Research status of additive manufacturing technology used for high temperature titanium alloys and titanium matrix composites

-

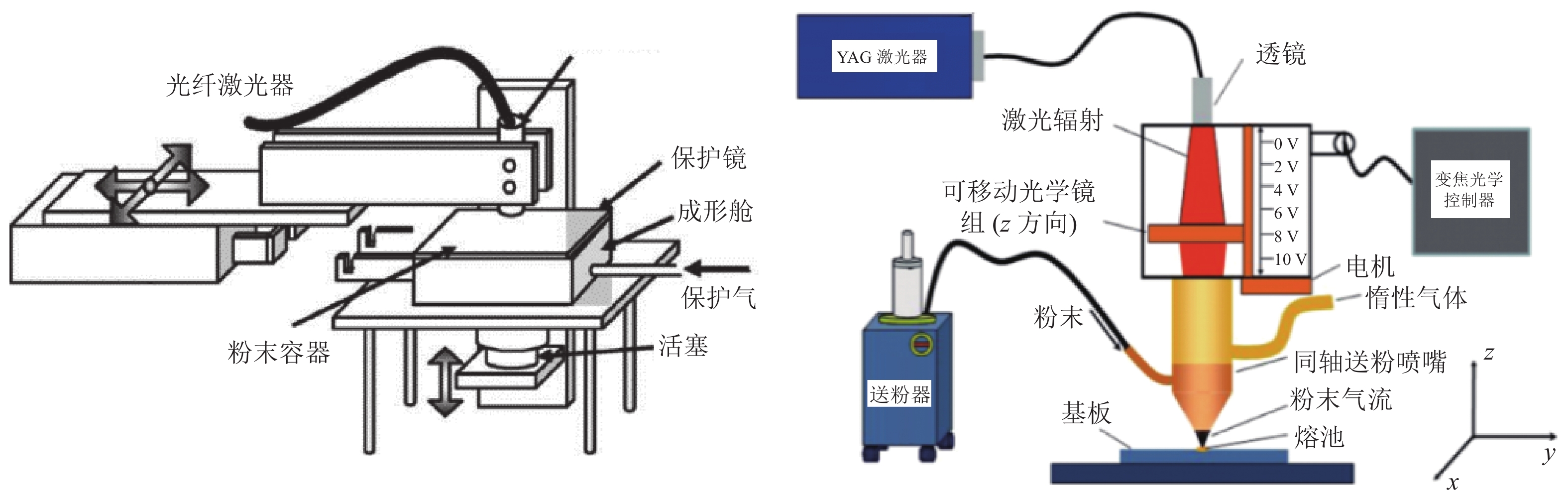

摘要: 高温钛合金及钛基复合材料因具有比强度高、比刚度高、耐腐蚀、耐高温等优异性能,近几年来受到了广泛的关注。钛基复合材料的力学性能往往与增强相组织有关,增材制造技术的快速凝固可以使颗粒增强钛基复合材料中晶粒细化,力学性能得到提升。本文综述了高温钛合金及钛基复合材料的研究进展,分析了增强相组织对材料力学性能的影响,总结了增材制造技术制备钛基梯度功能材料的应用。通过增材制造技术制备钛基复合材料不仅可以提高复合材料的硬度和强度,还可以提高复合材料的延展性,采用增材制造技术制备高性能钛基复合材料将会成为未来的发展趋势。Abstract: High temperature titanium alloys and titanium matrix composites (TMCs) have attracted the extensive attention in recent years due to the excellent properties, such as high specific strength, high specific stiffness, high corrosion resistance, and high temperature resistance. The mechanical properties of the titanium matrix composites are often related to the reinforcing phase microstructures. The rapid solidification of additive manufacturing technology can refine particles and improve the mechanical properties of the particle-reinforced titanium matrix composites. The research progress of high temperature titanium alloys and titanium matrix composites was reviewed in this paper. The influence of the reinforcing phase on the mechanical properties of the titanium alloys and titanium matrix composites was analyzed, and the application of additive manufacturing technology used for the titanium-based gradient functional materials was summarized. The additive manufacturing technology can not only improve the hardness and strength of the particle-reinforced titanium matrix composites, but also increase the ductility of the composites, which will become the future development trend.

-

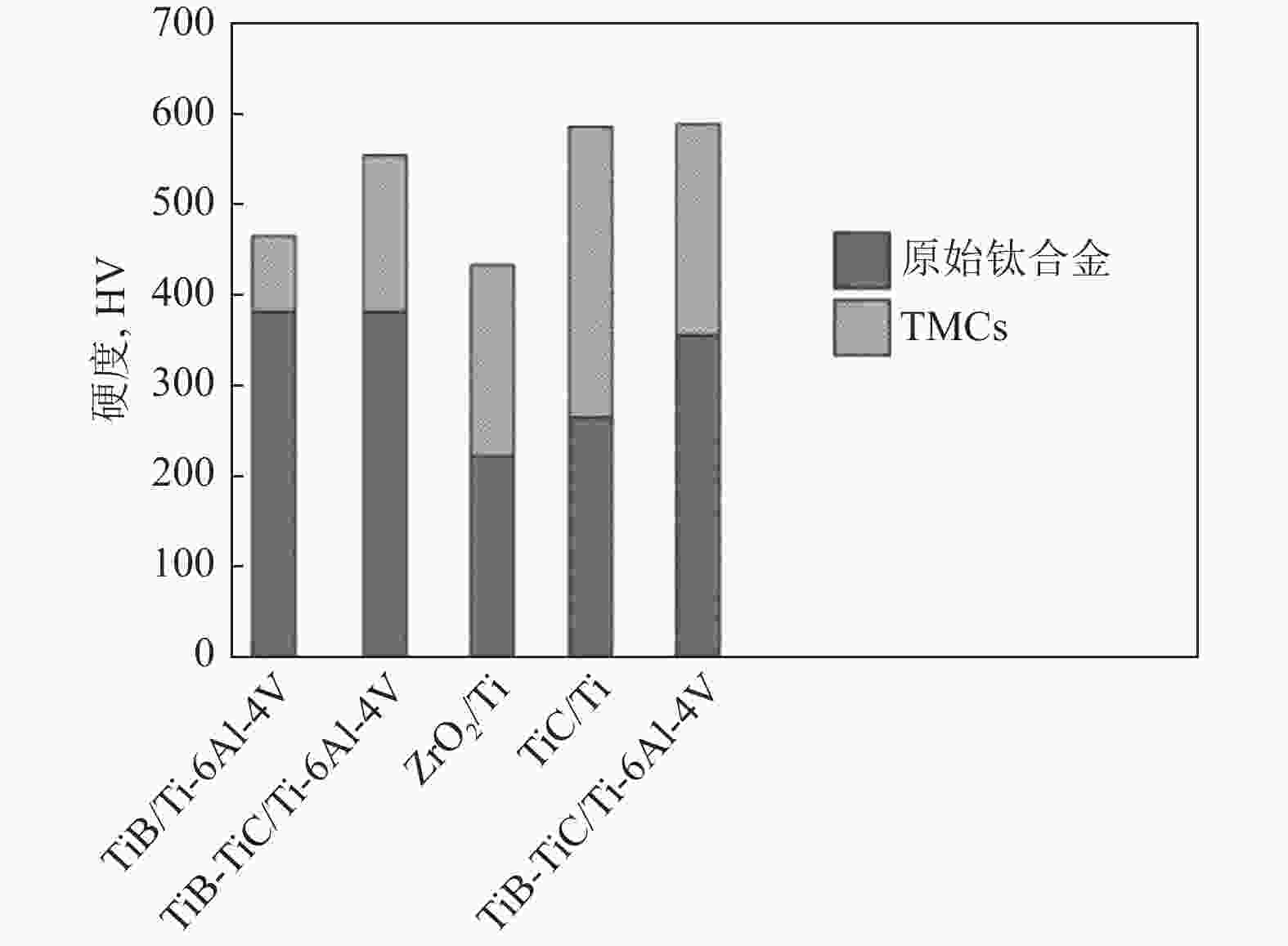

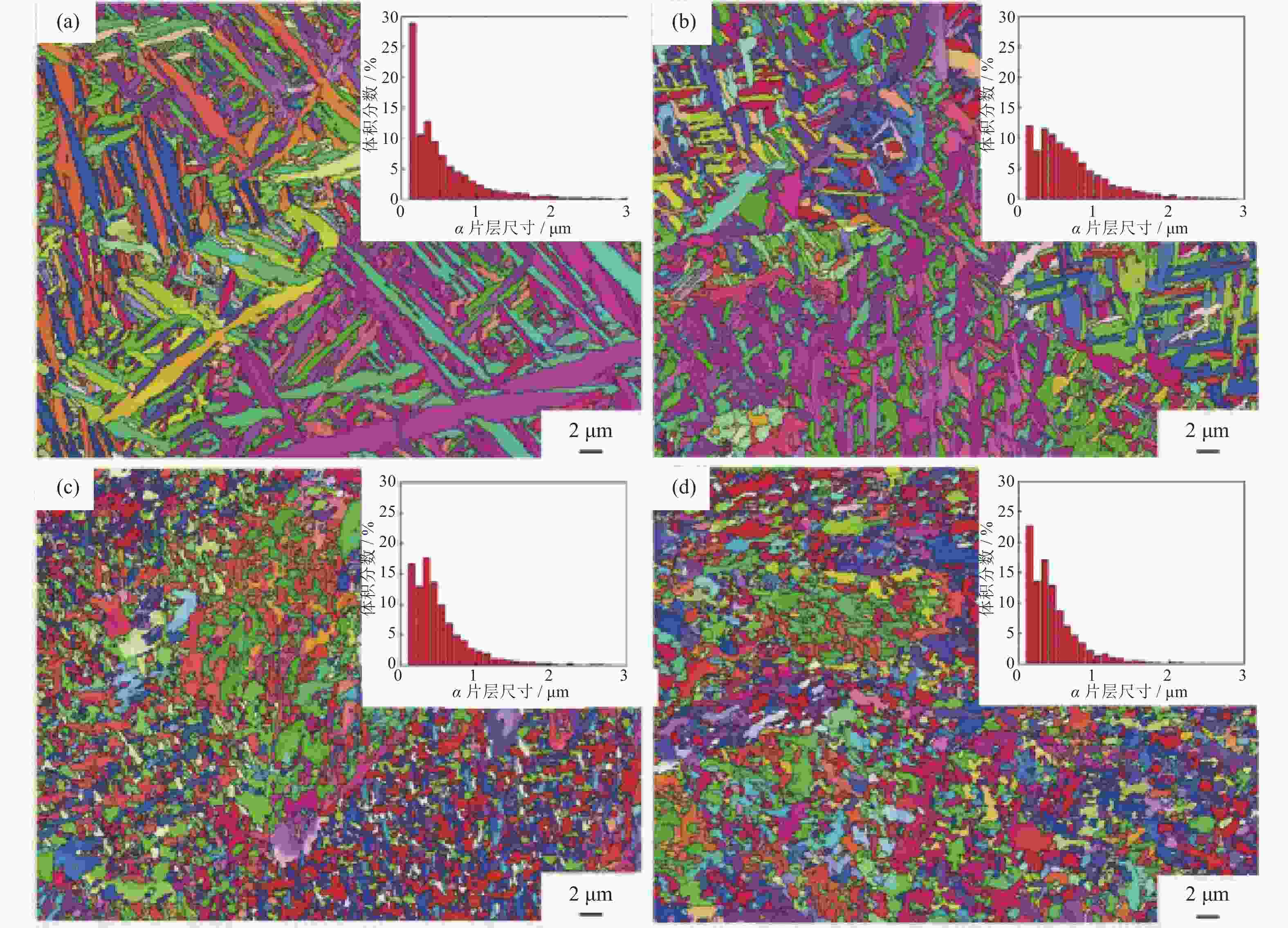

图 3 Ti合金及添加不同质量分数TiB2钛基复合材料的电子背散射衍射形貌和α片层尺寸分析[56]:(a)Ti‒6Al‒4V;(b)0.16%TiB2;(c)1.61%TiB2;(d)3.22%TiB2

Figure 3. Electron backscattered diffraction analysis and α lamella size of Ti alloys and TMCs with the different mass fraction of TiB2[56]: (a) Ti‒6Al‒4V; (b) 0.16%TiB2; (c) 1.61%TiB2; (d) 3.22%TiB2

表 1 航空领域常用高温钛合金牌号及成分

Table 1. Grades and components of the high-temperature titanium alloys

国家 钛合金牌号 服役温度 / ℃ 成分组成(质量分数) / % 美国 Ti6242 450 Ti‒6Al‒2Sn‒4Zr‒2Mo Ti6242s 520 Ti‒6Al‒2Sn‒4Zr‒2Mo‒0.1Si Ti1100 600 Ti‒6Al‒2.75Sn‒4Zr‒0.4Mo‒0.45Si 英国 IMI829 540 Ti‒5Al‒3.5Sn‒3Zr‒0.27Mo‒0.3Si‒1.0Nb IMI834 600 Ti‒5.8Al‒4.0Sn‒3.5Zr‒0.5Mo‒0.35Si‒0.7Nb‒0.06C 俄罗斯 BT18Y 550~600 Ti‒6.8Al‒2.5Sn‒4Zr‒0.7Mo‒0.2Si‒1Nb BT36 600 Ti‒6.3Al‒2.2Sn‒3.5Zr‒0.7Mo‒0.15Si‒5W 中国 Ti60 600 Ti‒5.8Al‒4.8Sn‒2Zr‒1Mo‒0.35Si‒0.85Nd Ti600 600 Ti‒6Al‒2.8Sn‒4Zr‒0.5Mo‒0.4Si‒0.1Y Ti65 650 Ti‒5.9Al‒4.0Sn‒3.5Zr‒0.3Mo‒0.4Si‒0.3Nb‒2.0Ta‒1.0W‒0.05C -

[1] Liu Z Y, He B, Lyu T Y, et al. A review on additive manufacturing of titanium alloys for aerospace applications: directed energy deposition and beyond Ti‒6Al‒4V. JOM, 2021, 73(6): 1804 doi: 10.1007/s11837-021-04670-6 [2] Blakey-Milner B, Gradl P, Snedden G, et al. Metal additive manufacturing in aerospace: a review. Mater Des, 2021, 209: 110008 doi: 10.1016/j.matdes.2021.110008 [3] Huang Z H, Qu H L, Deng C, et al. Development and application of aerial titanium and its alloys. Mater Rev, 2011, 25(1): 102黄张洪, 曲恒磊, 邓超, 等. 航空用钛及钛合金的发展及应用. 材料导报, 2011, 25(1): 102 [4] Liu Y Y, Chen Z Y, Jin T N, et al. Present situation and prospect of 600 ℃ high-temperature titanium alloys. Mater Rev, 2018, 32(6): 1863 doi: 10.11896/j.issn.1005-023X.2018.11.013刘莹莹, 陈子勇, 金头男, 等. 600 ℃高温钛合金发展现状与展望. 材料导报, 2018, 32(6): 1863 doi: 10.11896/j.issn.1005-023X.2018.11.013 [5] Li S, Deng T S, Zhang Y H, et al. Review on the creep resistance of high-temperature titanium alloy. Trans Indian Inst Met, 2021, 74: 215 doi: 10.1007/s12666-020-02137-x [6] Cai J M, Mi G B, Gao F, et al. Research and development of some advanced high temperature titanium alloys for aero-engine. J Mater Eng, 2016, 44(8): 1 doi: 10.11868/j.issn.1001-4381.2016.08.001蔡建明, 弭光宝, 高帆, 等. 航空发动机用先进高温钛合金材料技术研究与发展. 材料工程, 2016, 44(8): 1 doi: 10.11868/j.issn.1001-4381.2016.08.001 [7] Khataee A, Flower H M, West D R F. New titanium‒aluminum‒X alloys for aerospace applications. J Mater Eng, 1988, 10(1): 37 doi: 10.1007/BF02834112 [8] Wang H, Zhao L, Peng Y, et al. Research progress of TiAl-based alloys fabricated by additive manufacturing. Powder Metall Technol, 2022, 40(2): 110 doi: 10.19591/j.cnki.cn11-1974/tf.2020100009王虎, 赵琳, 彭云, 等. 增材制造TiAl基合金的研究进展. 粉末冶金技术, 2022, 40(2): 110 doi: 10.19591/j.cnki.cn11-1974/tf.2020100009 [9] Cao J X, Huang X, Mi G B, et al. Research progress on application technique of Ti‒V‒Cr burn resistant titanium alloys. J Aeron Mater, 2014, 34(4): 92 doi: 10.11868/j.issn.1005-5053.2014.4.009曹京霞, 黄旭, 弭光宝, 等. Ti‒V‒Cr系阻燃钛合金应用研究进展. 航空材料学报, 2014, 34(4): 92 doi: 10.11868/j.issn.1005-5053.2014.4.009 [10] Falodun O E, Obadele B A, Oke S R, et al. Titanium-based matrix composites reinforced with particulate, microstructure, and mechanical properties using spark plasma sintering technique: a review. Int J Adv Manuf Technol, 2019, 102(5): 1689 [11] Saheb N, Iqbal Z, Khalil A, et al. Spark plasma sintering of metals and metal matrix manocomposites: a review. J Nanomater, 2012, 2012: 983470 [12] Patil C S, Ansari M I, Selvan R, et al. Influence of micro B4C ceramic particles addition on mechanical and wear behavior of aerospace grade Al‒Li alloy composites. Sādhanā, 2021, 46(1): 11 [13] Kuang W, Wang M M, Li J X, et al. Microstructure and mechanical properties of In-situ synthesized (TiB+La2O3)/TC4 titanium matrix composite. Mater Mech Eng, 2015, 39(2): 67邝玮, 王敏敏, 李九霄, 等. 原位自生(TiB+La2O3)/TC4钛基复合材料的显微组织和力学性能. 机械工程材料, 2015, 39(2): 67 [14] Dadkhah M, Mosallanejad M H, Iuliano L, et al. A comprehensive overview on the latest progress in the additive manufacturing of metal matrix composites: potential, challenges, and feasible solutions. Acta Metall Sinica, 2021, 34(9): 1173 doi: 10.1007/s40195-021-01249-7 [15] Qi J Q. Microstructure and High-Temperature Deformation Behavior of TiC Reinforced High-Temperature Titanium Alloy Matrix Composites Produced by Melting-Casting Process [Dissertation]. Harbin: Harbin Institute of Technology, 2013戚继球. 熔铸法制备TiC增强高温钛合金基复合材料组织与高温变形行为[学位论文]. 哈尔滨: 哈尔滨工业大学, 2013 [16] Yamamoto T, Otsuki A, Ishihara K, et al. Synthesis of near net shape high density TiB/Ti composite. Mater Sci Eng A, 1997, A239-240: 647 [17] Liu B, Liu Y, He X Y, et al. Preparation and mechanical properties of particulate-reinforced powder metallurgy titanium matrix composites. Metall Mater Trans A, 2007, 38(11): 2825 doi: 10.1007/s11661-007-9329-9 [18] Durai Murugan P, Vijayananth S, Natarajan M P, et al. A current state of metal additive manufacturing methods: A review. Mater Today, 2022, 59: 1277 [19] Shakil S I, Smith N R, Yoder S P, et al. Post fabrication thermomechanical processing of additive manufactured metals: A review. J Manuf Process, 2022, 73: 757 doi: 10.1016/j.jmapro.2021.11.047 [20] Ahn D G. Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. Int J Precis Eng Manuf, 2016, 3(4): 381 [21] Pototzky P, Maier H J, Christ H J. Thermomechanical fatigue behavior of the high-temperature titanium alloy IMI 834. Metall Mater Trans A, 1998, 29(12): 2995 doi: 10.1007/s11661-998-0207-x [22] Wang Q J, Liu J R, Yang R. High temperature titanium alloys: status and perspective. J Aeron Mater, 2014, 34(4): 1 doi: 10.11868/j.issn.1005-5053.2014.4.001王清江, 刘建荣, 杨锐. 高温钛合金的现状与前景. 航空材料学报, 2014, 34(4): 1 doi: 10.11868/j.issn.1005-5053.2014.4.001 [23] Wang R Q, Ge P, Hou P, et al. Effects of solution treatment and aging temperature on microstructure and mechanical properties of IMI834 titanium alloy plate. Heat Treat Met, 2021, 46(3): 96 doi: 10.13251/j.issn.0254-6051.2021.03.019王瑞琴, 葛鹏, 侯鹏, 等. 固溶和时效温度对IMI834钛合金板材组织和性能的影响. 金属热处理, 2021, 46(3): 96 doi: 10.13251/j.issn.0254-6051.2021.03.019 [24] Shi P Y, Zhang Y Q, Sun F, et al. Influences of solution and aging temperature on microstructure and mechanical properties of the IM1834 alloy. Spec Cast Nonferrous Alloys, 2017, 37(9): 936 doi: 10.15980/j.tzzz.2017.09.003史蒲英, 张永强, 孙峰, 等. 固溶时效温度对IMI834钛合金组织和性能的影响. 特种铸造及有色合金, 2017, 37(9): 936 doi: 10.15980/j.tzzz.2017.09.003 [25] Che J D, Jiang B B, Wang Q, et al. Effects of minor additions of elements into Ti1100 on elevated temperature oxidation- and corrosion-resistance. Rare Met Mater Eng, 2018, 47(5): 1471车晋达, 姜贝贝, 王清, 等. 微量元素添加对Ti1100合金的高温抗氧化及耐蚀性能影响. 稀有金属材料与工程, 2018, 47(5): 1471 [26] Fu Y Y, Song Y Q, Hui S X, et al. Research and application of typical aerospace titanium alloys. Chin J Rare Met, 2006, 30(6): 850 doi: 10.3969/j.issn.0258-7076.2006.06.028付艳艳, 宋月清, 惠松骁, 等. 航空用钛合金的研究与应用进展. 稀有金属, 2006, 30(6): 850 doi: 10.3969/j.issn.0258-7076.2006.06.028 [27] He C Y, Zhang L J. The development and application of high temperature titanium alloy at domestic and abroad. World Nonferrous Met, 2016(1): 21何春艳, 张利军. 国内外高温钛合金的发展与应用. 世界有色金属, 2016(1): 21 [28] Fu B G. Effects of Alloying Elements on Microstructures and Properties of Cast Ti-1100 Alloys [Dissertation]. Harbin: Harbin Institute of Technology, 2015付彬国. 合金元素对铸造Ti-1100合金组织及性能影响[学位论文]. 哈尔滨: 哈尔滨工业大学, 2015 [29] Guo J, Yue K, Hu Z H, et al. Preparation of Ti60 high temperature titanium alloy ingot for aerospace. Iron Steel Vanadium Titanium, 2021, 42(6): 138 doi: 10.7513/j.issn.1004-7638.2021.06.019郭杰, 岳颗, 胡钊华, 等. 航空航天用Ti60高温钛合金铸锭制备工艺. 钢铁钒钛, 2021, 42(6): 138 doi: 10.7513/j.issn.1004-7638.2021.06.019 [30] Tang H F, Zhao Y Q, Hong Q, et al. Effects of rare earth elements on the structure and properties of high-temperature titanium alloy. Titanium Ind Prog, 2010, 27(1): 16 doi: 10.3969/j.issn.1009-9964.2010.01.003汤海芳, 赵永庆, 洪权, 等. 稀土元素对高温钛合金组织和性能的影响. 钛工业进展, 2010, 27(1): 16 doi: 10.3969/j.issn.1009-9964.2010.01.003 [31] Zhao Z B, Wang Q J, Liu J R, et al. Texture of Ti60 alloy precision bars and its effect of tensile properties. Acta Met Sin, 2015, 51(5): 561 doi: 10.11900/0412.1961.2014.00451赵子博, 王清江, 刘建荣, 等. Ti60合金棒材中的织构及其对拉伸性能的影响. 金属学报, 2015, 51(5): 561 doi: 10.11900/0412.1961.2014.00451 [32] Zhao L, Liu J R, Wang Q J, et al. Effect of precipitates on the high temperature creep and creep rupture properties of Ti60 alloy. Chin J Mater Res, 2009, 23(1): 1 doi: 10.3321/j.issn:1005-3093.2009.01.001赵亮, 刘建荣, 王清江, 等. 析出相对Ti60钛合金蠕变和持久性能的影响. 材料研究学报, 2009, 23(1): 1 doi: 10.3321/j.issn:1005-3093.2009.01.001 [33] Zhao H Y, Zhang M, Yu J S, et al. Research on microstructure and mechanical properties of graphene/Ti60 composites. Titanium Ind Prog, 2022, 39(2): 29 doi: 10.11782/j.issn.1009-9964.2022.2.tgyjz202202006赵会宇, 张媚, 于佳石, 等. 石墨烯/Ti60复合材料组织与力学性能研究. 钛工业进展, 2022, 39(2): 29 doi: 10.11782/j.issn.1009-9964.2022.2.tgyjz202202006 [34] Xie H Z, Liu G X, Peng H Y, et al. High temperature mechanical properties and influencing factors of Ti65 titanium alloy sheet. Ordn Mater Sci Eng, 2022, 45(2): 26 doi: 10.14024/j.cnki.1004-244x.20211129.001谢洪志, 刘广鑫, 彭皓云, 等. Ti65钛合金板材高温力学性能及影响因素. 兵器材料科学与工程, 2022, 45(2): 26 doi: 10.14024/j.cnki.1004-244x.20211129.001 [35] Zhao D, Fan J K, Zhang Z X, et al. Microstructure and texture variations in high temperature titanium alloy Ti65 sheets with different rolling modes and heat treatments. Materials, 2020, 13(11): 2466 doi: 10.3390/ma13112466 [36] Liu S F, Song X, Xue T, et al. Application and development of titanium alloy and titanium matrix composites in aerospace field. J Aeron Mater, 2020, 40(3): 77 doi: 10.11868/j.issn.1005-5053.2020.000061刘世锋, 宋玺, 薛彤, 等. 钛合金及钛基复合材料在航空航天的应用和发展. 航空材料学报, 2020, 40(3): 77 doi: 10.11868/j.issn.1005-5053.2020.000061 [37] Nyanor P, El-Kady O, Yehia H M, et al. Effect of bimodal-sized hybrid TiC-CNT reinforcement on the mechanical properties and coefficient of thermal expansion of aluminium matrix composites. Met Mater Int, 2021, 27(4): 753 doi: 10.1007/s12540-020-00802-w [38] Hu Y B, Cong W L, Wang X L, et al. Laser deposition-additive manufacturing of TiB‒Ti composites with novel three-dimensional quasi-continuous network microstructure: effects on strengthening and toughening. Composites Part B, 2018, 133: 91 doi: 10.1016/j.compositesb.2017.09.019 [39] Zheng B W, Yuan X G, Dong F Y, et al. Effect of La2O3 content on microstructures and wear resistance of IM834 matrix composites. Foundry, 2021, 70(8): 933 doi: 10.3969/j.issn.1001-4977.2021.08.006郑博文, 袁晓光, 董福宇, 等. La2O3含量对(TiC+TiB)/IMI834复合材料组织及耐磨性的影响. 铸造, 2021, 70(8): 933 doi: 10.3969/j.issn.1001-4977.2021.08.006 [40] Qin Y X, Zhang D, Lu W J, et al. Oxidation behavior of in situ-synthesized (TiB+TiC)/Ti6242 composites. Oxid Met, 2006, 66(5): 253 [41] Shen X B. Microstructure and Mechanical Properties of in situ TiB Reinforced Titanium Matrix Compositre Prepared by SPS [Dissertation]. Beijing: Beijing Institute of Technology, 2014神祥博. SPS制备TiB增强Ti基复合材料的组织结构和力学性能研究[学位论文]. 北京: 北京理工大学, 2014 [42] Attar H, Bönisch M, Calin M, et al. Comparative study of microstructures and mechanical properties of in situ Ti–TiB composites produced by selective laser melting, powder metallurgy, and casting technologies. J Mater Res, 2014, 29(17): 1941 doi: 10.1557/jmr.2014.122 [43] Li Y Y, Zhu F W, Qiao Z L. Study on mechanical alloying of TiB2 particulate reinforced titanium matrix composites. Appl Mech Mater, 2018, 875: 41 doi: 10.4028/www.scientific.net/AMM.875.41 [44] Zhang L L, Zhou Y, Liu S F, et al. Research progress in additive manufacturing and properties of die steel. China Metall, 2022, 32(3): 1 doi: 10.13228/j.boyuan.issn1006-9356.20210661张亮亮, 周阳, 刘世锋, 等. 模具钢增材制造及其性能的研究进展. 中国冶金, 2022, 32(3): 1 doi: 10.13228/j.boyuan.issn1006-9356.20210661 [45] Radhakrishnan M, Hassan M M, Long B E, et al. Microstructures and properties of Ti/TiC composites fabricated by laser-directed energy deposition. Addit Manuf, 2021, 46: 102198 [46] Attar H, Löber L, Funk A, et al. Mechanical behavior of porous commercially pure Ti and Ti–TiB composite materials manufactured by selective laser melting. Mater Sci Eng A, 2015, 625: 350 doi: 10.1016/j.msea.2014.12.036 [47] Attar H, Prashanth K G, Zhang L C, et al. Effect of powder particle shape on the properties of in situ Ti–TiB composite materials produced by selective laser melting. J Mater Sci Technol, 2015, 31(10): 1001 doi: 10.1016/j.jmst.2015.08.007 [48] Li H L, Jia D C, Yang Z H, et al. Effect of heat treatment on microstructure evolution and mechanical properties of selective laser melted Ti–6Al–4V and TiB/Ti–6Al–4V composite: a comparative study. Mater Sci Eng A, 2021, 801: 140415 doi: 10.1016/j.msea.2020.140415 [49] Cai C, Radoslaw C, Zhang J L, et al. In-situ preparation and formation of TiB/Ti‒6Al‒4V nanocomposite via laser additive manufacturing: microstructure evolution and tribological behavior. Powder Technol, 2019, 342: 73 doi: 10.1016/j.powtec.2018.09.088 [50] Sato Y, Tsukamoto M, Masuno S, et al. Investigation of the microstructure and surface morphology of a Ti6Al4V plate fabricated by vacuum selective laser melting. Appl Phys A, 2016, 122: 439 doi: 10.1007/s00339-016-9996-8 [51] Santos E C, Shiomi M, Osakada K, et al. Rapid manufacturing of metal components by laser forming. Int J Mach Tools Manuf, 2006, 46(12): 1459 [52] Yan L, Li W, Chen X Y, et al. Simulation of cooling rate effects on Ti–48Al–2Cr–2Nb crack formation in direct laser deposition. JOM, 2017, 69(3): 586 doi: 10.1007/s11837-016-2211-8 [53] Hong C, Gu D D, Dai D H, et al. Laser metal deposition of TiC/Inconel 718 composites with tailored interfacial microstructures. Opt Laser Technol, 2013, 54: 98 doi: 10.1016/j.optlastec.2013.05.011 [54] Wang L, Cheng J, Qiao Z H, et al. Tribological behaviors of in situ TiB2 ceramic reinforced TiAl-based composites under sea water environment. Ceram Int, 2017, 43(5): 4314 doi: 10.1016/j.ceramint.2016.12.075 [55] Ding H Y, Zhou C P, Zhang Y, et al. Corrosion resistance of Ti/TiB2 multilayers in Hank's solution. Chin J Vacuum Sci Technol, 2014, 34(6): 611丁红燕, 周长培, 章跃, 等. Ti/TiB2多层膜在Hank's模拟体液中耐蚀性研究. 真空科学与技术学报, 2014, 34(6): 611 [56] Qin L Y, Men J H, Zhao S, et al. Effect of TiB content on microstructure and mechanical properties of TiB/Ti‒6Al‒4V composites formed by selective laser melting. Chin J Lasers, 2021, 48(6): 0602102 doi: 10.3788/CJL202148.0602102钦兰云, 门继华, 赵朔, 等. TiB2含量对选区激光熔化TiB/Ti‒6Al‒4V复合材料组织及力学性能的影响. 中国激光, 2021, 48(6): 0602102 doi: 10.3788/CJL202148.0602102 [57] Kasperovich G, Haubrich J, Gussone J, et al. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater Des, 2016, 105: 160 doi: 10.1016/j.matdes.2016.05.070 [58] Li H L, Yang Z H, Cai D L, et al. Microstructure evolution and mechanical properties of selective laser melted bulk-form titanium matrix nanocomposites with minor B4C additions. Mater Des, 2020, 185: 108245 doi: 10.1016/j.matdes.2019.108245 [59] Fang M H, Han Y F, Shi Z S, et al. Embedding boron into Ti powder for direct laser deposited titanium matrix composite: Microstructure evolution and the role of nano-TiB network structure. Composites Part B, 2021, 211: 108683 doi: 10.1016/j.compositesb.2021.108683 [60] Xiao L H, Huang S Q, Wang Y, et al. Preparation and characterization of the anti-high temperature oxidation borosilicate glass coating on TC4 titanium alloy. J Mater Eng Perform, 2022, 31(1): 534 doi: 10.1007/s11665-021-06189-y [61] Ding C. Microstructures and Properties of Powder Metallurgy Ti600 Alloy [Dissertation]. Shenyang: Shenyang University of Technology, 2019丁超. 粉末冶金Ti600合金组织和性能的研究[学位论文]. 辽宁: 沈阳工业大学, 2019 [62] Bermingham M J, Mcdonald S D, Dargusch M S. Effect of trace lanthanum hexaboride and boron additions on microstructure, tensile properties and anisotropy of Ti‒6Al‒4V produced by additive manufacturing. Mater Sci Eng A, 2018, 719: 1 doi: 10.1016/j.msea.2018.02.012 [63] Feng Y Q, Feng K, Yao C W, et al. Microstructure and properties of in-situ synthesized (Ti3Al + TiB)/Ti composites by laser cladding. Mater Des, 2018, 157: 258 doi: 10.1016/j.matdes.2018.07.045 [64] Feng Y Q, Feng K, Yao C W, et al. Effect of LaB6 addition on the microstructure and properties of (Ti3Al + TiB)/Ti composites by laser cladding. Mater Des, 2019, 181: 107959 doi: 10.1016/j.matdes.2019.107959 [65] Nartu M S K K Y, Pole M, Mantri S A, et al. Process induced multi-layered titanium-boron carbide composites via additive manufacturing. Add Manuf, 2021, 46: 102156 [66] Zhang Y Z, Wei Z M, Shi L K, et al. Characterization of laser powder deposited Ti–TiC composites and functional gradient materials. J Mater Process Technol, 2008, 206(1): 438 -

下载:

下载: