-

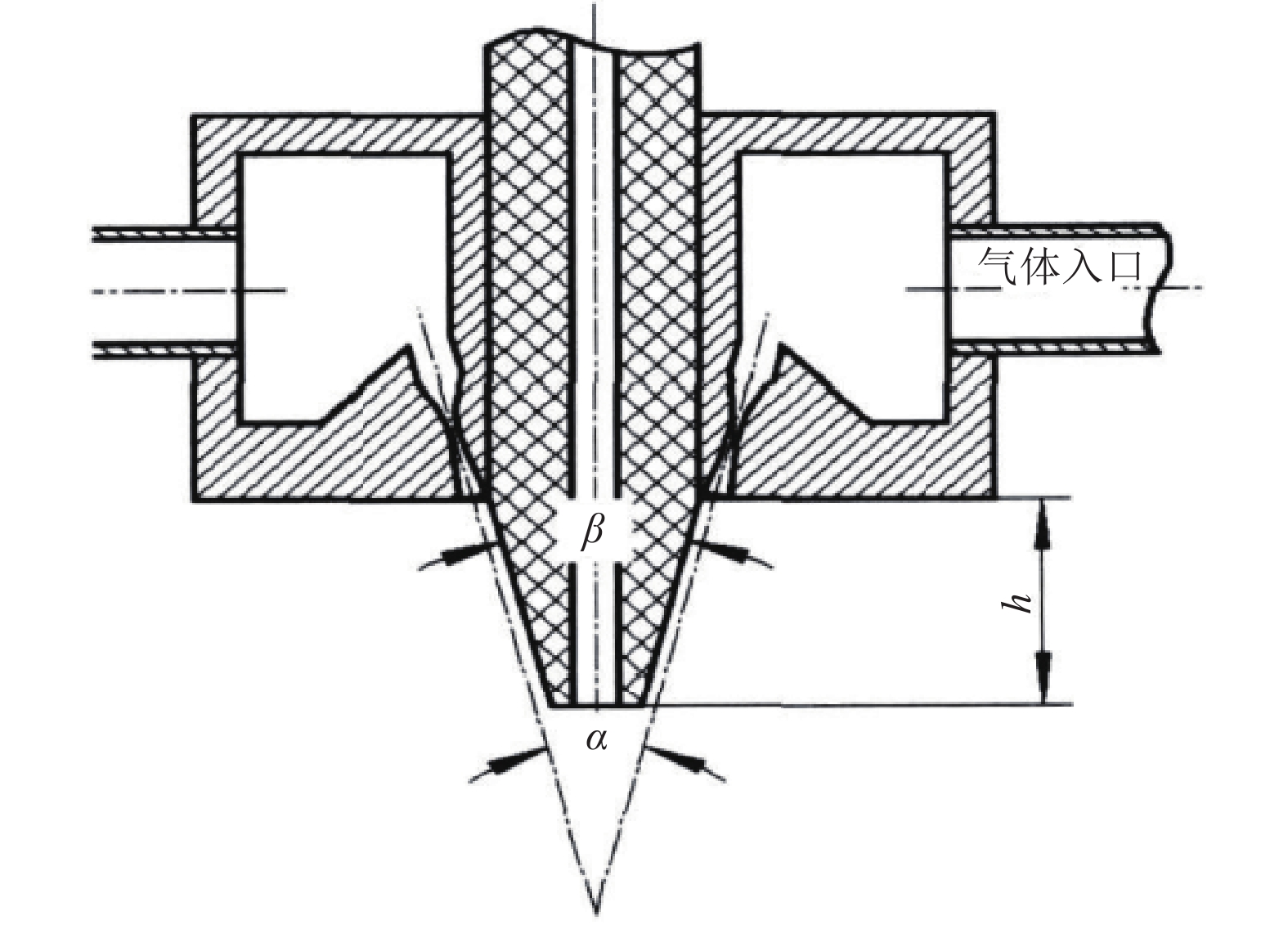

摘要: 采用紧耦合气雾化技术制备热喷涂NiCrAlY合金粉末,对NiCrAlY合金粉末的物理性能、粒度分布、粉末形貌、微观结构和物相组成等进行了分析。结果表明,粉末以球形和近球形颗粒为主,85%粉末粒径小于150 μm。粉末显微组织主要由树枝晶和胞状晶组成,粒径25~250 μm的粉末凝固冷速大约在4000~67000 K·s−1。粒径尺寸小于50 μm的粉末内部结构致密,少量尺寸大于50 μm的颗粒内部出现凝固缩孔和空心缺陷。粉末晶界和晶内存在Y、Si元素偏析,粉末物相结构主要由γ'-Ni3Al、γ-Ni固溶体相组成。

-

关键词:

- 紧耦合气雾化 /

- NiCrAlY合金粉末 /

- 热喷涂 /

- 显微组织 /

- 粉末性能

Abstract: NiCrAlY alloy powders used for the thermal spraying were fabricated by the closed-coupled gas atomization technology. The physical properties, particle size distribution, powder morphology, internal microstructure, and phase composition of the NiCrAlY alloy powders were investigated. The results show that, most of powders are spherical or nearly spherical particles, the particle size of 85% powders is less than 150 μm. The powder microstructures are mainly composed of dendrites and cellular crystals, and the solidification cooling rate of the powders with the particle size of 25~250 μm is about 4000~67000 K·s−1. The inner structure of the powders with the particle size less than 50 μm is dense, and a small number of particles with the particle size larger than 50 μm show the solidification shrinkage pore and hollow defects. There are Y and Si segregation in the crystal boundary and intracrystalline, and the powder phases are mainly composed of γ'-Ni3Al and γ-Ni solid solution phases. -

图 5 粒径为45~106 μm的NiCrAlY粉末断面扫描电镜背散射电子形貌:(a)粉末显微组织;(b)无缺陷颗粒;(c)凝固缩孔颗粒;(d)空心颗粒

Figure 5. SEM-BSE images of the NiCrAlY powders in the cross-section with the particle size of 45~106 μm: (a) overall microstructure of the powders; (b) featureless structure powder; (c) solidification shrinkage; (d) hollow defects

图 7 NiCrAlY粉末内部凝固组织和元素能谱分析:(a)粒径为120 μm左右的粉末颗粒;(b)图7(a)中B点能谱分析;(c)图7(a)中C点能谱分析

Figure 7. Solidification microstructure and EDS spectrum of the NiCrAlY powders: (a) microstructure of powders with the particle size of 120 μm; (b) EDS spectrum of spot B in Fig.7(a); (c) EDS spectrum of spot C in Fig.7(a)

表 1 不同粒径NiCrAlY合金粉的物理性能

Table 1. Physics properties of the NiCrAlY powders with the different particle sizes

粒径 / μm 松装密度 / (g·cm−3) 流动性 / [s·(50g)−1] 质量分数 / % O N 106~297 4.089 18.50 0.0078 0.0043 45~106 4.063 17.37 0.0057 0.0045 25~38 3.850 — 0.0231 0.0047 表 2 不同粒度NiCrAlY粉末的晶间距和冷速

Table 2. Grain spacing and cooling rate of the NiCrAlY powders with different particle sizes

粉末粒度 / μm 晶间距 / μm 颗粒冷速 / (K·s−1) 251.5 3.144 4020 145.9 2.456 8400 72.9 1.500 37000 40.6 1.350 51000 25.5 1.229 67000 表 3 图7(a)中各点能谱分析

Table 3. EDS analysis of each spots in Fig.7(a)

位置 质量分数 / % Al Si Y Cr Mn Ni 能谱面扫A 6.42 0.57 0.48 28.06 — 64.47 晶内B 9.05 0.21 0.29 27.15 — 63.30 晶界C 5.63 1.02 1.65 27.02 0.75 63.93 晶间D 6.65 0.67 0.58 27.74 0.39 63.96 名义含量 7.82 0.32 0.57 25.70 — 65.59 -

[1] Chen M Y, Hu D Y, Sun J G, et al. MCrAlTaY alloy powder prepared by vacuum atomization. Therm Spray Technol, 2010, 2(1): 27陈美英, 胡敦元, 孙建刚, 等. 真空雾化法制备MCrAlTaY合金粉末. 热喷涂技术, 2010, 2(1): 27 [2] Zhou S F, Liu J, Xiong Z, et al. Research progress on improving the high-temperature oxidation resistance of MCrAlY coatings. Laser Optoelectron Prog, 2015, 52(12): 120004 doi: 10.3788/LOP52.120004周圣丰, 刘佳, 熊征, 等. 提高MCrAlY涂层抗高温氧化性能方法的研究进展. 激光与光电子学进展, 2015, 52(12): 120004 doi: 10.3788/LOP52.120004 [3] Yang H Z, Zou J P, Shi Q, et al. Recent advances for interface diffusion behavior in MCrAlY coatings at elevated temperature oxidation. Rare Met Mater Eng, 2020, 49(7): 2240 [4] Xu H B, Gong S K, Liu F S, et al. Recent development in materials design of thermal barrier coatings for gas turbine. Acta Aeronaut Astronaut Sin, 2000, 21(1): 7徐惠彬, 宫声凯, 刘福顺, 等. 航空发动机热障涂层材料体系的研究. 航空学报, 2000, 21(1): 7 [5] Chang X C, Wang J Q, Hou W L, et al. Microstructure of supersonic gas atomized NiCoCrAlTaY alloy powder and high temperature oxidation resistance of coating. Surf Technol. 2000, 29(5): 9常新春, 王建强, 侯万良, 等. 超声雾化NiCoCrAlTaY合金粉末微观结构及涂层高温抗氧化性能. 表面技术, 2000, 29(5): 9 [6] Zhao X M, Xu J, Zhu X X, et al. Characterization of 316L stainless steel powders produced by supersonic gas atomization. Chin J Eng, 2009, 31(10): 1270赵新明, 徐骏, 朱学新, 等. 超音速气雾化制备316L不锈钢粉末的表征. 工程科学学报, 2009, 31(10): 1270 [7] Ouyang H W, Chen X, Yu W T, et al. Preparation of amorphous powders of Al-based alloy by close-coupled gas atomization. Rare Met Mater Eng, 2006, 35(6): 866欧阳鸿武, 陈欣, 余文焘, 等. 紧耦合气雾化制备Al基合金非晶粉末的研究. 稀有金属材料与工程, 2006, 35(6): 866 [8] Zhang Q, Zheng L, Xu W Y, et al. Research progress on argon atomized nickel-based powder metallurgy superalloys and powder characteristics. Powder Metall Technol, 2022, 40(5): 387张强, 郑亮, 许文勇, 等. 氩气雾化镍基粉末高温合金及粉末特性研究进展. 粉末冶金技术, 2022, 40(5): 387 [9] Hu B F. The adhering formation of argon-atomized FGH95 and imported René95 superalloy powders. J Univ Sci Technol Beijing, 1987, 9(Suppl 1): 19胡本芙. 氩气雾化的FGH95和René95合金粉末的粘结形式. 北京科技大学学报, 1987, 9(增刊 1): 19 [10] Hu W B, Jia C C, Hu B F, et al. Solidification microstructure of FGH96 superalloy powder prepared by argon gas atomization. Mater Sci Eng Powder Metall, 2011, 16(5): 671胡文波, 贾成厂, 胡本芙, 等. 氩气雾化法制备FGH96高温合金粉末颗粒的凝固组织. 粉末冶金材料科学与工程, 2011, 16(5): 671 [11] Pan J H, Zou Y Z, Zeng J M. The influences of SDAS on the aging kinetics of A357 alloy. Automot Eng, 2009, 31(5): 435潘杰花, 邹勇志, 曾建民. 二次枝晶臂间距对A357合金时效动力学的影响. 汽车工程, 2009, 31(5): 435 [12] Cao B, Liu Z M, Wang J C, et al. Microstructure and properties of Sc, Y microalloyed René104 nickel-based superalloy powders prepared by argon atomization. Mater Sci Eng Powder Metall, 2023, 28(2): 192曹镔, 刘祖铭, 王建川, 等. 氩气雾化Sc、Y微合金化René104镍基高温合金粉末的组织与性能. 粉末冶金材料科学与工程, 2023, 28(2): 192 [13] Nong B Z, Zhang Y Z, Liu Z M, et al. Microstrcture and properties of new nickel-based superalloy powder prepared by argon atomization. Mater Sci Eng Powder Metall, 2021, 26(6): 547农必重, 张亚洲, 刘祖铭, 等. 氩气雾化制备新型镍基高温合金粉末的微观结构和性能. 粉末冶金材料科学与工程, 2021, 26(6): 547 [14] Hu J Q, Wang C J, Wei L, et al. A comparative research of porosity in stainless steel powders manufactured by vacuum induction-melting gas atomization and plasma rotating electrode process. Powder Metall Ind, 2021, 31(4): 11胡家齐, 王长军, 魏来, 等. VIGA法与PREP法制备不锈钢粉末的内部孔洞对比研究. 粉末冶金工业, 2021, 31(4): 11 [15] Zhao S Y, Wang L Q, Tan P, et al. Preparation and properties of spherial Ti–35.8Al–18.4Nb alloy powders by VIGA-CC method. Powder Metall Technol, 2020, 38(6): 443赵少阳, 王利卿, 谈萍, 等. VIGA-CC法制备球形Ti–35.8Al–18.4Nb合金粉末及其性能研究. 粉末冶金技术, 2020, 38(6): 443 [16] Yang L B, Ren X N, Xia M, et al. Study on powder characteristics and effect factors of droplets size during electrode induction melting gas atomization. Rare Met Mater Eng, 2020, 49(6): 2017杨乐彪, 任晓娜, 夏敏, 等. 电极感应熔化气雾化粉末特性及液滴尺寸影响因素的研究. 稀有金属材料与工程, 2020, 49(6): 2017 [17] Gao Z J, Zhang G Q, Li Z, et al. Microstructure characteristics of superalloy powders during rapid solidification prepared by argon atomization. Powder Metall Technol, 2011, 29(2): 93高正江, 张国庆, 李周, 等. 氩气雾化高温合金粉末的凝固组织特征. 粉末冶金技术, 2011, 29(2): 93 [18] Liu Z M, Huang B Y, Liu Y, et al. Fabrication of Al82Ni10Y8 amorphous structured powders by argon gas atomization. J Cent South Univ Sci Technol, 2004, 35(5): 707刘祖铭, 黄伯云, 刘咏, 等. 氩气雾化制备Al82Ni10Y8非晶态结构粉末. 中南大学学报(自然科学版), 2004, 35(5): 707 [19] Wang X M, Zhu S, Yang B J, et al. Preparation of Al86Ni6Y4.5Co2La1.5 amorphous powder by closed-coupled gas atomization and its characterization analysis. Rare Met Mater Eng, 2017, 46(9): 2667王晓明, 朱胜, 杨柏俊, 等. 紧耦合雾化制备Al86Ni6Y4.5Co2La1.5非晶粉末及其表征分析. 稀有金属材料与工程, 2017, 46(9): 2667 [20] Li Z F, Tan P, Shen L, et al. Preparation and characterization of Ti–Al–8V–5Fe alloy powders. Powder Metall Technol, 2022, 40(6): 564李增峰, 谈萍, 沈垒, 等. Ti–Al–8V–5Fe合金粉末的制备及性能. 粉末冶金技术, 2022, 40(6): 564 -

下载:

下载: