Effect of rotary swaging deformation on microstructure and mechanical properties of tungsten alloys

-

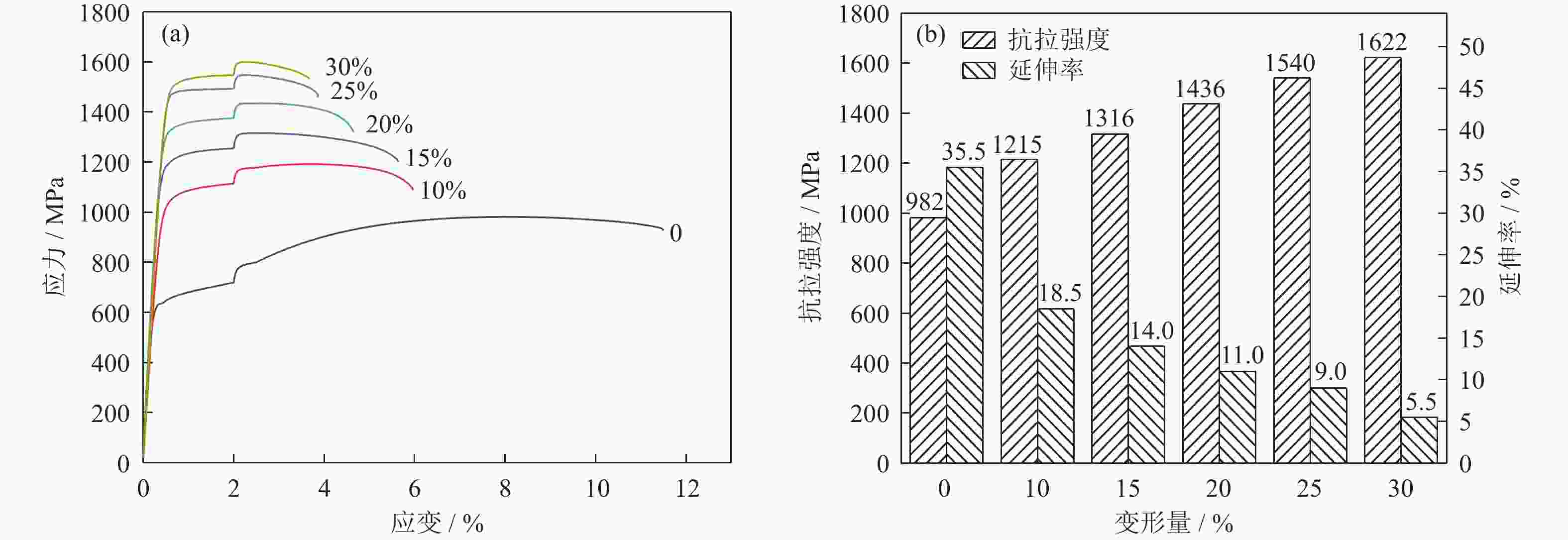

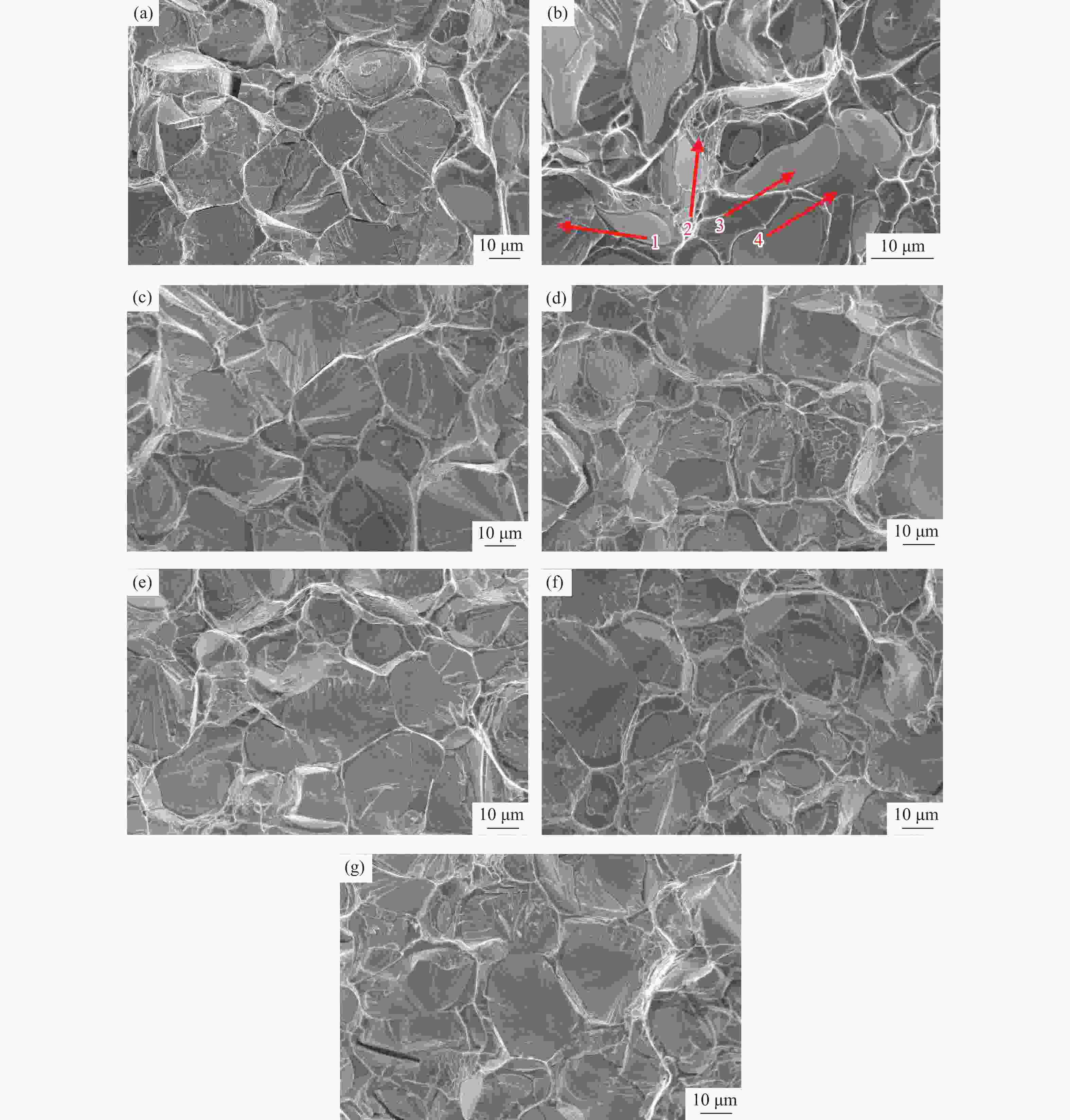

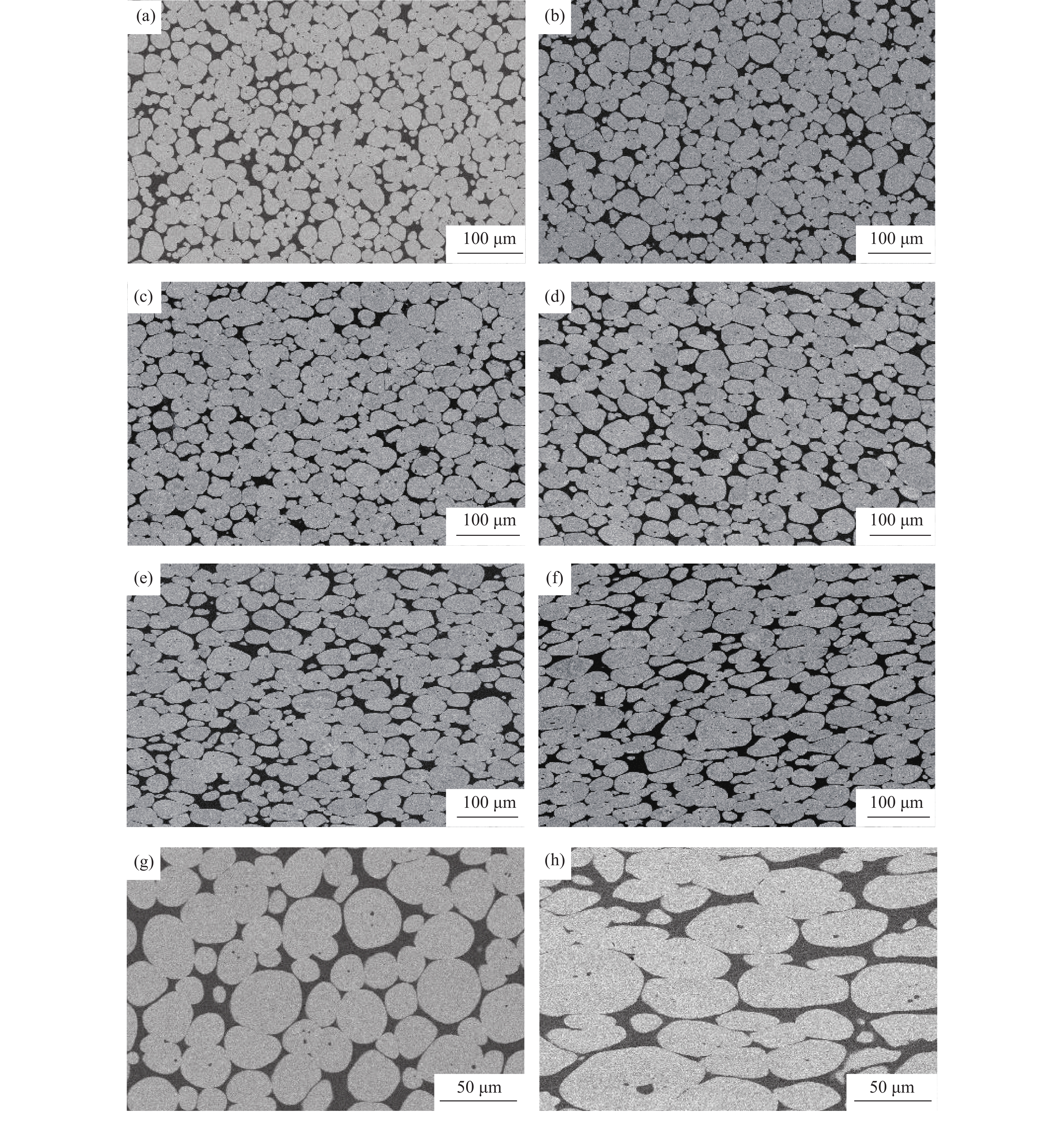

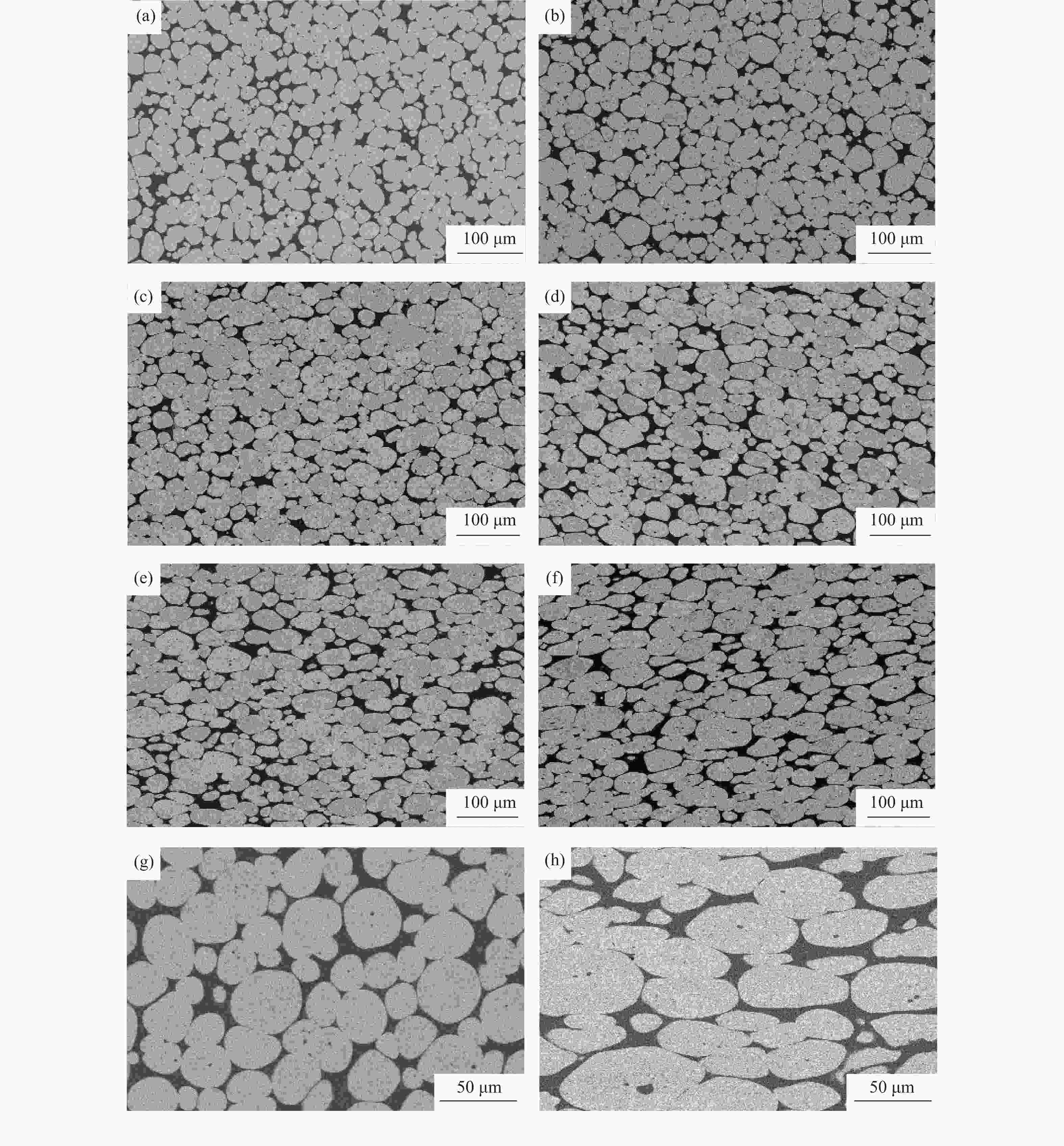

摘要: 为了获得高性能钨合金,对93WNiFe钨合金进行旋锻变形加工,研究旋锻变形量对93WNiFe钨合金力学性能及组织的影响。结果表明,随着变形量的增加,93WNiFe钨合金组织中W晶粒由圆球状逐渐被拉长成长条状,室温抗拉强度随变形量的增加而增加,由982 MPa增加到1622 MPa,断后延伸率随变形量的增加快速降低,由35.5%下降到5.5%。当旋锻变形量小于15%时,随着变形量的增加,93WNiFe合金洛氏硬度快速增加,室温冲击韧性快速降低;当变形量大于15%后,合金洛氏硬度增加变缓,室温冲击韧性值降低变缓;当变形量为30%时,洛氏硬度最大为HRC 47.2,室温冲击韧性值最小为30.80 J·cm−2。未变形的烧结态93WNiFe合金断口形貌中存在少量W晶粒解理断裂、大量W–粘结相界面断裂、W–W界面断裂和粘结相韧窝断裂;随着锻造变形量的增加,断口形貌中W晶粒解理断裂数量逐渐增加,W–粘结相界面断裂、W–W界面断裂和粘结相韧窝断裂数量逐渐减少。Abstract: The 93WNiFe alloys were deformed by rotary swaging process to obtain the high-performance tungsten alloys. The effect of rotary swaging deformation on the mechanical properties and microstructure of the 93WNiFe tungsten alloys were studied. The results show that, with the increase of deformation, the W grains in 93WNiFe tungsten alloys are elongated from spheroid to long strip, the tensile strength at room temperature increases from 982 MPa to 1622 MPa, and the elongation decreases from 35.5% to 5.5%. When the deformation of rotary swaging is less than 15%, the Rockwell hardness of the 93WNiFe alloys increases rapidly and the impact toughness decreases rapidly at room temperature with the increase of deformation. When the deformation is greater than 15%, the Rockwell hardness increases slowly, and the impact toughness decreases slowly at room temperature. When the deformation is 30%, the maximum Rockwell hardness is HRC 47.2, and the minimum impact toughness at room temperature is 30.80 J·cm−2. There are a small number of W grain cleavage fractures, a large number of W–bond phase interface fractures, W–W interface fractures, and binder phase dimple fractures in the sintered 93WNiFe alloys without deformation. With the increase of deformation, the number of W grain cleavage fractures increases gradually, and the number of W–bond phase interface fractures, W–W interface fractures, and binder phase dimple fractures decrease gradually.

-

Key words:

- tungsten alloys /

- rotary swaging /

- deformation /

- mechanical properties /

- fracture morphology

-

图 1 不同变形量下93WNiFe合金微观组织:(a)烧结态;(b)10%;(c)15%;(d)20%;(e)25%;(f)30%;(g)烧结态放大图;(h)30%放大图

Figure 1. Microstructures of the 93WNiFe alloys under the different deformations: (a) sintering state; (b) 10%; (c) 15%; (d) 20%; (e) 25%; (f) 30%; (g) amplification diagram of the sintering state; (h) amplification diagram of 30%

表 1 93WNiFe合金旋锻工艺参数

Table 1. Rotary swaging process parameters of the 93WNiFe alloys

锻造火次 加热制度 锻后直径 / mm 总变形量 / % 1 800 ℃×1 h 19.0 10 2 18.4 15 3 17.9 20 4 17.3 25 5 16.7 30 表 2 不同变形量下93WNiFe合金硬度及冲击韧性

Table 2. Hardness and impact toughness of the 93WNiFe alloys under the different deformations

变形量 / % 硬度,HRC 冲击韧性 / (J·cm−2) 0 27.6 157.60 10 41.5 61.80 15 43.4 48.60 20 44.3 39.50 25 46.6 32.10 30 47.2 30.80 -

[1] Wang L, Qin Y N, Shan D D, et al. Effect of Ni/Cu ratio on property and microstructure of WNiCu alloy. Powder Metall Ind, 2022, 32(4): 106王玲, 秦颖楠, 单东栋, 等. Ni、Cu比对钨镍铜合金性能及金相组织的影响规律研究. 粉末冶金工业, 2022, 32(4): 106 [2] Zhou G A, Zhang S Q, Huang J H, et al. Effect of swaging on performance and microstructure of 93W alloy micro-alloyed by Co, Mn. Powder Metall Technol, 1997, 15(3): 178周国安, 张守全, 黄继华, 等. 旋锻对钴、锰微合金化93W合金性能和组织的影响. 粉末冶金技术, 1997, 15(3): 178 [3] Peng Y D, Yi J H, Wu B, et al. Microwave sintering on W–Ni–Fe heavy-density alloy and its analysis on mechanism. Rare Met Mater Eng, 2008, 37(1): 125 doi: 10.3321/j.issn:1002-185X.2008.01.030彭元东, 易健宏, 吴彬, 等. 微波烧结W–Ni–Fe高比重合金及其机理研究. 稀有金属材料与工程, 2008, 37(1): 125 doi: 10.3321/j.issn:1002-185X.2008.01.030 [4] Yao H L, Xiong N, Wang L, et al. Effect of cyclic heat treatment on impact toughness of 93W–5Ni–2Fe tungsten heavy alloy. Powder Metall Technol, 2021, 39(3): 269姚惠龙, 熊宁, 王玲, 等. 循环热处理对93W–5Ni–2Fe高比重钨合金冲击韧性的影响. 粉末冶金技术, 2021, 39(3): 269 [5] Kumar M, Gurao N P, Upadhyaya A. Evolution of microstructure and crystallographic texture during cold rolling of liquid phase sintered tungsten heavy alloy. Int J Refract Met Hard Mater, 2022, 105: 105849 doi: 10.1016/j.ijrmhm.2022.105849 [6] Liu Y. Technology and Mechanism of Large Deformation Strengthening for Tungsten Heavy Alloy [Dissertation]. Nanjing: Nanjing University of Science & Technology, 2016刘勇. 钨重合金大变形强化技术及机制研究[学位论文]. 南京: 南京理工大学, 2016 [7] Quan J L, Liang Z F, Yan F. Research progress of tungsten alloy materials for air defense and antimissile warhead. J Ordn Equip Eng, 2020, 41(2): 94 doi: 10.11809/bqzbgcxb2020.02.021全嘉林, 梁争峰, 闫峰. 防空反导战斗部用钨基高比重合金研究进展. 兵器装备工程学报, 2020, 41(2): 94 doi: 10.11809/bqzbgcxb2020.02.021 [8] Li S H, Wang F C, Tan C W, et al. Effects of deformation on microstructure performance and adiabatic shearing sensitivity of tungsten heavy alloy. Spec Cast Nonferrous Alloys, 2005, 25(11): 664李淑华, 王富耻, 谭成文, 等. 变形对钨合金微观组织性能及绝热剪切敏感性的影响. 特种铸造及有色金属, 2005, 25(11): 664 [9] Zhu W T, Liu W S, Ma Y Z, et al. Influence of microstructure on crack initiation and propagation behavior in swaged tungsten heavy alloy during Charpy impact process. Mater Sci Eng A, 2023, 862: 1 [10] Zhang B S, Kang Z J. Penetration characteristics of high density tungsten alloy and its application. China Tungsten Ind, 1999, 14(5-6): 178张宝生, 康志君. 高密度钨合金的穿甲特性及其应用. 中国钨业, 1999, 14(5-6): 178 [11] Luo R M. Study on Penetration Mechanism of Fine-grained Tungsten Heavy Alloy Penetrator [Dissertation]. Nanjing: Nanjing University of Science & Technology, 2016罗荣梅. 细晶钨合金穿甲弹靶作用机理研究[学位论文]. 南京: 南京理工大学, 2016 [12] Yu Y, Wang E D, Hu L X, et al. Effects of microstructure and properties of 93W–4.9Ni–2.1Fe alloys by deformation strengthening. Mater Sci Technol, 2005, 13(4): 442于洋, 王尔德, 胡连喜, 等. 形变强化对93W–4.9Ni–2.1Fe合金组织及性能的影响. 材料科学与工艺, 2005, 13(4): 442 [13] Zhou S H. Research on Mechanical Alloying and Strengthened Sintering Technologies of Tungsten Heavy Alloy [Dissertation]. Harbin: Harbin Institute of Technology, 2016周少华. 高密度钨合金机械合金化及强化烧结工艺研究[学位论文]. 哈尔滨: 哈尔滨工业大学, 2016 [14] Chen W G, Ye H. Structure and properties of WCu alloy wire by swaging process. Powder Metall Technol, 2011, 29(1): 13陈文革, 叶恒. 旋锻法制备WCu25合金线材的组织与性能研究. 粉末冶金技术, 2011, 29(1): 13 [15] Wang G D, Yang H B, Liu G R, et al. Research progress in deformation processing of tungsten heavy alloys. Powder Metall Technol, 2014, 32(3): 221王广达, 杨海兵, 刘桂荣, 等. 高比重合金变形加工研究进展. 粉末冶金技术, 2014, 32(3): 221 [16] Fan J L. Tungsten Alloy and New Preparation Technology. Beijing: Metallurgical Industry Press, 2006范景莲. 钨合金及其制备新技术. 北京: 冶金工业出版社, 2006 [17] Alam M E, Odette G R. Improving the fracture toughness and ductility of liquid-phase sintered WNiFe tungsten heavy alloys by high-temperature annealing. Materials, 2023, 16(3): 916 doi: 10.3390/ma16030916 [18] Yu Y, Zhang W C, Chen Y, et al. Effect of swaging on microstructure and mechanical properties of liquid-phase sintered 93W-4.9(Ni, Co)–2.1Fe alloy. Int J Refract Met Hard Mater, 2014, 44: 103 -

下载:

下载: