Research progress on argon atomized nickel-based powder metallurgy superalloys and powder characteristics

-

摘要: 概述了国内外镍基粉末高温合金的发展、氩气雾化制粉技术的特点、氩气雾化镍基高温合金粉末的特性和增材制造用镍基高温合金粉末的发展方向,重点介绍了镍基高温合金粉末的形貌与粒度控制、氧化特性、气体脱附行为和缺陷形成及控制措施。讨论了镍基高温合金粉末特性与合金缺陷之间的内在关系,总结了缺陷消除措施的研究进展,明确了未来粉末涡轮盘用氩气雾化镍基高温合金粉末质量优化的发展方向,并对高品质氩气雾化镍基高温合金粉末促进增材制造技术在航空航天领域的应用进行了展望。Abstract: The development of nickel-based powder metallurgy (PM) superalloy, the technical features of argon atomized (AA) powder manufacturing, the characteristics of AA nickel-based superalloy powders, and the development direction of nickel-based superalloy powders for additive manufacturing (AM) were summarized in this paper. Meanwhile, the powder morphology, particle size control, oxidation characteristics, degassing behavior, and formation and control of defects for the nickel-based superalloy powders were mainly emphasized. The internal relationship between the powder characteristics and alloy defects was discussed, the research progress of the defect elimination measures was analyzed, and the quality optimization future of nickel-based superalloy powders used for the turbine disk was clarified. Moreover, the application of high-quality AA nickel-based superalloy powders to promote the AM technology in the aerospace field was prospected.

-

图 5 不同尺寸氩气雾化FGH96粉末的表面和内部凝固组织:(a)表面组织,104~147 μm;(b)表面组织,61~104 μm;(c)表面组织,38~61 μm;(d)表面组织,<38 μm;(e)内部组织,104~147 μm;(f)内部组织,61~104 μm;(g)内部组织,38~61 μm;(h)内部组织,<38 μm[23]

Figure 5. Surface and interior microstructures of the argon atomized FGH96 powders with the different particle sizes: (a) surface microstructures, 104~147 μm; (b) surface microstructures, 61~104 μm; (c) surface microstructures, 38~61 μm; (d) surface microstructures, <38 μm; (e) interior microstructures, 104~147 μm; (f) interior microstructures, 61~104 μm; (g) interior microstructures, 38~61 μm; (h) interior microstructures, <38 μm[23]

图 7 FGH96高温合金粉末表面氧化层分布[30]:(a)表面氧化层纳米束电子衍射图谱;(b)表面氧化层高角环形暗场扫描透射显微形貌;(c)Ni、O、Ti、Cr、Co和Al能谱分析

Figure 7. Surface oxide layer distribution of the FGH96 superalloy powders[30]: (a) nano-beam electron diffraction patterns of the surface layer regions; (b) high angle annular dark field-scanning transmission electron microscope image of the surface oxide layers; (c) the corresponding energy disperse spectroscope maps of Ni, O, Ti, Cr, Co, and Al

图 12 热等静压态FGH96高温合金中原始颗粒边界缺陷的组成[48]:(a)原始颗粒边界缺陷;(b)原始颗粒边界缺陷各种析出相分布;(c)γ′相选区电子衍射斑;(d)MC型碳化物选区电子衍射斑;(e)ZrO2选区电子衍射斑;(f)Al2O3选区电子衍射斑

Figure 12. Composition of the PPBs defects in HIPed FGH96 superalloys[48]: (a) PPBs; (b) precipitation phase distribution in PPBs; (c) selected area electron diffraction (SAED) patterns of γ′ phase; (d) SAED patterns of MC-type carbides; (e) SAED patterns of ZrO2; (f) SAED patterns of Al2O3

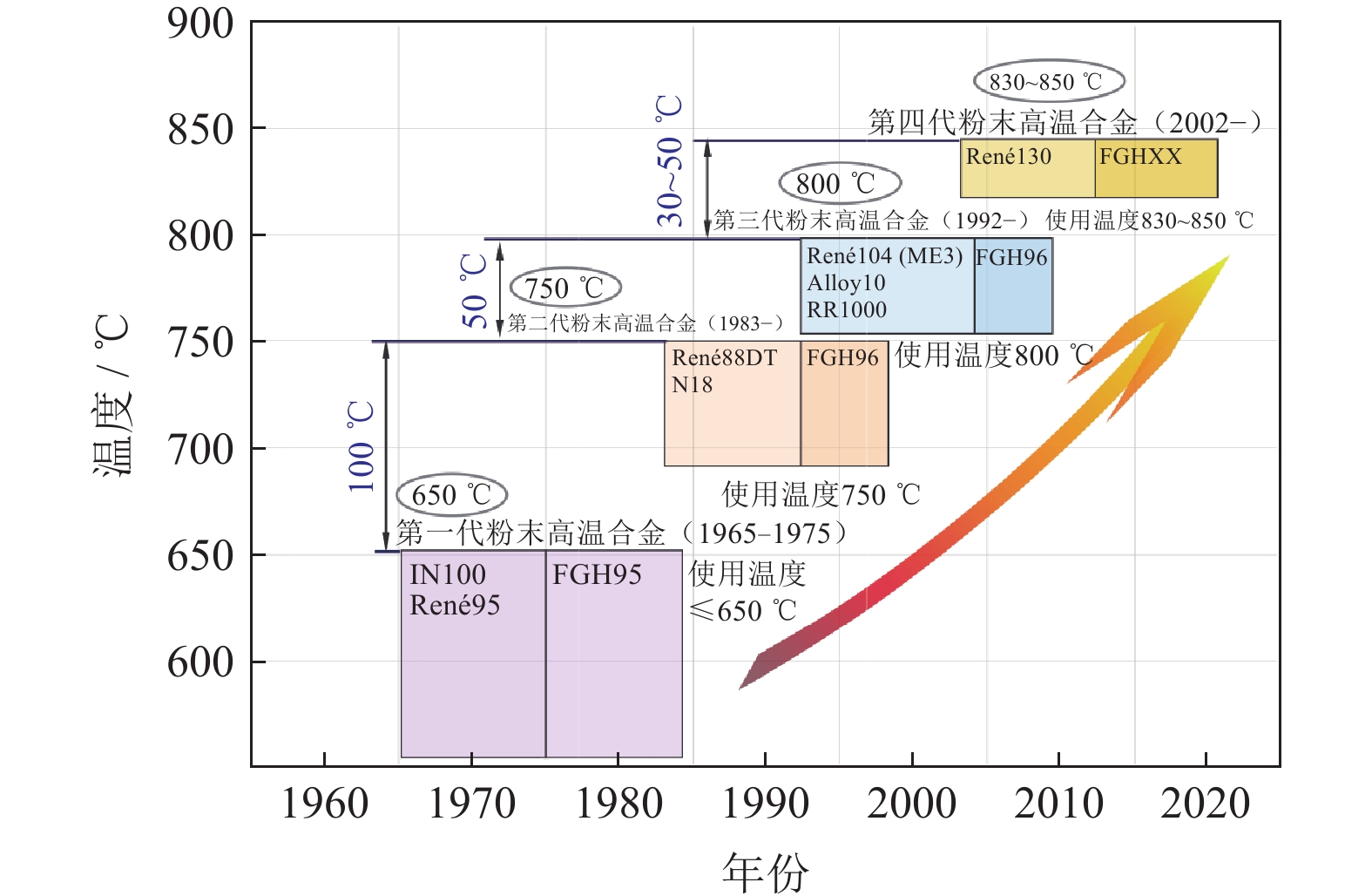

代次 合金牌号 国家 γ′相质量分数 / % γ′相完全溶解温度 / ℃ 密度 / (g·cm‒3) 第一代 René95 美国 50 1160 8.26 IN100 美国 61 1185 7.90 MERL76 美国 64 1190 7.95 APK-1 美国 45 1145 8.02 эп741нп 俄罗斯 60 1180 8.35 第二代 René88DT 美国 42 1130 8.36 N18 法国 55 1190 8.00 U720Li 美国 37 1150 8.10 第三代 LSHR 美国 60 1160 8.29 RR1000 英国 46 1160 8.14 Alloy10 美国 55 1180 8.41 NR3 法国 53 1205 8.05 René104/ME3 美国 51 1160 8.30 第四代 ME501 美国 55 1182 8.15 V202KHN2

(Alloy A)英国 49 1140 8.25 V202KHN2+Nb

(Alloy B)英国 50 1150 8.30 -

[1] Zhang G Q, Zhang Y W, Zheng L, et al. Research progress in powder metallurgy superalloys and manufacturing technologies for aero-engine application. Acta Metall Sin, 2019, 55(9): 1133 doi: 10.11900/0412.1961.2019.00119张国庆, 张义文, 郑亮, 等. 航空发动机用粉末高温合金及制备技术研究进展. 金属学报, 2019, 55(9): 1133 doi: 10.11900/0412.1961.2019.00119 [2] Shi C X, Zhong Z Y. Development and innovation of superalloy in China. Acta Metall Sin, 2010, 46(11): 1281师昌绪, 仲增墉. 我国高温合金的发展与创新. 金属学报, 2010, 46(11): 1281 [3] Reed R C. The Superalloys: Fundamentals and Applications. London: Cambridge University Press, 2008 [4] Qu X H, Zhang G Q, Zhang L. Applications of powder metallurgy technologies in aero-engines. J Aeron Mater, 2014, 34(1): 1曲选辉, 张国庆, 章林. 粉末冶金技术在航空发动机中的应用. 航空材料学报, 2014, 34(1): 1 [5] Zheng B L, Ashford D, Zhou Y Z, et al. Influence of mechanically milled powder and high pressure on spark plasma sintering of Mg–Cu–Gd metallic glasses. Acta Mater, 2013, 61(12): 4414 doi: 10.1016/j.actamat.2013.04.011 [6] Dai D H, Gu D D. Influence of thermodynamics within molten pool on migration and distribution state of reinforcement during selective laser melting of AlN/AlSi10Mg composites. Int J Mach Tools Manuf, 2016, 100: 14 doi: 10.1016/j.ijmachtools.2015.10.004 [7] Whitman C A, O’ flynn J T, Rayner A J, et al. Determining the oxidation behavior of metal powders during heating through thermogravimetric and evolved gas analysis using a coupled thermogravimetry-gas chromatography-mass spectrometry technique. Thermochimica Acta, 2016, 638: 124 doi: 10.1016/j.tca.2016.06.019 [8] Zhang Y W, Liu J T, Jia J, et al. Recent development of fourth generation powder metallurgy superalloys in America and Europe. Powder Metall Ind, 2022, 32(1): 1 doi: 10.13228/j.boyuan.issn1006-6543.20210105张义文, 刘建涛, 贾建, 等. 欧美第四代粉末高温合金研究进展. 粉末冶金工业, 2022, 32(1): 1 doi: 10.13228/j.boyuan.issn1006-6543.20210105 [9] Tian T. Microstructure and Properties of The New Third Generation Powder Metallurgy Superalloy Prepared by Spray Forming Processing [Dissertation]. Beijing: University of Science and Technology Beijing, 2020田甜. 喷射成形制备新型第三代粉末高温合金的组织和性能[学位论文]. 北京: 北京科技大学, 2020 [10] Huang B Y, Wei W F, Li S L, et al. Development of modern powder metallurgy materials and technology. Chin J Nonferrous Met, 2019, 29(9): 1917 doi: 10.19476/j.ysxb.1004.0609.2019.09.08黄伯云, 韦伟峰, 李松林, 等. 现代粉末冶金材料与技术进展. 中国有色金属学报, 2019, 29(9): 1917 doi: 10.19476/j.ysxb.1004.0609.2019.09.08 [11] Zhang Y W, Chi Y, Liu J T. Recent development of new type powder metallurgy superalloys in Russia. Powder Metall Ind, 2015, 25(4): 1张义文, 迟悦, 刘建涛. 俄罗斯新型粉末高温合金研制进展. 粉末冶金工业, 2015, 25(4): 1 [12] Zhang Y W, Jia J, Liu J T, et al. Recent development of new type powder metallurgy superalloys in Russia. Powder Metall Ind, 2020, 30(6): 102 doi: 10.13228/j.boyuan.issn1006-6543.20200193张义文, 贾建, 刘建涛, 等. 俄罗斯新型粉末高温合金研究最新进展. 粉末冶金工业, 2020, 30(6): 102 doi: 10.13228/j.boyuan.issn1006-6543.20200193 [13] Zhang Y W, Liu J T. Development in powder metallurgy superalloy. Mater China, 2013, 32(1): 1 doi: 10.7502/j.issn.1674-3962.2013.01.01张义文, 刘建涛. 粉末高温合金研究进展. 中国材料进展, 2013, 32(1): 1 doi: 10.7502/j.issn.1674-3962.2013.01.01 [14] Zhang M. Study on Microstructure and Properties of FGH98 Alloy for Advanced Aero Engine Turbine Disk [Dissertation]. Beijing: University of Science and Technology Beijing, 2018张明. 先进航空发动机涡轮盘用FGH98合金组织与性能研究[学位论文]. 北京: 北京科技大学, 2018 [15] Su Y J, Fu H D, Bai Y, et al. Progress in materials genome engineering in China. Acta Metall Sin, 2020, 56(10): 1313 doi: 10.11900/0412.1961.2020.00199宿彦京, 付华栋, 白洋, 等. 中国材料基因工程研究进展. 金属学报, 2020, 56(10): 1313 doi: 10.11900/0412.1961.2020.00199 [16] Wei M W, Chen S Y, Sun M, et al. Atomization simulation and preparation of 24CrNiMoY alloy steel powder using VIGA technology at high gas pressure. Powder Technol, 2020, 367: 724 doi: 10.1016/j.powtec.2020.04.030 [17] Czisch C, Fritsching U. Flow-adapted design option for free-fall atomizers. Atomiz Sprays, 2008, 18(6): 511 doi: 10.1615/AtomizSpr.v18.i6.30 [18] Li Z, Zhang G, Zhang Y, et al. Structures and properties of argon-gas atomized superalloy powders. J Chin J Nonferrous Met, 2005, 15(S2): 335李周, 张国庆, 张翼飞, 等. 氩气雾化高温合金粉末的制备及其组织与性能. 中国有色金属学报, 2005, 15(S2): 335 [19] Zhang G Q, Liu N, Li Z. Research progress of atomization and forming technology of high performance metallic materials. J Aeron Mater, 2020, 40(3): 95 doi: 10.11868/j.issn.1005-5053.2020.000093张国庆, 刘娜, 李周. 高性能金属材料雾化与成形技术研究进展. 航空材料学报, 2020, 40(3): 95 doi: 10.11868/j.issn.1005-5053.2020.000093 [20] Jia W M, Chen S Y, Wei M W, et al. Characteristics and printability of K417G nickel-base alloy powder prepared by VIGA method. Powder Metall, 2019, 62(1): 30 doi: 10.1080/00325899.2018.1546921 [21] Yang L B, Ren X N, Xia M, et al. Study on powder characteristics and effect factors of droplets size during electrode induction melting gas atomization. Rare Met Mater Eng, 2020, 49(6): 2017杨乐彪, 任晓娜, 夏敏, 等. 电极感应熔化气雾化粉末特性及液滴尺寸影响因素的研究. 稀有金属材料与工程, 2020, 49(6): 2017 [22] Huang C S, Liu Z Q, Wu Y B, et al. Properties and characterization of Ti-6Al-4V alloy fine powders prepared by electrode induction melting gas atomization (EIGA) technique. Rare Met Mater Engg, 2019, 48(10): 3302黄传收, 柳中强, 吴苑标, 等. 电极感应熔炼气雾化制备Ti-6Al-4V合金粉末的性能及其表征. 稀有金属材料与工程, 2019, 48(10): 3302 [23] Gao Z J, Zhang G Q, Li Z, et al. Microstructure characteristics of superalloy powders during rapid solidification prepared by argon atomization. Powder Metall Technol, 2011, 29(2): 93 doi: 10.19591/j.cnki.cn11-1974/tf.2011.02.003高正江, 张国庆, 李周, 等. 氩气雾化高温合金粉末的凝固组织特征. 粉末冶金技术, 2011, 29(2): 93 doi: 10.19591/j.cnki.cn11-1974/tf.2011.02.003 [24] Yuan H, Li Z, Xu W Y, et al. The study of argon atomized superalloy powders. Powder Metall Ind, 2010, 20(4): 1 doi: 10.3969/j.issn.1006-6543.2010.04.001袁华, 李周, 许文勇, 等. 氩气雾化制备高温合金粉末的研究. 粉末冶金工业, 2010, 20(4): 1 doi: 10.3969/j.issn.1006-6543.2010.04.001 [25] Zeoli N, Gu S. Computational validation of an isentropic plug nozzle design for gas atomisation. Comput Mater Sci, 2008, 42(2): 245 doi: 10.1016/j.commatsci.2007.07.013 [26] Liu Y, Li Z, Zhang G Q, et al. Flow field of double layer atomizer. J Aeron Mater, 2015, 35(5): 63 doi: 10.11868/j.issn.1005-5053.2015.5.010刘杨, 李周, 张国庆, 等. 双层雾化器流场的模拟研究. 航空材料学报, 2015, 35(5): 63 doi: 10.11868/j.issn.1005-5053.2015.5.010 [27] Liu Y, Zhang G Q, Li Z, et al. Application of non-contact measurement techniques in gas atomization powder preparation research. Mater China, 2020, 39(3): 206 doi: 10.7502/j.issn.1674-3962.201908016刘杨, 张国庆, 李周, 等. 非接触式测试技术在气雾化制粉研究中的应用. 中国材料进展, 2020, 39(3): 206 doi: 10.7502/j.issn.1674-3962.201908016 [28] Sun J F, Cao F Y, Cui C S, et al. Dynamic behaviors of gas velocity field during metal atomization. Powder Metall Technol, 2002, 20(2): 79 doi: 10.3321/j.issn:1001-3784.2002.02.004孙剑飞, 曹福洋, 崔成松, 等. 金属雾化过程中气体流场动力学行为. 粉末冶金技术, 2002, 20(2): 79 doi: 10.3321/j.issn:1001-3784.2002.02.004 [29] Zhang Q, Zheng L, Yuan H, et al. Influence of storage conditions on powder surface state and hot deformation behavior of a powder metallurgy nickel-based superalloy. Adv Eng Mater, 2022, 24(8): 2101615 doi: 10.1002/adem.202101615 [30] Zhang Q, Zheng L, Yuan H, et al. Effects of composition and particle size on the surface state and degassing behavior of nickel-based superalloy powders. Appl Surf Sci, 2021, 556: 149793 doi: 10.1016/j.apsusc.2021.149793 [31] Rao G A, Srinivas M, Sarma D S. Effect of oxygen content of powder on microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718. Mater Sci Eng:A, 2006, 435-436: 84 doi: 10.1016/j.msea.2006.07.053 [32] Guo Y L, Jia L N, Kong B, et al. Microstructure and surface oxides of rapidly solidified Nb-Si based alloy powders. Mater Des, 2017, 120: 109 doi: 10.1016/j.matdes.2017.02.014 [33] Chasoglou D, Hryha E, Norell M, et al. Characterization of surface oxides on water-atomized steel powder by XPS/AES depth profiling and nano-scale lateral surface analysis. Appl Surface Sci, 2013, 268: 496 doi: 10.1016/j.apsusc.2012.12.155 [34] Hryha E, Gierl C, Nyborg L, et al. Surface composition of the steel powders pre-alloyed with manganese. Appl Surface Sci, 2010, 256(12): 3946 doi: 10.1016/j.apsusc.2010.01.055 [35] Bai Q, Lin J, Tian G, et al. Review and analysis of powder prior boundary (PPB) formation in powder metallurgy processes for nickel-based super alloys. J Powder Metall Min, 2015, 4: 127 [36] Appa Rao G, Prasad K S, Kumar M, et al. Characterisation of hot isostatically pressed nickel base superalloy Inconel* 718. Mater Sci Technol, 2003, 19(3): 313 doi: 10.1179/026708303225010605 [37] Estrada J L, Duszczyk J, Korevaar B M. Gas entrapment and evolution in prealloyed aluminium powders. J Mater Sci, 1991, 26(6): 1431 doi: 10.1007/BF00544650 [38] Iwamoto K, Yamasaki M, Kawamura Y. Vacuum degassing behavior of rapidly solidified Al–Mn–Zr alloy powders. Mater Sci Eng:A, 2007, 449-451: 1013 doi: 10.1016/j.msea.2006.02.252 [39] Yamasaki M, Iwamoto K, Tamagawa H, et al. Vacuum degassing behavior of Zr-, Ni- and Cu-based metallic glass powders. Mater Sci Eng:A, 2007, 449-451: 907 doi: 10.1016/j.msea.2006.02.340 [40] Yamasaki M, Kawamura Y. Changes in the surface characteristics of gas-atomized pure aluminum powder during vacuum degassing. Mater Trans, 2006, 47(8): 1902 doi: 10.2320/matertrans.47.1902 [41] Yamasaki M, Kawamura Y. Effect of vacuum degassing on surface characteristics of rapidly solidified Al-based alloy powders. Mater Trans, 2004, 45(4): 1335 doi: 10.2320/matertrans.45.1335 [42] Liu Y F, Liu N, Zheng L, et al. Effect of HIP temperatures and powder particle size on microstructure and properties of PM TiAl alloy. Rare Met Mater Eng, 2019, 48(10): 3227刘玉峰, 刘娜, 郑亮, 等. HIP温度和粉末粒度对PM TiAl合金组织和性能的影响. 稀有金属材料与工程, 2019, 48(10): 3227 [43] Rabin B H, Smolik G R, Korth G E. Characterization of entrapped gases in rapidly solidified powders. Mater Sci Eng:A, 1990, 124(1): 1 doi: 10.1016/0921-5093(90)90328-Z [44] Hou W Q, Meng J, Liang J J, et al. Preparation technology and research progress of superalloy powders used for additive manufacturing. Powder Metall Technol, 2022, 40(2): 131 doi: 10.19591/j.cnki.cn11-1974/tf.2021030038侯维强, 孟杰, 梁静静, 等. 增材制造用高温合金粉末制备技术及研究进展. 粉末冶金技术, 2022, 40(2): 131 doi: 10.19591/j.cnki.cn11-1974/tf.2021030038 [45] Luo S, Wang H Z, Gao Z Y, et al. Interaction between high-velocity gas and liquid in gas atomization revealed by a new coupled simulation model. Mater Des, 2021, 212: 110264 doi: 10.1016/j.matdes.2021.110264 [46] Guo W M, Wu J T, Chen G S, et al. The influence of vacuum degassing pretreatment on microstructure and properties of superalloy FGH95. J Aeron Mater, 2003, 23(Suppl 1): 21国为民, 吴剑涛, 陈淦生, 等. 真空脱气预处理工艺与FGH95合金热诱导孔洞的改善和性能提高的研究. 航空材料学报, 2003, 23(增刊1): 21 [47] Guan S W, Liu S C, Shi J, et al. Research progress and prospect of metal powder preparation by gas atomization. Foundry, 2022, 71(2): 136 doi: 10.3969/j.issn.1001-4977.2022.02.002关书文, 刘世昌, 时坚, 等. 气雾化制备金属粉末的研究进展及展望. 铸造, 2022, 71(2): 136 doi: 10.3969/j.issn.1001-4977.2022.02.002 [48] Tan L M, Li Y P, Liu C Z, et al. The evolution history of superalloy powders during hot consolidation and plastic deformation. Mater Charact, 2018, 140: 30 doi: 10.1016/j.matchar.2018.03.039 [49] Riener K, Oswald S, Winkler M, et al. Influence of storage conditions and reconditioning of AlSi10Mg powder on the quality of parts produced by laser powder bed fusion (LPBF). Addit Manuf, 2021, 39: 101896 [50] Appa Rao G, Srinivas M, Sarma D S. Effect of thermomechanical working on the microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718. Mater Sci Eng:A, 2004, 383(2): 201 doi: 10.1016/j.msea.2004.05.062 [51] Appa Rao G, Srinivas M, Sarma D S. Effect of solution treatment temperature on microstructure and mechanical properties of hot isostatically pressed superalloy Inconel* 718. Mater Sci Technol, 2004, 20(9): 1161 doi: 10.1179/026708304225022124 [52] Chang L T, Sun W R, Cui Y Y, et al. Influences of hot-isostatic-pressing temperature on microstructure, tensile properties and tensile fracture mode of Inconel 718 powder compact. Mater Sci Eng:A, 2014, 599: 186 doi: 10.1016/j.msea.2014.01.095 [53] Qiu C L, Attallah M M, Wu X H, et al. Influence of hot isostatic pressing temperature on microstructure and tensile properties of a nickel-based superalloy powder. Mater Sci Eng:A, 2013, 564: 176 doi: 10.1016/j.msea.2012.11.084 [54] Zhang Y B, Zheng L, Xu W Y, et al. Interfacial reaction between mullite-based inclusions and PM superalloy FGH96. J Aeron Mater, 2022, 42(2): 20 doi: 10.11868/j.issn.1005-5053.2021.000159张轶波, 郑亮, 许文勇, 等. 莫来石基耐火材料夹杂物与粉末冶金高温合金FGH96界面反应. 航空材料学报, 2022, 42(2): 20 doi: 10.11868/j.issn.1005-5053.2021.000159 [55] Zheng L, Zhang G Q, Gorley M J, et al. Effects of vacuum on gas content, oxide inclusions and mechanical properties of Ni-based superalloy using electron beam button and synchrotron diffraction. Mater Des, 2021, 207: 109861 doi: 10.1016/j.matdes.2021.109861 [56] Huron E S, Roth P G. The influence of inclusions on low cycle fatigue life in a P/M nickel-base disk superalloy // Superalloys 1996. Champion, PA: TMS, 1996: 359 [57] Li S X, Weng Y Q, Hui W J, et al. Very High Cycle Fatigue Properties of High Strength Steels: Effeccts of Nonmetallic Inclusions. Beijing: Metallurgical Industry Press, 2010李守新, 翁宇庆, 惠卫军, 等. 高强度钢超高周疲劳性能: 非金属夹杂物的影响. 北京: 冶金工业出版社, 2010 [58] Zhang Y B, Zheng L, Xu W Y, et al. Effects of heat treatment temperature on microstructure and particle shedding of corundum-based refractory materials. J Mater Eng, 2022, 50(6): 138张轶波, 郑亮, 许文勇, 等. 热处理温度对刚玉基耐火材料组织和微粒脱落的影响. 材料工程, 2022, 50(6): 138 [59] Hou J. Influences of Microstructure Characteristics and Microscale Particles on Fatigue Crack Propagation for P/M Superalloy FGH96 [Dissertation]. Beijing: University of Science and Technology Beijing, 2018侯杰. 组织特征和微米级颗粒对粉末高温合金FGH4096疲劳裂纹扩展的影响[学位论文]. 北京: 北京科技大学, 2018 [60] Kennedy S K, Dalley A M, Kotyk G J. Additive manufacturing: Assessing metal powder quality through characterizing feedstock and contaminants. J Mater Eng Perform, 2019, 28(2): 728 doi: 10.1007/s11665-018-3841-5 [61] Herzog D, Seyda V, Wycisk E, et al. Additive manufacturing of metals. Acta Mater, 2016, 117: 371 doi: 10.1016/j.actamat.2016.07.019 [62] Han S B, Zhang Y W, Tian X J, et al. Research and application of high quality 3D printing metal powders for aerospace use. Powder Metall Ind, 2017, 27(6): 44 doi: 10.13228/j.boyuan.issn1006-6543.20170100韩寿波, 张义文, 田象军, 等. 航空航天用高品质3D打印金属粉末的研究与应用. 粉末冶金工业, 2017, 27(6): 44 doi: 10.13228/j.boyuan.issn1006-6543.20170100 -

下载:

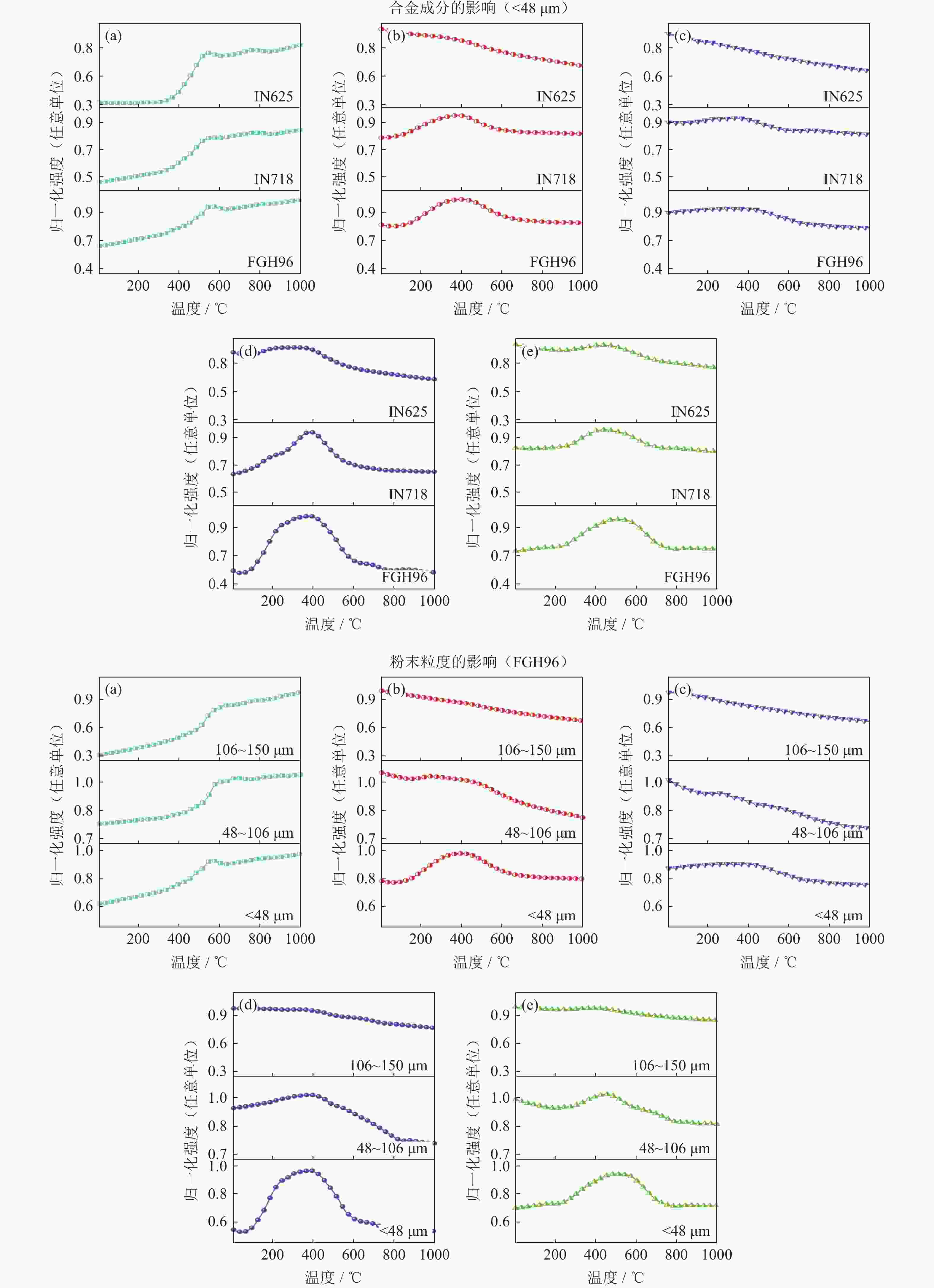

下载: