Pore structure and performance of porous GH4169 superalloys preparedby laser additive manufacturing

-

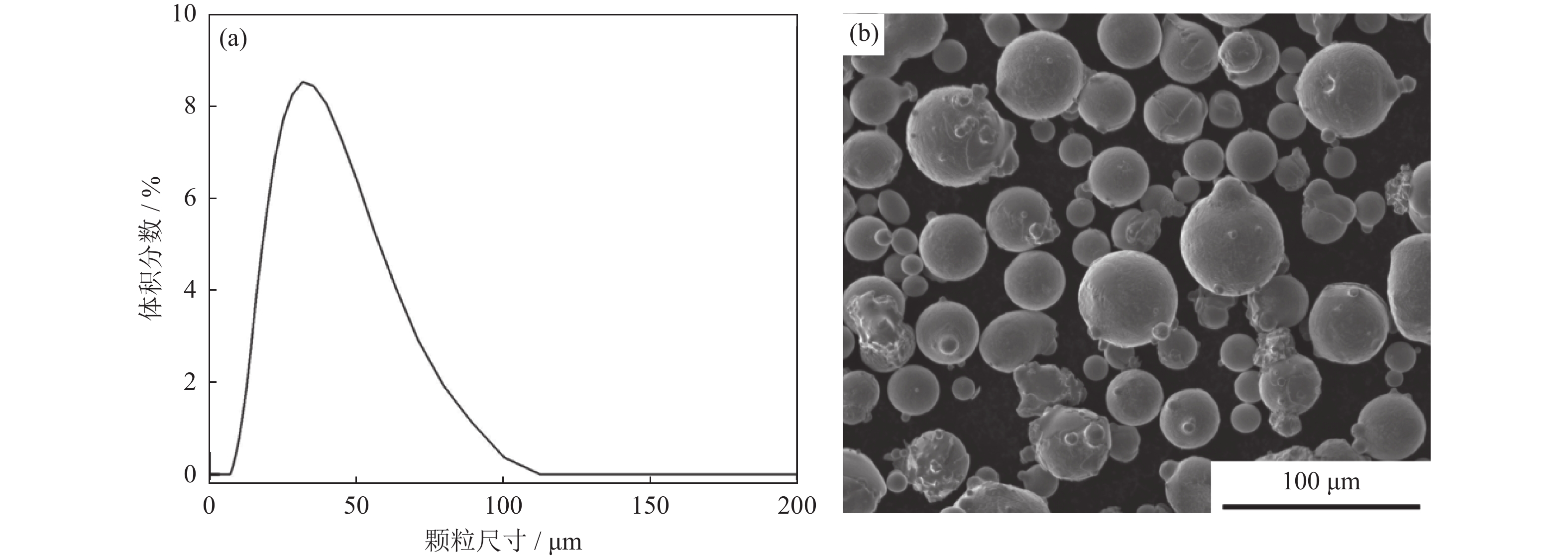

摘要: 利用选区激光熔化技术制备出具有不同孔隙结构的多孔GH4169高温合金材料,对制备样品进行扫描电镜观察以及毛细曲线和压缩应力应变曲线测试,系统研究了孔结构对多孔材料毛细抽吸性能及压缩力学性能的影响。结果表明,随着激光功率从285 W减小到160 W,多孔高温合金样品总孔隙率从3.5%增加到46.1%;随着开孔率从15.6%增加到21.7%,多孔高温合金样品的毛细抽吸速度从4.44 mg/(s·cm3)增加到6.56 mg/(s·cm3),毛细抽吸质量从91.3 mg/cm3下降到81.7 mg/cm3,毛细抽吸质量的减少可能与样品孔径增大导致毛细力下降有关。孔隙率增加也导致多孔材料样品弹性模量从53 GPa减小到11 GPa,弹性极限从768 MPa减小到217 MPa,孔材料样品均展现出较好的抗压缩变形能力。Abstract: Porous GH4169 superalloy materials with the different pore structures were prepared by selective laser melting technology. The effects of pore structure on the capillary and compressive mechanical properties were investigated by scanning electron microscopy (SEM), capillary curves, and compressive stress strain curves. The results show that, the porosity of the porous superalloy specimens increases from 3.5% to 46.1% with decreasing the laser power from 285 W to 160 W. With the increase of porosity from 15.6% to 21.7%, the capillary pumping rate of the porous superalloy specimens increases from 4.44 to 6.56 mg/(s·cm3), and the capillary pumping mass decreases from 91.3 to 81.7 mg/cm3, due to the decrease of capillary force caused by the increased pore size of the porous materials. Increasing the porosity of the porous materials leads to the decrease of elastic modulus from 53 to 11 GPa and the decrease of elastic limit from 768 to 217 MPa. It also can be found that all of the porous superalloy specimens show the good resistance to the compression deformation.

-

图 8 激光增材制造多孔GH4169高温合金样品压缩变形前和变形后形貌:(a)变形前;(b)变形后S1;(c)变形后S2;(d)变形后S3;(e)变形后S4;(f)变形后S5

Figure 8. Morphologies of the porous GH4169 superalloy specimens produced by laser additive manufacturing before and after compression deformation: (a) before compression deformation; (b) S1 after compression deformation; (c) S2 after compression deformation; (d) S3 after compression deformation; (e) S4 after compression deformation; (f) S5 after compression deformation

表 1 GH4169合金粉末化学成分(质量分数)

Table 1. Chemical composition of the GH4169 alloy powders

% Ni Fe Cr Mo Nb Ti Al Cu 其他 53.70 16.30 19.20 3.12 4.95 0.98 0.62 0.30 <1.00 表 2 多孔GH4169高温合金样品激光增材制造工艺参数

Table 2. Laser additive manufacturing process parameters for the porous GH4169 superalloy specimens

样品编号 激光功率 / W 扫描速率 / (mm·s−1) 扫描间隔 / s S1 285 960 0.25 S2 285 960 0.35 S3 200 960 0.25 S4 180 960 0.25 S5 160 960 0.25 表 3 激光增材制造多孔GH4169高温合金样品密度及孔隙率

Table 3. Density and porosity of the porous GH4169 superalloy specimens produced by laser additive manufacturing

样品编号 密度 / (g·cm−3) 总孔隙率 / % 开孔率 / % S1 7.95 3.5 0.3 S2 7.52 8.7 0.8 S3 7.23 12.2 1.4 S4 5.21 36.8 15.6 S5 4.44 46.1 21.7 表 4 激光增材制造多孔GH4169高温合金样品毛细性能

Table 4. Capillary performance of the porous GH4169 superalloy specimens produced by laser additive manufacturing

样品编号 抽吸速度 / [mg·(s·cm3)−1] 单位体积抽吸质量 / (mg·cm−3) S4 4.44 91.3 S5 6.56 81.7 表 5 激光增材制造多孔GH4169高温合金样品压缩性能

Table 5. Compression performance of the porous GH4169 superalloy specimens produced by laser additive manufacturing

样品编号 弹性模量 / GPa 弹性极限 / MPa S1 83±4 768±21 S2 57±2 508±14 S3 45±5 413±23 S4 16±2 221±19 S5 11±1 217±12 -

[1] Bai B H. Investigation of Heat Transfer Enhancement by Flow Phase Change in High Temperature Heat Pipe [Dissertation]. Beijing: North China Electric Power University, 2021白冰鹤. 高温热管内部流动相变强化传热研究[学位论文]. 北京: 华北电力大学, 2021 [2] Liu D H, Zheng X P, Wang F, et al. Heat conduction and thermal protection mechanism of heat pipe cooled thermal protection structures. J Tsinghua Univ Sci Technol, 2010, 50(7): 1094刘冬欢, 郑小平, 王飞, 等. 内置高温热管热防护结构的传热防热机理. 清华大学学报(自然科学版), 2010, 50(7): 1094 [3] Li F. Dredging Thermal Protection. Beijing: China Aerospace Press, 2017李锋. 疏导式热防护. 北京: 中国宇航出版社, 2017 [4] Chen L Z, Ou D B. Elementary research on the application of high temperature heat-pipe to the thermal protection. J Exp Fluid Mech, 2010, 24(1): 51 doi: 10.3969/j.issn.1672-9897.2010.01.010陈连忠, 欧东斌. 高温热管在热防护中应用初探. 实验流体力学, 2010, 24(1): 51 doi: 10.3969/j.issn.1672-9897.2010.01.010 [5] Ding L, Zhang H, Xu H, et al. Startup characteristics of high temperature heat pipe in solar power receiver. J Nanjing Univ Technol Nat Sci, 2009, 31(5) : 79丁莉, 张红, 许辉, 等. 太阳能接收器中高温热管启动性能. 南京工业大学学报(自然科学版), 2009, 31(5): 79 [6] Liu X, Tian Z X, Wang C L, et al. Experimental study on heat transfer performance of high temperature potassium heat pipe. Nucl Power Eng, 2020, 41(Suppl 1): 106刘逍, 田智星, 王成龙, 等. 高温热管传热特性实验研究. 核动力工程, 2020, 41(增刊1): 106 [7] Niu T, Zhang Y L, Hou H L, et al. Properties of high-temperature heat pipe and tts experimental. Acta Aeronaut Astronaut Sin, 2016, 37(Suppl 1): S59牛涛, 张艳苓, 侯红亮, 等. 高温热管性能分析与试验. 航空学报, 2016, 37(增刊1): S59 [8] Yu P, Zhang H, Xu H, et al. Startup performance of high-temperature sodium heat pipe with triangularg groove wick. J Nanjing Univ Technol Nat Sci, 2015, 37: 99于萍, 张红, 许辉, 等. 三角沟槽高温钠热管的启动性能. 南京工业大学学报(自然科学版), 2015, 37: 99 [9] Shen Y, Zhang H, Xu H, et al. Heat transfer characteristics of high temperature heat pipe with triangular grooved wick under variable heat fluxes. CIESC J, 2014, 65: 3830 doi: 10.3969/j.issn.0438-1157.2014.10.012沈妍, 张红, 许辉, 等. 三角沟槽高温热管变热流传热特性. 化工学报, 2014, 65: 3830 doi: 10.3969/j.issn.0438-1157.2014.10.012 [10] He D, Wang L, Liu R T, et al. Pore characteristic and performance of sintered copper-based porous wicks. Mater Sci Eng Powder Metall, 2018, 23(4): 389 doi: 10.3969/j.issn.1673-0224.2018.04.008何达, 汪琳, 刘如铁, 等. 烧结铜基多孔毛细芯的孔隙特征及性能. 粉末冶金材料科学与工程, 2018, 23(4): 389 doi: 10.3969/j.issn.1673-0224.2018.04.008 [11] Kumar P, Wangaskar B, Khandekar S, et al. Thermal-fluidic transport characteristics of bi-porous wicks for potential loop heat pipe systems. Exp Therm Fluid Sci, 2018, 94: 355 doi: 10.1016/j.expthermflusci.2017.12.003 [12] Li Q, Gan X P, Li Z Y, et al. Fabrication and mechanical properties of porous Ni wicks. Mater Sci Eng Powder Metall, 2018, 23(4): 361黎强, 甘雪萍, 李志友, 等. 多孔镍毛细芯的制备及其力学性能. 粉末冶金材料科学与工程, 2018, 23(4): 361 [13] Deng D X, Tang Y, Huang G H, et al. Characterization of capillary performance of composite wicks for two-phase heat transfer devices. Int J Heat Mass Trans, 2013, 56(1-2): 283 doi: 10.1016/j.ijheatmasstransfer.2012.09.002 [14] Zhao H J, Lu Z L, Cao J W, et al. Preparation and mechanical properties of oriented porous GH3536. Rare Met Mater Eng, 2020, 49(5): 1694赵洪炯, 鲁中良, 曹继伟, 等. 定向多孔GH3536制备及其学性能. 稀有金属材料与工程, 2020, 49(5): 1694 [15] Mi G F, Liu X Y, Li H Y, et al. Research on the structure and mechanical properties of Ni−Cr−Co−W−Mo−Al−Ti porous superalloy. Powder Metall Technol, 2007, 25(5): 329米国发, 刘翔宇, 李红宇, 等. Ni−Cr−Co−W−Mo−Al−Ti合金制备多孔材料的组织与性能研究. 粉末冶金技术, 2007, 25(5): 329 [16] Zhou F, Zhou Y, Jiang M, et al. Ni-based aligned plate intermetallic nanostructures as effective catalysts for hydrogen evolution reaction. Mater Lett, 2020, 272: 127831 doi: 10.1016/j.matlet.2020.127831 [17] Jafari D, Wits W W, Geurts B J. Metal 3D-printed wick structures for heat pipe application: Capillary performance analysis. Appl Therm Eng, 2018, 143: 403 doi: 10.1016/j.applthermaleng.2018.07.111 [18] Esarte J, Blanco J M, Bernardini A, et al. Optimizing the design of a two-phase cooling system loop heat pipe: Wick manufacturing with the 3D selective laser melting printing technique and prototype testing. Appl Therm Eng, 2017, 111: 407 doi: 10.1016/j.applthermaleng.2016.09.123 [19] Taylor S L, Shah R N, Dunand D C. Ni−Mn−Ga micro-trusses via sintering of 3D-printed inks containing elemental powders. Acta Mater, 2018, 143: 20 doi: 10.1016/j.actamat.2017.10.002 [20] Mooraj S, Welborn S S, Jiang S Y, et al. Three-dimensional hierarchical nanoporous copper via direct ink writing and dealloying. Scripta Mater, 2020, 177: 146 doi: 10.1016/j.scriptamat.2019.10.013 [21] Zhu M, Yang Q, Wang B, et al. Effect of laser parameters on powders melting behavior in off-axis laser cladding process. Laser Optoelectron Prog, 2023, 60(1): 294朱明, 杨骞, 王博, 等. 激光参数对旁轴送粉激光熔覆粉末熔化行为的影响. 激光与光电子学进展, 2023, 60(1): 294 [22] Li J, Liu T T, Liao W H, et al. Study on forming characteristics and defects of GH3536 superalloy by selective laser melting. Chin J Lasers, DOI: 10.3788/CJL221084李军, 刘婷婷, 廖文和, 等. 激光选区熔化GH3536高温合金成形特征与缺陷研究. 中国激光, DOI: 10.3788/CJL221084 -

下载:

下载: