-

摘要: 钼及其合金具有优异的高温力学性能,被广泛应用于冶金、机械、化工、航空和核工业等领域。粉末冶金是钼合金的主要制备方法。通过固溶强化、第二相强化、细晶强化等多种强化手段可以提高钼合金的力学性能,从而拓宽钼合金的应用范围。本文介绍了粉末冶金制备钼合金的研究进展,包括粉体制备方法、压制工艺及坯体烧结工艺等,讨论了钼合金的强韧化方法及其机理,并展望了粉末冶金法制备钼合金的发展方向,以期对钼合金的设计和制备提供一些思路。Abstract: Molybdenum and molybdenum alloys prepared by the powder metallurgy method are widely used in metallurgy, machinery, chemical industry, aviation and nuclear industry, attributing to the outstanding mechanical properties at elevated temperatures. The mechanical properties of molybdenum alloys can be improved by solid-solution strengthening, second phase strengthening, fine grain strengthening, and other strengthening methods, broadening the application of molybdenum alloys. The research progress of molybdenum alloys prepared by powder metallurgy was introduced in this paper, including the powder preparation method, pressing process, and bulk sintering process. Moreover, the methods and mechanisms of strengthening and toughening for the molybdenum alloys were discussed in details. Finally, the development direction of molybdenum alloys prepared by powder metallurgy method was prospected to provide some ideas for the design and preparation of the molybdenum alloys.

-

Key words:

- molybdenum alloys /

- powder preparation /

- sintering technology /

- strengthening mechanism

-

表 1 钼合金的性能和应用

Table 1. Properties and applications of the molybdenum alloys

合金种类 主要性能 产品或应用 二元系合金 Mo‒Cu 导电导热性好、加工性好 电子封装材料、电触头材料、散热器 Mo‒W 高温强度高、耐腐蚀 锌冶炼炉耐蚀部件 Mo‒Re 低温延展性好 热离子交换器、电子元器件 Mo‒Ti 高温强度高、抗蠕变性好 航天结构材料、大功率陶瓷管栅极 Mo‒Zr 再结晶温度、高温强度高、蠕变速率低 航天结构材料、核工业材料 Mo‒Hf 再结晶温度、高温强度高 航天结构材料、核工业材料 Mo‒Si 高温强度高、抗蠕变性好 飞机和航空航天工业高温应用 Mo‒Al2O3 高温强度高、再结晶温度高 高温喷嘴喷管、穿孔不锈钢管的钼顶头 Mo‒Ni 耐腐蚀 合金靶材、常用于酸性环境下 Mo‒Na 耐火度高、高温抗蠕变性能好 旋转溅射管形靶材、高温炉板料 ODS‒Mo 高温强度高、抗蠕变性好 电源灯丝、核工业材料、电极、坩埚 多元系合金 TZM 高温强度高、抗蠕变性好 电子管栅极材料、压铸模具 MHC 高温强度高、抗蠕变性好 火箭助推器、烧结舟皿 ZHM 高温强度高、低温延展性好 高温合金的等温铸造模具 MWH 强度、硬度高、高温性能好、抗烧蚀 火箭高温构件、电子管的灯丝、零件 Mo‒Si‒Al‒K 再结晶温度高、塑性好 灯脚、芯线丝和支架丝 Mo‒Si‒B 力学性能好、抗氧化 飞机和航空航天工业高温应用 Mo‒W‒Cu 高强度、 耐高温和抗烧蚀 燃气舵、喉衬等耐烧蚀部件 注:MHC指Mo‒Hf‒C合金,成分是Mo‒1.2Hf‒0.005C;ZHM指Mo‒Hf‒Zr‒C合金,成分是Mo‒0.5Zr‒1.5Hf‒0.2C;MWH指Mo‒W‒Hf‒C合金,成分是Mo‒23.72W‒1.2Hf‒0.08C。 -

[1] Xu J Y, Yang X M, Liu M, et al. State of China molybdenum industry development in 2013. China Molybd Ind, 2014, 38(3): 5许洁瑜, 杨晓明, 刘萌, 等. 2013年中国钼工业发展状况. 中国钼业, 2014, 38(3): 5 [2] Jiang L J, Li L P, Yao Y F, et al. Annual review of molybdenum in 2014. China Molybd Ind, 2015, 39(1): 1 doi: 10.13384/j.cnki.cmi.1006-2602.2015.01.001蒋丽娟, 李来平, 姚云芳, 等. 2014年钼业年评. 中国钼业, 2015, 39(1): 1 doi: 10.13384/j.cnki.cmi.1006-2602.2015.01.001 [3] Wang M, Deng Y S. Global molybdenum market in 2015. China Molybd Ind, 2016, 40(1): 55 doi: 10.13384/j.cnki.cmi.1006-2602.2016.01.013王敏, 邓永山. 2015年全球钼市场评述. 中国钼业, 2016, 40(1): 55 doi: 10.13384/j.cnki.cmi.1006-2602.2016.01.013 [4] Xu B. Study on Microstructure and Properties of High Performance Sintered Molybdenum Materials for Extrusion Dies [Dissertation]. Changsha: Central South University, 2010徐兵. 挤压模具用高性能烧结钼材料组织与性能的研究[学位论文]. 长沙: 中南大学, 2010 [5] Wang J P, Zhang H C, Wang J G, et al. Analysis of global molybdenum resource supply and demand structure and some suggestions. China Min Mag, 2016, 25(Suppl 2): 1 doi: 10.3969/j.issn.1004-4051.2016.z2.001王家鹏, 张洪川, 王建国, 等. 全球钼资源供需形势分析及对策建议. 中国矿业, 2016, 25(增刊 2): 1 doi: 10.3969/j.issn.1004-4051.2016.z2.001 [6] Cheng H Z, Fan J L, Liu T, et al. Preparation and research development of TZM molybdenum alloys. China Molybd Ind, 2008, 32(6): 40 doi: 10.3969/j.issn.1006-2602.2008.06.011成会朝, 范景莲, 刘涛, 等. TZM钼合金制备技术及研究进展. 中国钼业, 2008, 32(6): 40 doi: 10.3969/j.issn.1006-2602.2008.06.011 [7] Wang D H, Yuan X B, Li Z K, et al. Progress of research and application for Mo metal and its alloys. Rare Met Lett, 2006, 25(12): 1王东辉, 袁晓波, 李中奎, 等. 钼及钼合金研究与应用进展. 稀有金属快报, 2006, 25(12): 1 [8] Jia Z C, Lin B T. Progress in increasing low temperature ductility and high temperature oxidation resistance of Mo alloys. Powder Metall Ind, 2009, 19(1): 49 doi: 10.3969/j.issn.1006-6543.2009.01.011贾佐诚, 林冰涛. 提高钼合金低温塑性和高温抗氧化性的新进展. 粉末冶金工业, 2009, 19(1): 49 doi: 10.3969/j.issn.1006-6543.2009.01.011 [9] Zhou T J, Feng W, Zhao H B, et al. Coupling effects of tungsten and molybdenum on microstructure and stress-rupture properties of a nickel-base cast superalloy. Prog Nat Sci Mater Int, 2018, 28(1): 45 doi: 10.1016/j.pnsc.2017.12.003 [10] Primg S, Clemens H, Knabl W, et al. Orientation dependent recovery and recrystallization behavior of hot-rolled molybdenum. Int J Refract Met Hard Mater, 2015, 48(3): 179 [11] An G, Sun J, Sun Y J, et al. Preparation and influencing factors of molybdenum targets and magnetron-sputter-deposited molybdenum thin films. Mater Sci Forum, 2018, 913: 853 doi: 10.4028/www.scientific.net/MSF.913.853 [12] Xue K M, Wang Z, Liu M, et al. Mechanical properties of micro- and nano-scale during high pressure torsion of pure molybdenum. Rare Met Mater Eng, 2019, 48(6): 2033薛克敏, 王喆, 刘梅, 等. 纯钼高压扭转过程中微纳尺度的力学性能. 稀有金属材料与工程, 2019, 48(6): 2033 [13] Chen Z X. Research on development strategy of molybdenum mine in Heilongjiang Province. World Nonferrous Met, 2019(9): 63陈忠新. 黑龙江省钼矿发展战略研究. 世界有色金属, 2019(9): 63 [14] Liu H, Ju J H, Zhang J L, et al. Strengthening and toughening of molybdenum alloy and its development trend. China Molybd Ind, 2011, 35(2): 26 doi: 10.3969/j.issn.1006-2602.2011.02.007刘辉, 巨建辉, 张军良, 等. 钼合金的强韧化与发展趋势. 中国钼业, 2011, 35(2): 26 doi: 10.3969/j.issn.1006-2602.2011.02.007 [15] Ju Y P, Wang A Q. Current research status of Mo alloys. Powder Metall Ind, 2015, 25(4): 58 doi: 10.13228/j.boyuan.issn1006-6543.20150017居炎鹏, 王爱琴. 钼合金研究现状. 粉末冶金工业, 2015, 25(4): 58 doi: 10.13228/j.boyuan.issn1006-6543.20150017 [16] Liu P P, Fan J L, Cheng H C, et al. Effect of La on microstructure and mechanical property of Mo-alloy. Powder Metall Technol, 2009, 27(3): 185刘拼拼, 范景莲, 成会朝, 等. 稀土La对钼合金组织和性能的影响. 粉末冶金技术, 2009, 27(3): 185 [17] Wang L, Sun J, Sun Y J, at al. Effect of doping methods on microstructure and mechanical properties of Mo-La2O3 alloy. Rare Met Mater Eng, 2007, 36(10): 1827 doi: 10.3321/j.issn:1002-185x.2007.10.030王林, 孙军, 孙院军, 等. 掺杂方式对Mo-La2O3合金组织和力学性能的影响. 稀有金属材料与工程, 2007, 36(10): 1827 doi: 10.3321/j.issn:1002-185x.2007.10.030 [18] He H C, Wang K S, Hu P, et al. Effect of lanthanum doping on recrystallization behavior of TZM alloy sheet. Rare Met Mater Eng, 2015, 44(5): 1297何欢承, 王快社, 胡平, 等. 掺杂稀土元素镧对TZM合金板材再结晶行为的影响. 稀有金属材料与工程, 2015, 44(5): 1297 [19] He B H, Yang H L, Ruan J M. Effect of Y2O3 content on microstructure and properties of molybdenum alloy. Mater Sci Eng Powder Metall, 2012, 17(2): 234 doi: 10.3969/j.issn.1673-0224.2012.02.016何斌衡, 杨海林, 阮建明. Y2O3含量对钼合金组织和性能的影响. 粉末冶金材料科学与工程, 2012, 17(2): 234 doi: 10.3969/j.issn.1673-0224.2012.02.016 [20] Zhou M L, Li J, Zuo T Y. Study on the structure and properties of La–Mo wire. Chin J Nonferrous Met, 1994, 4(2): 45 doi: 10.3321/j.issn:1004-0609.1994.02.013周美玲, 李俊, 左铁镛. 镧钼丝组织结构和性能的研究. 中国有色金属学报, 1994, 4(2): 45 doi: 10.3321/j.issn:1004-0609.1994.02.013 [21] Wang J S, Dong L R, Liu W, et al. Progress on RE2O3-Mo/W matrix secondary emitter materials. Sci China Technol Sci, 2017, 60(10): 1439 doi: 10.1007/s11431-017-9040-7 [22] Wang J S, Zhou M L, Zuo T Y. Advance in rare earth cathode doped refractory metal materials. Mater China, 2009, 28(3): 1王金淑, 周美玲, 左铁镛. 稀土难熔金属阴极材料的研究进展. 中国材料进展, 2009, 28(3): 1 [23] Wang J S, Li B Z, Zhou M L. A study of the emission property and mechanism of La‒Mo cathode. Vac Electron, 2007(6): 5王金淑, 李保真, 周美玲. La‒Mo阴极发射性能及机理研究. 真空电子技术, 2007(6): 5 [24] Liu G, Zhang G J, Jiang F, et al. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat Mater, 2013, 12(2): 344 [25] Zhang G J, Liu G, Sun Y J, et al. TEM in situ observation of crack propagation in lanthanum oxide dispersion strengthened molybdenum alloy. Rare Met Mater Eng, 2010, 39(5): 828张国君, 刘刚, 孙院军, 等. 氧化镧弥散强化钼合金裂纹扩展的TEM原位观察. 稀有金属材料与工程, 2010, 39(5): 828 [26] Subramanian R, Shankar P, Kavithaa S, et al. Synthesis of nanocrystalline yttria by sol-gel method. Mater Lett, 2001, 48(6): 342 doi: 10.1016/S0167-577X(00)00324-4 [27] Dong L R, Li J H, Wang J S, et al. Fabrication and reduction process of dispersive Er2O3 doped Mo super-fine powders comparing with La2O3 doped Mo powders. Powder Technol, 2019, 346: 78 doi: 10.1016/j.powtec.2019.01.073 [28] Cheng P M, Yang C, Zhang R, et al. Enhancing the high-temperature creep properties of Mo alloys via nanosized La2O3 particle addition. J Mater Sci Technol, 2022, 130: 53 doi: 10.1016/j.jmst.2022.04.043 [29] Dong Z, Ma Z Q, Liu Y C. Accelerated sintering of high-performance oxide dispersion strengthened alloy at low temperature. Acta Mater, 2021, 220: 117309 doi: 10.1016/j.actamat.2021.117309 [30] Zhang D D, Ni F, Xu L J, et al. Effects of doping methods on microstructure and properties of A12O3/MO composite material. Rare Met Cement Carb, 2011, 39(3): 35 doi: 10.3969/j.issn.1004-0536.2011.03.009张丹丹, 倪锋, 徐流杰, 等. 掺杂方式对Al2O3/Mo复合材料组织及性能的影响. 稀有金属与硬质合金, 2011, 39(3): 35 doi: 10.3969/j.issn.1004-0536.2011.03.009 [31] Wang S Q, Ni D Z, Zhang N, Study on production technology of high temperature molybdenum billet. Rare Met Mater Eng, 1998, 27(4): 46王思清, 倪德忠, 张楠. 高温钼坯生产工艺研究. 稀有金属材料与工程, 1998, 27(4): 46 [32] Li D C, An G, Liu G J, et al. Sub-micron MoC powders prepared by high-energy mechanochemistry method. Powder Metall Technol, 2008, 26(3): 205李大成, 安耿, 刘高杰, 等. 高能机械化学法制备亚微米MoC粉体. 粉末冶金技术, 2008, 26(3): 205 [33] Wei S Z, Zhou Y C, Duan S H, et al. Effect of lanthanum oxide content on microstructure and properties of molybdenum plate. J Henan Univ Sci Technol Nat Sci, 2013, 34(2): 1魏世忠, 周玉成, 段素红, 等. 氧化镧含量对钼板组织与性能的影响. 河南科技大学学报(自然科学版), 2013, 34(2): 1 [34] Hu W Q, Sun T, Liu C X, et al. Refined microstructure and enhanced mechanical properties in Mo‒Y2O3 alloys prepared by freeze-drying method and subsequent low temperature sintering. J Mater Sci Technol, 2021, 88: 36 doi: 10.1016/j.jmst.2021.01.064 [35] Hu W Q, Wang L, Ma Z Q, et al. Nano Mo‒La‒O particles strengthened Mo alloys fabricated via freeze-drying technology and low temperature sintering. Mater Sci Eng A, 2021, 818: 141448 doi: 10.1016/j.msea.2021.141448 [36] Cao Q G, Zhao P C, Rong W, et al. Preparation of molybdenum alloy micropowder via spray drying method. Rare Met Mater Eng, 2020, 49(10): 3627操齐高, 赵盘巢, 戎万, 等. 喷雾干燥法制备钼合金微粉的研究. 稀有金属材料与工程, 2020, 49(10): 3627 [37] Xu L J, Wei S Z, Li J W, et al. Preparation, microstructure and properties of molybdenum alloys reinforced by in-situ Al2O3 particles. Int J Refract Met Hard Mater, 2012, 30(1): 208 doi: 10.1016/j.ijrmhm.2011.08.012 [38] Zhao H. Research and development on the sintering techniques of molybdenum and molybdenum alloys. Powder Metall Technol, 2019, 37(5): 382赵虎. 钼及钼合金烧结技术研究及发展. 粉末冶金技术, 2019, 37(5): 382 [39] Dong D, Huang H T, Xiong N, et al. Application of molybdenum and molybdenum alloys in nuclear reactors. China Molybd Ind, 2018, 42(4): 6董帝, 黄洪涛, 熊宁, 等. 钼及钼合金在核反应堆中的应用. 中国钼业, 2018, 42(4): 6 [40] Yu Z T, Wang K S, Hu P, et al. Progress of low oxygen TZM molybdenum alloy. Mater Rep, 2015, 29(1): 92于志涛, 王快社, 胡平, 等. 低氧TZM合金研究进展. 材料导报, 2015, 29(1): 92 [41] Zheng X, Bai R, Wang D H, et al. Research development of refractory metal materials used in the field of aerospace. Rare Met Mater Eng, 2011, 40(10): 1871郑欣, 白润, 王东辉, 等. 航天航空用难熔金属材料的研究进展. 稀有金属材料与工程, 2011, 40(10): 1871 [42] Wang C Y, Chang Y, Zhang H L, et al. Effect of ZrO2 content on microstructure and properties of molybdenum alloys. Powder Metall Technol, 2021, 39(5): 429王承阳, 常洋, 张林海, 等. 氧化锆含量对钼合金组织和性能的影响. 粉末冶金技术, 2021, 39(5): 429 [43] Feng P F, Fu J B, Liu R Z, et al. Analysis on time sequence characteristics of occurrence status of lanthanum in Mo alloy wires. Chin J Rare Met, 2011, 35(4): 486 doi: 10.3969/j.issn.0258-7076.2011.04.003冯鹏发, 付静波, 刘仁智, 等. La元素在钼合金丝中赋存形式的时序性分析. 稀有金属, 2011, 35(4): 486 doi: 10.3969/j.issn.0258-7076.2011.04.003 [44] Yang Q L, Meng Q L, Feng P F, et al. Effect of rare-earth Y and Ce on the mechanical properties of Mo alloy. China Molybd Ind, 2012, 36(5): 51 doi: 10.3969/j.issn.1006-2602.2012.05.014杨秦莉, 孟庆乐, 冯鹏发, 等. 稀土Y、Ce对钼合金力学性能的影响. 中国钼业, 2012, 36(5): 51 doi: 10.3969/j.issn.1006-2602.2012.05.014 [45] Cao W C. Effect of Y2O3 doped on the mechanics performance of molybdenum alloys. China Molybd Ind, 2006, 30(3): 40 doi: 10.3969/j.issn.1006-2602.2006.03.012曹维成. 氧化钇掺杂对合金烧结钼组织及性能的影响. 中国钼业, 2006, 30(3): 40 doi: 10.3969/j.issn.1006-2602.2006.03.012 [46] Chen G Q, Zhu D R, Zhan R, et al. Highly dense Mo/Cu composites fabricated by squeeze casting and their thermal conduction properties. Chin J Nonferrous Met, 2005, 15(11): 1864 doi: 10.3321/j.issn:1004-0609.2005.11.039陈国钦, 朱德志, 占荣, 等. 挤压铸造法制备高致密Mo/Cu及其导热性能. 中国有色金属学报, 2005, 15(11): 1864 doi: 10.3321/j.issn:1004-0609.2005.11.039 [47] Zhou H L, Feng K Q, Ke S X, et al. Study on the microwave sintering of the novel Mo‒W‒Cu alloys. J Alloys Compd, 2021, 881: 160584 doi: 10.1016/j.jallcom.2021.160584 [48] Zhou H L, Feng K Q, Liu Y F. Densification, microstructure, and properties of W‒Mo‒Cu alloys prepared with nano-sized Cu powders via large electric current sintering. Adv Powder Technol, 2022, 33(8): 103703 doi: 10.1016/j.apt.2022.103703 [49] Lu Y, Yang D L. High-performance ultra-fine grain Mo alloy prepared by SPS sintering. Hot Work Technol, 2021, 50(10): 40卢瑶, 杨栋林. SPS烧结制备高性能超细晶钼合金. 热加工工艺, 2021, 50(10): 40 [50] Li Z F, Tang H P, Liu H Y, et al. Influence of activating element Ni on performance of Mo‒Cu alloy. Mater Sci Eng Powder Metall, 2006, 11(3): 185 doi: 10.3969/j.issn.1673-0224.2006.03.013李增峰, 汤慧萍, 刘海彦, 等. 活化元素Ni对Mo‒Cu合金性能的影响. 粉末冶金材料科学与工程, 2006, 11(3): 185 doi: 10.3969/j.issn.1673-0224.2006.03.013 [51] Lu M Y, Fang J L, Cheng C H, et al. Influence of TiC addition on properties and microstructure of Mo‒Ti alloy. Rare Met Mater Eng, 2010, 39(6): 985卢明园, 范景莲, 成会朝, 等. TiC的添加对Mo‒Ti合金性能与组织结构的影响. 稀有金属材料与工程, 2010, 39(6): 985 [52] Leichtfried G, Schneibel J H, Heilmaier M. Ductility and impact resistance of powder-metallurgical rhenium alloys. Metall Mater Trans A, 2006, 37(10): 2955 doi: 10.1007/s11661-006-0177-9 [53] Cao W C, Liu J, Ren Y X. Effect of doping different trace elements on properties of molybdenum materials. Rare Met Lett, 2006, 25(8): 29曹维成, 刘静, 任宜霞. 掺杂不同微量元素对钼材性能的影响. 稀有金属快报, 2006, 25(8): 29 [54] Fan J L, Qian Z, Cheng H Z, et al. Effect of trace TiC/ZrC on property and microstructure of TZM alloy at room and high temperature. Rare Met Mater Eng, 2013, 42(4): 853 doi: 10.3969/j.issn.1002-185X.2013.04.041范景莲, 钱昭, 成会朝, 等. 微量TiC/ZrC对TZM合金室温及高温性能与组织的影响. 稀有金属材料与工程, 2013, 42(4): 853 doi: 10.3969/j.issn.1002-185X.2013.04.041 [55] Lu K, Lu L, Suresh S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science, 2009, 324: 349 doi: 10.1126/science.1159610 [56] Zhou Y H, Hu P, Chang T, et al. Research progress of strengthening and toughening modes and mechanisms of molybdenum alloys. J Funct Mater, 2018, 49(1): 1026周宇航, 胡平, 常恬, 等. 钼合金强韧化方式及机理研究进展. 功能材料, 2018, 49(1): 1026 [57] Chen X, Li B, Wang T, et al. Strengthening mechanisms of Mo‒La2O3 alloys processed by solid-solid doping and vacuum hot-pressing sintering. Vacuum, 2018, 152: 70 doi: 10.1016/j.vacuum.2018.03.012 -

下载:

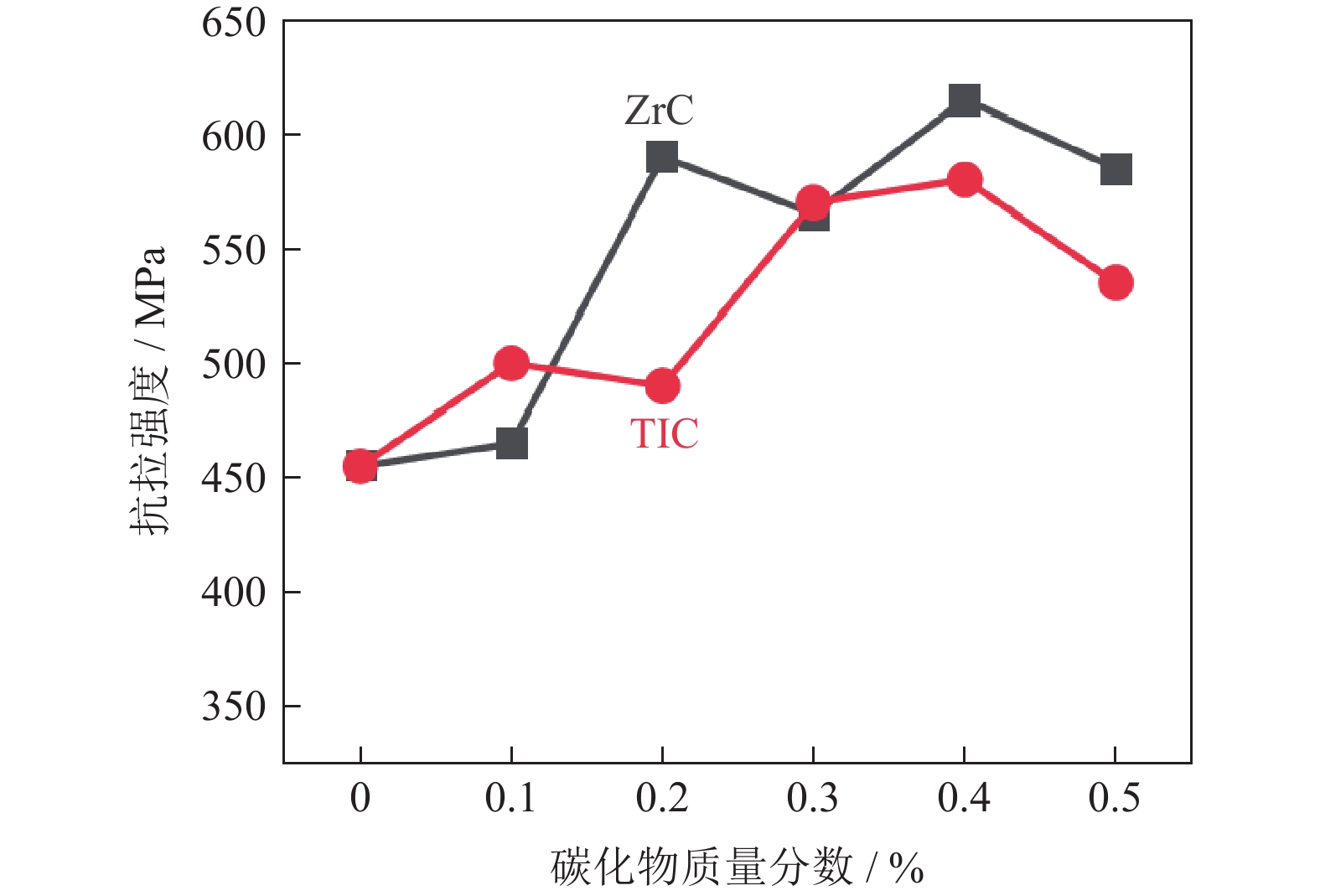

下载: