-

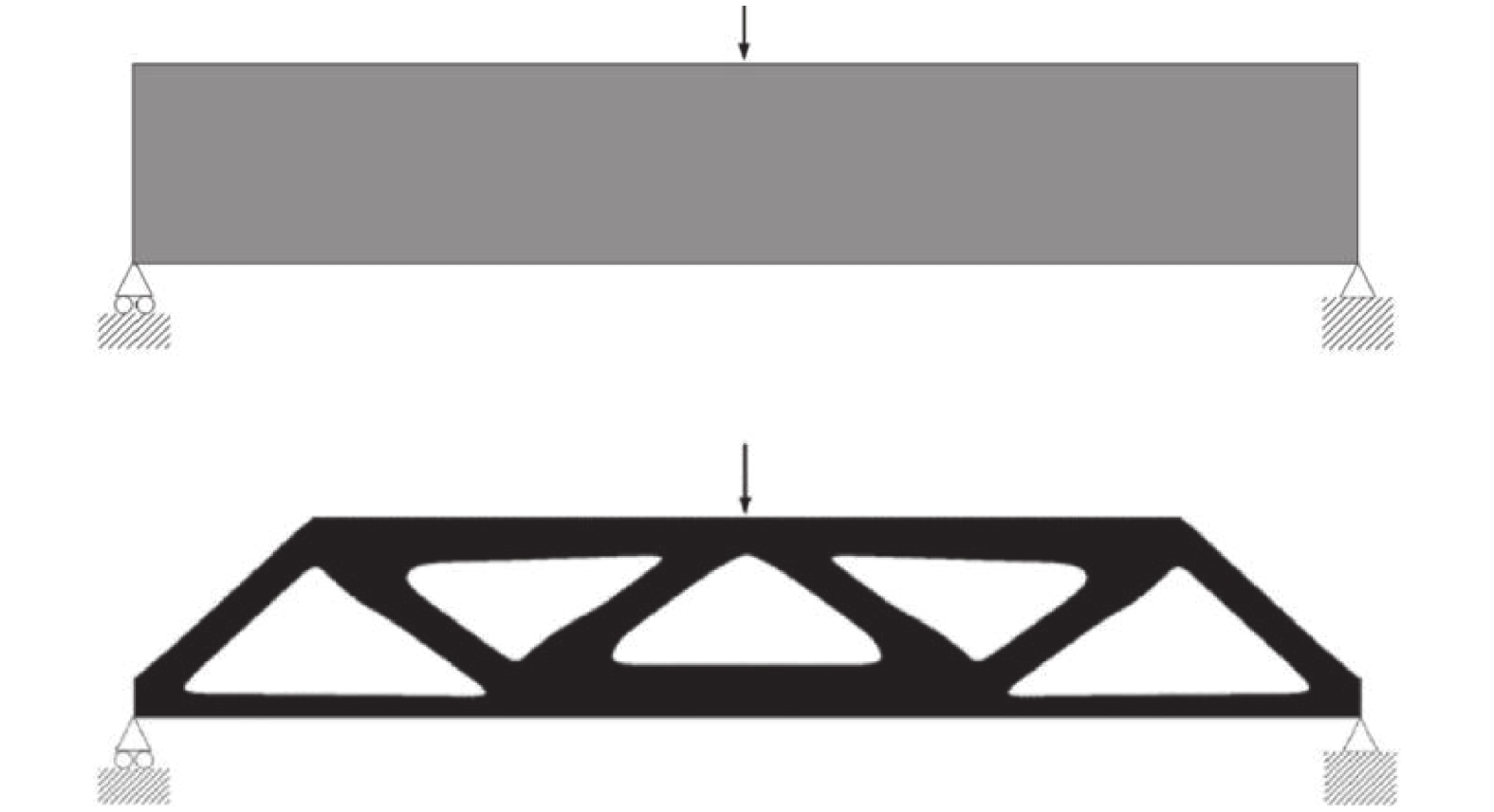

摘要: 3D打印又称为增材制造(additive manufacturing,AM),是一种通过三维设计数据和材料逐层累加的方法来制造实体零件的技术。随着信息技术和智能控制被应用到3D打印技术之中,3D打印技术日趋成熟,并逐步实现了商业化。制造工艺的飞速发展往往需要设计技术的快速跟进,拓扑优化方法不依赖初始构型及工程师经验,能够获得意想不到的创新构型,已成为结构创新设计的重要工具。嵌入式技术是一种由内部计算机控制并执行专用功能的设备或系统,与通用型计算机系统相比,嵌入式系统功耗低、功能强大、实时性强、支持多任务、占用空间小、效率高,面向特定应用可根据需要灵活定制,在3D打印设备中有着更好的使用优势。本文总结了拓扑优化设计和嵌入式数字技术在3D打印中的应用,介绍了拓扑优化在3D打印中的应用案例和拓扑优化主流软件,分析了嵌入式技术在3D打印中的应用优势及案例,展望了拓扑优化设计及嵌入式数字技术在3D打印中的应用。Abstract: 3D printing, also known as additive manufacturing (AM), is a technology that uses 3D design data to build physical parts by adding materials layer by layer. With the application of information technology and intelligent control to 3D printing technology, the 3D printing technology is becoming more and more mature and commercialized gradually. The rapid development of manufacturing technology often requires the rapid follow-up of design technology. Topology optimization method has become an important tool for the structural innovative design because it is independent of the initial configuration and the engineer experience and can obtain completely unexpected innovative configurations. Embedded technology is a device or system that is controlled by an internal computer and performs a special function. Compared with the general purpose computer systems, the embedded systems have the advantages in 3D printing, such as low power consumption, powerful functions, strong real-time performance, multi-task support, small space occupation, and high efficiency, and the specific applications can be customized according to the needs of flexible. The application of topology optimization design and embedded digital technology in 3D printing was summarized in this paper, the application cases of topology optimization and the mainstream software of topology optimization were introduced, the application advantages and cases of the embedded technology in 3D printing were analyzed, and the future topology optimization design and the application of embedded digital technology in 3D printing were prospected.

-

Key words:

- topology optimization /

- additive manufacturing /

- 3D printing /

- light weight /

- embedded technology

-

图 7 微结构构型拓扑形状优化(泊松比为−0.8~0.8)[17]:(a)拓扑优化设计的单元格;(b)3D打印的单元格;(c)3×3单远格组成的构造化材料

Figure 7. Optimized architectures by topology and shape with Poisson ratio of −0.8~0.8[17]: (a) designed unit cells by topology optimization; (b) 3D printed unit cells; (c) 3×3 unit cells of the corresponding architectures

图 11 具有拓扑优化结构的多孔CP–Ti透射电子显微形貌[22]:(a)透射电镜明场图像;(b)孪晶薄片的明场图像;(c)相应孪晶区域的电子衍射图;(d)孪晶界面的原子尺度图像

Figure 11. Transmission electron microscopy images of the porous CP–Ti with the topology-optimized structure[22]: (a) bright-field image; (b) bright-field image of the twinned flakes; (c) electron diffraction pattern of the corresponding twinned region; (d) atomic-scale image of the twinned interface

表 1 拓扑优化软件性能对比分析

Table 1. Performance comparison of the topology optimization software

拓扑优化软件 界面操作 材料数据库 性能分析 制造约束分析功能 自动化几何重构 与3D打印集成度 Altair Inspire 简单 丰富 支持 强 较高 很高 Siemens NX 较复杂 较丰富 支持 较强 高 高 PTC Creo 较简单 较丰富 支持 较强 高 较高 Autodesk Netfabb 简单 丰富 支持 较强 较高 很高 -

[1] Lu P H, Li D C. Development of the additive manufacturing (3D printing) technology. Mach Build Autom, 2013, 42(4): 1 doi: 10.19344/j.cnki.issn1671-5276.2013.04.001卢秉恒, 李涤尘. 增材制造(3D打印)技术发展. 机械制造与自动化, 2013, 42(4): 1 doi: 10.19344/j.cnki.issn1671-5276.2013.04.001 [2] Ni X Q, Kong D C, Wen Y, et al. Influence factors and improvement methods on the porosity of 3D printing metal materials. Powder Metall Technol, 2019, 37(3): 163 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.001倪晓晴, 孔德成, 温莹, 等. 3D打印金属材料中孔隙率的影响因素和改善方法. 粉末冶金技术, 2019, 37(3): 163 doi: 10.19591/j.cnki.cn11-1974/tf.2019.03.001 [3] Liu Z Y, Zhao B B, Li L J, et al. Research progress of metal materials for 3D printing technology. Powder Metall Ind, 2020, 30(2): 83 doi: 10.13228/j.boyuan.issn1006-6543.20180139柳朝阳, 赵备备, 李兰杰, 等. 金属材料3D打印技术研究进展. 粉末冶金工业, 2020, 30(2): 83 doi: 10.13228/j.boyuan.issn1006-6543.20180139 [4] Wang Y, Liu Y M, Liu J W, et al. Research progress on numerical simulation of metal additive-manufacturing process. Powder Metall Technol, 2022, 40(2): 179王岩, 刘雨萌, 刘江伟, 等. 金属增材制造数值模拟研究进展. 粉末冶金技术, 2022, 40(2): 179 [5] Zhang G X, Liu S F, Yang X, et al. Research progress on preparation of biological implant materials by additive manufacturing. Powder Metall Technol, 2019, 37(4): 312 doi: 10.19591/j.cnki.cn11-1974/tf.2019.04.012张光曦, 刘世锋, 杨鑫, 等. 增材制造技术制备生物植入材料的研究进展. 粉末冶金技术, 2019, 37(4): 312 doi: 10.19591/j.cnki.cn11-1974/tf.2019.04.012 [6] Liu S T, Li Q H, Chen W J, et al. Combining topology optimization and additive manufacturing: an integrated approach to design and manufacturing. Aeron Manuf Technol, 2017(10): 26刘书田, 李取浩, 陈文炯, 等. 拓扑优化与增材制造结合: 一种设计与制造一体化方法. 航空制造技术, 2017(10): 26 [7] Zhu J H, Zhang W H, Xia L. Topology optimization in aircraft and aerospace structures design. Arch Comput Meth Eng, 2016, 23: 595 doi: 10.1007/s11831-015-9151-2 [8] Ge H Y, Luo M X, Zhang J H, et al. Hardware development of embedded control system for 3D printing. Ind Control Comput, 2018, 31(1): 9 doi: 10.3969/j.issn.1001-182X.2018.01.004葛红宇, 罗茂炫, 张建华, 等. 3D打印嵌入式工业控制系统硬件设计. 工业控制计算机, 2018, 31(1): 9 doi: 10.3969/j.issn.1001-182X.2018.01.004 [9] Li J. Application and research progress of computer simulation used in powder metallurgy process. Powder Metall Technol, 2021, 39(4): 366 doi: 10.19591/j.cnki.cn11-1974/tf.2021060001李静. 计算机仿真在粉末冶金过程的应用及研究进展. 粉末冶金技术, 2021, 39(4): 366 doi: 10.19591/j.cnki.cn11-1974/tf.2021060001 [10] Liu S T, Hu R, Li Q H, et al. Topology optimization-based lightweight primary mirror design of a large-aperture space telescope. Appl Opt, 2014, 53(35): 8318 doi: 10.1364/AO.53.008318 [11] Gao J C. Structural Topology Optimization Considering the Overhang Constraint in Additive Manufacturing [Dissertation]. Dalian: Dalian University of Technology, 2019高进城. 考虑增材制造中悬空角度约束的结构拓扑优化[学术论文]. 大连: 大连理工大学, 2019 [12] Wang R, Yang W Q. SLM technology and topology optimization for lighter aerospace components. Mod Manuf Eng, 2018(12): 24 doi: 10.16731/j.cnki.1671-3133.2018.12.005王仁, 杨伟群. 选择性激光熔化技术及面向航空组件的拓扑优化研究. 现代制造工程, 2018(12): 24 doi: 10.16731/j.cnki.1671-3133.2018.12.005 [13] Luo Y, Du P, Zhu L J, et al. A case study of topology optimization design based on Inspire software. Manuf Technol Mach Tool, 2021(11): 31 doi: 10.19287/j.cnki.1005-2402.2021.11.005罗勇, 杜平, 朱丽君, 等. 基于Inspire软件的拓扑优化设计案例分析. 制造技术与机床, 2021(11): 31 doi: 10.19287/j.cnki.1005-2402.2021.11.005 [14] Wang L X, Du W F, Zhang F, et al. Topology optimization and 3D printing manufacturing of four-branch cast-steel joint. J Build Struct, 2021, 42(6): 37 doi: 10.14006/j.jzjgxb.2020.0297王龙轩, 杜文风, 张 帆, 等. 四分叉铸钢节点拓扑优化及3D打印制造. 建筑结构学报, 2021, 42(6): 37 doi: 10.14006/j.jzjgxb.2020.0297 [15] Xu W P, Wang W M, Li H, et al. Topology optimization for minimal volume in 3D printing. J Comput Res Develop, 2015, 52(1): 38 doi: 10.7544/issn1000-1239.2015.20140108徐文鹏, 王伟明, 李航, 等. 面向3D打印体积极小的拓扑优化技术. 计算机研究与发展, 2015, 52(1): 38 doi: 10.7544/issn1000-1239.2015.20140108 [16] Wang F W, Sigmund O, Jensen J S. Design of materials with prescribed nonlinear properties. J Mech Phys Solids, 2014, 69: 156 doi: 10.1016/j.jmps.2014.05.003 [17] Clausen A, Wang F W, Jensen J S, et al. Topology optimized architectures with programmable Poisson's ratio over large deformations. Adv Mater, 2015, 27: 5523 doi: 10.1002/adma.201502485 [18] Shi G H, Guan C Q, Quan D L, et al. An aerospace bracket designed by thermo-elastic topology optimization and manufactured by additive manufacturing. Chin J Aeron, 2020, 33(4): 1252 doi: 10.1016/j.cja.2019.09.006 [19] Tang Y L, Dong G Y, Zhou Q X, et al. Lattice structure design and optimization with additive manufacturing constraints. IEEE Trans Autom Sci Eng, 2018, 15(4): 1546 doi: 10.1109/TASE.2017.2685643 [20] Zhu J H, Zhou H, Wang C, et al. Status and future of topology optimization for additive manufacturing. Aeron Manuf Technol, 2020, 60(10): 24 doi: 10.16080/j.issn1671-833x.2020.10.024朱继宏, 周 涵, 王 创, 等. 面向增材制造的拓扑优化技术发展现状与未来. 航空制造技术, 2020, 60(10): 24 doi: 10.16080/j.issn1671-833x.2020.10.024 [21] Gao C H, Wu W H, Zhang L. Research status of additive manufacturing technology used for high temperature titanium alloys and titanium matrix composites. Powder Metall Technol, 2023, 41(1): 55高楚寒, 吴文恒, 张亮. 高温钛合金及钛基复合材料增材制造技术研究现状. 粉末冶金技术, 2023, 41(1): 55 [22] Liu Y J, Ren D C, Li S J, et al. Enhanced fatigue characteristics of a topology-optimized porous titanium structure produced by selective laser melting. Add Manuf, 2020: 101060 [23] Wu W H, Wu K Q, Xiao Y F, et al. Effect of atomization pressure on the properties of 316L stainless steel powders used in 3D printing. Powder Metall Technol, 2017, 35(2): 83 doi: 10.3969/j.issn.1001-3784.2017.02.001吴文恒, 吴凯琦, 肖逸凡, 杨启云. 气雾化压力对3D打印用316L不锈钢粉末性能的影响. 粉末冶金技术, 2017, 35(2): 83 doi: 10.3969/j.issn.1001-3784.2017.02.001 [24] Liang X, Du P, Zhu L J, et al. Analysis of topology optimization design module for additive manufacturing. Manuf Technol Mach Tool, 2021(5): 76 doi: 10.19287/j.cnki.1005-2402.2021.05.009梁雄, 杜平, 朱丽君, 等. 面向增材制造的拓扑优化设计模块分析. 制造技术与机床, 2021(5): 76 doi: 10.19287/j.cnki.1005-2402.2021.05.009 [25] Li J. Development of 3D Printing Upper Computer Software Based on ARM and Research of Filling Algorithms [Dissertation]. Xi’an: Xi’an University of Technology, 2019李佳. 基于ARM的3D打印上位机软件开发及填充算法研究[学术论文]. 西安: 西安理工大学, 2019 [26] Wang S Z, Shu Z B, Li J. Design and implementation of control system for FDM 3D printer based on ARM. Chin J Electron Dev, 2017, 40(5): 1324王苏洲, 舒志兵, 李俊. 基于ARM的桌面型3D打印机控制系统的设计与优化. 电子器件, 2017, 40(5): 1324 [27] Kong M R, Wang H Y, Jiao Y Y, et al. Development and design of 3D control system for orthodontics based on embedded system. Electron Sci Technol, 2017, 30(7): 114 doi: 10.16180/j.cnki.issn1007-7820.2017.07.031孔明茹, 王海艳, 教莹莹, 等. 基于嵌入式的口腔正畸3D打印控制系统设计. 电子科技, 2017, 30(7): 114 doi: 10.16180/j.cnki.issn1007-7820.2017.07.031 [28] Feng Q X, A Z W. Design of multi-platform rapid prototyping software. Manuf Technol Mach Tool, 2014(4): 33 doi: 10.3969/j.issn.1005-2402.2014.04.014冯清秀, 阿占文. 多平台快速成型软件设计. 制造技术与机床, 2014(4): 33 doi: 10.3969/j.issn.1005-2402.2014.04.014 -

下载:

下载: