-

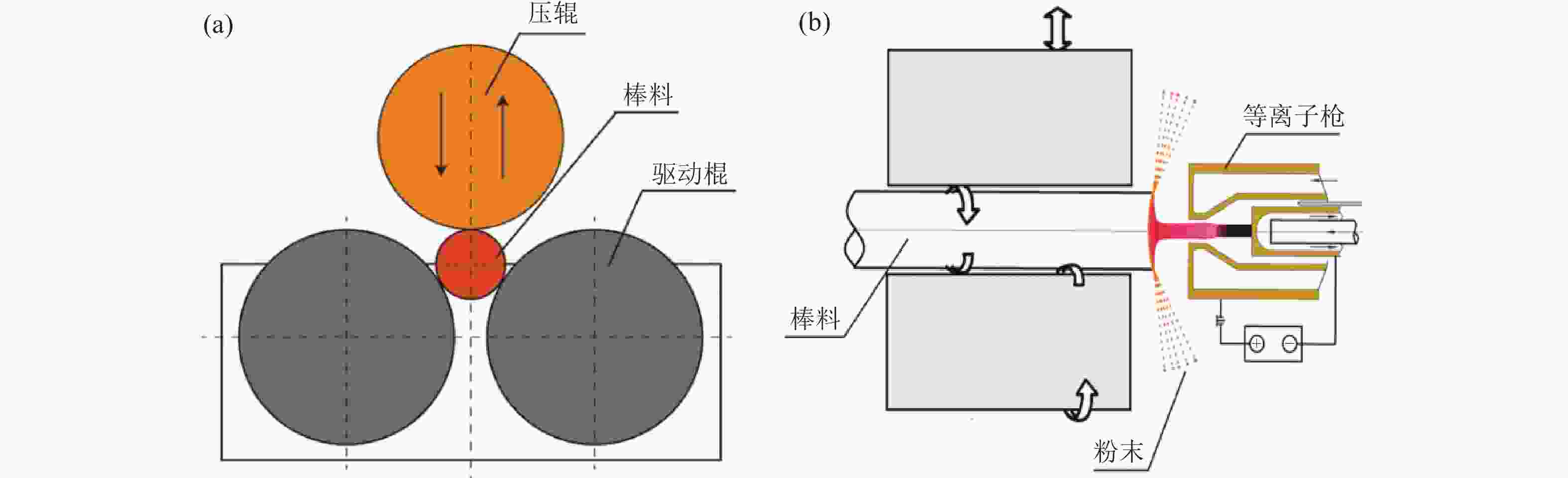

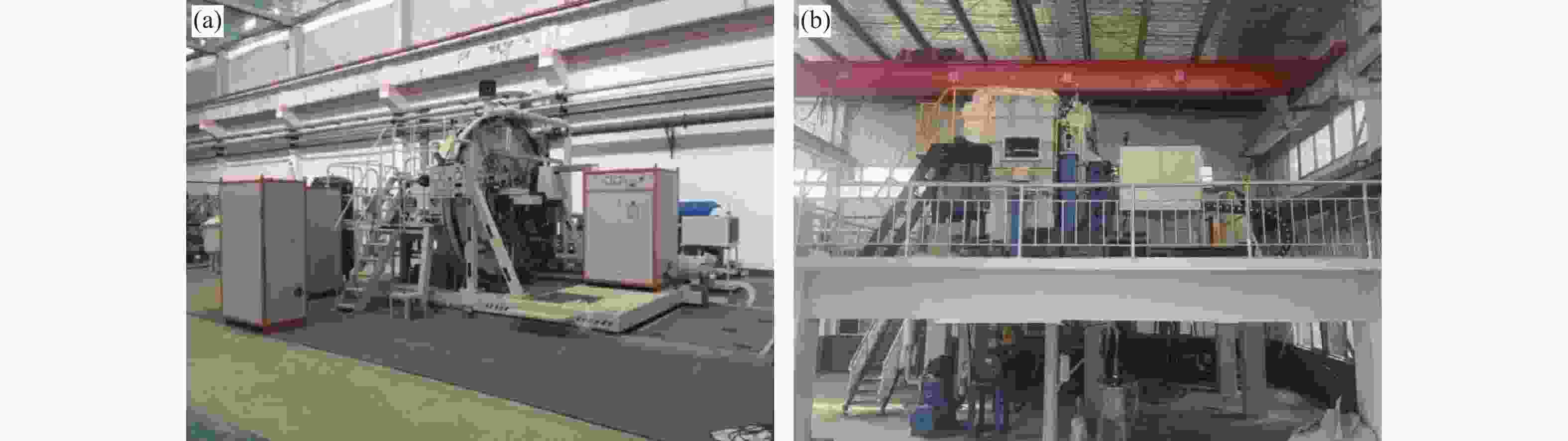

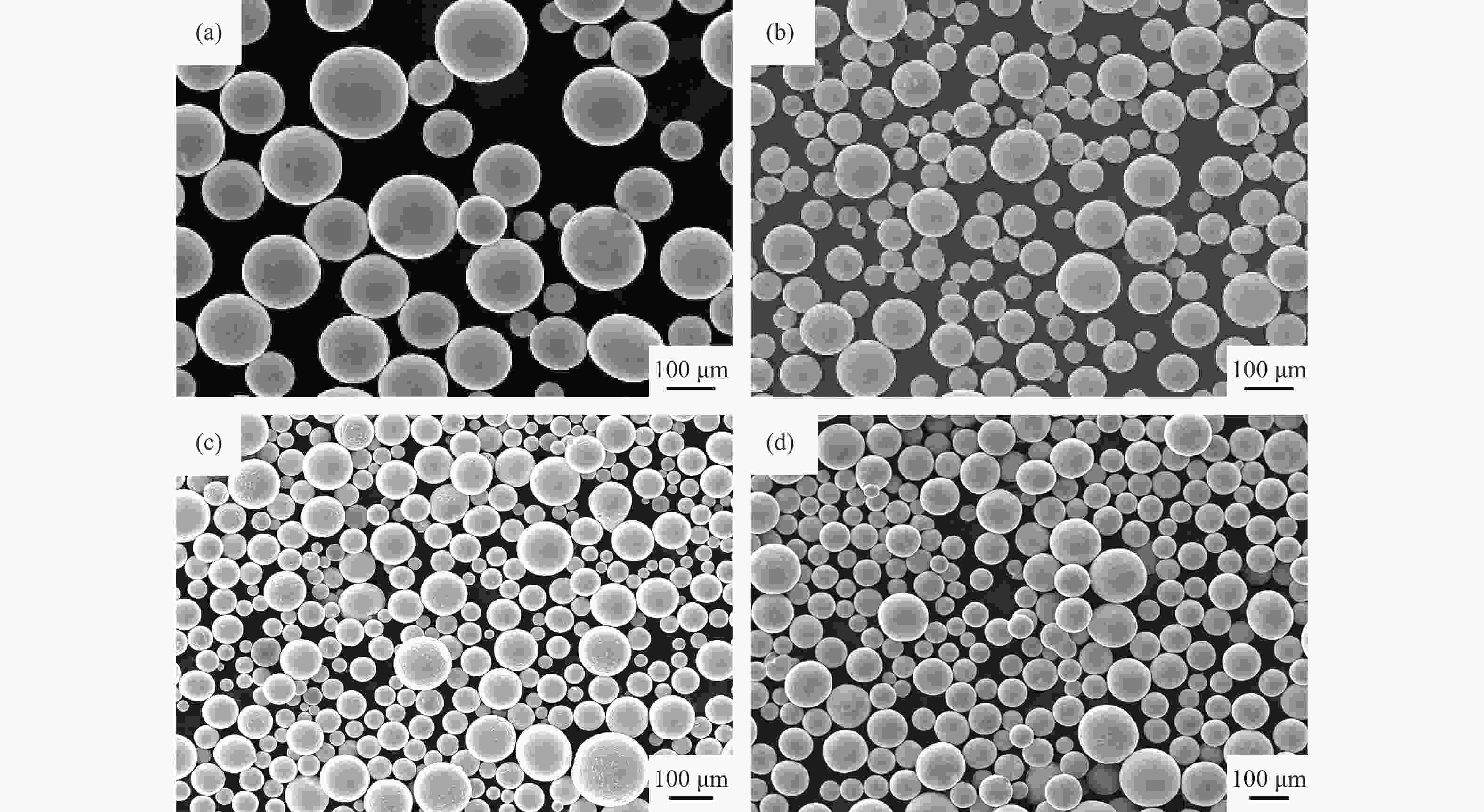

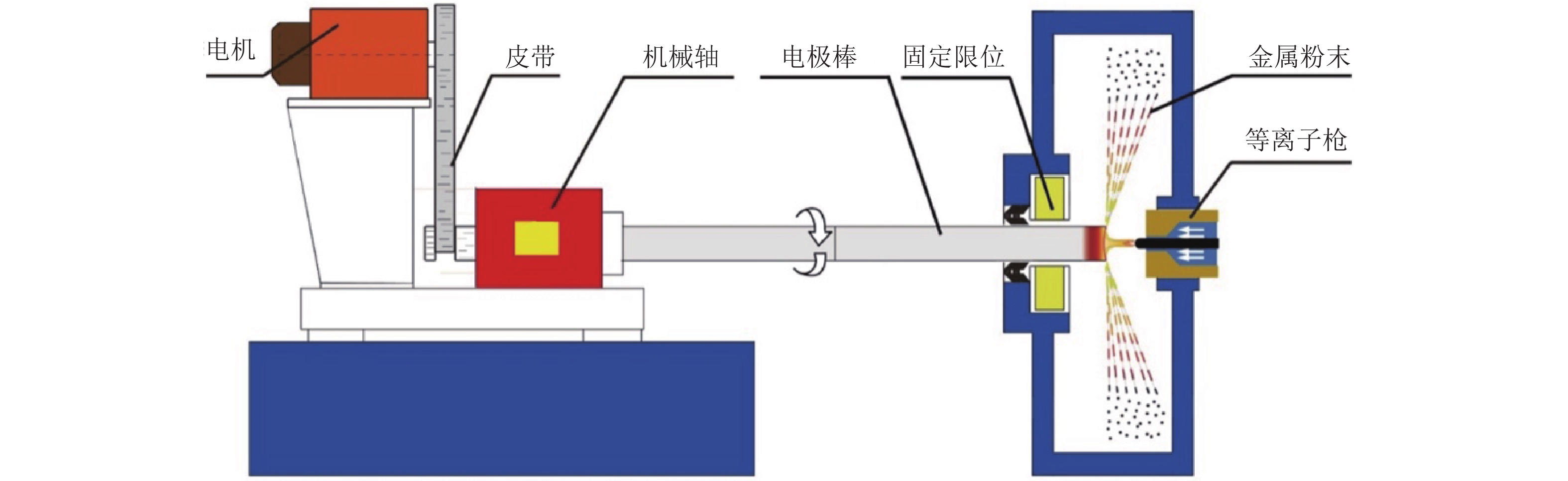

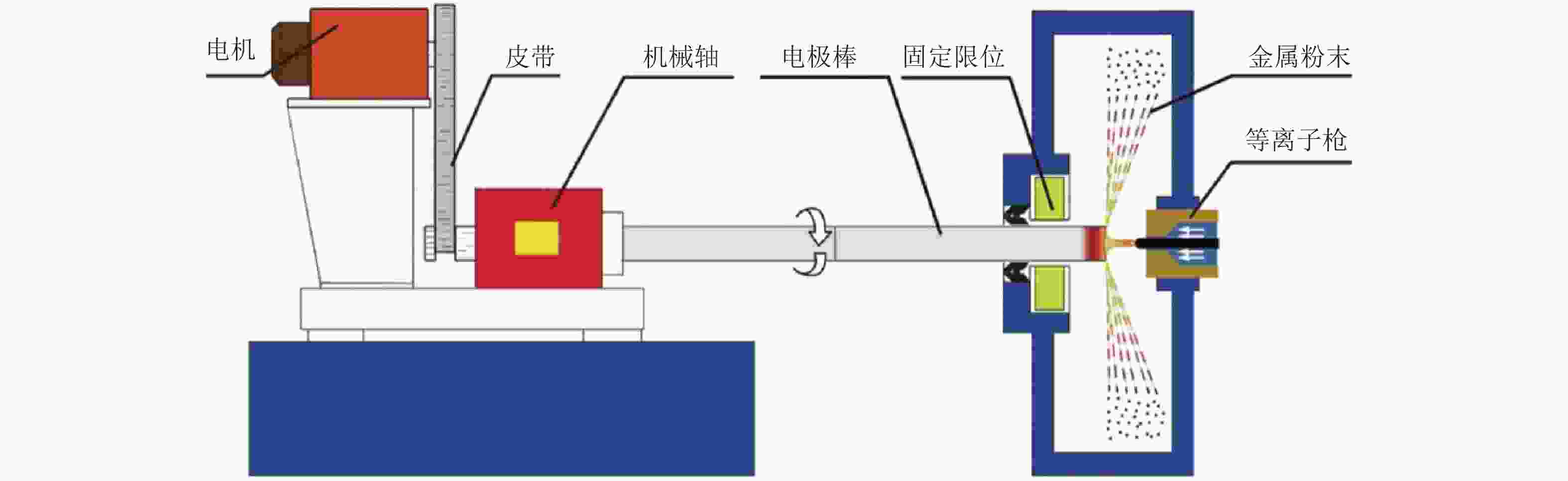

摘要: 等离子旋转电极制粉技术是当前生产高品质球形金属粉末的重要技术之一,通过电极高速旋转产生的离心力将液膜甩出形成液滴,在惰性气氛中雾化凝固成球形粉末。该技术制备的粉末已成为增材制造、热等静压、表面喷涂等制造技术的重要原料。本文回顾了国内外等离子旋转电极制粉技术的发展历史,综述了近年来国内外发展现状,特别是总结了等离子旋转电极装备和技术在中国的发展情况,指出了该技术尚需研究的科学技术问题和发展方向。Abstract: Plasma rotating electrode process (PREP) is one of the key technologies for producing high quality spherical metal powders. The liquid film is thrown out to form the droplets by the centrifugal force generated by the high-speed rotation of the electrode, which will atomize and solidify into the spherical powders in an inert atmosphere. The metal powders prepared by PREP have become the important raw materials for additive manufacturing, hot isostatic pressing, surface spraying, and other manufacturing technologies. The history and current status of PREP technology at home and abroad were reviewed in this paper, and the development situation of the PREP equipment and technology in China was summarized. Finally, the development trends and the main scientific issues were pointed out for the further research.

-

Key words:

- plasma rotating electrode /

- metal powders /

- equipments /

- additive manufacturing /

- powder metallurgy

-

表 1 典型等离子旋转电极金属粉末氧质量分数和氧增量[1]

Table 1. Oxygen mass fraction and oxygen increment of the typical PREP metal powders[1]

材料 原材料氧质量分数 / ×10‒6 粉末氧质量分数 / ×10‒6 氧增量 / ×10‒6 IN718 54 70 16 TC4 600 700 100 17-4PH 95 130 35 316L 160 200 40 Ta1 20 30 10 W 30 50 20 TiAl4822 560 650 90 Cu(T2) 10 30 20 Mo 75 110 35 注:TiAl4822为Ti48Al2Cr2Nb缩写。 表 2 典型等离子旋转电极粉末流动性与松装/振实密度[1]

Table 2. Fluidity and loose/tap density of the typical PREP powders[1]

材料 流动性 / [s·(50g)‒1] 松装密度 / (g·cm‒3) 振实密度 / (g·cm‒3) IN718 12.50 4.74 5.23 TC4 28.30 2.64 2.70 17-4PH 14.10 4.59 4.82 316L 12.80 4.72 4.98 Ta1 6.00 9.97 10.60 W 5.70 11.62 12.00 TiAl4822 29.40 2.30 2.40 Cu(T2) 14.40 5.18 5.70 Mo 11.20 5.98 6.41 -

[1] Yang X B, Zhu J L, Chen B K, et al. Research status of plasma rotating electrode atomization technology and powder particle size control. Powder Metall Ind, 2022, 32(2): 90 doi: 10.13228/j.boyuan.issn1006-6543.20210047杨星波, 朱纪磊, 陈斌科, 等. 等离子旋转电极雾化技术及粉末粒度控制研究现状. 粉末冶金工业, 2022, 32(2): 90 doi: 10.13228/j.boyuan.issn1006-6543.20210047 [2] Yang H T, Lu Z H, Sun Z Y, et al. Domestic research status of plasma rotation electrode process equipment. Powder Metall Ind, 2021, 31(4): 88 doi: 10.13228/j.boyuan.issn1006-6543.20200190杨洪涛, 卢志辉, 孙志杨, 等. 等离子旋转电极雾化制粉设备国内研究现状. 粉末冶金工业, 2021, 31(4): 88 doi: 10.13228/j.boyuan.issn1006-6543.20200190 [3] Demir F, Yurtkuran E, Unal R, et al. 3D Cfd modelling of non-transferred argon plasma torch. Mater Today Proceed, 2020, 32(1): 10 [4] Kaufmann A R. Production of Pure, Spherical Powders: United State Patent, 3802816. 1974-4-9 [5] Ozols A, Sirkin H R, Vicente E E. Segregation in stellite powders produced by the plasma rotating electrode process. Mater Sci Eng A, 1999, 262(1-2): 64 doi: 10.1016/S0921-5093(98)01021-1 [6] Sun N G, Chen B K, Xiang C S, et al. The plasma rotating electrode processing technology current situation and innovation. Powder Metall Ind, 2020, 30(5): 84 doi: 10.13228/j.boyuan.issn1006-6543.20190133孙念光, 陈斌科, 向长淑, 等. 等离子旋转电极雾化制粉技术现状和创新. 粉末冶金工业, 2020, 30(5): 84 doi: 10.13228/j.boyuan.issn1006-6543.20190133 [7] Zhang Y W, Chi Y. Recent developments of Powders metallurgy superalloy in Russia. Powder Metall Ind, 2012, 22(5): 37 doi: 10.3969/j.issn.1006-6543.2012.05.009张义文, 迟悦. 俄罗斯粉末冶金高温合金研制新进展. 粉末冶金工业, 2012, 22(5): 37 doi: 10.3969/j.issn.1006-6543.2012.05.009 [8] Zhang Y. Production technology of powder metallurgy superalloy turbine disk in Russia. J Iron Steel Res, 2000, 12(3): 63 doi: 10.3321/j.issn:1001-0963.2000.03.015张莹. 俄罗斯粉末高温合金涡轮盘的生产工艺. 钢铁研究学报, 2000, 12(3): 63 doi: 10.3321/j.issn:1001-0963.2000.03.015 [9] Zhang Y W, Jia J, Liu J T, et al. Recent development of new type powder metallurgy superalloys in Russia. Powder Metall Ind, 2020, 30(6): 102 doi: 10.13228/j.boyuan.issn1006-6543.20200193张义文, 贾建, 刘建涛, 等. 俄罗斯新型粉末高温合金研究最新进展. 粉末冶金工业, 2020, 30(6): 102 doi: 10.13228/j.boyuan.issn1006-6543.20200193 [10] Sun J, Zou J W, Liu P Y. Research and development of powder metallurgy superalloy. Aviat Mainten Eng, 2001(1): 28孙兼, 邹金文, 刘培英. 盘件用粉末高温合金的研究与发展. 航空工程与维修, 2001(1): 28 [11] Zhao F Q, Wang C J. Design and manufacture of plasma generator in plasma rotating electrode pulverizing equipment. Rare Met Mater Eng, 1988, 17(6): 66 doi: 10.3321/j.issn:1002-185X.1988.06.012赵风琴, 王长京. 等离子旋转电极制粉设备中的等离子发生器装置的设计与制造. 稀有金属材料与工程, 1988, 17(6): 66 doi: 10.3321/j.issn:1002-185X.1988.06.012 [12] Zhang Y W, Zhang Y, Chen S D, et al. Characteristics of PREP in preparing superalloy powder. Powder Metall Technol, 2001, 19(1): 12 doi: 10.3321/j.issn:1001-3784.2001.01.003张义文, 张莹, 陈生大, 等. PREP制取高温合金粉末的特点. 粉末冶金技术, 2001, 19(1): 12 doi: 10.3321/j.issn:1001-3784.2001.01.003 [13] Miller S. Rotating electrode process //ASM Handbook Vol 7. Geauga: ASM International, 1998 [14] Arkon Ltd. PREP powder production unit for additive manufacturing. [2022-06-09]. https://arkon3d.ru/en/equipment_category/prep-powder-production-unit-for-additive-manufacturing/ [15] China Machinery Institute of Advanced Materials. Plasma rotary electrode powder making equipment. [2022-06-09]. http://campowder.com/index.php/cases_20.html中机新材料研究院. 等离子旋转电极制粉设备. [2022-06-09]. http://campowder.com/index.php/cases_20.html [16] Cui Y J, Zhao Y F, Numata H, et al. Effects of process parameters and cooling gas on powder formation during the plasma rotating electrode process. Powder Technol, 2021, 393: 301 doi: 10.1016/j.powtec.2021.07.062 [17] Cui Y J, Zhao Y F, Numata H, et al. Effects of plasma rotating electrode process parameters on the particle size distribution and microstructure of Ti‒6Al‒4V alloy powder. Powder Technol, 2020, 376: 363 doi: 10.1016/j.powtec.2020.08.027 [18] Zhao Y F, Cui Y J, Numata H, et al. Centrifugal granulation behavior in metallic powder fabrication by plasma rotating electrode process. Sci Rep, 2020, 10: 18446 doi: 10.1038/s41598-020-75503-w [19] Kaplanskii Y Y, Zaitsev A A, Sentyurina Z A, et al. The structure and properties of pre-alloyed NiAl‒Cr(Co, Hf) spherical powders produced by plasma rotating electrode processing for additive manufacturing. J Mater Res Technol, 2018, 7(4): 461 doi: 10.1016/j.jmrt.2018.01.003 [20] Yamanoglu R, German R, Karagoz S, et al. Microstructural investigation of as cast and PREP atomised Ti–6Al–4V alloy. Powder Metall, 2011, 54(5): 604 doi: 10.1179/1743290110Y.0000000006 [21] Tao Y, Feng D, Zhang Y W, et al. Study on improving the yield of FGH95 alloy powder in plasma rotating electrode process. Powder Metall Ind, 2003, 13(2): 33 doi: 10.3969/j.issn.1006-6543.2003.02.007陶宇, 冯涤, 张义文, 等. 优化等离子旋转电极工艺提高FGH95合金粉末的收得率. 粉末冶金工业, 2003, 13(2): 33 doi: 10.3969/j.issn.1006-6543.2003.02.007 [22] Tao Y, Feng D, Zhang Y W, et al. Effect of PREP process parameters on powder properties for FGH95 superalloy. J Iron Steel Res, 2003, 15(5): 46 doi: 10.3321/j.issn:1001-0963.2003.05.011陶宇, 冯涤, 张义文, 等. PREP工艺参数对FGH95高温合金粉末特性的影响. 钢铁研究学报, 2003, 15(5): 46 doi: 10.3321/j.issn:1001-0963.2003.05.011 [23] Liu J T, Zhang Y W. Microstructure of FGH96 superalloy powders atomized plasma rotating electrode process. Trans Mater Heat Treat, 2012, 33(1): 31 doi: 10.13289/j.issn.1009-6264.2012.01.002刘建涛, 张义文. 等离子旋转电极雾化工艺制备FGH96合金粉末颗粒的组织. 材料热处理学报, 2012, 33(1): 31 doi: 10.13289/j.issn.1009-6264.2012.01.002 [24] Zhang Y, Huang H B, Liu M D, et al. Abnormal particles in Ni-base superalloy powder by PREP process. Rare Met Mater Eng 2017, 46(11): 3485张莹, 黄虎豹, 刘明东, 等. PREP工艺制取镍基高温合金粉末中的异常颗粒. 稀有金属材料与工程, 2017, 46(11): 3485 [25] Hu J Q, Wang C J, Wei L, et al. A comparative research of porosity in stainless steel powders manufactured by vacuum induction-melting gas atomization and plasma rotating electrode process. Powder Metall Ind, 2021, 31(4): 11 doi: 10.13228/j.boyuan.issn1006-6543.20190073胡家齐, 王长军, 魏来, 等. VIGA法与PREP法制备不锈钢粉末的内部孔洞对比研究. 粉末冶金工业, 2021, 31(4): 11 doi: 10.13228/j.boyuan.issn1006-6543.20190073 [26] Wang C, Zhao X H, Ma Y C, et al. Study of the spherical HoCu powders prepared by supreme-speed plasma rotating electrode process. Powder Metall Technol, 2020, 38(3): 227 doi: 10.19591/j.cnki.cn11-1974/tf.2020.03.011王晨, 赵霄昊, 马逸驰, 等. 超高转速等离子旋转电极工艺制备钬铜球形粉末的研究. 粉末冶金技术, 2020, 38(3): 227 doi: 10.19591/j.cnki.cn11-1974/tf.2020.03.011 [27] Wang H, Chen L L, Zhai Z H. Effect of heat treatment cooling rate on microstructure and properties of powder TC11. New Technol New Prod China, 2021(11): 84 doi: 10.3969/j.issn.1673-9957.2021.11.029王华, 陈蕾蕾, 瞿宗宏. 热处理冷却速率对粉末TC11组织及性能的影响. 中国新技术新产品, 2021(11): 84 doi: 10.3969/j.issn.1673-9957.2021.11.029 [28] Lan J, Liu L K, Wang Q X, et al. Preparation of Co25Cr5W5Mo alloy powder for dentistry and its performance analysis of SLM printed parts. Powder Metall Ind, 2021, 31(6): 13 doi: 10.13228/j.boyuan.issn1006-6543.20200273兰剑, 刘立科, 王庆相, 等. 齿科用Co25Cr5W5Mo合金粉末制备及激光选区熔化成形打印件性能分析. 粉末冶金工业, 2021, 31(6): 13 doi: 10.13228/j.boyuan.issn1006-6543.20200273 [29] Xiang M, Han Z Y, Yan F, et al. Effect of hot isostatic press process on microstructure and properties of PM Ti6Al4V alloy part. Titanium Ind Prog, 2017, 34(4): 30相敏, 韩志宇, 闫飞, 等. 热等静压对Ti6Al4V粉末冶金件组织和性能的影响. 钛工业进展, 2017, 34(4): 30 [30] Kang L, Wang S, Li X, et al. Metallurgy Method for Improving Yield of Centrifugal Atomization Fine Powder of Nickel-based Metal: China Patent, 201711397083. 2018-05-04康路, 王松, 李鑫, 等. 一种提高镍基金属离心雾化细粉收得率的冶金方法: 中国专利, 201711397083. 2018-05-04 [31] Liu Y, Han Z Y, Wang Q X, et al. Rotating Electrode Preparing Micro Spherical Metal Powder and Method of Rotating Electrode: China Patent, 201611174429. 2017-05-17刘洋, 韩志宇, 王庆相, 等. 一种制备微细球形金属粉末的设备及方法: 中国专利, 201611174429. 2017-05-17 [32] Han Z Y, Liang S Y, Zeng G, et al. Device for Removing Nonmetallic Inclusions in Metallic Powder: China Patent, 201420231747. 2014-08-27韩志宇, 梁书锦, 曾光, 等. 一种去除金属粉末中非金属夹杂的装置: 中国专利, 201420231747. 2014-08-27 [33] Zhao X H, Wang C, Pan F F, et al. A review on the methods and additive manufacturing application of spherical titanium alloy powder. Powder Metall Ind, 2019, 29(6): 71 doi: 10.13228/j.boyuan.issn1006-6543.20180092赵霄昊, 王晨, 潘霏霏, 等. 球形钛合金粉末制备技术及增材制造应用研究进展. 粉末冶金工业, 2019, 29(6): 71 doi: 10.13228/j.boyuan.issn1006-6543.20180092 [34] Liu Y, Zhao X H, Lai Y J, et al. A brief introduction to the selective laser melting of Ti6Al4V powders by supreme-speed plasma rotating electrode process. Prog Nat Sci Mater Int, 2020, 30(1): 94 doi: 10.1016/j.pnsc.2019.12.004 [35] Liu Y, Liang S J, Han Z Y, et al. A novel model of calculating particle sizes in plasma rotating electrode process for superalloys. Powder Technol, 2018, 336: 406 doi: 10.1016/j.powtec.2018.06.002 [36] Frost A R. Rotary atomization in the ligament formation mode. J Agric Eng Res, 1981, 26(1): 63 doi: 10.1016/0021-8634(81)90127-X [37] Tao Z D, Zhen S H. Powder Engineering and Equipment. Beijing: Chemical Industry Press, 2010陶珍东, 郑少华. 粉体工程与设备. 北京: 化学工业出版社, 2010 [38] Han Z Y, Zhang P X, Lei L M, et al. Morphology and particle analysis of the Ni3Al-based spherical powders manufactured by supreme-speed plasma rotating electrode process. J Mater Res Technol, 2020, 9(6): 13937 doi: 10.1016/j.jmrt.2020.09.102 [39] Jin Y Y, He W W, Chen B K, et al. Preparation of spherical refractory metal powders. Aeron Manuf Technol, 2019, 62(22): 64 doi: 10.16080/j.issn1671-833x.2019.22.064金园园, 贺卫卫, 陈斌科, 等. 球形难熔金属粉末的制备技术. 航空制造技术, 2019, 62(22): 64 doi: 10.16080/j.issn1671-833x.2019.22.064 [40] Li X H, Chen B K, Feng Z H, et al. Preparation and properties of spherical tungsten powders by plasma rotating electrode process for additive manufacturing. Powder Metall Ind, 2022, 32(1): 15 doi: 10.13228/j.boyuan.issn1006-6543.20210017李晓辉, 陈斌科, 凤治华, 等. 等离子旋转电极雾化制备钨粉及性能表征. 粉末冶金工业, 2022, 32(1): 15 doi: 10.13228/j.boyuan.issn1006-6543.20210017 [41] He W, Liu Y, Tang H, et al. Microstructural characteristics and densification behavior of high-Nb TiAl powder produced by plasma rotating electrode process. Mater Des, 2017, 132: 275 doi: 10.1016/j.matdes.2017.06.072 [42] Qiu S, Chen B K, Xiang C S. Preparation and properties of spherical Mo powders by plasma rotating electrode process for additive manufacturing. Mater Sci Forum, 2020, 993: 391 doi: 10.4028/www.scientific.net/MSF.993.391 [43] Chen G, Zhao S Y, Tan P, et al. Shape memory TiNi powders produced by plasma rotating electrode process for additive manufacturing. Trans Nonferrous Met Soc China, 2017, 27(12): 2647 doi: 10.1016/S1003-6326(17)60293-0 [44] Yin J O, Chen G, Zhao S Y, et al. Microstructural characterization and properties of Ti-28Ta at.% powders produced by plasma rotating electrode process. J Alloys Compd, 2017, 713: 222 [45] Yang X, Xi Z P, Liu Y, et al. Characterization of TiAl powders prepared by plasma rotating electrode processing. Rare Met Mater Eng, 2010, 39(12): 2251杨鑫, 奚正平, 刘咏, 等. 等离子旋转电极法制备钛铝粉末性能表征. 稀有金属材料与工程, 2010, 39(12): 2251 [46] Chen G, Zhao S Y, Tan P, et al. A comparative study of Ti6Al4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization. Powder Technol, 2018, 333: 38 doi: 10.1016/j.powtec.2018.04.013 [47] Zhao S Y, Yin J G, Shen L, et al. Ti‒60Ta powders produced by PREP and their properties. Rare Met Mater Eng, 2017, 46(6): 1679赵少阳, 殷京瓯, 沈垒, 等. PREP法制备Ti‒60Ta合金粉末及其性能. 稀有金属材料与工程, 2017, 46(6): 1679 [48] Nie Y, Tang J, Teng J, et al. Particle defects and related properties of metallic powders produced by plasma rotating electrode process. Adv Powder Technol, 2020, 31(7): 2912 doi: 10.1016/j.apt.2020.05.018 [49] Nie Y, Tang J, Yang B, et al. Comparison in characteristic and atomization behavior of metallic powders produced by plasma rotating electrode process. Adv Powder Technol, 2020, 31(5): 2152 doi: 10.1016/j.apt.2020.03.006 [50] Liu W, Duan Y, Ma Y, et al. Surface characterization of plasma rotating electrode atomized 30CrMnSiNi2A steel powder. Appl Surf Sci, 2020, 528: 147004 doi: 10.1016/j.apsusc.2020.147004 [51] Tang J, Nie Y, Lei Q, et al. Characteristics and atomization behavior of Ti‒6Al‒4V powder produced by plasma rotating electrode process. Adv Powder Technol, 2019, 30(10): 2330 doi: 10.1016/j.apt.2019.07.015 [52] Li Q J, Zhang L, Chen X, et al. Characterization of plasma rotating electrode atomized Nb-Ti based alloy powder. Met Powder Rep, 2020, 75(2): 82 doi: 10.1016/j.mprp.2019.04.064 [53] Chen H M, Hu B F, Li H Y, et al. Microstructure characteristics of FGH95 superalloy powders prepared by PREP. Acta Metall Sinica, 2003, 39(1): 30 doi: 10.3321/j.issn:0412-1961.2003.01.008陈焕铭, 胡本芙, 李慧英, 等. 等离子旋转电极雾化FGH95高温合金粉末颗粒凝固组织特征. 金属学报, 2003, 39(1): 30 doi: 10.3321/j.issn:0412-1961.2003.01.008 [54] Chen H M, Hu B F, Yu Q M, et al. Heat transfer and solidification behavior of droplets during plasma rotating electrode processing. Chin J Nonferrous Met, 2002, 12(5): 883 doi: 10.3321/j.issn:1004-0609.2002.05.006陈焕铭, 胡本芙, 余泉茂, 等. 等离子旋转电极雾化熔滴的热量传输与凝固行为. 中国有色金属学报, 2002, 12(5): 883 doi: 10.3321/j.issn:1004-0609.2002.05.006 [55] Li L, Dai Y, Lü P. Study on the technology of producing AlSi10Mg aluminum alloy powder by plasma rotating electrode method. Adv Mater Ind, 2018(12): 23 doi: 10.19599/j.issn.1008-892x.2018.12.006李礼, 戴煜, 吕攀. 等离子旋转电极法制取AlSi10Mg铝合金粉末工艺的研究. 新材料产业, 2018(12): 23 doi: 10.19599/j.issn.1008-892x.2018.12.006 [56] Wang H, Bai R M, Zhou X M, et al. Comparative analysis of Inconel 718 powder prepared by PREP method and AA method. New Technol New Prod China, 2019(19): 1 doi: 10.3969/j.issn.1673-9957.2019.19.002王华, 白瑞敏, 周晓明, 等. PREP法和AA法制取Inconel 718粉末对比分析. 中国新技术新产品, 2019(19): 1 doi: 10.3969/j.issn.1673-9957.2019.19.002 [57] Hsu T I, Wei C M, Wu L D, et al. Nitinol powders generate from plasma rotation electrode process provide clean powder for biomedical devices used with suitable size, spheroid surface and pure composition. Sci Rep, 2018, 8(1): 13776 doi: 10.1038/s41598-018-32101-1 -

下载:

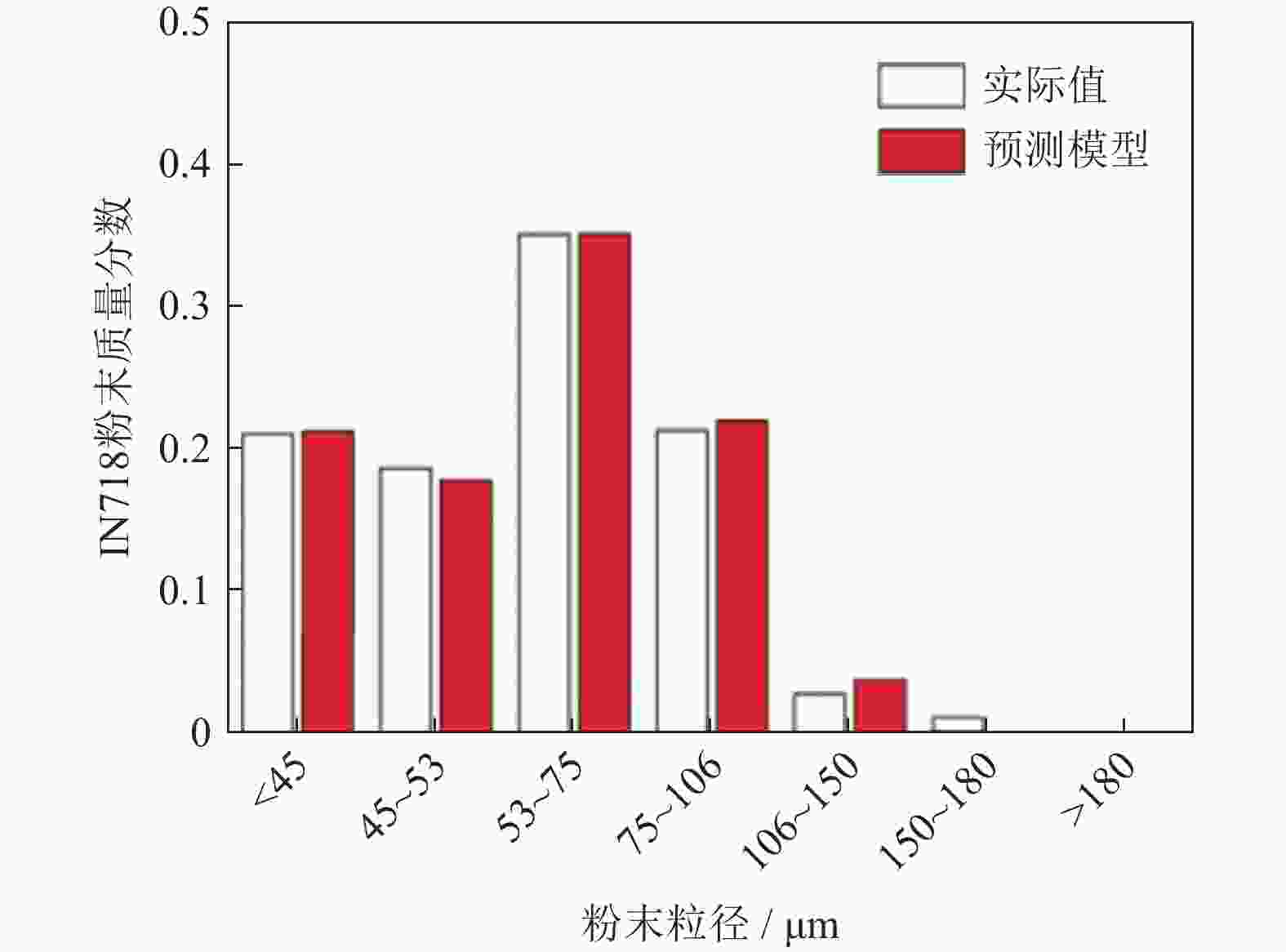

下载: