-

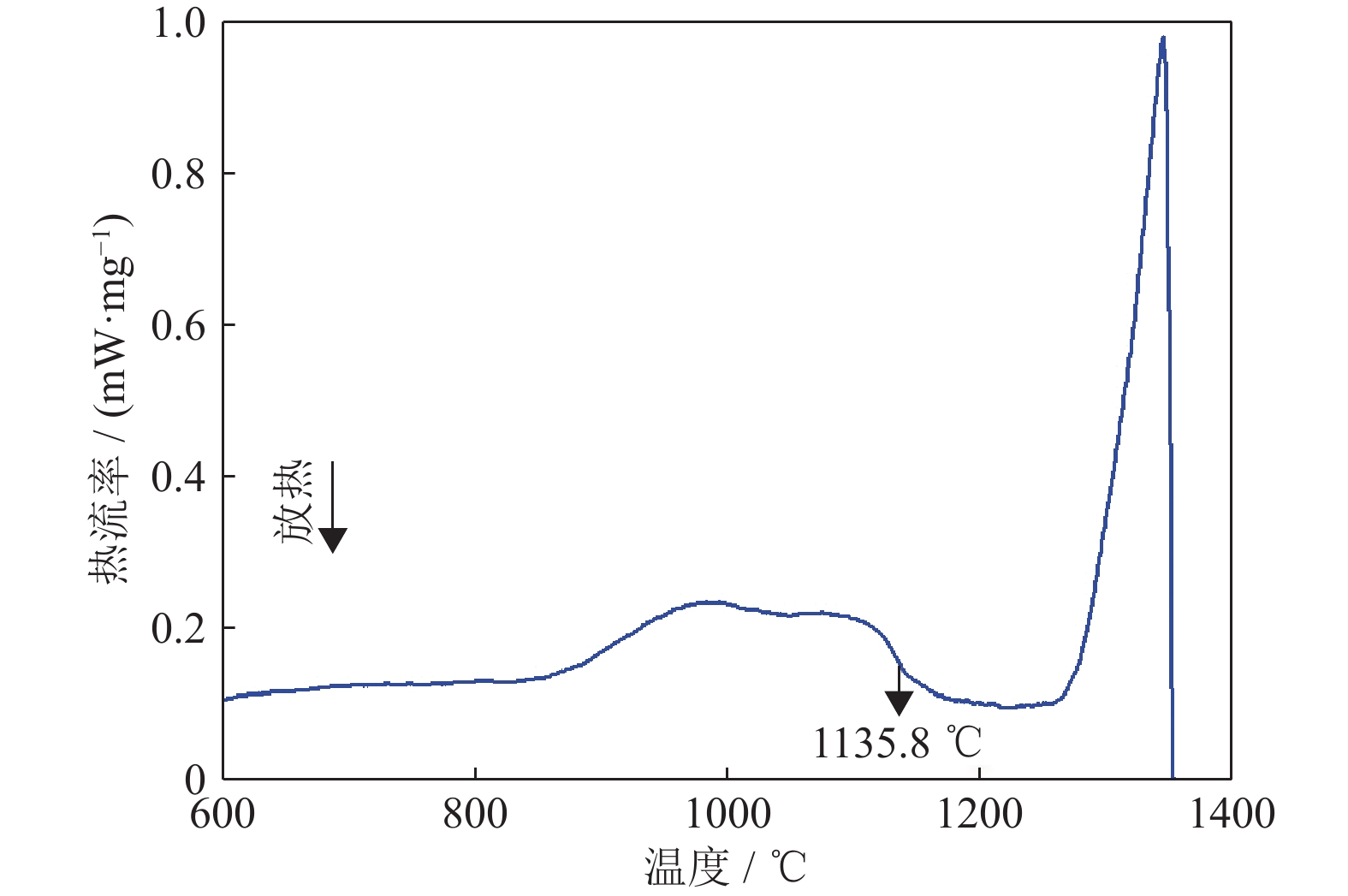

摘要: 通过热处理实验研究了热处理过程中FGH96合金的微观组织演化,量化了固溶温度和保温时间对晶粒尺寸、γ′相尺寸、面积分数及晶粒分布的影响,分析了γ′相和应变存储能对晶粒演变的影响。结果表明:在热处理过程中,含有大量应变存储能的变形晶粒发生静态再结晶,晶粒细化,而动态再结晶晶粒发生晶粒长大,当两者平衡时可获得均匀细小的晶粒组织。合金在1060 ℃保温120 min后,γ′相尺寸和晶粒尺寸分布较为均匀,平均晶粒尺寸为7.37 μm。γ′相的面积分数随固溶温度和保温时间的增加而减小,一次γ′相在亚固溶保温过程中存在粗化和分裂现象,使得一次γ′相的面积分数和尺寸先增加后减小。γ′相的非均匀溶解会导致局部晶粒长大较快,形成混晶。Abstract: The microstructure evolution of FGH96 alloys during the heat treatment was studied. The effects of solution temperature and holding time on the grain size, γ′ precipitate size, area fraction, and grain distribution were quantified. The influences of γ′ precipitate and strain storage energy on the grain evolution were analyzed. The results show that, the deformed grains containing a large amount of strain storage energy during heat treatment undergo the static recrystallization and refine the grains, while the dynamic recrystallization grains grow. The uniform fine grain structure can be obtained as the two processes are balanced. After the alloy is held at1060 ℃ for 120 min, the distribution of γ′ precipitate size and grain size are more uniform, and the average grain size is 7.37 μm. The area fraction of the γ′ precipitate decreases with the increase of solution temperature and holding time, while the coarsening and splitting of the primary γ′ precipitate during the subsolvus solution make the area fraction and size of the primary γ′ precipitate increase first and then decrease. The inhomogeneous dissolution of γ′ precipitate leads to the rapid growth of the local grains, forming the mixed crystals.

-

Key words:

- FGH96 alloys /

- microstructure /

- heat treatment /

- static recrystallization /

- γ′ precipitate

-

图 8 FGH96合金晶界分布:(a)1060 ℃,30 min;(b)1060 ℃,120 min;(c)1090 ℃,30 min;(d)1090 ℃,120 min;(e)1160 ℃,30 min;(f)1160 ℃,120 min

Figure 8. Grain boundary distribution of the FGH96 alloys: (a) 1060 ℃, 30 min; (b) 1060 ℃, 120 min; (c) 1090 ℃, 30 min; (d) 1090 ℃, 120 min; (e) 1160 ℃, 30 min; (f) 1160 ℃, 120 min

表 1 FGH96合金主要化学成分(质量分数)

Table 1. Chemical composition of the FGH96 alloys

% Co Cr Mo W Al Ti Nb Fe Ni 13.01 15.90 4.13 4.02 2.16 3.81 0.71 0.03 余量 -

[1] Osada T, Gu Y F, Nagashima N, et al. Optimum microstructure combination for maximizing tensile strength in a polycrystalline superalloy with a two-phase structure. Acta Mater, 2013, 61(5): 1820 doi: 10.1016/j.actamat.2012.12.004 [2] Reed R C. The Superalloys: Fundamentals and Applications. Cambridge: Cambridge University Press, 2008 [3] Liu G X, Wang X F, Yang J, et al. Effect of local interference on the surface microstructure of FGH96 alloys in quenching process. Powder Metall Technol, 2023, 41(2): 143刘光旭, 王晓峰, 杨杰, 等. 淬火处理过程中的局部干涉对FGH96合金表面组织的影响. 粉末冶金技术, 2023, 41(2): 143 [4] Liu J T, Zhang Y W, Tao Y, et al. Grain growth behavior of FGH96 alloy forging disc during heat treatment. Heat Treat Met, 2006, 31(6): 40 doi: 10.3969/j.issn.0254-6051.2006.06.011刘建涛, 张义文, 陶宇, 等. FGH96合金锻造盘坯热处理过程中的晶粒长大行为. 金属热处理, 2006, 31(6): 40 doi: 10.3969/j.issn.0254-6051.2006.06.011 [5] Wan Z P, Wang T, Li Z, et al. Influence of grain boundary primary γ′ precipitates on grain growth behavior of GH4720Li superalloy. Trans Mater Heat Treat, 2020, 41(8): 173 doi: 10.13289/j.issn.1009-6264.2020-0069万志鹏, 王涛, 李钊, 等. 晶界一次γ′相对GH4720Li合金晶粒长大行为的影响. 材料热处理学报, 2020, 41(8): 173 doi: 10.13289/j.issn.1009-6264.2020-0069 [6] Semiatin S L, Shank J M, Shiveley A R, et al. The effect of forging variables on the supersolvus heat-treatment response of powder-metallurgy nickel-base superalloys. Metall Mater Trans A, 2014, 45: 6231 doi: 10.1007/s11661-014-2572-y [7] Wang G, Xu D S, Payton E J, et al. Mean-field statistical simulation of grain coarsening in the presence of stable and unstable pinning particles. Acta Mater, 2011, 59(11): 4587 doi: 10.1016/j.actamat.2011.04.004 [8] Charpagne M A, Franchet J M, Bozzolo N. Overgrown grains appearing during sub-solvus heat treatment in a polycrystalline γ-γ' nickel-based superalloy. Mater Des, 2018, 144: 353 doi: 10.1016/j.matdes.2018.02.048 [9] Hou Q, Tao Y, Jia J. Grain refinement Mechanism in multi-fire isothermal Forging of novel powder superalloys. Chin J Eng, 2019, 41(2): 209侯琼, 陶宇, 贾建. 新型粉末高温合金多火次等温锻造过程中晶粒细化机制. 工程科学学报, 2019, 41(2): 209 [10] Huang H L, Liu G Q, Wang H, et al. Dissolution behavior and kinetics of γ′ phase during solution treatment in powder metallurgy nickel-based superalloy. Metall Mater Trans A, 2020, 51(3): 1075 doi: 10.1007/s11661-019-05581-7 [11] Umantsev A, Olson G B. Ostwald ripening in multicomponent alloys. Scr Metall Mater, 1993, 29(8): 1135 doi: 10.1016/0956-716X(93)90191-T [12] Philippe T, Voorhees P W. Ostwald ripening in multicomponent alloys. Acta Mater, 2013, 61(11): 4237 doi: 10.1016/j.actamat.2013.03.049 [13] Kim K, Voorhees P W. Ostwald ripening of spheroidal particles in multicomponent alloys. Acta Mater, 2018, 152: 327 doi: 10.1016/j.actamat.2018.04.041 [14] Masoumi F, Jahazi M, Shahriari D, et al. Coarsening and dissolution of γʹ precipitates during solution treatment of AD730TM Ni-based superalloy: Mechanisms and kinetics model. J Alloys Compd, 2016, 658: 981 doi: 10.1016/j.jallcom.2015.11.002 [15] Randle V. Mechanism of twinning-induced grain boundary engineering in low stacking-fault energy materials. Acta Mater, 1999, 47: 4187 doi: 10.1016/S1359-6454(99)00277-3 [16] Semiatin S L, Mcclary K E, Rollett A D, et al. Microstructure evolution during supersolvus heat treatment of a powder metallurgy nickel-base superalloy. Metall Mater Trans A, 2012, 43(5): 1649 doi: 10.1007/s11661-011-1035-y -

下载:

下载: