-

摘要: 选用不同载荷(F)和摩擦速度(V)进行正交对比实验,研究TC4钛合金金属丝在干摩擦条件下的摩擦磨损性能,得出载荷和摩擦速度与TC4细丝摩擦系数和磨损率间的相关规律。采用扫描电子显微镜和能谱仪观察并分析了TC4细丝表面磨损形貌、元素种类及物相组成,并讨论了TC4细丝的磨损机制。结果表明:在摩擦速度相同时,载荷增大,摩擦系数先增大后减小,磨损率则持续增大;当载荷不变时,摩擦速度与摩擦系数呈负相关,与磨损率呈正相关。在TC4磨损机制中,氧化磨损和磨粒磨损主要出现在低载荷和低速情况下,氧化磨损和粘着磨损主要出现在中载荷和中速情况下,磨粒磨损主要出现在高载荷情况下,而氧化磨损则出现在高速下。随F∙V值增大,摩擦系数先减小后增大,磨损率与F∙V值呈正相关。Abstract: The friction and wear properties of the TC4 titanium alloy wire under the dry friction conditions were studied. The influence of load (F) and friction speed (V) on the friction coefficient and wear rate of the TC4 wire was investigated. The scanning electron microscope (SEM) and energy dispersive spectrometer (EDS) were used to observe and analyze the surface morphology, element composition, and phase component of the TC4 wire worn surface, and the wear mechanism was discussed. The results show that, when the sliding speed is the same, as the load increases, the friction coefficient increases first and then decreases, and the wear rate continues to increase. When the load is constant, the sliding speed is negatively correlated with the friction coefficient and positively correlated with the wear rate. For the TC4 wear mechanism, the oxidative wear and abrasive wear mainly occur under the low load and low speed, the oxidative wear and adhesive wear mainly occur under the medium load and medium speed, the abrasive wear mainly occurs at high load, while the oxidative wear occurs at high speed. The friction coefficient first decreases and then increases with the increase of F∙V value, and the wear rate is positively correlated with F∙V value.

-

Key words:

- TC4 /

- friction and wear /

- wear mechanism /

- load /

- friction speed

-

表 1 不同试验条件下F∙V值

Table 1. F∙V value under the different conditions

编号 载荷,F / N 摩擦速度,V / (mm·min‒1) F∙V / (N·m·s‒1) 1# 5 240 0.02 2# 10 240 0.04 3# 20 240 0.08 4# 10 120 0.02 5# 10 180 0.03 6# 10 300 0.05 -

[1] Zhu Z S. Recent research and development of titanium alloys for aviation application in China. J Aeronaut Mater, 2014, 34(4): 44朱知寿. 我国航空用钛合金技术研究现状及发展. 航空材料学报, 2014, 34(4): 44 [2] Ji Z Y, Li C F, Song K H, et al. Application research and development of metal-rubber. Hot Work Technol, 2011, 40(16): 96季正勇, 李春福, 宋开红, 等. 金属橡胶的应用研究及其进展. 热加工工艺, 2011, 40(16): 96 [3] Hu L Q, Miao Q, Liang W P, et al. Effect of loads on tribological characteristics of oxynitrided TC4 titanium alloy. Heat Treat, 2019, 34(3): 1胡林泉, 缪强, 梁文萍, 等. 载荷对经氧‒氮共渗的TC4钛合金摩擦学性能的影响. 热处理, 2019, 34(3): 1 [4] Jing P F, Yu S R, Song W, et al. Effect of contact load on fretting wear behavior of TC4 titanium alloy. Surf Technol, 2019, 48(11): 266景鹏飞, 俞树荣, 宋伟, 等. 接触载荷对TC4钛合金微动磨损行为的影响. 表面技术, 2019, 48(11): 266 [5] Liang S X, Yin L X, Zheng L Y, et al. The microstructural evolution and grain growth kinetics of TZ20 alloy during isothermal annealing. Mater Des, 2016, 99(6): 396 [6] Li X X, Zhou Y, Ji X L, et al. Effects of sliding velocity on Tribo-oxides and wear behavior of Ti‒6Al‒4V alloy. Tribol Int, 2015, 91(2): 228 [7] Li X X, Zhou Y, Li Y X, et al. Dry sliding wear characteristics of Ti‒6.5Al‒3.5Mo‒1.5Zr‒0.3Si alloy at various sliding speeds. Metall Mater Trans A, 2015, 46(9): 4360 [8] Guo W, Li J, Huang S M, et al. Effect of fretting amplitude on friction properties of Ti‒6Al‒4V alloy. Titanium Ind Prog, 2016, 33(5): 16郭薇, 李健, 黄淑梅, 等. 微动幅值对Ti‒6Al‒4V合金摩擦特性的影响. 钛工业进展, 2016, 33(5): 16 [9] Liu Y, Yang D Z, He S Y, et al. Study on dry sliding wear of TC4 alloy in vacuum. Rare Met Mater Eng, 2005, 34(1): 128刘勇, 杨德庄, 何世禹, 等. TC4合金的磨损率及磨损表面层的显微组织变化. 稀有金属材料与工程, 2005, 34(1): 128 [10] Liu Y, Yang D Z, He S Y, et al. Drying sliding wear behavior of Ti‒6Al‒4V alloy in air. J Harbin Inst Technol, 2002, 9(1): 67 [11] Liu Y, Yang D Z, He S Y, et al. Drying sliding wear of Ti‒6Al‒4V alloy in air and vacuum. Trans Nonferrous Met Soc China, 2003, 3(5): 1137 [12] Xu Y L, Wang S H, Liang Y M, et al. Environmental atmosphere effect on fretting wear characteristics of titanium alloy. J Aeronaut Mater, 1990, 10(2): 13徐永利, 王世洪, 梁佑明, 等. 环境气氛对钛合金微动磨损特性的影响. 航空材料学报, 1990, 10(2): 13 [13] Du Y, Lü X R, Li S J. Research progress on dry friction and wear of titanium alloys and wear reduction methods. Met Mater Metall Eng, 2021, 49(1): 30杜洋, 吕晓仁, 李述军. 钛合金干摩擦磨损及减磨方法研究进展. 金属材料与冶金工程, 2021, 49(1): 30 [14] Yao X F, Xie F Q, Han Y, et al. Effects of temperature on wear properties and friction coefficient of TC4 alloy. Rare Met Mater Eng, 2012, 41(8): 1463姚小飞, 谢发勤, 韩勇, 等. 温度对TC4钛合金摩擦磨损性能和摩擦系数的影响. 稀有金属材料与工程, 2012, 41(8): 1463 [15] Yao X F, Xie F Q, Han Y, et al. Comparison of friction wear properties between TC4 titanium alloy and P110 tubing steel. Rare Met Mater Eng, 2012, 41(9): 1539姚小飞, 谢发勤, 韩勇, 等. TC4合金和P110油管钢摩擦磨损性能的比较. 稀有金属材料与工程, 2012, 41(9): 1539 [16] Lu H F, Miao Q, Liang W P, et al. Effect of different temperatures on tribological properties of TC4-DT alloy. J Nanjing Univ Aeronaut Astronaut, 2016, 48(1): 29 doi: 10.16356/j.1005-2615.2016.01.005陆海峰, 缪强, 梁文萍, 等. 不同温度对TC4-DT钛合金摩擦磨损性能的影响. 南京航空航天大学学报, 2016, 48(1): 29 doi: 10.16356/j.1005-2615.2016.01.005 [17] Qu J, Blau P J, Watkins T R, et al. Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear, 2005, 258(9): 1348 doi: 10.1016/j.wear.2004.09.062 [18] Ying Y, Li L, Zhao B, et al. Friction and wear properties of titanium alloys and the improving methods. Nonferrous Met Mater Eng, 2019, 40(3): 49应扬, 李磊, 赵彬, 等. 钛合金的摩擦磨损性能及其改善方法. 有色金属材料与工程, 2019, 40(3): 49 [19] Zhang Q, Ding H, Zhou G, et al. Dry sliding wear behavior of a selected titanium alloy against counterface steel of different hardness levels. Metall Mater Trans A, 2019, 50: 220 doi: 10.1007/s11661-018-4993-5 [20] Guo H F, Sun T, Li J L. Tribological properties of TC4 alloy under different friction conditions. Hot Working Technol, 2014, 43(10): 40郭华锋, 孙涛, 李菊丽. 不同摩擦条件下TC4钛合金摩擦学性能研究. 热加工工艺, 2014, 43(10): 40 [21] Huang M J, Han J L, Dong X P. Tribological properties of the SLM-316L filament under the grease lubrication condition. Chin J Eng, 2021, 43(6): 835黄明吉, 韩建磊, 董秀萍. SLM-316L细丝脂润滑摩擦磨损性能. 工程科学学报, 2021, 43(6): 835 [22] Huang M J, Li B, Dong X P, et al. Effect of wire diameter on friction and wear behavior of 316L stainless steel wire. Tribology, 2021, 41(2): 206 doi: 10.16078/j.tribology.2020101黄明吉, 李斌, 董秀萍, 等. 丝径对316L不锈钢丝摩擦磨损行为的影响. 摩擦学学报, 2021, 41(2): 206 doi: 10.16078/j.tribology.2020101 [23] Grützmacher P G, Rammacher S, Rathmann D, et al. Interplay between microstructural evolution and tribo-chemistry during dry sliding of metals. Friction, 2019, 7(6): 637 doi: 10.1007/s40544-019-0259-5 [24] Chelliah N, Kailas S V. Synergy between tribo-oxidation and strain rate response on governing the dry sliding wear behavior of titanium. Wear, 2009, 266(7): 704 [25] Mao Y S, Wang L, Chen K M, et al. Tribo-layer and its role in dry sliding wear of Ti‒6Al‒4V alloy. Wear, 2013, 297(1): 1032 [26] Cui X H, Mao Y S, Wei M X, et al. Wear characteristics of Ti‒6Al‒4V alloy at 20~400 ℃. Tribol Trans, 2012, 55(2): 185 doi: 10.1080/10402004.2011.647387 [27] Wang L, Zhang Q Y, Li X X, et al. Severe-to-mild wear transition of titanium alloys as a function of temperature. Tribol Lett, 2014, 53(3): 511 doi: 10.1007/s11249-013-0289-5 [28] Wang L, Zhang Q Y, Li X X, et al. Dry sliding wear behavior of Ti‒6.5Al‒3.5Mo‒1.5Zr‒0.3Si alloy. Metall Mater Trans A, 2014, 45(4): 2284 doi: 10.1007/s11661-013-2167-z [29] He Y N, Yu S R, Li S X, et al. Effect of tribo-oxide layers on wear properties and coefficient of friction of TC4 alloy in fretting. Rare Met Mater Eng, 2021, 50(4): 1417何燕妮, 俞树荣, 李淑欣, 等. 摩擦氧化层对TC4合金磨损行为和摩擦系数的影响. 稀有金属材料与工程, 2021, 50(4): 1417 [30] Straffelini G, Molinari A. Mild sliding wear of Fe‒0.2%C, Ti‒6%Al‒4%V and Al-7072: a comparative study. Tribol Lett, 2011, 41: 227 -

下载:

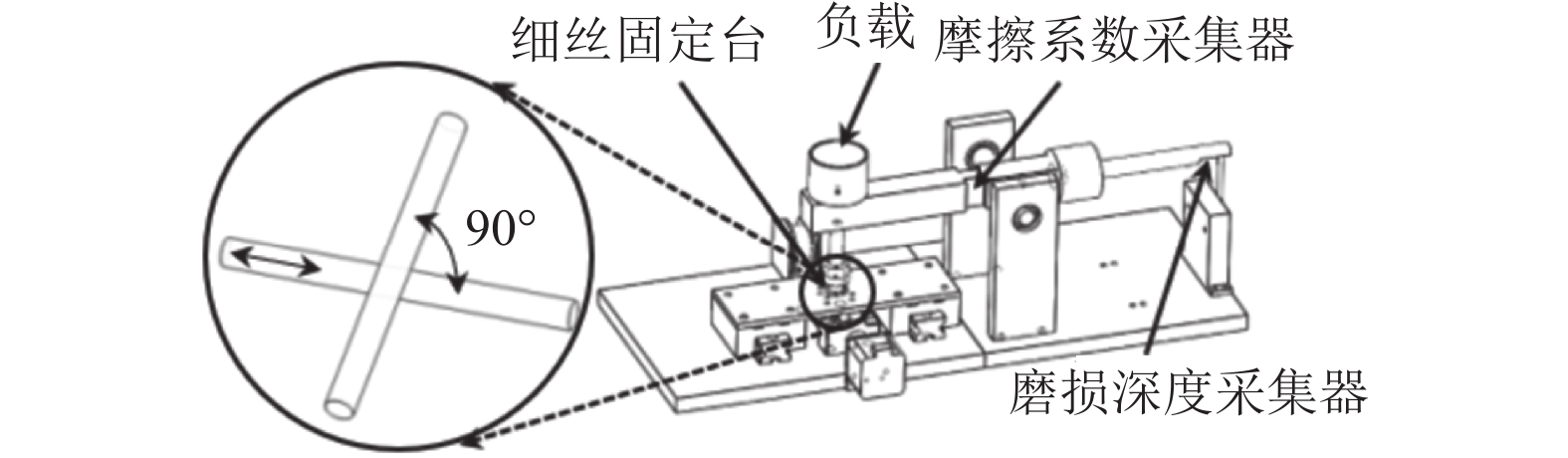

下载: