Research status of prior particle boundaries for powder superalloy prepared by hot isostatic pressing

-

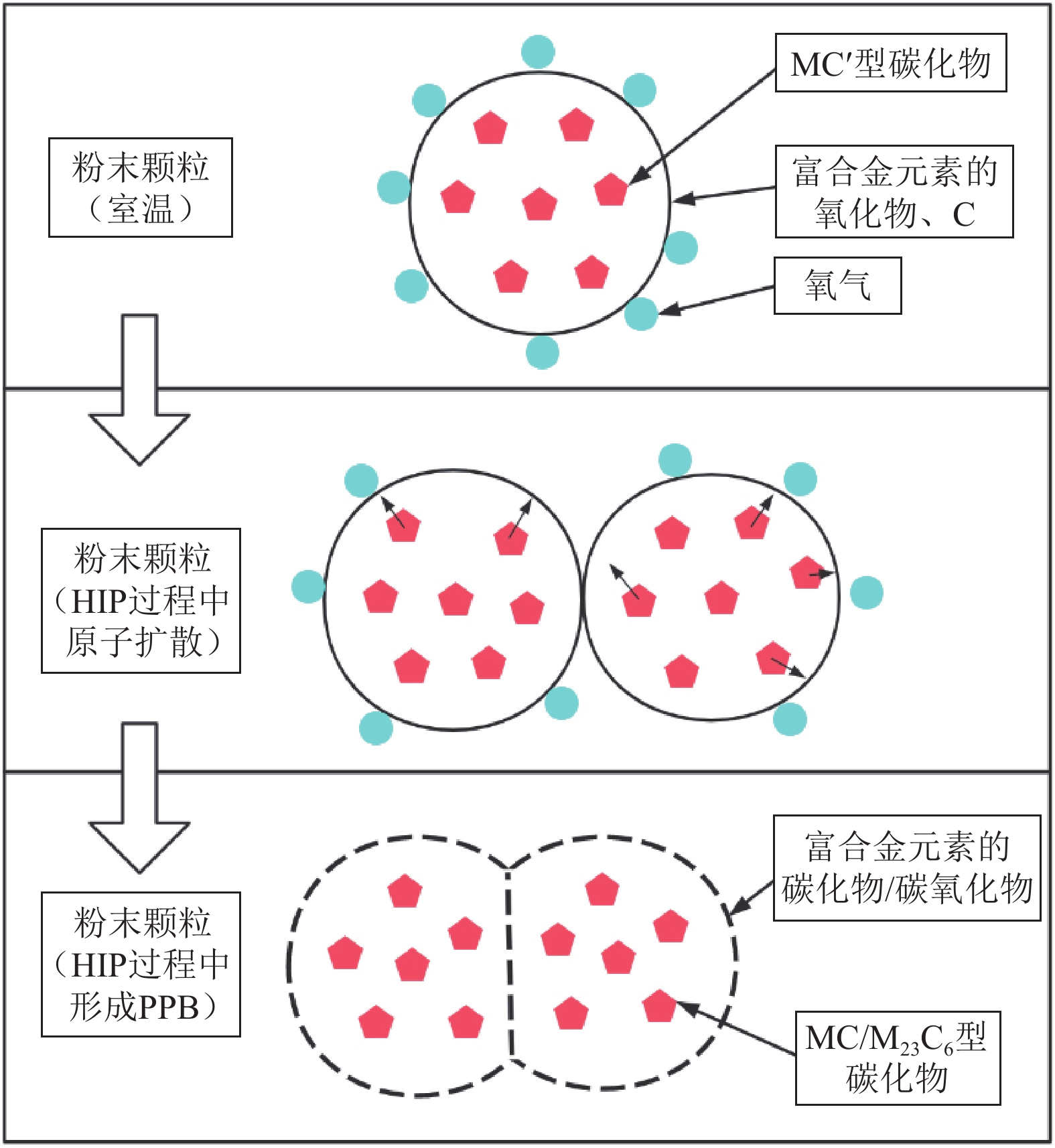

摘要: 粉末高温合金作为先进高温材料被广泛应用于航空航天领域。热等静压(hot isostatic pressing,HIP)是粉末高温合金构件的制备方法之一,但是原始颗粒边界(prior particle boundaries,PPBs)的存在会极大的影响构件的性能。本文综述了热等静压制备粉末高温合金原始颗粒边界的研究现状,概述了原始颗粒边界的形成机理及其影响,总结了粉末高温合金中原始颗粒边界的消除方法,并对这些方法应用的可行性及有效性进行了分析和展望。原始颗粒边界的消除方法主要包括向粉末添加Hf、Nb等强碳化物形成元素,对粉末进行预热处理,真空动态脱气处理或等离子体滴凝处理;优化粉末制备工艺,选用纯度更高、尺寸分布更均匀的粉末;选用合适的热等静压工艺参数和工艺方式;对制件采取热挤压、退火、固溶处理和热等静压后处理等。Abstract: Powder metallurgy superalloy is an advanced high-temperature material, which has been widely used in the aerospace fields. Hot isostatic pressing (HIP) is one of the preparation methods for powder superalloy components. However, the presence of prior particle boundaries (PPBs) adversely affects the performance of the components significantly. The research status of PPBs for powder metallurgy superalloys prepared by HIP was reviewed in this paper, the formation mechanism and influence of PPBs in components were summarized, the removal PPBs methods in powder superalloys were proposed, and the feasibility and effectiveness of these methods were analyzed and prospected, including adding Hf, Nb, and other strong carbide forming elements to the powder, preheating the powder, using the vacuum dynamic degassing treatment or plasma droplet re-fining (PDR) treatment, optimizing the powder preparation process, selecting powders with higher purity and more uniform size distribution, selecting the appropriate HIP process parameters and methods, and applying hot extrusion, annealing, solution treatment and HIP post-treatment on the components.

-

Key words:

- powder metallurgy /

- superalloys /

- hot isostatic pressing /

- prior particle boundaries

-

图 3 添加不同Ta质量分数的FGH4098粉末颗粒表面和内部碳化物显微形貌[21]:(a)0% Ta,粉末颗粒表面;(b)0% Ta,粉末内部碳化物;(c)2.4% Ta,粉末颗粒表面;(d)2.4% Ta,粉末内部碳化物

Figure 3. SEM images of the particle surfaces and internal carbides in FGH4098 powders with different Ta mass fraction[21]: (a) particle surface without Ta; (b) internal carbides without Ta; (c) particle surface with 2.4% Ta; (d) internal carbides with 2.4% Ta

图 6 热挤压前后合金微观组织[43]:(a)热挤压前,低倍;(b)热挤压前,高倍;(c)热挤压后,横向低倍;(d)热挤压后,横向高倍;(e)热挤压后,纵向低倍;(f)热挤压后,纵向高倍

Figure 6. Microstructures of the alloys before and after hot extrusion[43]: (a) before hot extrusion, low magnification; (b) before hot extrusion, high magnification; (c) after hot extrusion, transverse low magnification; (d) after hot extrusion, transverse high magnification; (e) after hot extrusion, vertical high magnification (f) after hot extrusion, vertical high magnification

-

[1] Zhang Y W, Liu J T. Development in powder metallurgy superalloy. Progr Chin Mater, 2013, 32(1): 1张义文, 刘建涛. 粉末高温合金研究进展. 中国材料进展, 2013, 32(1): 1 [2] Xu L, Guo R P, Wu J, et al. Progress in hot isostatic pressing technology of titanium alloy powder. Acta Metall Sin, 2018, 54(11): 1537徐磊, 郭瑞鹏, 吴杰, 等. 钛合金粉末热等静压近净成形研究进展. 金属学报(中文版), 2018, 54(11): 1537 [3] Ji C H, Lang L H, Huang X N, et al. Research on powder-solid interface and coupling deformation of Ti6Al4V alloy powder during high temperature and high pressure. J Central South Univ(Sci Technol), 2019, 50(1): 29季晨昊, 郎利辉, 黄西娜, 等. Ti6Al4V合金粉末高温高压成形过程中粉固界面及其耦合变形研究. 中南大学学报(自然科学版), 2019, 50(1): 29 [4] Yang J L, Zhu X M, Tan J J, et al. Microstructure and properties of argon atomization FGH97 P/M superalloy. Rare Met Mater Eng, 2019, 48(12): 4093杨金龙, 朱晓闽, 谭建均, 等. 氩气雾化制粉FGH97高温合金的组织和性能. 稀有金属材料与工程, 2019, 48(12): 4093 [5] Zhou J Y, Liu C K, Zhao W X, et al. Prior particle boundary of PM FGH96 superalloy and its in-situ high-cycle fatigue at elevated temperature. J Aeron Mater, 2017, 37(5): 83 doi: 10.11868/j.issn.1005-5053.2016.000130周静怡, 刘昌奎, 赵文侠, 等. 粉末高温合金FGH96原始颗粒边界及高温原位高周疲劳研究. 航空材料学报, 2017, 37(5): 83 doi: 10.11868/j.issn.1005-5053.2016.000130 [6] Crompton J S, Hertzberg R W. Analysis of second phase particles in a powder metallurgy HIP nickel-base superalloy. J Mater Sci, 1986, 21(10): 3445 doi: 10.1007/BF02402986 [7] Liu L Y, Tao C H, Liu C K, et al. Fracture causes of powder metallurgy high pressure turbine disk of an engine. Mater Mechan Eng, 2014, 38(8): 108刘丽玉, 陶春虎, 刘昌奎, 等. 发动机粉末合金高压涡轮盘断裂的原因. 机械工程材料, 2014, 38(8): 108 [8] Zhao J P, Tao Y, Yuan S Q, et al. The problem of prior particle boundary precipitation in P/M superalloys. Powder Metall Ind, 2010, 20(4): 43赵军普, 陶宇, 袁守谦, 等. 粉末冶金高温合金中的原始颗粒边界(PPB)问题. 粉末冶金工业, 2010, 20(4): 43 [9] Mao J, Yu K L, Zhou R F. Effect of pre-heat treatment on P/M Rene’95 superalloy microstructure. Powder Metall Technol, 1989, 7(4): 213毛健, 俞克兰, 周瑞发. 粉末预热处理对热等静压Rene’95粉末高温合金组织的影响. 粉末冶金技术, 1989, 7(4): 213 [10] Ma W B, Liu G Q, Hu B F, et al. Formation of previous particle boundary of nickel base PM superalloy FGH96. Acta Metall Sin, 2013, 49(10): 1248 doi: 10.3724/SP.J.1037.2013.00125马文斌, 刘国权, 胡本芙, 等. 镍基粉末高温合金FGH96中原始粉末颗粒边界的形成机理. 金属学报, 2013, 49(10): 1248 doi: 10.3724/SP.J.1037.2013.00125 [11] Qiu C L, Yang D L, Wang G Q, et al. Microstructural development and tensile behavior of a hot isostatically pressed nickel-based superalloy. Mater Sci Eng, 2020, 769: 138461 doi: 10.1016/j.msea.2019.138461 [12] Bai Q, Lin J, Tian G, et al. Review and analysis of powder prior boundary (PPB) formation in powder metallurgy processes for nickel-based super alloys. J Powder Metall Min, 2015, 4(2): 1 [13] Zhao J P. Study on Prior Particle Boundary (PPB) Precipitation in P/M Superalloy FGH96 [Dissertation]. Xi’an: Xi’an University of Architecture and Technology, 2010赵军普. FGH96粉末高温合金原始颗粒边界(PPB)问题的研究[学位论文]. 西安: 西安建筑科技大学, 2010 [14] Sreenu B, Sarkar R, Kumar S S, et al. Microstructure and mechanical behaviour of an advanced powder metallurgy nickel base superalloy processed through hot isostatic pressing route for aerospace applications. Mater Sci Eng:A, 2020, 797: 1 [15] Chang L T, Jin H. A mechanistic study for the fracture mode and ductility variation in a powder metallurgy superalloy hot-isostatic-pressed at sub- and super-solvus temperatures. Mater Sci Eng:A, 2019, 743: 733 doi: 10.1016/j.msea.2018.11.144 [16] Zhang M D, Liu J T, Zhang Y W, et al. Discussion on mechanism of eliminating prior particle boundary in powder metallurgy superalloy. Powder Metall Ind, 2021, 31(2): 41张梦迪, 刘建涛, 张义文, 等. 消除粉末高温合金中原始颗粒边界机制. 粉末冶金工业, 2021, 31(2): 41 [17] Zhang Y, Zhang Y W, Sun Z K, et al. Influence of PPB on fatigue crack growth rate of PM Ni-based superalloy. Rare Metal Mater Eng, 2019, 48(10): 3282张莹, 张义文, 孙志坤, 等. PPB对镍基粉末高温合金裂纹扩展行为的影响. 稀有金属材料与工程, 2019, 48(10): 3282 [18] Gessinger G H. Powder Metallurgy of Superalloys. 1st Ed. Zhang Y W transl. Beijing: Metallurgical Industry Press, 2017格辛格. 粉末高温合金. 1版. 张义文译. 北京: 冶金工业出版社, 2017 [19] Ingesten N G, Warren R, Winberg L. The Nature and Origin of Previous Particle Boundary Precipitates in P/M Superalloys. Berlin: Springer Netherlands press, 1982 [20] Yang F B, Jing Y H, Li D, et al. Influence of hot isostatic pressing and the subsequent heat treatment on microstructure and properties of MIM418 turbine alloy. Trans Mater Heat Treat, 2015, 36(Suppl 1): 128杨福宝, 景艳红, 李丹, 等. 热等静压及后续热处理对MIM418涡轮合金组织与性能的影响. 材料热处理学报, 2015, 36(增刊1): 128 [21] Zhang M D, Liu J T, Zhang Y W, et al. Relationship between prior particle boundary of powder metallurgy superalloy and solubility of MC carbides. Trans Mater Heat Treat, 2021, 42(5): 50张梦迪, 刘建涛, 张义文, 等. 粉末高温合金原始颗粒边界与MC型碳化物溶解度的关系. 材料热处理学报, 2021, 42(5): 50 [22] Liu Y F, Li Z, Liu N, et al. Effect of oxygen content of powders on previous particle boundaries in hot isostatic pressed TiAl alloy // High Performance Structural Materials. Singapore, 2018: 779 [23] Wang M Y, Ji Z, Zhang Y F, et al. Research progress on the prior particle boundary of a powder metallurgy superalloy. Powder Metall Technol, 2017, 35(2): 142王梦雅, 纪箴, 张一帆, 等. 粉末高温合金中原始粉末颗粒边界研究进展. 粉末冶金技术, 2017, 35(2): 142 [24] Kuo Y L, Kakehi K. Effect of the prior particle boundary on the microstructure and mechanical properties of hot-isostatic-pressed IN718 alloy. Mater Trans, 2017, 58(7): 1042 doi: 10.2320/matertrans.M2017045 [25] Zhao L, Zhang X H, Deng T Q, et al. Develop an effective oxygen removal method for copper powder. Adv Powder Technol, 2018, 29(8): 1904 doi: 10.1016/j.apt.2018.05.001 [26] Han Z Y, Zeng G, Liang S J, et al. Development in powder production technology of Ni-based superalloy. Mater China, 2014, 33(12): 748韩志宇, 曾光, 梁书锦, 等. 镍基高温合金粉末制备技术的发展现状. 中国材料进展, 2014, 33(12): 748 [27] Hou W Q, Meng J, Liang J J, et al. Preparation technology and research progress of superalloy powders used for additive manufacturing. Powder Metall Technol, 2022, 40(2): 131侯维强, 孟杰, 梁静静, 等. 增材制造用高温合金粉末制备技术及研究进展. 粉末冶金技术, 2022, 40(2): 131 [28] He G A, Ding H H, Liu C Z, et al. Effects of powder characteristics on microstructure and deformation activation energy of nickel based superalloy. Chin J Nonferrous Met, 2016, 26(1): 37何国爱, 丁晗晖, 刘琛仄, 等. 粉末特性对镍基粉末冶金高温合金组织及热变形行为的影响. 中国有色金属学报, 2016, 26(1): 37 [29] Tan J J, Yang J L, Long A P, et al. Microstructure and low cycle fatigue property of FGH97 alloy with different atomization methods. Chin J Rare Met, 2019, 43(1): 52谭建均, 杨金龙, 龙安平, 等. 制粉方式对FGH97合金组织和低周疲劳性能的影响. 稀有金属, 2019, 43(1): 52 [30] Sergi A, Khan R H U, Attallah M M. The role of powder atomisation route on the microstructure and mechanical properties of hot isostatically pressed Inconel 625. Mater Sci Eng:A, 2021, 808: 140950 doi: 10.1016/j.msea.2021.140950 [31] Irukuvarghula S, Hassanin H, Cayron C, et al. Evolution of grain boundary network topology in 316L austenitic stainless steel during powder hot isostatic pressing. Acta Mater, 2017, 133(17): 269 [32] Irukuvarghula S, Hassanin H, Cayron C, et al. Effect of powder characteristics and oxygen content on modifications to the microstructural topology during hot isostatic pressing of an austenitic steel. Acta Mater, 2019, 172: 6 doi: 10.1016/j.actamat.2019.03.038 [33] Zhang Jiaqing. Study on Formation Mechanism and Evolution Law of FGH96 Alloy Original Powder Particle Boundary [Dissertation]. Taiyuan: North University of China, 2017张佳庆. FGH96合金原始粉末颗粒边界形成机理及演化规律研究[学位论文]. 太原: 中北大学, 2017 [34] Tan L M, He G A, Liu F, et al. Effects of temperature and pressure of hot isostatic pressing on the grain structure of powder metallurgy superalloy. Materials, 2018, 11(2): 328 doi: 10.3390/ma11020328 [35] Xie J, Tian S G, Zhou X M, et al. Effect of microstructure of FGH95 nickel-based alloy on durability properties. J Central South Univ(Sci Technol), 2012, 43(7): 2547谢君, 田素贵, 周晓明, 等. FGH95镍基合金组织结构对持久性能的影响. 中南大学学报(自然科学版), 2012, 43(7): 2547 [36] Teng Q, Wei Q S, Xue P J, et al. Effects of processing temperatures on FGH4097 superalloy fabricated by hot isostatic pressing: Microstructure evolution, mechanical properties and fracture mechanism. Mater Sci Eng, 2019, 739: 118 doi: 10.1016/j.msea.2018.08.030 [37] Huang J, Xue P J, Cai C, et al. Mechanical properties of Ti6Al4V alloy prepared by two different hot isostatic pressing processes. Chin J Rare Met, 2016, 40(2): 97黄俊, 薛鹏举, 蔡超, 等. 两种热等静压工艺对Ti6Al4V合金力学性能影响的研究. 稀有金属, 2016, 40(2): 97 [38] Cai C, Pan K K, Teng Q, et al. Simultaneously enhanced strength and ductility of FGH4097 nickel-based alloy via a novel hot isostatic pressing strategy. Mater Sci Eng:A, 2019, 760: 19 doi: 10.1016/j.msea.2019.05.081 [39] Chang L T, Sun W R, Cui Y Y, et al. Preparation of hot-isostatic-pressed powder metallurgy superalloy Inconel 718 free of prior particle boundaries. Mater Sci Eng A, 2017, 682: 341 doi: 10.1016/j.msea.2016.11.031 [40] Rao G A, Srinivas M, Sarma D S. Effect of oxygen content of powder on microstructure and mechanical properties of hot isostatically pressed superalloy Inconel 718. Mater Sci Eng A, 2006, 435: 84 [41] Liu C Y, Wang S Y, Li F G, et al. The procedure and mechanics research of extrusion deformation for FGH96 alloy. Forg Equip Manufact Technol, 2009, 44(1): 84 doi: 10.3969/j.issn.1672-0121.2009.01.031刘趁意, 王淑云, 李付国, 等. 粉末高温合金挤压变形组织及变形机理研究. 锻压装备与制造技术, 2009, 44(1): 84 doi: 10.3969/j.issn.1672-0121.2009.01.031 [42] Qin Z J, Liu C Z, Wang Z, et al. Formation and microstructure evolution of precipitation on prior particle boundaries in P/M nickel-base superalloys. Chin J Nonferrous Met, 2016, 26(1): 50 doi: 10.19476/j.ysxb.1004.0609.2016.01.007秦子珺, 刘琛仄, 王子, 等. 镍基粉末高温合金原始颗粒边界形成及组织演化特征. 中国有色金属学报, 2016, 26(1): 50 doi: 10.19476/j.ysxb.1004.0609.2016.01.007 [43] He G A, Yang C, Liu F, et al. Effects of hot extrusion on microstructures and hot deformation behavior of powder metallurgy Ni-base superalloy PM-0002. Mater Mech Eng, 2016, 40(4): 65何国爱, 杨川, 刘锋, 等. 热挤压对粉末冶金PM-0002镍基高温合金组织及热变形行为的影响. 机械工程材料, 2016, 40(4): 65 [44] Fu H, Wang M Y, Ji Z, et al. Effect of thermal deformation on prior particle boundary of FGH96 superalloy. Powder Metall Technol, 2018, 36(3): 201傅豪, 王梦雅, 纪箴, 等. 热变形对FGH96高温合金原始颗粒边界的影响. 粉末冶金技术, 2018, 36(3): 201 [45] Higashi M, Kanno N. Evaluation of hot workability of powder metallurgy Ni-based superalloy with different initial microstructures. Metall Mater Trans A, 2020, 52(1): 1 [46] Song F Y, Zhang J, Guo H M, et al. Research on application of hot isostatic pressing technology in the field of nickel-based cast superalloys. J Mater Eng, 2021, 49(1): 65 doi: 10.11868/j.issn.1001-4381.2020.000396宋富阳, 张剑, 郭会明, 等. 热等静压技术在镍基铸造高温合金领域的应用研究. 材料工程, 2021, 49(1): 65 doi: 10.11868/j.issn.1001-4381.2020.000396 [47] Huang X N, Lang L H, Wang G. Effect of HIP post-treatment on the HIPed Ti6Al4V powder compacts. Powder Metall, 2019, 62(1): 8 doi: 10.1080/00325899.2018.1534425 -

下载:

下载: