-

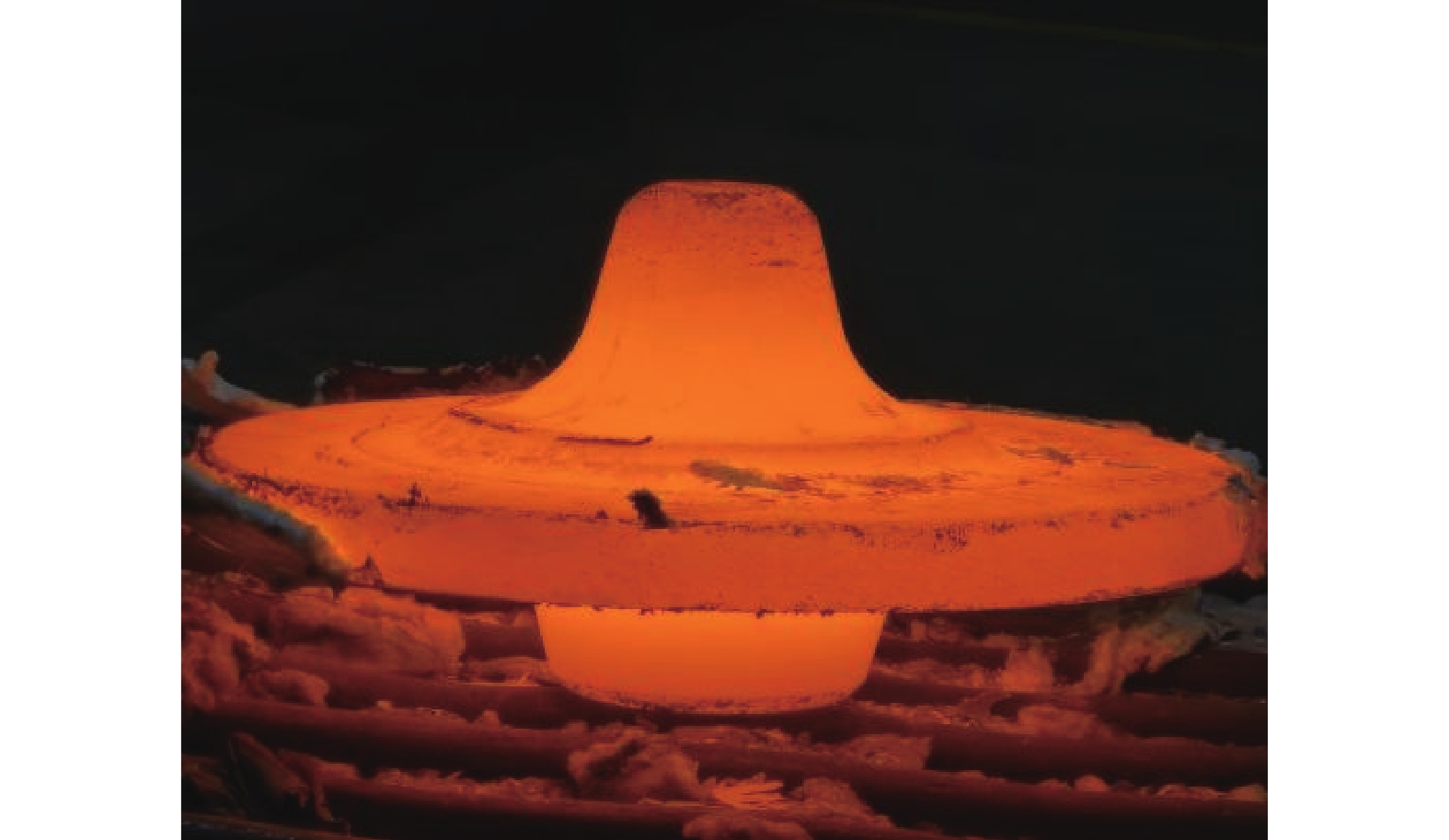

摘要: 以新型镍基粉末高温合金FGH4113A(WZ-A3)为研究对象,采用“真空感应熔炼+氩气雾化制粉+热等静压+热挤压+等温锻造”工艺路线制备全尺寸涡轮盘,系统研究了锻造态FGH4113A合金在不同热处理状态下的微观组织和力学性能。结果表明:FGH4113A合金全尺寸涡轮盘宏观形貌良好,微观晶粒组织细小均匀;经亚固溶热处理后,平均晶粒度ASTM 11~13级,室温和550 ℃的屈服强度分别为1249和1185 MPa,抗拉强度分别为1674和1656 MPa,断后伸长率分别为23.5%和19.5%,在温度700 ℃,应变范围0~0.8%,加载频率0.33 Hz条件下的疲劳寿命均值为35000周次;经过固溶热处理后,平均晶粒度ASTM 6~8级,700和800 ℃的屈服强度分别为1063和966 MPa,抗拉强度分别为1403和1112 MPa,断后伸长率分别为17.5%和12.0%,在温度800 ℃,应力330 MPa,蠕变伸长量0.2%条件下的蠕变寿命均值为384 h,在温度700 ℃,应力强度因子范围30 MPa·m0.5条件下的裂纹扩展速率小于5×10−4 mm·cycle−1。Abstract: A novel nickel-based powder metallurgy superalloy FGH4113A (WZ-A3) was used to manufacture the full-size turbine disks by the process route of “vacuum induction melting + argon atomization + hot isostatic pressing + hot extrusion + isothermal forging”. The microstructure and mechanical properties of the forged FGH4113A alloys under the different heat treatment conditions were systematically studied. The results show that, the full-size turbine disks prepared by FGH4113A alloy have the good macro morphology and homogeneous grain structure. After the subsolvus heat treatment, the average grain size is ASTM 11~13, the yield strength at room temperature and 550 ℃ are 1249 and 1185 MPa, the tensile strength are 1674 and 1656 MPa, and the elongation after fracture are 23.5% and 19.5%, respectively. The mean fatigue life under the conditions of temperature 700 ℃, strain range 0~0.8% and loading frequency 0.33 Hz is 35000 cycles. After the supersolvus heat treatment, the average grain size is ASTM 6~8, the yield strength at 700 ℃ and 800 ℃ are 1063 and 966 MPa, the tensile strength are 1403 and 1112 MPa, and the elongation after fracture are 17.5% and 12.0%, respectively. The mean creep life under the conditions of temperature 800 ℃, stress 330 MPa and creep elongation 0.2% is 384 h. The crack propagation rate under the conditions of temperature 700 ℃ and stress intensity factor range 30 MPa·m0.5 is less than 5×10−4 mm·cycle−1.

-

表 1 FGH4113A及几种典型镍基粉末高温合金的名义化学成分[9–13](质量分数)

Table 1. Chemical composition of FGH4113A and the several typical Ni-based PM superalloys[9–13]

% 合金 Co Cr Mo W Al Ti Nb Ta Hf、Zr、B、C Ni FGH4113A 19.0 13.0 4.0 4.0 3.0 3.7 1.2 1.0 微量 余量 RR1000 18.5 15.0 5.0 — 3.0 3.6 — 1.9 微量 余量 René104 (ME3) 20.7 12.8 3.8 2.0 3.4 3.7 0.9 2.3 微量 余量 LSHR 20.4 12.5 2.7 4.3 3.5 3.5 1.5 1.6 微量 余量 FGH98 20.4 12.7 3.8 2.1 3.5 3.7 0.9 2.4 微量 余量 FGH99 20.0 13.0 2.7 4.3 3.6 3.5 1.5 1.6 微量 余量 ME501 18.0 12.0 2.9 3.0 3.0 3.0 1.5 4.8 微量 余量 Alloy A 23.4 13.6 3.0 1.6 2.9 4.0 — 3.8 微量 余量 Alloy B 23.3 13.5 3.0 1.6 2.9 4.0 1.6 3.7 微量 余量 TSNA-1 19.0 10.9 2.6 4.5 2.9 3.0 1.4 5.0 微量 余量 -

[1] Zhang G Q, Zhang Y W, Zheng L, et al. Research progress in powder metallurgy superalloys and manufacturing technologies for aero-engine application. Acta Metall Sinica, 2019, 55(9): 1133 doi: 10.11900/0412.1961.2019.00119张国庆, 张义文, 郑亮, 等. 航空发动机用粉末高温合金及制备技术研究进展. 金属学报, 2019, 55(9): 1133 doi: 10.11900/0412.1961.2019.00119 [2] Reed R C. The Superalloys: Fundamentals and Applications. London: Cambridge University Press, 2008 [3] Fu H, Wang M Y, Ji Z, et al. Effect of thermal deformation on prior particle boundary of FGH96 superalloy. Powder Metall Technol, 2018, 36(3): 201 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.007傅豪, 王梦雅, 纪箴, 等. 热变形对FGH96高温合金原始颗粒边界的影响. 粉末冶金技术, 2018, 36(3): 201 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.007 [4] Zhang Q, Zheng L, Xu W Y, et al. Research progress on argon atomized nickel-based powder metallurgy superalloys and powder characteristics. Powder Metall Technol, 2022, 40(5): 387张强, 郑亮, 许文勇, 等. 氩气雾化镍基粉末高温合金及粉末特性研究进展. 粉末冶金技术, 2022, 40(5): 387 [5] Qiu C L, Wu X H, Mei J F, et al. Influence of heat treatment on microstructure and tensile behavior of a hot isostatically pressed nickel-based superalloy. J Alloys Compd, 2013, 578: 454 doi: 10.1016/j.jallcom.2013.06.045 [6] Huang H L. Research on Related Fundamental Issues of Preparation and Property Characterization of Advanced PM Superalloy FGH98 [Dissertation]. Beijing: University of Science and Technology Beijing, 2020黄海亮. 先进PM高温合金FGH98合金制备和性能表征相关基础问题的研究[学位论文]. 北京: 北京科技大学, 2020 [7] Chen J Y, Xiong J Y, Liu C F, et al. Sub-solvus heat treatment study on the γ' distribution of novel nickel-based superalloy. Rare Met Mater Eng, 2023, 52(2): 699 doi: 10.12442/j.issn.1002-185X.20220067程俊义, 熊江英, 刘朝峰, 等. 一种新型第三代镍基粉末高温合金亚固溶热处理调控γ'相分布的研究. 稀有金属材料与工程, 2023, 52(2): 699 doi: 10.12442/j.issn.1002-185X.20220067 [8] Chen J Y, Zhu L H, Ma X D, et al. Super-solvus heat treatment study of novel nickel-based superalloy. Rare Met Mater Eng, 2022, 51(10): 3722程俊义, 朱立华, 马向东, 等. 一种新型镍基粉末高温合金的过固溶热处理研究. 稀有金属材料与工程, 2022, 51(10): 3722 [9] Ma X D, He Y J, Li Y, et al. Superplastic deformation behavior of nickel-based powder superalloy during isothermal hot compression. Rare Met Mater Eng, 2022, 51(9): 3307马向东, 何英杰, 李远, 等. 一种新型镍基粉末高温合金等温热压缩过程中的超塑性变形行为研究. 稀有金属材料与工程, 2022, 51(9): 3307 [10] Yang J L, Ma X D, Li Y, et al. Thermal deformation behavior of novel ni-based PM superalloy under different initial conditions. Rare Met Mater Eng, 2022, 51(2): 651杨金龙, 马向东, 李远, 等. 一种新型镍基粉末高温合金不同状态热变形行为. 稀有金属材料与工程, 2022, 51(2): 651 [11] Gabb T P, Telesman J, Kantzos P T, et al. Characterization of the temperature capabilities of advanced disk alloy ME3. NASA/TM, 2002: 211796 [12] Gabb T P, Gayda J, Kantzos P T, et al. Thermal and mechanical property characterization of the advanced disk alloy LSHR. NASA/TM, 2005: 213645 [13] Huang H L, Liu G Q, Wang H, et al. Effect of cooling rate and resulting microstructure on tensile properties and deformation mechanisms of an advanced PM nickel-based superalloy. J Alloys Compd, 2019, 805: 1254 doi: 10.1016/j.jallcom.2019.07.221 [14] Gayda J, Furrer D. Dual-micro structure heat treatment. Adv Mater Processes, 2003, 161(7): 36 [15] Mitchell R J, Lemsky J A, Ramanathan R, et al. Process development and microstructure and mechanical property evaluation of a dual microstructure heat treated advanced nickel disc alloy // Superalloys 2008. Champion, 2008: 347 [16] Guo J T. Materials Science and Engineering for Superalloys. Beijing: Science Press, 2008郭建亭. 高温合金材料学. 北京: 科学出版社, 2008 [17] Mcdowell D L. Viscoplasticity of heterogeneous metallic materials. Mater Sci Eng R, 2008, 62(3): 67 doi: 10.1016/j.mser.2008.04.003 [18] Jiang R, Song Y D, Reed P A. Fatigue crack growth mechanisms in powder metallurgy Ni-based superalloys—A review. Int J Fatigue, 2020, 141: 105887 doi: 10.1016/j.ijfatigue.2020.105887 [19] Bache M R, O’Hanlon J, Child D J, et al. High temperature fatigue behaviour in an advanced nickel based superalloy: The effects of oxidation and stress relaxation at notches. Theor Appl Fract Mech, 2016, 84: 64 doi: 10.1016/j.tafmec.2016.03.007 [20] Jiang R, Zhang L C, Zhang W T, et al. Low cycle fatigue and stress relaxation behaviours of powder metallurgy Ni-based superalloy FGH4098. Mater Sci Eng A, 2021, 87: 141421 [21] Liu L Z, Gao Y F, Wu X H, et al. High-temperature fatigue crack growth behaviour of GH4169 alloys with different heat treatment methods. Int J Fatigue, 2022, 236(2): 161 -

下载:

下载: