In-situ observation of short crack growth behavior for powder superalloys with different gradient grain microstructures

-

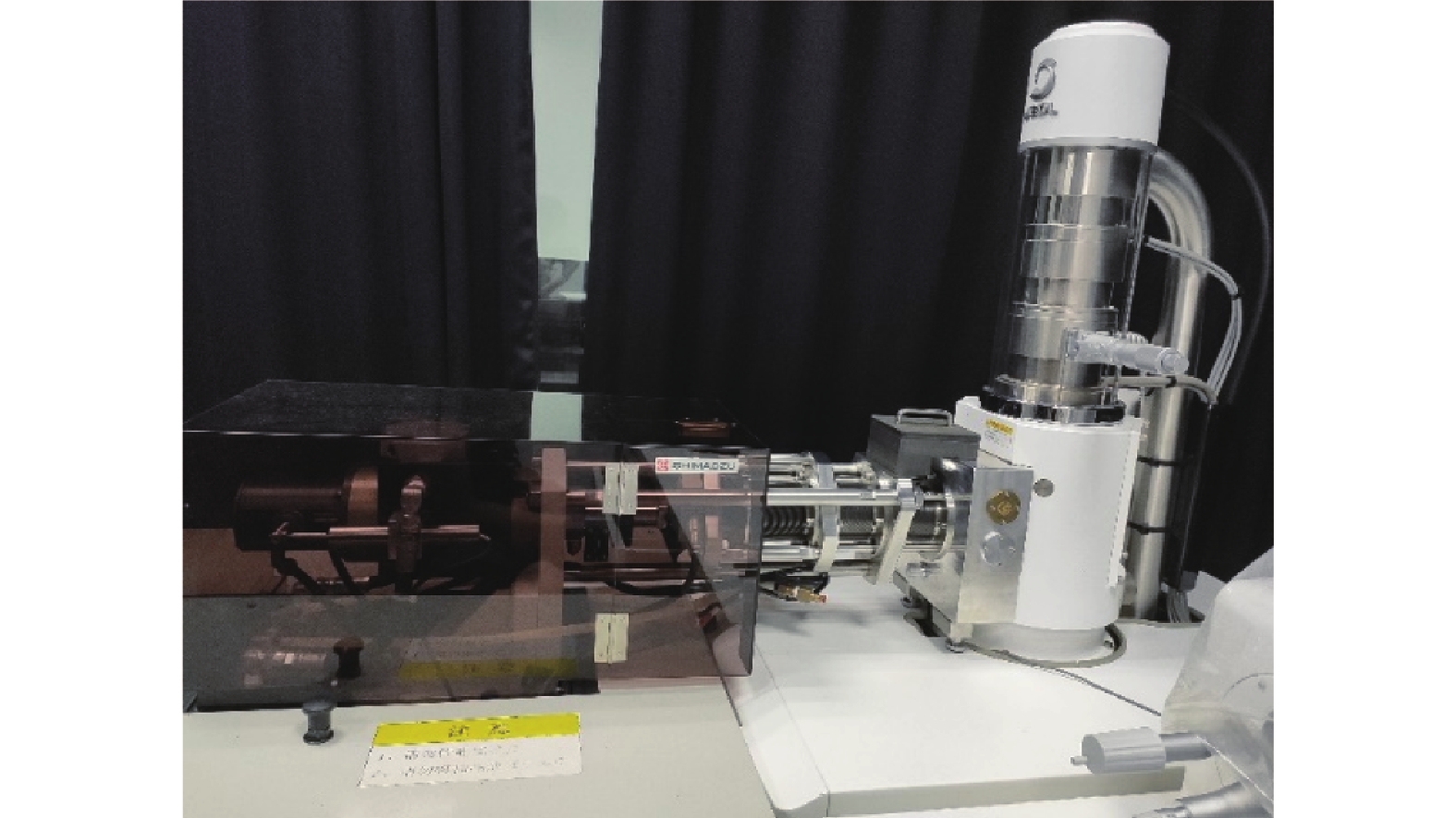

摘要: 采用扫描电子显微镜原位观察的方法对某第三代粉末高温合金不同微观组织的疲劳裂纹萌生和小裂纹扩展行为进行了研究,揭示了双性能粉末涡轮盘轮缘(粗晶组织)、轮心(细晶组织)及晶粒过渡区(梯度结构组织)的微观组织对疲劳小裂纹扩展的影响规律。结果表明:缺口处的一次强化相易成为裂纹萌生位置,其中梯度结构组织呈现出从晶界处开裂的多裂纹萌生特征。对于梯度结构试样,室温下的小裂纹扩展行为受微观结构影响显著,疲劳裂纹扩展速率波动较大。在应力强度因子范围较低时,粗晶试样的裂纹扩展速率高于细晶;随着应力强度因子范围逐渐增大,细晶试样的疲劳裂纹扩展速率增加更快,并高于粗晶试样;这与较长的滑移路径、增强的滑移可逆性和较少的晶界阻碍、减弱的不连续度之间的竞争机制相关。Abstract: The fatigue crack initiation and short crack propagation behavior of a 3rd generation powder superalloy with the different microstructures were studied by in-situ scanning electron microscope (SEM) observation. The effects of microstructures at the wheel rim (coarse grain structure), wheel centre (fine grain structure), and grain transition zone (gradient grain tructure) of the dual performance powder turbine disk on the fatigue short crack propagation were investigated. The results show that, the crack prefers to nucleate from the first hardening phase at the notch. The gradient microstructure exhibits the multiple cracking at the grain boundaries. For the specimens with the gradient microstructure, the short crack growth behavior at room temperature is significantly affected by the microstructures, and the fatigue crack growth rate shows the large fluctuation. At the lower stress intensity factor range, the crack propagation rate of the coarse grains is higher than that of the fine grains. With the increase of stress intensity factor range, the crack propagation rate of the fine grains is increased faster and finally higher than that of the coarse grains, which mainly attributes to the competition mechanism of the long slip path, the enhanced slip reversibility, the few grain boundary barriers, and the reduced discontinuity.

-

Key words:

- powder superalloys /

- in-situ observation /

- short fatigue crack /

- grain size /

- gradient microstructure

-

表 1 实验用粉末镍基高温合金名义成分(质量分数)

Table 1. Chemical composition of the tested nickel-based powder metallurgy superalloys

% Cr Co Mo Ti Al Ta W Nb C Ni 11.00~14.00 18.00~22.00 3.00~4.00 3.00~4.00 3.00~4.00 2.00~4.00 2.00~3.00 0.70~1.20 0.04~0.07 余量 表 2 试样信息及试验条件

Table 2. Specimen information and the testing conditions

材料 试样编号 加载波形(频率) 温度 / ℃ 试样厚度 / mm 试验载荷 / N 粗晶结构组织(CG) CG 1 正弦波(5 Hz) 650 0.96 2400 CG 2 正弦波(5 Hz) 650 0.97 2500 细晶结构组织(FG) FG 1 正弦波(5 Hz) 650 0.95 2100 FG 2 正弦波(5 Hz) 650 0.96 2250 梯度结构组织(GS) GS 1 正弦波(5 Hz) 室温 0.97 2800 GS 2 正弦波(5 Hz) 650 0.96 2250 GS 3 正弦波(5 Hz) 650 0.92 1950 表 3 疲劳裂纹扩展数据

Table 3. Data of the fatigue crack growth

试样编号 首次观测到裂纹时的

裂纹长度 / μm裂纹总长度 /

μm扩展循环数 CG 1 5.781 121.600 4051 CG 2 48.188 143.924 1080 FG 1 56.625 150.000 500 FG 2 0.924 105.375 2700 GS 1 3.625 60.000 23500 GS 2 — — 1400 GS 3 — — 10200 -

[1] Zhang Q, Zheng L, Xu W Y, et al. Research progress on argon atomized nickel-based powder metallurgy superalloys and powder characteristics. Powder Metall Technol, 2022, 40(5): 387张强, 郑亮, 许文勇, 等. 氩气雾化镍基粉末高温合金及粉末特性研究进展. 粉末冶金技术, 2022, 40(5): 387 [2] Tian G F, Chen Y, Wang Y. Research on microstructure characterization in residual dendrite zones of FGH96 alloy with gradient microstructure. Powder Metall Technol, 2018, 36(6): 403田高峰, 陈阳, 汪煜. 梯度组织FGH96合金残余枝晶区的组织特征研究. 粉末冶金技术, 2018, 36(6): 403 [3] Liu G X, Wang X F, Yang J, et al. Effect of heat treatment on microstructure evolution and mechanical properties of P/M Ni-based superalloy at diffusion bonding interface. Powder Metall Technol, 2022, 40(3): 218刘光旭, 王晓峰, 杨杰, 等. 热处理对镍基粉末高温合金扩散连接界面组织演变及性能的影响. 粉末冶金技术, 2022, 40(3): 218 [4] Luo X J, Wang J, Zhao W, et al. Research on diffusion bonding of FGH91 powder metallurgy superalloy and K418B casted blade by hot isostatic pressing. Powder Metall Technol, 2021, 39(4): 291 doi: 10.19591/j.cnki.cn11-1974/tf.2021010002罗学军, 王珏, 赵巍, 等. FGH91粉末高温合金与K418B铸造叶环热等静压扩散连接研究. 粉末冶金技术, 2021, 39(4): 291 doi: 10.19591/j.cnki.cn11-1974/tf.2021010002 [5] Miao J, Pollock T M, Wayne J J. Crystallographic fatigue crack initiation in nickel-based superalloy René 88DT at elevated temperature. Acta Mater, 2009, 57(20): 5964 doi: 10.1016/j.actamat.2009.08.022 [6] Pang H T, Reed P A S. Effects of microstructure on room temperature fatigue crack initiation and short crack propagation in Udimet 720Li Ni-base superalloy. Int J Fatigue, 2008, 30(10): 2009 [7] Jiang R, Song Y D, Reed P A S. Fatigue crack growth mechanisms in powder metallurgy Ni-based superalloys—A review. Int J Fatigue, 2020, 141: 105887 doi: 10.1016/j.ijfatigue.2020.105887 [8] Pineau A, Mcdowell D L, Busso E P, et al. Failure of metals II: Fatigue. Acta Mater, 2016, 107: 484 doi: 10.1016/j.actamat.2015.05.050 [9] Gao Y, Stölken J S, Kumar M, et al. High-cycle fatigue of nickel-base superalloy René 104 (ME3): Interaction of microstructurally small cracks with grain boundaries of known character. Acta Mater, 2007, 55(9): 3155 doi: 10.1016/j.actamat.2007.01.033 [10] Jiang R, Proprentner D, Callisti M, et al. Role of oxygen in enhanced fatigue cracking in a PM Ni-based superalloy: Stress assisted grain boundary oxidation or dynamic embrittlment? Corros Sci, 2018, 139: 141 doi: 10.1016/j.corsci.2018.05.001 [11] Kitaguchi H S, Li H Y, Evans H E, et al. Oxidation ahead of a crack tip in an advanced Ni-based superalloy. Acta Mater, 2013, 61(6): 1968 doi: 10.1016/j.actamat.2012.12.017 [12] Pang H T, Reed P A S. Microstructure effects on high temperature fatigue crack initiation and short crack growth in turbine disc nickel-base superalloy Udimet 720Li. Mater Sci Eng A, 2007, 448(1): 67 [13] Zhang L C, Jiang R, Wang Y C, et al. Effects of microstructure and temperature on short fatigue crack propagation behaviour of powder metallurgy superalloy FGH4098 in vacuum. Mater Sci Eng A, 2022, 852: 143637 doi: 10.1016/j.msea.2022.143637 [14] Zhang D G. Crack Propagation Mechanism and Model of a Nickel-base Powder Superalloy [Dissertation]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019张冬阁. 某镍基粉末高温合金裂纹扩展机理与模型研究[学位论文]. 南京: 南京航空航天大学, 2019 [15] Wan Y W, Zhou B, Hu X T, et al. High temperature fatigue crack growth behavior and model of a nickel-based powder metallurgy superalloy. J Propul Technol, 2023, 44(2): 262万煜玮, 周斌, 胡绪腾, 等. 某镍基粉末合金高温疲劳裂纹扩展行为与模型研究. 推进技术, 2023, 44(2): 262 [16] Ma W B, Liu G Q, Hu B F, et al. Effect of Hf on carbides of FGH4096 superalloy produced by hot isostatic pressing. Mater Sci Eng A, 2013, 587: 313 doi: 10.1016/j.msea.2013.05.015 [17] Kim D, Jiang R, Evangelou A, et al. Effects of γʹ size and carbide distribution on fatigue crack growth mechanisms at 650°C in an advanced Ni-based superalloy. Int J Fatigue, 2021, 145: 106086 doi: 10.1016/j.ijfatigue.2020.106086 [18] Jiang R, Karpasitis N, Gao N, et al. Effects of microstructures on fatigue crack initiation and short crack propagation at room temperature in an advanced disc superalloy. Mater Sci Eng A, 2015, 641: 148 doi: 10.1016/j.msea.2015.05.065 [19] Lu Y W, Lupton C, Zhu M L, et al. In situ experimental study of near-tip strain evolution of fatigue cracks. Exp Mech, 2015, 55(6): 1175 doi: 10.1007/s11340-015-0014-4 -

下载:

下载: