Effects of surface state for Mo–Cu interlayer materials on interface bonding of multi-layer Cu/MoCu/Cu composites

-

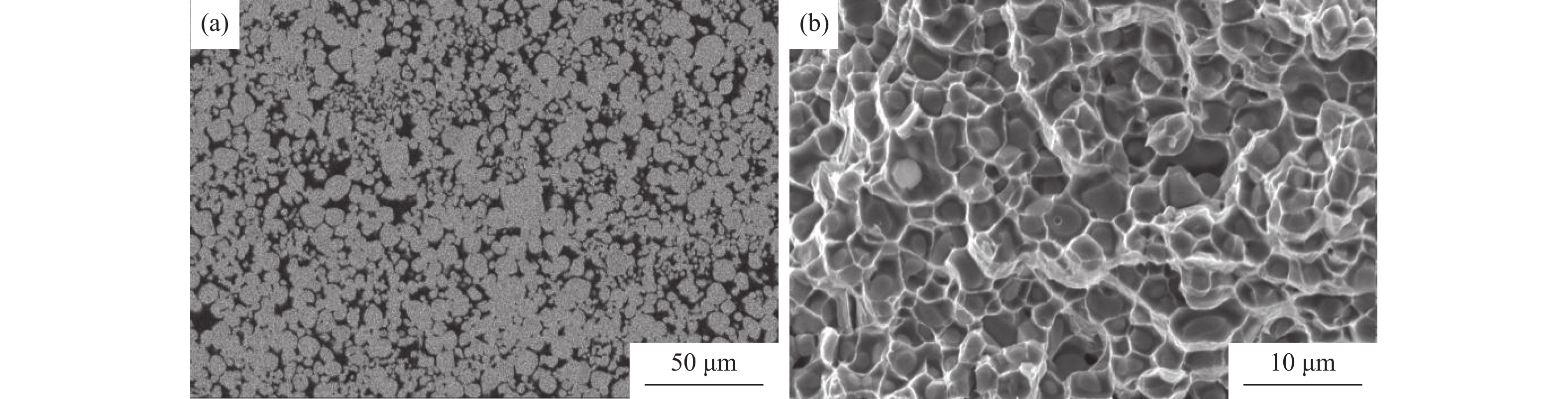

摘要: 采用粉末冶金熔渗法制备Mo–30Cu合金板坯,Mo–30Cu板坯和无氧铜板经轧制后在30 MPa、970 ℃的条件下进行热压复合,制得5层铜/钼铜/铜(Cu/MoCu/Cu,CPC)复合材料。通过金相组织观察、超声波扫描分析、高温热考核、漏气率测试等方法,研究了不同Mo–30Cu芯材表面处理方式对多层CPC复合材料层间结合强度的影响。结果表明,采用拉丝处理的Mo–30Cu芯材制备的多层CPC复合材料经830 ℃高温烘烤10 min热考核后,材料内部无空洞缺陷,漏气率小于5×10−3 Pa·cm3·s−1。采用研磨处理的Mo–30Cu芯材所制备的多层CPC复合材料经热考核后,材料出现鼓包现象,内部存在明显空洞缺陷,漏气率大于5×10−3 Pa·cm3·s−1。Abstract: Mo–30Cu alloy billets were prepared by powder metallurgy infiltration method, the rolled Mo–30Cu billets and oxygen-free copper plates were hot-pressed at 970 ℃ with a pressure of 30 MPa to obtain 5-layer Cu/MoCu/Cu (CPC) composites. The effects of the Mo–30Cu surface treatments on the interface bonding strength of the multi-layer CPC composites were studied by the microstructure observation, ultrasonic scanning analysis, high-temperature thermal examination, and air leakage rate testing. The results show that, the multi-layer CPC composites prepared by Mo–30Cu interlayer materials treated by wiredrawing have no cavity defects after being heated at 830 ℃ for 10 min, and the leakage rate is less than 5×10−3 Pa·cm3·s−1. The multi-layer CPC composites prepared by Mo–30Cu interlayer materials treated by grinding show the bulging phenomenon after the thermal examination, have the obvious cavity defects in the interior, and the leakage rate is greater than 5×10−3 Pa·cm3·s−1.

-

表 1 Mo–30Cu芯材化学成分(质量分数)

Table 1. Chemical composition of the Mo–30Cu interlayers

% Cu Fe K Al Si Ca Mo 29.1200 0.0017 0.0042 0.0015 0.0010 0.0004 余量 表 2 拉丝态芯材和研磨态芯材制备的5层CPC复合材料漏气率

Table 2. Leakage rate of the 5-layer CPC composites prepared by wiredrawing and grinding

芯材表面处理 漏气率 / (Pa·cm3·s−1) 热压后裸片 电镀镍 热考核 拉丝态芯材 0.26×10−3 0.38×10−3 0.40×10−3 研磨态芯材 6.60×10−3 6.80×10−3 9.70×10−3 -

[1] Huang L M, Luo L M, Ding X Y, et al. Research progress of W–Cu composites. Mater Mech Eng, 2014, 38(4): 1黄丽枚, 罗来马, 丁孝禹, 等. 钨铜复合材料的研究进展. 机械工程材料, 2014, 38(4): 1 [2] Zhang T, Zhang Z Q, Zhang J X, et al. Preparation of SiC ceramics by aqueous gelcasting and pressureless sintering. Mater Sci Eng A, 2007, 443: 257 doi: 10.1016/j.msea.2006.08.047 [3] Long L. Current status development trend of electronic packaging technology. Electron Packag, 2012, 12(1): 39 doi: 10.3969/j.issn.1681-1070.2012.01.013龙乐. 电子封装技术发展现状及趋势. 电子与封装, 2012, 12(1): 39 doi: 10.3969/j.issn.1681-1070.2012.01.013 [4] Yang C, Qi G C, Fan G N, et al. Effect of sintering temperature on microstructure and properties of molybdenum-copper alloy. China Molybd Ind, 2020, 44(2): 52 doi: 10.13384/j.cnki.cmi.1006-2602.2020.02.013杨晨, 齐国超, 范广宁, 等. 烧结温度对钼铜合金组织和性能的影响. 中国钼业, 2020, 44(2): 52 doi: 10.13384/j.cnki.cmi.1006-2602.2020.02.013 [5] Wang T G, Liang Q C, Qin Q. Research on microstructure and properties of Mo–Cu alloy prepared by powder metallurgy. Mater Rev, 2015, 29(5): 97王天国, 梁启超, 覃群. 粉末冶金法制备Mo–Cu合金及其性能的研究. 材料导报, 2015, 29(5): 97 [6] Wang J F, Bu C Y, He K, et al. Preparation of ultra-fine molybdenum-cooper composite powders and fine-grained molybdenum copper alloys. Powder Metall Technol, 2021, 39(1): 24 doi: 10.19591/j.cnki.cn11-1974/tf.2020040008王敬飞, 卜春阳, 何凯, 等. 超细钼铜复合粉体及细晶钼铜合金的制备. 粉末冶金技术, 2021, 39(1): 24 doi: 10.19591/j.cnki.cn11-1974/tf.2020040008 [7] Hou H T, Li D X, Li K, et al. Preparation and densification of Mo-Cu alloy. Powder Metall Ind, 2009, 19(5): 12侯海涛, 李笃信, 李昆, 等. Mo–Cu合金制备及其致密化行为研究. 粉末冶金工业, 2009, 19(5): 12 [8] Song P, Liu G H, Xiong N, et al. Preparation and properties of CPC electronic packaging materials. Powder Metall Technol, 2016, 34(6): 403宋鹏, 刘国辉, 熊宁, 等. 电子封装CPC复合材料的制备及其性能研究. 粉末冶金技术, 2016, 34(6): 403 [9] Lei H, Cui S, Zhou Z L, et al. Research and development of Cu/Mo/Cu laminated composite material. Powder Metall Technol, 2011, 29(3): 218雷虎, 崔舜, 周增林, 等. Cu/Mo/Cu平面层状复合材料的研究进展. 粉末冶金技术, 2011, 29(3): 218 [10] Li M J, Ma Y, Gao J, et al. Research progress of diamond/Cu composites for thermal management. China Surf Eng, 2022, 35(4): 140李明君, 马永, 高洁, 等. 高导热金刚石/铜复合材料研究进展. 中国表面工程, 2022, 35(4): 140 [11] Zhang M, Wang C X, Niu T, et al. Application of diamond/Al in microwave power modules. Electro-Mech Eng, 2020, 36(4): 53张眯, 王从香, 牛通, 等. 金刚石/铝在微波功率组件中的应用研究. 电子机械工程, 2020, 36(4): 53 [12] Zhang S Y, He P, Shao J H, et al. Research status and challenges of simulation technology in electronic packaging. Microelectron Comput, 2023, 40(1): 75 doi: 10.19304/J.ISSN1000-7180.2022.0563张墅野, 何鹏, 邵建航, 等. 电子封装领域的仿真研究现状及挑战. 微电子学与计算机, 2023, 40(1): 75 doi: 10.19304/J.ISSN1000-7180.2022.0563 [13] Wei H G, Huang C H, Liang Y, et al. Reliability analysis of plastic ball grid array double-bump lead-free solder joints under thermal cycle. Trans China Weld Inst, 2013, 34(10): 91韦何耕, 黄春跃, 梁颖, 等. 热循环加载条件下PBGA叠层无铅焊点可靠性分析. 焊接学报, 2013, 34(10): 91 [14] Lin J, Lei Y P, Zhao H Y, et al. Thermal fatigue crack growth of solder joint in electronic circuit. J Mech Eng, 2010, 46(6): 120 doi: 10.3901/JME.2010.06.120林健, 雷永平, 赵海燕, 等. 电子电路中焊点的热疲劳裂纹扩展规律. 机械工程学报, 2010, 46(6): 120 doi: 10.3901/JME.2010.06.120 [15] Yi Z W. Life prediction of PCB under thermal cycling and random vibration loading condition. Electron Compon Mater, 2019, 38(1): 89宜紫薇. 热循环与随机振动加载下电路板的寿命预测. 电子元件与材料, 2019, 38(1): 89 [16] Liu J N, Wang J Y, Wang Y B. Fatigue life prediction of electronic packaging structures under thermal cyclic loading. Electron Compon Mater, 2021, 41(9): 987刘江南, 王俊勇, 王玉斌. 热循环加载下电子封装结构的疲劳寿命预测. 电子元件与材料, 2021, 41(9): 987 -

下载:

下载: