Effects of powder size and sintering temperature on microstructure and properties of porous K418 superalloys

-

摘要: 以气雾化K418镍基高温合金球形粉末为原料,经过粉末松装烧结制备出高温合金多孔材料。通过对多孔材料微观结构、渗透性能、毛细性能及压缩强度进行表征,研究了原始粉末粒径和烧结温度对多孔吸液芯样品显微结构及性能的影响。结果表明,随烧结温度增加,样品的平均孔径和孔隙率减小;在相同烧结温度下,随着原始粉末粒径增加,样品的平均孔径和孔隙率增大。在烧结温度为1230 ℃,粉末粒径为53~150 μm的条件下,多孔材料样品综合性能最优,渗透率为13.69×10−15 m2,毛细压力为22.1 kPa,压缩强度为86 MPa。Abstract: The porous superalloy materials were prepared by loose packing sintering using the atomized K418 nickel-based superalloy spherical powders as the raw materials. The microstructure, permeability, capillarity, and compressive strength of the sintered porous material samples were analyzed, and the effects of sintering temperature and original powder particle size on the microstructure and properties of the porous K418 superalloys were investigated. The results show that, the average pore size and porosity decrease with the increase of sintering temperature. At the same sintering temperature, the average pore size and porosity of the sintered samples increase with the increase of the original powder particle size. At the sintering temperature of 1230 ℃ and the powder particle size of 53~150 μm, the comprehensive performance of the porous material samples is the best, the permeability is 13.69×10−15 m2, the capillary pressure is 22.1 kPa, and compressive strength is 86 MPa.

-

Key words:

- porous wick /

- powder particle size /

- sintering temperatur /

- permeability /

- capillary pressure /

- compressive strength

-

图 3 不同粒径金属粉末在不同烧结温度下制得的高温合金多孔材料显微形貌:(a)1200A;(b)1200B;(c)1200C;(d)1230A;(e)1230B;(f)1230C;(g)1250A;(h)1250B;(i)1250C

Figure 3. SEM images of the porous material samples in the different particle size at the different temperatures: (a) 1200A; (b) 1200B; (c) 1200C; (d) 1230A; (e) 1230B; (f) 1230C; (g) 1250A; (h) 1250B; (i) 1250C

表 1 K418合金粉末主要化学成分(质量分数)

Table 1. Main chemical composition of the K418 alloy powders

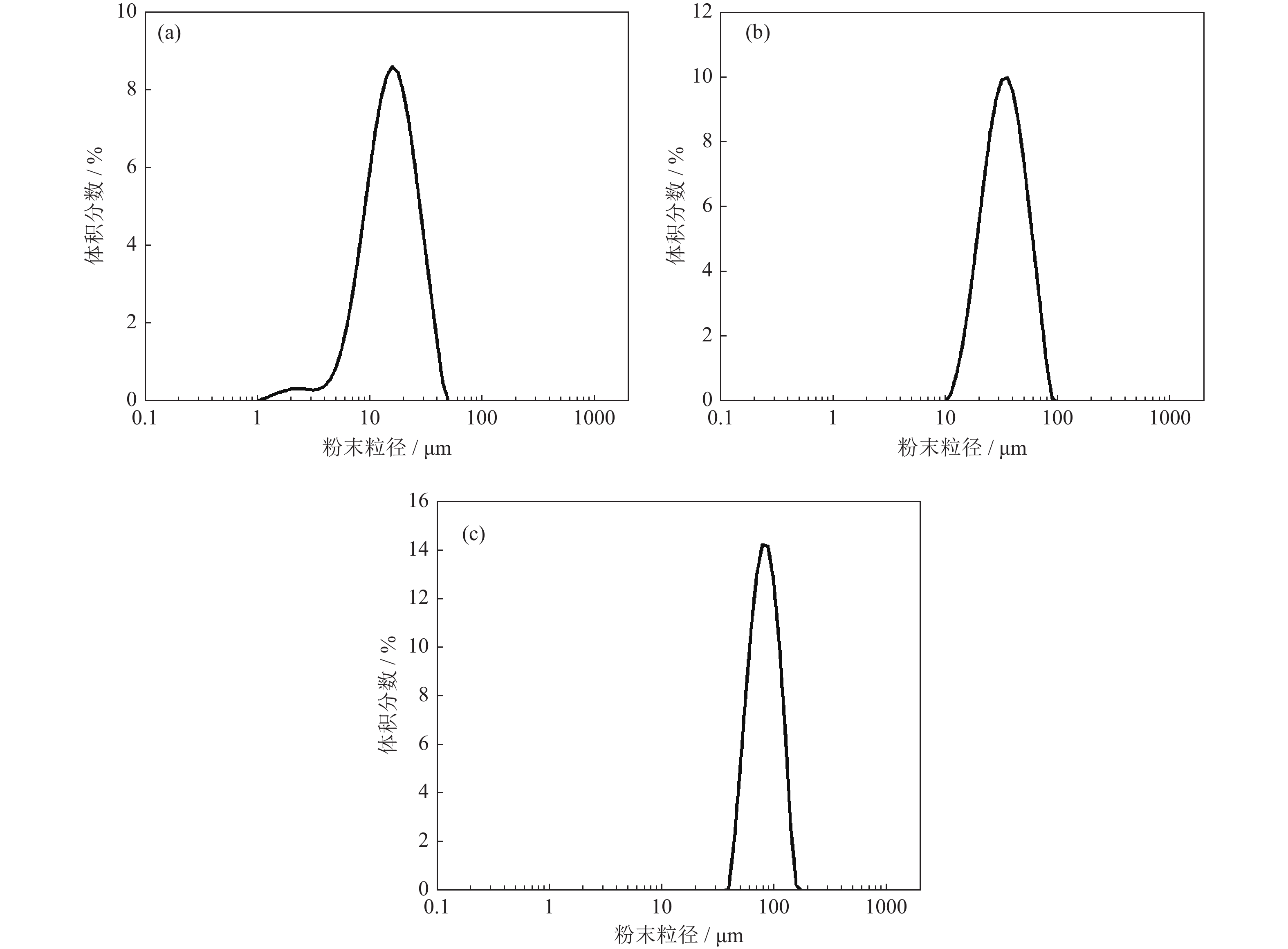

% Ni Cr Al Mo Nb Ti 其他 73.10 12.93 5.96 4.26 2.10 0.28 <1 表 2 通过积分计算得到的K418高温合金粉末平均粒径

Table 2. Average particle size of the K418 superalloy powders calculated by integrating

金属粉末 粒径分布范围 / μm 平均粒径,D50 / μm 细粉(A) 0~15 14.5 中粉(B) 15~53 31.7 粗粉(C) 53~150 77.6 表 3 K418高温合金多孔材料样品制备参数及命名

Table 3. Preparation parameters and names of the porous material samples

烧结温度 / ℃ 粉末粒径 / μm 0~15 15~53 53~150 1200 1200A 1200B 1200C 1230 1230A 1230B 1230C 1250 1250A 1250B 1250C 表 4 实验样品孔隙率

Table 4. Porosity of the porous material samples

% 1200A 1200B 1200C 1230A 1230B 1230C 1250A 1250B 1250C 27.7 35.7 41.7 17.2 23.9 36.9 15.0 15.3 35.8 表 5 实验样品平均孔径

Table 5. Average pore size of the porous material samples

μm 1200A 1200B 1200C 1230A 1230B 1230C 1250A 1250B 1250C 15.0 25.6 46.8 11.3 19.9 44.2 10.8 15.2 36.8 表 6 实验样品的渗透率

Table 6. Permeability of the porous material samples

(×10−15 m2) 1200A 1200B 1200C 1230A 1230B 1230C 1250A 1250B 1250C — 1.89 39.1 — — 3.68 — — 2.68 表 7 实验样品的毛细压力

Table 7. Capillary pressure of the porous material samples

kPa 1200A 1200B 1200C 1230A 1230B 1230C 1250A 1250B 1250C — 9.02 18.00 — — 22.10 — — 6.85 表 8 实验样品的室温压缩强度

Table 8. Compressive strength of the porous material samples at room temperature

MPa 1200C 1230C 1250C 1200B 1230B 1250B 1200A 1230A 1250A 74 86 410 380 490 640 126 — 745 -

[1] Andrews J. Heat Pipe Technology. New York: Pergamon Press, 1997 [2] Guo B J, Li W J. Structural materials and thermal protection system of hypersonic vehicle. Process Mater, 2010(4): 88 doi: 10.16338/j.issn.1009-1319.2010.04.005郭朝邦, 李文杰. 高超声速飞行器结构材料与热防护系统. 飞航导弹, 2010(4): 88 doi: 10.16338/j.issn.1009-1319.2010.04.005 [3] Peng W G. Theoretical and Simulation Study on Thermal Protection Mechanism of Metal Structural Heat Pipe for Hypersonic Vehicle [Dissertation]. Harbin: Harbin Institute of Technology, 2011彭稳根. 高超声速飞行器金属结构热管热防护机制理论与模拟研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2011 [4] Yu P L, Yin F X. Heat pipes and metal porous materials in heat pipes technology. Powder Metall Technol, 2011, 29(5): 380 doi: 10.19591/j.cnki.cn11-1974/tf.2011.05.011余培良, 尹凤霞. 热管及热管技术中的金属多孔材料. 粉末冶金技术, 2011, 29(5): 380 doi: 10.19591/j.cnki.cn11-1974/tf.2011.05.011 [5] Zhu M H, Bai P F, Hu Y X, et al. Heat transfer performance of ultra-thin plate heat pipe with sintered porous channels structures wick. CIESC J, 2019, 70(4): 1349朱明汉, 白鹏飞, 胡艳鑫, 等. 烧结多孔槽道吸液芯超薄平板热管的传热性能. 化工学报, 2019, 70(4): 1349 [6] Guan W L. Preparation of Iron-Based Porous Materials and Its Application in Water [Dissertation]. Qingdao: Qingdao University of Science and Technology, 2020关文岚. 铁基多孔材料的制备及其在水体中的应用研究[学位论文]. 青岛: 青岛科技大学, 2020 [7] Ding C S, Soni G, Bozorgi P, et al. A flat heat pipe architecture based on nanostructured titania. J Microelectromech System, 2010, 19(4): 878 doi: 10.1109/JMEMS.2010.2051019 [8] Jafari D, Wits W W, Geurts B J. Metal 3D-printed wick structures for heat pipe application: Capillary performance analysis. Appl Therm Eng, 2018, 143: 403 doi: 10.1016/j.applthermaleng.2018.07.111 [9] Wang D Z, Wang X Y, Zhou P, et al. Effect of sintering process on properties of Ni porous capillary wicks for loop heat pipe. Mater Sci Eng Powder Metall, 2014, 19(5): 687王德志, 王小鹰, 周盼, 等. 烧结工艺对环路热管用Ni多孔吸液芯性能的影响. 粉末冶金材料科学与工程, 2014, 19(5): 687 [10] Li Q, Gan X P, Li Z Y, et al. Fabrication and mechanical properties of porous Ni wicks. Mater Sci Eng Powder Metall, 2018, 23(4): 361 doi: 10.3969/j.issn.1673-0224.2018.04.004黎强, 甘雪萍, 李志友, 等. 多孔镍毛细芯的制备及其力学性能. 粉末冶金材料科学与工程, 2018, 23(4): 361 doi: 10.3969/j.issn.1673-0224.2018.04.004 [11] Liu F X, Yuan W M, Tang X. Influences of structures on low cycle fatigue life of K418 alloy. J Aeron Mater, 1996, 16(2): 31刘发信, 袁文明, 汤鑫. K418合金的组织对低周疲劳性能的影响. 航空材料学报, 1996, 16(2): 31 [12] Liu G Q. Experimental Study on Cutting Properties of K418 Nickel-Based Superalloy [Dissertation]. Nanjing: Nanjing University of Technology, 2006刘高群. 铸造镍基高温合金K418切削性能试验研究[学位论文]. 南京: 南京理工大学, 2006 [13] Chi S V. Heat Pipe Theory and Practice: A Sourcebook. New York: Hemisphere Publishing Corp, 1976 [14] Mishra D K, Saravanan T T, Khanra G P, et al. Studies on the processing of nickel base porous wicks for capillary pumped loop for thermal management of spacecrafts. Adv Powder Technol, 2010, 21(6): 658 doi: 10.1016/j.apt.2010.07.011 -

下载:

下载: