-

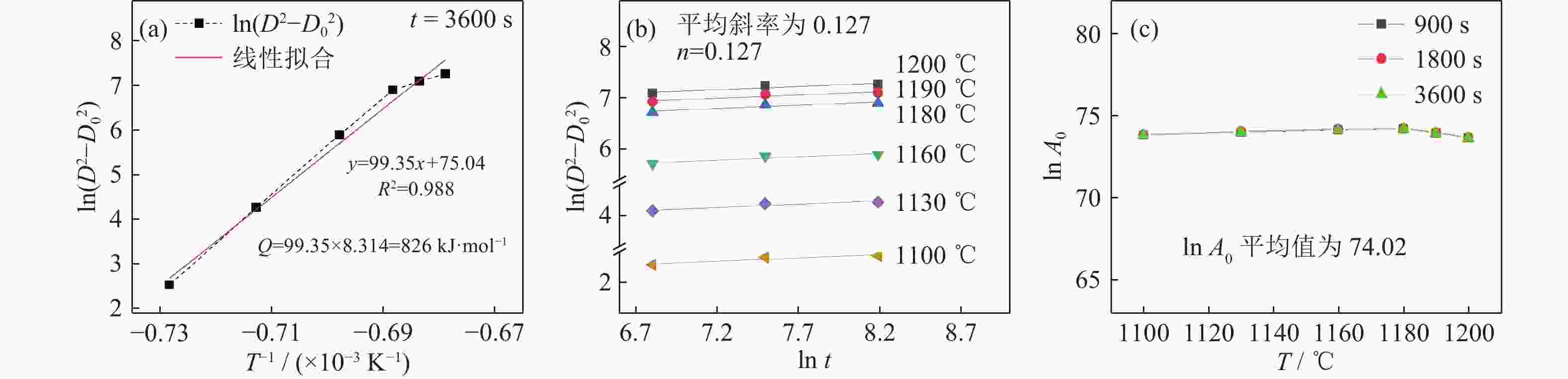

摘要: 对第四代粉末高温合金FGH4108晶粒长大行为进行研究。结果表明,γ′相在完全溶解温度以下固溶处理时,晶粒长大幅度较小,与初始组织差别不大(锻态,3~4 μm);当达到γ′相完全溶解温度时,晶粒发生明显长大;超过γ′相完全溶解温度时,晶粒尺寸大幅增加(30~40 μm),过固溶的几个温度下晶粒尺寸差别不大;保温初期晶粒尺寸显著增加,一定保温时间后晶粒尺寸不再随时间明显变化。温度和时间对晶粒尺寸的影响都与γ′相对晶界迁移的阻碍作用有关,根据温度和时间的影响,对传统晶粒长大模型中界面迁移的表观激活能(Q)、时间指数(n)和广义迁移率常数(A0)进行修正,构建了新的模型,模型预测值与实验值的决定系数(R2)为0.9997,均方误差为0.12 μm,预测精度较高,晶粒长大曲线各项特征能被准确预测出来。Abstract: The grain growth behavior of the fourth generation powder metallurgy (PM) superalloys was studied. The results indicate that the grain growth range is small when the heat treatment temperature is below the γ′ solution temperature, which is similar to the initial microstructure (as-forged, 3~4 μm). However, the grain size greatly increases to 30~40 μm when the heat treatment temperature exceeds the γ′ solution temperature, and there is little difference in grain size at the several temperatures over the γ′ solution temperature. The grain size increases significantly at the initial stage of heat treatment, and no longer changes after a certain holding time. The influence of temperature and time on grain size is related to the pinning effect of γ′ on grain boundary migration. A new model is established by modifying the parameters such as the activation energy for boundary migration (Q), the time exponent (n), and the generalized mobility constant (A0) based on the traditional grain growth model. The determination coefficient (R2) and the mean-square error (MSE) between the predicted and the experimental values are 0.9997 and 0.12 μm, respectively, showing the high prediction accuracy, and the various characteristics of the grain growth curves can also be predicted accurately.

-

Key words:

- powder metallurgy superalloys /

- solution heat treatment /

- grain growth /

- prediction model

-

图 2 不同温度下平均晶粒尺寸随时间变化曲线和对应显微组织:(a)晶粒尺寸随时间变化曲线;(b)、(c)1190 ℃显微组织;(d)、(e)1160 ℃显微组织;(f),(g)1100 ℃显微组织

Figure 2. Grain growth curves at different temperatures and the corresponding microstructures: (a) grain growth curves at different temperatures; (b), (c) SEM images at 1190 ℃; (d), (e) SEM images at 1160 ℃; (f), (g) SEM images at 1100 ℃

表 1 式(3)参数拟合结果

Table 1. Fitting results of parameters in Eq.(3)

Q1 / (kJ·mol−1) Q2 / (kJ·mol−1) T0 / ℃ ΔT / ℃ 914 293 1170 4.2 表 2 各温度下的γ′相体积分数和尺寸数据

Table 2. γ′ phase volume fraction and size at various temperatures

T / ℃ r / μm φ (φ·r−1) / μm−1 1200 0 0 — 1190 0 0 — 1180 0.15142 0.00101 0.00667 1160 0.55211 0.05112 0.09259 1130 1.01630 0.09915 0.09756 1100 1.91278 0.20154 0.10013 表 3 式(4)参数拟合结果

Table 3. Fitting results of parameters in Eq.(4)

n0 nA t1 / s 7×10−4 0.838 875 表 4 式(5)参数拟合结果

Table 4. Fitting results of parameters in Eq.(5)

lnA1′ lnA2′ T0 / ℃ ΔT / ℃ 83 31 1170 4.2 -

[1] Li X Y, Zhang H P, Bai J M, et al. The evolution of γ′ precipitates and hardness response of a novel PM Ni-based superalloy during thermal exposure. J Alloys Compd, 2023, 942: 168757 doi: 10.1016/j.jallcom.2023.168757 [2] Gabb T P, Kantzos P T, Telesman J, et al. Fatigue resistance of the grain size transition zone in a dual microstructure superalloy disk. Int J Fatigue, 2011, 33(3): 414 doi: 10.1016/j.ijfatigue.2010.09.022 [3] Thébaud L, Villechaise P, Crozet C, et al. Is there an optimal grain size for creep resistance in Ni-based disk superalloys? Mater Sci Eng A, 2018, 716: 274 [4] Zhang X Y, Chen Y, Cao L Y, et al. Microstructures and tensile properties of a grain-size gradient nickel-based superalloy. J Alloys Compd, 2023, 960: 170344 doi: 10.1016/j.jallcom.2023.170344 [5] Mourer D P, Williams J L. Dual heat treat process development for advanced disk applications // Superalloys 2004: Proceedings of the 10th International Symposium on Superalloys. Champion, 2004: 401 [6] Hyzak J M, Macintyre C A, Sundberg D V. Dual structure turbine disks via partial immersion heat treatment // Superalloys 1988: Proceedings of the Tenth International Symposium on Superalloys. Champion, 1988: 121 [7] Mitchell R J, Lemsky J A, Ramanathan R, et al. Process development and microstructure and mechanical property evaluation of a dual microstructure heat treated advanced nickel disc alloy // Superalloys 2008: Proceedings of the 11th International Symposium on Superalloys. Champion, 2008: 347 [8] Hu H, Rath B B. On the time exponent in isothermal grain growth. Metall Mater Trans B, 1970, 1(11): 3181 doi: 10.1007/BF03038435 [9] Beck P A, Holzworth M L, Hu H. Instantaneous rates of grain growth. Phys Rev, 1948, 73(5): 526 doi: 10.1103/PhysRev.73.526 [10] Holmes E L, Winegard W C. Grain growth in zone-refined tin. Acta Metall, 1959, 7(6): 411 doi: 10.1016/0001-6160(59)90051-3 [11] Song X Y, Liu G Q, Gu N J. Computer simulation of the influence of the second-phase particle size on grain growth. Acta Metall Sin, 1999, 35(6): 565宋晓艳, 刘国权, 谷南驹. 第二相粒子尺寸对基体晶粒长大影响的仿真研究. 金属学报, 1999, 35(6): 565 [12] Song K, Aindow M. Grain growth and particle pinning in a model Ni-based superalloy. Mater Sci Eng A, 2008, 479: 365 doi: 10.1016/j.msea.2007.09.055 [13] Andersen I, Grong Ø, Ryum N. Analytical modelling of grain growth in metals and alloys in the presence of growing and dissolving precipitates-II. Abnormal grain growth. Acta Metall Mater, 1995, 43(7): 2689 [14] Fu L M, Shan A D, Wang W. Effect of Nb solute drag and NbC precipitate pinning on the recrystallization grain growth in low carbon Nb-microalloyed steel. Acta Metall Sin, 2010, 46(7): 832 doi: 10.3724/SP.J.1037.2010.00832付立铭, 单爱党, 王巍. 低碳Nb微合金钢中Nb溶质拖曳和析出相NbC钉扎对再结晶晶粒长大的影响. 金属学报, 2010, 46(7): 832 doi: 10.3724/SP.J.1037.2010.00832 [15] Collins D M, Conduit B D, Stone H J, et al. Grain growth behaviour during near-γ′ solvus thermal exposures in a polycrystalline nickel-base superalloy. Acta Mater, 2013, 61(9): 3378 doi: 10.1016/j.actamat.2013.02.028 [16] Collins D M, Stone H J. A modelling approach to yield strength optimisation in a nickel-base superalloy. Int J Plast, 2014, 54: 96 doi: 10.1016/j.ijplas.2013.08.009 [17] Exner H E. Analysis of grain-and particle-size distributions in metallic materials. Int Metall Rev, 1972, 17(1): 25 doi: 10.1179/095066072790137729 [18] Zhang B J, Zhao G P, Zhang W Y, et al. Deformation mechanisms and microstructural evolution of γ+γ′ duplex aggregates generated during thermomechanical processing of nickel-base superalloys // Proceedings of the 13th International Symposium on Superalloys. Champion, 2016: 487 [19] Zhang M, Liu G Q, Hu B F, et al. Finite element simulation and experimental verification on hot extrusion of a novel nickel-base P/M superalloy. Powder Metall Technol, 2018, 36(3): 223张明, 刘国权, 胡本芙, 等. 新型镍基粉末高温合金热挤压工艺有限元模拟与实验验证. 粉末冶金技术, 2018, 36(3): 223 [20] Zhang M, Liu G Q, Hu B F. Effect of microstructure instability on hot plasticity during thermomechanical processing in PM nickel-based superalloy. Acta Metall Sin, 2017, 53(11): 1469 doi: 10.11900/0412.1961.2017.00172张明, 刘国权, 胡本芙. 镍基粉末高温合金热加工变形过程中显微组织不稳定性对热塑性的影响. 金属学报, 2017, 53(11): 1469 doi: 10.11900/0412.1961.2017.00172 [21] Zhang M, Liu G Q, Wang H, et al. Study on the kinetics and reverse coarsening effect of multi generations precipitation during continuous cooling in high performance Ni-base PM superalloy. Rare Met Mater Eng, 2019, 48(10): 3258张明, 刘国权, 王浩, 等. 高性能镍基粉末高温合金固溶连续冷却γ′相多阶段析出行为和尺寸粗化动力学研究. 稀有金属材料与工程, 2019, 48(10): 3258 [22] Li C, Chen L L, Qu Z H, et al. Measurement of complete dissolution temperature of γ' phase in nickel-based P/M superalloy FGH4096. Heat Treat Met, 2021, 46(11): 174李昌, 陈蕾蕾, 瞿宗宏, 等. 镍基粉末高温合金FGH4096中γ'相完全溶解温度的测定. 金属热处理, 2021, 46(11): 174 [23] Alvarado K, Janeiro I, Florez S, et al. Dissolution of the primary γ′ precipitates and grain growth during solution treatment of three nickel base superalloys. Metals, 2021, 11(12): 1921 doi: 10.3390/met11121921 [24] Qiao S C, Wang Y, Lv L X, et al. Normal and abnormal grain growth in a FGH96 superalloy during thermomechanical treatment. J Mater Res Technol, 2021, 15: 7033 doi: 10.1016/j.jmrt.2021.11.142 [25] Xu S, Dickson J I, Koul A K. Grain growth and carbide precipitation in superalloy, UDIMET 520. Metall Mater Trans A, 1998, 29: 2687 doi: 10.1007/s11661-998-0309-5 [26] Zhang Y Y, Li J K, Wu Y, et al. Microstructure evolution of a nickel-based powder metallurgy superalloy under different solution treatment temperatures. Adv Eng Mater, 2022, 24(9): 2200004 doi: 10.1002/adem.202200004 [27] Semiatin S L, McClary K E, Rollett A D, et al. Plastic flow and microstructure evolution during thermomechanical processing of a PM nickel-base superalloy. Metall Mater Trans A, 2013, 44: 2778 doi: 10.1007/s11661-013-1675-1 [28] Zhou D Q, Liu X J, Wu Y, et al. Recrystallization behavior and its influences on mechanical properties of an alumina-forming austenitic stainless steels. Acta Metall Sin, 2014, 50(10): 1217 doi: 10.11900/0412.1961.2014.00312周德强, 刘雄军, 吴渊, 等. 新型奥氏体耐热不锈钢再结晶行为及其对力学性能的影响. 金属学报, 2014, 50(10): 1217 doi: 10.11900/0412.1961.2014.00312 [29] Guo S W, Zhang Y S, Tong K F, et al. Kinetic study on the growth of precipitated γ′ phase during long time aging in GH4199 superalloy. J Northeastern Univ Nat Sci, 2003, 24(6): 576 doi: 10.3321/j.issn:1005-3026.2003.06.017郭士文, 张玉锁, 童开峰, 等. 镍基高温合金长期时效后γ′相长大动力学. 东北大学学报(自然科学版), 2003, 24(6): 576 doi: 10.3321/j.issn:1005-3026.2003.06.017 [30] Burachynsky V, Cahoon J R. A theory for solute impurity diffusion, which considers engel-brewer valences, balancing the Fermi energy levels of solvent and solute, and differences in zero point energy. Metall Mater Trans A, 1997, 28(3): 563 doi: 10.1007/s11661-997-0043-4 [31] Tian G F, Jia C C, Liu J T, et al. Experimental and simulation on the grain growth of P/M nickel-base superalloy during the heat treatment process. Mater Des, 2009, 30(3): 433 doi: 10.1016/j.matdes.2008.06.007 -

下载:

下载: