sci Eng A, 2020, 797: 140254 doi: 10.1016/j.msea.2020.140254 [5] You D D, Wang Y H, Yang C, et al. Comparative analysis of the hot-isostatic-pressing densification behavior of atomized and milled Ti6Al4V powders. J Mater Res Technol, 2020, 9(3): 3091 doi: 10.1016/j.jmrt.2020.01.055 [6] Guo R P, Xu L, Chen Z Y, et al. Effect of powder surface state on microstructure and tensile properties of a novel near α-Ti alloy using hot isostatic pressing. Mater Sci Eng A, 2017, 706: 57 doi: 10.1016/j.msea.2017.08.096 [7] Shulga A V. Enhancing the ductility of ferritic/martensitic stainless steel through the use of PM HIP manufacturing techniques. Eng Fail Anal, 2015, 56: 512 doi: 10.1016/j.engfailanal.2014.11.019 [8] Irukuvarghula S, Hassanin H, Cayron C, et al. Effect of powder characteristics and oxygen content on modifications to the microstructural topology during hot isostatic pressing of an austenitic steel. Acta Mater, 2019, 172: 6 doi: 10.1016/j.actamat.2019.03.038 [9] Sergi A, Khan R H U, Attallah M M. The role of powder atomisation route on the microstructure and mechanical properties of hot isostatically pressed Inconel 625. Mater Sci Eng A, 2021, 808: 140950 doi: 10.1016/j.msea.2021.140950 [10] Long A P, Li S L, Wang H, et al. Characterization of oxide on the water-atomized FeMn powder surface. Appl Surf Sci, 2014, 295: 180 doi: 10.1016/j.apsusc.2013.12.183 [11] Gao Z J, Zhang G Q, Li Z, et al. Effect of size distribution and oxygen content of powder on microstructure of HIPed superalloy FGH96. Chin J Rare Met, 2012, 36(4): 665 doi: 10.3969/j.issn.0258-7076.2012.04.026高正江, 张国庆, 李周, 等. 粉末粒度和氧含量对HIP态FGH96合金组织的影响. 稀有金属, 2012, 36(4): 665 doi: 10.3969/j.issn.0258-7076.2012.04.026 [12] Mostafaei A, Hilla C, Stevens E L, et al. Comparison of characterization methods for differently atomized nickel-based alloy 625 powders. Powder Technol, 2018, 333: 180 doi: 10.1016/j.powtec.2018.04.014 [13] Guo R P, Xu L, Zong B Y P, et al. Characterization of prealloyed Ti–6Al–4V powders from EIGA and PREP process and mechanical properties of HIPed powder compacts. Acta Metall Sinica, 2017, 30(8): 735 doi: 10.1007/s40195-017-0540-4 [14] Chen Y, Zhang J Y, Wang B, et al. Comparative study of IN600 superalloy produced by two powder metallurgy technologies: argon atomizing and plasma rotating electrode process. Vacuum, 2018, 156: 302 doi: 10.1016/j.vacuum.2018.07.050 [15] Hou W Q, Meng J, Liang J J, et al. Preparation technology and research progress of superalloy powders used for additive manufacturing. Powder Metall Technol, 2022, 40(2): 131 doi: 10.19591/j.cnki.cn11-1974/tf.2021030038侯维强, 孟杰, 梁静静, 等. 增材制造用高温合金粉末制备技术及研究进展. 粉末冶金技术, 2022, 40(2): 131 doi: 10.19591/j.cnki.cn11-1974/tf.2021030038 [16] Ohtani H, Okaguchi S, Fujishiro Y, et al. Morphology and properties of low-carbon bainite. Metall Trans A, 1990, 21(3): 877 doi: 10.1007/BF02656571 [17] Shim D H, Lee T, Lee J, et al. Increased resistance to hydrogen embrittlement in high-strength steels composed of granular bainite. Mater Sci Eng A, 2017, 700: 473 doi: 10.1016/j.msea.2017.06.043 [18] He G A, Ding H H, Liu C Z, et al. Effect of powder characteristics on microstructure and deformation activation energy of nickel based superalloy. Chin J Nonferrous Met, 2016, 26(1): 37 doi: 10.19476/j.ysxb.1004.0609.2016.01.006何国爱, 丁晗晖, 刘琛仄, 等. 粉末特性对镍基粉末冶金高温合金组织及热变形行为的影响. 中国有色金属学报, 2016, 26(1): 37 doi: 10.19476/j.ysxb.1004.0609.2016.01.006 [19] Zumsande K, Weddeling A, Hryha E, et al. Characterization of the surface of Fe–19Mn–18Cr–C–N during heat treatment in a high vacuum—An XPS study. Mater Charact, 2012, 71: 66 doi: 10.1016/j.matchar.2012.06.002 -

下载:

下载: