Effect of microstructure evolution on tensile properties of novel nickel-based powder metallurgy superalloys during long-term aging

-

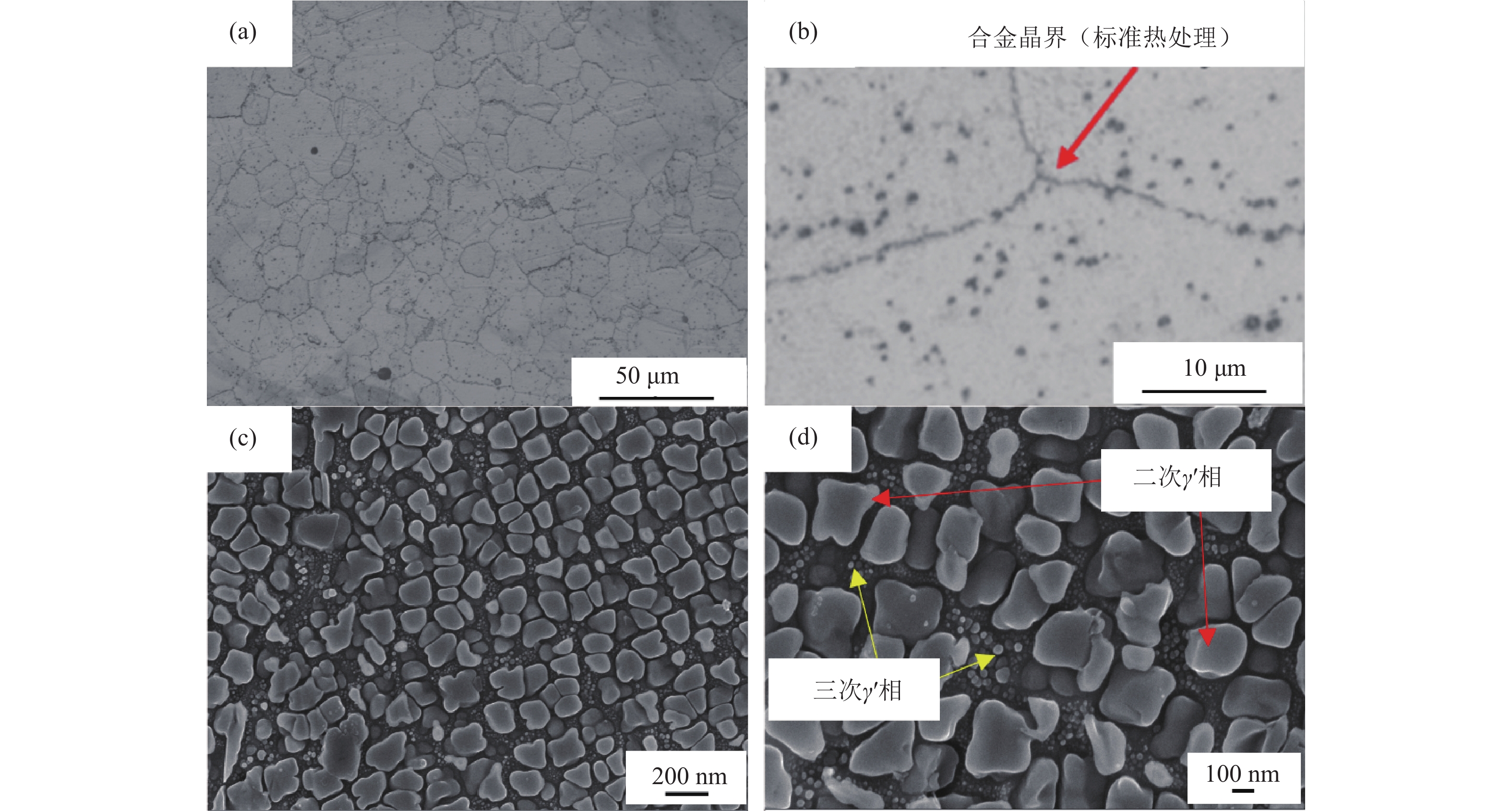

摘要: 研究了新型镍基粉末高温合金在800 ℃时效100~5000 h后显微组织对拉伸性能的影响。结果表明:随着时效时间的增加,合金的晶粒尺寸未发生明显变化,晶界粗化并呈现为不连续“锯齿状”;二次γ′相发生合并粗化,粗化符合LSW理论;TCP相的析出量随时效时间的增加而增大,1000 h后在晶界处呈现细小白条状析出,2000 h后在晶内呈现大量长条形针状析出,5000 h时TCP相含量达到最大;受二次γ′相粗化的影响,合金的700 ℃拉伸强度和塑性随时效时间的增加而逐渐降低;拉伸断口具有颈缩和韧窝特征,断裂均为韧窝断裂。Abstract: The influence of microstructure evolution on the tensile properties of the novel nickel-based powder metallurgy superalloys after long-term aging at 800 ℃ for 100~5000 h was studied. The results show that the grain size of the alloys does not change significantly with the increase of aging time, and the grain boundaries are coarsened and appear the discontinuous “sawtooth”. Secondary γ′ phase particles obviously coarsen which conforms to the LSW theory. The content of TCP phases precipitated increases with the increase of aging time. After aging for 1000 h, the intermittent long white precipitates are observed at the grain boundary. After aging for 2000 h, a large number of elongate needle-like precipitates appear in the grain. The content of TCP phases reaches the maximum after aging for 5000 h. Due to the coarsening of the secondary γ′ phase, the tensile strength and plasticity of the alloys at 700 ℃ gradually decrease with increasing the aging time. The tensile fracture has the characteristics of necking and dimple, and the fracture shows the dimple fracture.

-

表 1 镍基粉末高温合金化学成分(质量分数)

Table 1. Chemical composition of the nickel-based powder metallurgy superalloys

% Cr Co Mo Ta W Al Nb Ti C B Zr Ni 11.0~13.0 19.0~22.0 3.5~6.0 2.4~4.0 2.1~2.5 3.0~5.0 0.5~1.0 3.0~4.5 0.05 0.03 0.05 余量 表 2 800 ℃长期时效合金晶粒尺寸

Table 2. Grain size of the alloys aged at 800 ℃ for different times

时效时间 / h 晶粒尺寸 / μm 标准差 100 13.80 6.78 500 14.48 6.27 1000 14.97 8.34 2000 12.97 6.46 5000 14.78 7.22 表 3 800 ℃长期时效合金二次γ′相平均尺寸

Table 3. Size of the secondary γ′ phases aged at 800 ℃ for different times

时效时间 / h 二次γ′相平均尺寸(半径) / nm 100 71.4 500 71.4 1000 85.6 2000 110.0 5000 132.3 表 4 800 ℃长期时效合金TCP相含量

Table 4. Content of the TCP phases aged at 800 ℃ for different times

时效时间 / h TCP相面积分数 / % 100 — 500 — 1000 0.392 2000 2.430 5000 2.667 -

[1] Gessinger G H. Powder Metallurgy of Superalloys. Zhang Y W, Transl. Beijing: Metallurgical Industry Press, 2017Gessinger G H. 粉末高温合金. 张义文, 译. 北京: 冶金工业出版社, 2017 [2] Reed R C. The Superalloys Fundamentals and Applications. Cambridg: Cambridge University Press, 2006 [3] Li J R, Xiong J C, Tang D Z. Advanced High Temperature Structural Materials and Technology. Beijing: National Defense Industry Press, 2012李嘉荣, 熊继春, 唐定中. 先进高温结构材料与技术. 北京: 国防工业出版社, 2012 [4] Zhang G Q, Zhang Y W, Zheng L, et al. Research progress in powder metallurgy superalloys and manufacturing technologies for aero-engines. Acta Metall Sin, 2019, 55(9): 1133 doi: 10.11900/0412.1961.2019.00119张国庆, 张义文, 郑亮, 等. 航空发动机用粉末高温合金及制备技术研究进展. 金属学报, 2019, 55(9): 1133 doi: 10.11900/0412.1961.2019.00119 [5] Hou W Q, Meng J, Liang J J, et al. Preparation technology and research progress of superalloy powders used for additive manufacturing. Powder Metall Technol, 2022, 40(2): 131侯维强, 孟杰, 梁静静, 等. 增材制造用高温合金粉末制备技术及研究进展. 粉末冶金技术, 2022, 40(2): 131 [6] Jia J, Tao Y, Zhang Y W, et al. Recent development of third generation P/M superalloy René104. Powder Metall Ind, 2007, 17(3): 36 doi: 10.3969/j.issn.1006-6543.2007.03.008贾建, 陶宇, 张义文, 等. 第三代粉末冶金高温合金René104的研究进展. 粉末冶金工业, 2007, 17(3): 36 doi: 10.3969/j.issn.1006-6543.2007.03.008 [7] Gabb T P, Telesman J, Kantzos P T, et al. Characterization of the temperature capabilities of advanced disk alloy ME3. NASA/TM-2002-211796. Washington D C, 2002 [8] Yang L B, Ren X N, Ge C C, et al. Status and development of powder metallurgy nickel-based disk superalloys. Int J Mater Res, 2019, 110(10): 901 doi: 10.3139/146.111820 [9] Gabb T P, Gayda J, Telesman J, et al. Realistic subscale evaluations of the mechanical properties of advanced disk superalloys. NASA/TM-2003-212086. Washington D C, 2003 [10] Bakradze M M, Ovsepyan S V, Buiakina A A, et al. Development of Ni-base superalloy with operating temperature up to 800 ℃ for gas turbine disks. Inorg Mater Appl Res, 2019, 9(6): 1044 [11] Cheng C, Dong J X, Zhang M C. Characteristics and development of three generations of powder metallurgy superalloys. World Iron Steel, 2011, 11(5): 43 doi: 10.3969/j.issn.1672-9587.2011.05.008程茜, 董建新, 张麦仓. 三代粉末高温合金的特征及发展. 世界钢铁, 2011, 11(5): 43 doi: 10.3969/j.issn.1672-9587.2011.05.008 [12] Tian G F, Wang Y, Yang J, et al. Thermodynamic calculation of equilibrium precipitated phases in P/M nickel-base superalloy. Powder Metall Technol, 2012, 30(4): 243 doi: 10.3969/j.issn.1001-3784.2012.04.001田高峰, 汪煜, 杨杰, 等. Ni基粉末冶金高温合金平衡析出相的热力学研究. 粉末冶金技术, 2012, 30(4): 243 doi: 10.3969/j.issn.1001-3784.2012.04.001 [13] Chen Y, Tian G F, Yang J, et al. Effect of deformation parameter on solution heat-treated microstructure of extruded Ni-based powder metallurgy superalloy. J Aeron Mater, 2019, 39(4): 19 doi: 10.11868/j.issn.1005-5053.2019.000049陈阳, 田高峰, 杨杰, 等. 变形参数对挤压成型镍基粉末高温合金固溶热处理晶粒组织的影响. 航空材料学报, 2019, 39(4): 19 doi: 10.11868/j.issn.1005-5053.2019.000049 [14] Zhang Q, Zheng L, Xu W Y, et al. Research progress on argon atomized nickel-based powder metallurgy superalloys and powder characteristics. Powder Metall Technol, 2022, 40(5): 387张强, 郑亮, 许文勇, 等. 氩气雾化镍基粉末高温合金及粉末特性研究进展. 粉末冶金技术, 2022, 40(5): 387 [15] Yang G H, Tian G F, Zhang X L, et al. Effect of long-term aging on microstructure stability of a novel nickel base powder superalloy. J Alloys Compd, 2022, 906: 164297 doi: 10.1016/j.jallcom.2022.164297 [16] Huang Y S, Wang X G, Cui C Y, et al. The effect of coarsening of γ′ precipitate on creep properties of Ni-based single crystal superalloys during long-term aging. Mater Sci Eng A, 2020, 773: 138886 doi: 10.1016/j.msea.2019.138886 [17] Xiao X, Zhou L Z, Guo J T. Microstructural stability and creep behavior of nickel base superalloy U720Li. Acta Metall Sin, 2001, 37(11): 1159 doi: 10.3321/j.issn:0412-1961.2001.11.006肖璇, 周兰章, 郭建亭. 镍基高温合金U720Li的组织稳定性及蠕变行为. 金属学报, 2001, 37(11): 1159 doi: 10.3321/j.issn:0412-1961.2001.11.006 [18] Picasso A, Somoza A, Tolley A. Nucleation, growth and coarsening of γ′-precipitates in a Ni–Cr–Al-based commercial superalloy during artificial aging. J Alloys Compd, 2009, 479(1-2): 129 doi: 10.1016/j.jallcom.2008.12.068 [19] Mehdizadeh M, Hassan F. Effects of different elevated temperature and long-term exposure on microstructural evolution and mechanical characteristics of IN617 Ni-based superalloy. Mater Sci Eng A, 2022, 841: 143025 doi: 10.1016/j.msea.2022.143025 [20] Wang M Y, Ji Z, Zhang Y F, et al. Research progress on the prior particle boundary of a powder metallurgy superalloy. Powder Metall Technol, 2017, 35(2): 142 doi: 10.3969/j.issn.1001-3784.2017.02.011王梦雅, 纪箴, 张一帆, 等. 粉末高温合金中原始粉末颗粒边界研究进展. 粉末冶金技术, 2017, 35(2): 142 doi: 10.3969/j.issn.1001-3784.2017.02.011 [21] Powell A, Bain K, Wessman A, et al. Advanced supersolvus nickel powder disk alloy DOE: chemistry, properties, phase formations and thermal stability // Superalloys 2016: Proceedings of the 13th International Symposium on Superalloys. Hoboken, 2016: 189 [22] Wang J, Zhou L Z, Sheng L Y, et al. The microstructure evolution and its effect on the mechanical properties of a hot-corrosion resistant Ni-based superalloy during long-term thermal exposure. Mater Des, 2012, 39: 55 doi: 10.1016/j.matdes.2012.02.020 [23] Tan L M, Zhang Y W, Jia J, et al. Precipitation of μ phase in nickel-based powder metallurgy superalloy FGH97. J Iron Steel Res, 2016, 23(8): 851 doi: 10.1016/S1006-706X(16)30130-3 [24] Rae C M F, Reed R C. The precipitation of topologically close-packed phases in rhenium-containing superalloys. Acta Mater, 2001, 49(19): 4113 doi: 10.1016/S1359-6454(01)00265-8 [25] Wu K, Liu G Q, Hu B F, et al. Alloy design of a new type high-performance P/M turbine disk superalloy. Procedia Eng, 2012, 27: 939 doi: 10.1016/j.proeng.2011.12.541 -

下载:

下载: