Rheological property and solvent debinding behavior of microcrystalline wax based feedstocks for injection molding

-

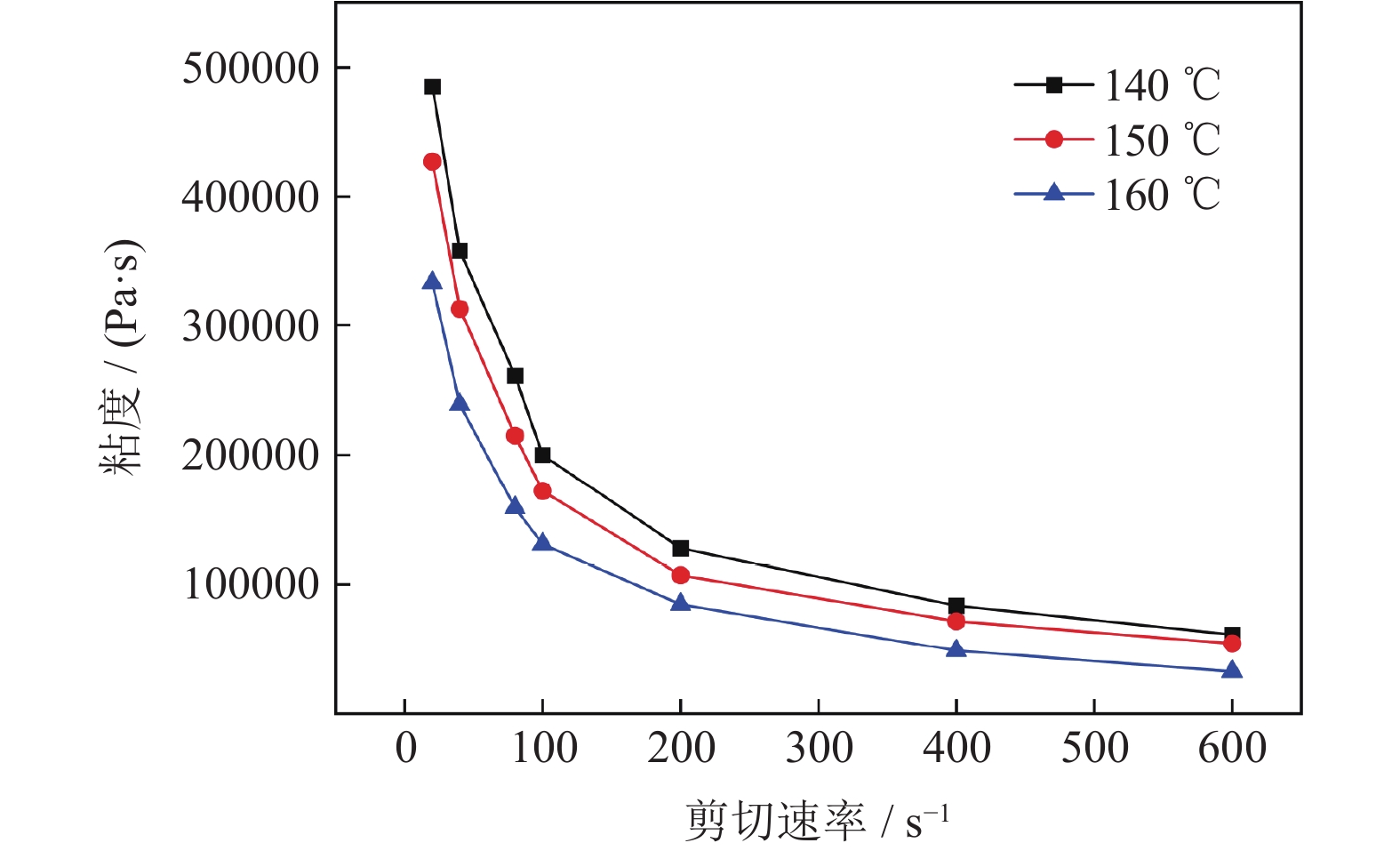

摘要: 以微晶蜡为粘结剂主要组元,与WC–10Co(YG10)粉末密炼混合,得到注射成形喂料。通过线性拟合计算出喂料的非牛顿指数、粘流活化能和综合流变学因子,考察不同温度与剪切速率下喂料的流变性能。对成形坯体在不同温度下于不同脱脂溶剂中的失重进行分析,考察坯体的溶剂脱脂动力学行为。结果表明,微晶蜡基喂料呈现假塑性流体的剪切稀化特征,对剪切速率和温度的敏感性较为稳定,综合流变性能良好。可溶性粘结剂组元的脱除主要发生在脱脂前期,由扩散所控制,且随着坯体厚度和体积的减小及脱脂温度的升高,扩散系数增大。Abstract: Microcrystalline wax was mixed with the WC–10Co (YG10) powders to obtain the injection molding feedstocks as the main component of the binders. The non-Newtonian index, viscous flow activation energy, and synthetic rheological factor of the feedstocks were calculated by linear fitting, and the rheological properties of the feedstocks at the different temperatures and shear rates were investigated. The kinetic behavior of the solvent debinding for green bodies was investigated by analyzing the weight loss of the green bodies in the different debinding solvents at the different temperatures. The results show that, the microcrystalline wax based feedstocks exhibit the shear thinning characteristics of pseudoplastic fluid. The feedstocks have the stable sensitivity to the shear rate and temperature fluctuation, and show the good comprehensive rheological properties. The removal of soluble binder components mainly occurs in the pre-solvent debinding stage, which is controlled by diffusion, and the diffusion coefficient increases with the decrease of the thickness and volume of the green body and the increase of the debinding temperature.

-

图 9 正庚烷中不同脱脂时间下坯体表面和断面的显微形貌:(a)生坯表面;(b)1 h表面;(c)3 h表面;(d)5 h表面;(e)生坯断面;(f)1 h断面;(g)3 h断面;(h)5 h断面

Figure 9. Surface and section SEM images of the green parts in the different debinding times: (a) surface, 0 h; (b) surface, 1 h; (c) surface, 3 h; (d) surface, 5 h; (e) section, 0 h; (f) section, 1 h (g) section, 3 h; (h) section, 5 h

表 1 不同溶剂与温度的动力学参数

Table 1. Kinetic parameters in the different solvents at the different temperatures

溶剂 30 ℃扩散系数 / (×10‒3 mm2·s‒1) 35 ℃扩散系数 / (×10‒3 mm2·s‒1) 40 ℃扩散系数 / (×10‒3 mm2·s‒1) A B A B A B 三氯乙烯 3.81 9.70 4.22 11.26 4.66 13.01 正庚烷 2.45 9.27 3.01 10.89 3.68 12.74 煤油 1.73 6.96 1.98 7.78 2.26 8.66 -

[1] Chen R Z, Zheng S, Zhou R, et al. Development of cemented carbides with CoxFeNiCrCu high-entropy alloyed binder prepared by spark plasma sintering. Int J Refract Met Hard Mater, 2022, 103: 105751 doi: 10.1016/j.ijrmhm.2021.105751 [2] Sun Z Y, Qin M L, Li R, et al. Preparation of high performance soft magnetic alloy Fe–4Si–0.8P by metal injection molding. Adv Powder Technol, 2017, 28(10): 2687 [3] Prathabrao M, Amin S Y M, Ibrahim M H I. Review on sintering process of WC–Co cemented carbide in metal injection molding technology // Colloquium of Advanced Materials. Johor, 2017: 143 [4] Liu C, Kong X J, Wu S W, et al. Research on powder injection molding of Ti6Al4V alloys for biomedical application. Powder Metall Technol, 2018, 36(3): 7 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.010刘超, 孔祥吉, 吴胜文, 等. 生物医用Ti6Al4V合金粉末注射成形工艺研究. 粉末冶金技术, 2018, 36(3): 7 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.010 [5] Lin D G, Sanetrnik D, Cho H, et al. Rheological and thermal debinding properties of blended elemental Ti–6Al–4V powder injection molding feedstock. Powder Technol, 2017, 311: 357 doi: 10.1016/j.powtec.2016.12.071 [6] Gao C P, Luo T G, Liu S L, et al. Debinding and sintering properties of titanium alloys prepared by powder injection molding. Powder Metall Technol, 2021, 39(5): 410 doi: 10.19591/j.cnki.cn11-1974/tf.2021030018高春萍, 罗铁钢, 刘胜林, 等. 粉末注射成形钛合金的脱脂和烧结性能. 粉末冶金技术, 2021, 39(5): 410 doi: 10.19591/j.cnki.cn11-1974/tf.2021030018 [7] Chang W G, Oh J W, Song G W, et al. Rheological and thermal debinding behaviors of silicon nitride in powder injection molding. Ceram Int, 2019, 45(14): 16982 doi: 10.1016/j.ceramint.2019.05.247 [8] Hu K, Yang S S, Zou L M, et al. Effect of powder shape on rheological properties of tungsten feedstocks for metal powder injection molding. Rare Met Mater Eng, 2020, 49(10): 3472胡可, 杨世松, 邹黎明, 等. 粉末粒形对钨粉末注射成形喂料流变性能的影响. 稀有金属材料与工程, 2020, 49(10): 3472 [9] Cui D W, Qu X H, Wei W Q, et al. Characteristics of high nitrogen stainless steel powder by milling and rheological properties of its MIM feedstock. Rare Met Mater Eng, 2015, 44(12): 3173崔大伟, 曲选辉, 魏文庆, 等. 球磨高氮不锈钢粉末特性及注射喂料流变性能. 稀有金属材料与工程, 2015, 44(12): 3173 [10] Yang Z C, Li D X, Lu R W, et al. Effect of microcrystalline wax content on the rheology of 17-4PH stainless steel feedstock. Mater Sci Eng Powder Metall, 2013, 18(6): 926 doi: 10.3969/j.issn.1673-0224.2013.06.025杨忠臣, 李笃信, 卢仁伟, 等. 微晶蜡含量对17-4PH不锈钢喂料流变性的影响. 粉末冶金材料科学与工程, 2013, 18(6): 926 doi: 10.3969/j.issn.1673-0224.2013.06.025 [11] Claudel D, Mohamed S, Thierry B, et al. Influence of particle-size distribution and temperature on the rheological properties of highly concentrated Inconel feedstock alloy 718. Powder Technol, 2017, 322: 273 doi: 10.1016/j.powtec.2017.08.049 [12] Chen G, Cao P, Wen G A, et al. Debinding behaviour of a water soluble PEG/PMMA binder for Ti metal injection moulding. Mater Chem Phys, 2013, 139(2-3): 557 doi: 10.1016/j.matchemphys.2013.01.057 [13] You L, Liu Y J, Pan Y, et al. Research progress of titanium alloy binder system for powder injection molding. Powder Metall Technol, 2021, 39(6): 563 doi: 10.19591/j.cnki.cn11-1974/tf.2020090009尤力, 刘艳军, 潘宇, 等. 粉末注射成形钛合金粘结剂体系的研究进展. 粉末冶金技术, 2021, 39(6): 563 doi: 10.19591/j.cnki.cn11-1974/tf.2020090009 [14] Zhao M M, Qiao L, Zheng J W, et al. Investigation of the solvent debinding in the injection molding of ZrO2 ceramics using LDEP, HDPE and wax binders. Ceram Int, 2019, 45(3): 3894 doi: 10.1016/j.ceramint.2018.11.062 [15] Wahab N A, Ahmad I N, Omar M A, et al. Determination of optimised solvent debinding parameters of injection moulded 316L stainless steel using Taguchi approach. Mater Today Proc, 2019, 16: 2357 doi: 10.1016/j.matpr.2019.06.139 [16] Luo M, Zhou F, Song X W. A powder injection molding debinding process for iron-based alloys. Powder Metall Ind, 2019, 29(5): 68 doi: 10.13228/j.boyuan.issn1006-6543.20180037罗蒙, 周芬, 宋希文. 一种铁基合金的粉末注射成形脱脂工艺研究. 粉末冶金工业, 2019, 29(5): 68 doi: 10.13228/j.boyuan.issn1006-6543.20180037 [17] Askari A, Momeni V. Rheological investigation and injection optimization of Fe–2Ni–2Cu feedstock for metal injection molding process. Mater Chem Phys, 2021, 271: 124926 doi: 10.1016/j.matchemphys.2021.124926 [18] Park J M, Han J S, Gal C W, et al. Effect of binder composition on rheological behavior of PMN-PZT ceramic feedstock. Powder Technol, 2018, 330: 19 doi: 10.1016/j.powtec.2018.02.027 [19] Liu W S, Long L P, Ma Y Z, et al. Solvent debinding processing of 93W–Ni–Fe powder extrusion molding compacts. Chin J Nonferrous Met, 2012, 22(2): 441刘文胜, 龙路平, 马运柱, 等. 93W–Ni–Fe粉末挤压成形坯溶剂脱脂工艺. 中国有色金属学报, 2012, 22(2): 441 -

下载:

下载: