Effect of high temperature oxidation on the surface state of FGH96 superalloy powders

-

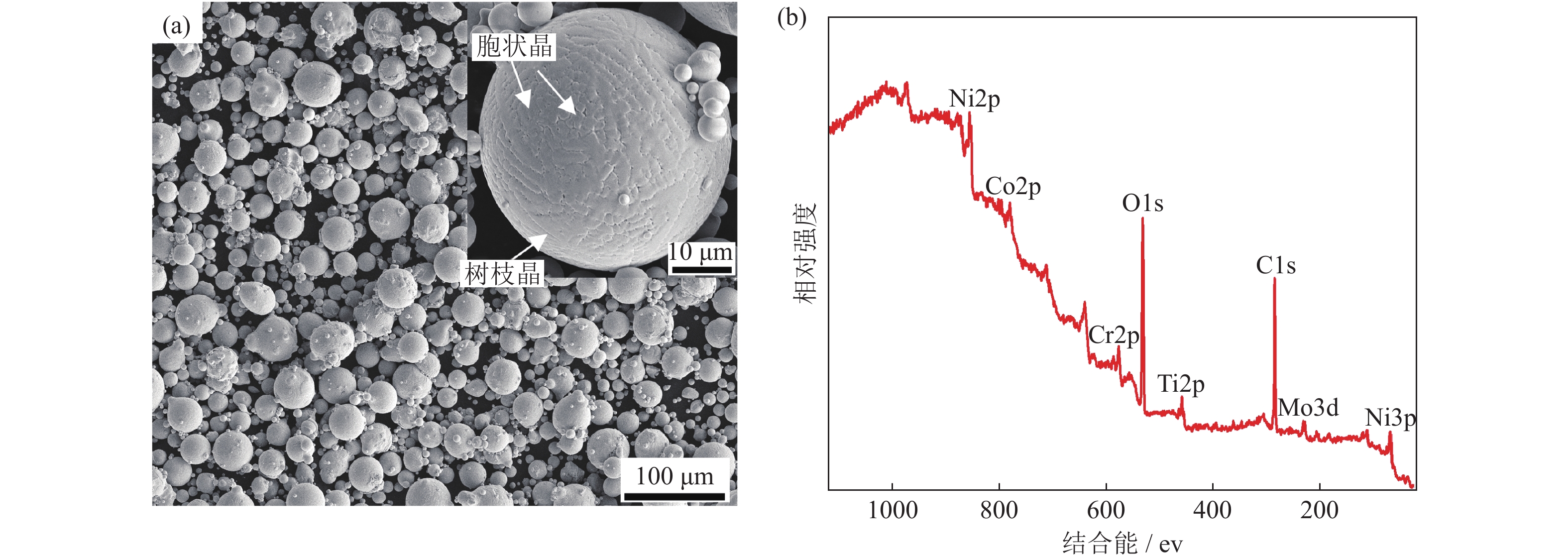

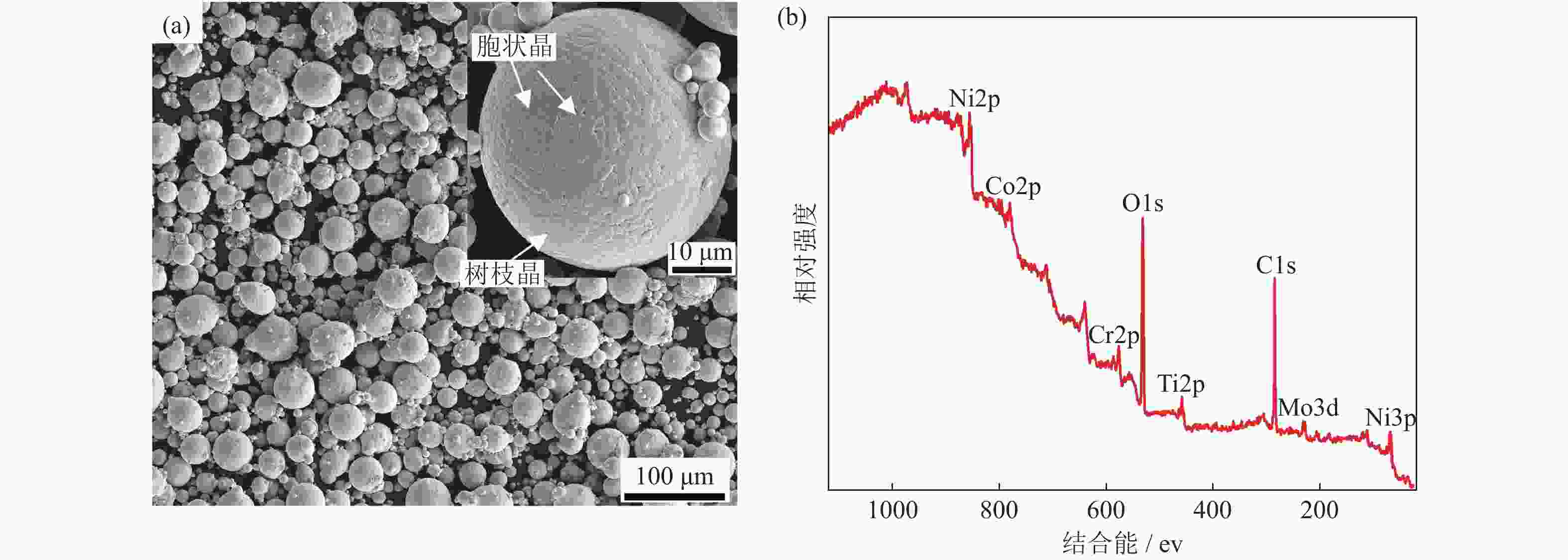

摘要: 通过模拟FGH96高温合金粉末在热等静压固结阶段的高温加热过程,利用多种表面分析方法,研究高温氧化对粉末表面状态的影响。结果表明,近热等静压加热温度条件下的高温氧化过程显著改变了FGH96高温合金粉末的表面形貌、表面元素分布和析出相组成。随加热温度的升高和保温时间的延长,胞状晶为主、树枝晶为辅的表面凝固组织被氧化物/碳化物层所覆盖,高温氧化过程促进粉末基体内部的Ni、Ti、Zr、Nb、Al和C原子逐渐扩散到粉末表面,粉末表面预先存在的氧化物(ZrO2)为MC型碳化物((Ti, Nb)C)的形核提供了结构条件。控制粉末表面氧化物的形成可以有效限制合金中形成原始颗粒边界缺陷。

-

关键词:

- FGH96高温合金粉末 /

- 高温氧化 /

- 粉末表面状态 /

- 原始颗粒边界

Abstract: The effect of high temperature oxidation on the surface state of FGH96 superalloy powders was studied by simulating the high temperature heating process during hot isostatic pressing (HIP) consolidation. The results indicate that the surface morphology, surface element distribution, and precipitate composition of the FGH96 superalloy powders are significantly changed by high temperature oxidation at near HIP temperature. With the increase of heating temperature and the extension of holding time, the surface solidification structure of cell crystals and dendritic crystals are covered by oxide/carbide layers. The high temperature oxidation process promotes the diffusion of Ni, Ti, Zr, Nb, Al, and C atoms inside the powder matrix to the powder surface. The pre-existing oxides (ZrO2) on the powder surface provide the structural conditions for the nucleation of MC carbides (Ti, Nb)C. Controlling the formation of oxides on the powder surface can effectively limit the formation of prior particle boundaries (PPBs) defects in the alloys. -

图 2 不同条件高温氧化后FGH96高温合金粉末的表面形貌:(a)~(d)1020、1070、1120、1170 ℃,保温10 min;(e)~(h)1020、1070、1120、1170 ℃,保温60 min;(i)~(l)1020、1070、1120、1170 ℃,保温240 min

Figure 2. Surface morphology of the FGH96 superalloy powders with the different high temperature oxidation conditions: (a)~(d) 1020, 1070, 1120, 1170 ℃ for 10 min; (e)~(h) 1020, 1070, 1120, 1170 ℃ for 60 min; (i)~(l) 1020, 1070, 1120, 1170 ℃for 240 min

表 1 实验用FGH96高温合金粉末的化学成分(质量分数)

Table 1. Chemical compositions of the investigated FGH96 superalloy powders

% Ni C Cr Mo Nb Fe Co W Ti Al Zr 余量 0.045 16.000 0.510 0.790 0.060 13.200 4.100 4.000 2.200 0.060 -

[1] Pollock T M, Tin S. Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. J Propul Power, 2006, 22(2): 361 doi: 10.2514/1.18239 [2] Reed R C. The Superalloys: Fundamentals and Applications. Cambridge: Cambridge University Press, 2008 [3] Fang B, Ji Z, Liu M, et al. Critical strain and models of dynamic recrystallization for FGH96 superalloy during two-pass hot deformation. Mater Sci Eng A, 2014, 593: 8 doi: 10.1016/j.msea.2013.11.016 [4] Cai C, Song B, Xue P, et al. Effect of hot isostatic pressing procedure on performance of Ti6Al4V: Surface qualities, microstructure and mechanical properties. J Alloys Compd, 2016, 686: 55 doi: 10.1016/j.jallcom.2016.05.280 [5] Atkinson H, Davies S. Fundamental aspects of hot isostatic pressing: an overview. Metall Mater Trans A, 2000, 31(12): 2981 doi: 10.1007/s11661-000-0078-2 [6] Bai Q, Lin J, Tian G, et al. Review and analysis of powder prior boundary (PPB) formation in powder metallurgy processes for nickel-based super alloys. J Powder Metall Min, 2015, 4(1): 1 [7] Rao G A, Prasad K S, Kumar M, et al. Characterisation of hot isostatically pressed nickel base superalloy Inconel* 718. Mater Sci Technol, 2013, 19(3): 313 [8] Qiu C, Yang D, Wang G, et al. Microstructural development and tensile behavior of a hot isostatically pressed nickel-based superalloy. Mater Sci Eng A, 2020, 769: 138461 doi: 10.1016/j.msea.2019.138461 [9] Irukuvarghula S, Hassanin H, Cayron C, et al. Effect of powder characteristics and oxygen content on modifications to the microstructural topology during hot isostatic pressing of an austenitic steel. Acta Mater, 2019, 172: 6 doi: 10.1016/j.actamat.2019.03.038 [10] Chang L, Sun W, Cui Y, et al. Influences of hot-isostatic-pressing temperature on microstructure, tensile properties and tensile fracture mode of Inconel 718 powder compact. Mater Sci Eng A, 2014, 599: 186 doi: 10.1016/j.msea.2014.01.095 [11] Hou J, Dong J, Yao Z, et al. Influences of PPB, PPB affect zone, grain boundary and phase boundary on crack propagation path for a P/M superalloy FGH4096. Mater Sci Eng A, 2018, 724: 17 doi: 10.1016/j.msea.2018.03.066 [12] Teng Q, Wei Q, Xue P, et al. Effects of processing temperatures on FGH4097 superalloy fabricated by hot isostatic pressing: Microstructure evolution, mechanical properties and fracture mechanism. Mater Sci Eng A, 2019, 739: 118 doi: 10.1016/j.msea.2018.08.030 [13] Tan L, Li Y, Liu C, et al. The evolution history of superalloy powders during hot consolidation and plastic deformation. Mater Charact, 2018, 140: 30 doi: 10.1016/j.matchar.2018.03.039 [14] Chang L, Sun W, Cui Y, et al. Preparation of hot-isostatic-pressed powder metallurgy superalloy Inconel 718 free of prior particle boundaries. Mater Sci Eng A, 2017, 682: 341 doi: 10.1016/j.msea.2016.11.031 [15] Zhang Q, Zheng L, Yuan H, et al. Influence of storage conditions on powder surface state and hot deformation behavior of a powder metallurgy nickel-based superalloy. Adv Eng Mater, 2022, 24: 2101615 doi: 10.1002/adem.202101615 [16] Zheng L, Zhang M, Dong J. Oxidation behavior and mechanism of powder metallurgy Rene95 nickel based superalloy between 800 and 1000 °C. Appl Surface Sci, 2010, 256(24): 7510 doi: 10.1016/j.apsusc.2010.05.098 [17] Zhang Q, Zheng L, Yuan H, et al. Effects of composition and particle size on the surface state and degassing behavior of nickel-based superalloy powders. Appl Surface Sci, 2021, 556: 149793 doi: 10.1016/j.apsusc.2021.149793 [18] Fan X, Guo Z, Wang X, et al. Morphology evolution of γ′ precipitates in a powder metallurgy Ni-base superalloy. Mater Charact, 2018, 139: 382 doi: 10.1016/j.matchar.2018.02.038 [19] Lu J, Li L, Zhang H, et al. Oxidation behavior of gas-atomized AlCoCrFeNi high-entropy alloy powder at 900-1100 ℃. Corros Sci, 2021, 181: 109257 doi: 10.1016/j.corsci.2021.109257 [20] Qiu C L, Attallah M M, Wu X H, et al. Influence of hot isostatic pressing temperature on microstructure and tensile properties of a nickel-based superalloy powder. Mater Sci Eng A, 2013, 564: 176 doi: 10.1016/j.msea.2012.11.084 [21] Zhang Q, Zheng L, Yuan H, et al. Effect of humid atmosphere on the microstructure and mechanical properties of a PM Ni-based superalloy: From powders to bulk alloys. Mater Charact, 2023, 202: 113019 doi: 10.1016/j.matchar.2023.113019 [22] Ingesten N, Warren R, Winberg L. The nature and origin of previous particle boundary precipitates in P/M superalloys // High Temperature Alloys for Gas Turbines 1982. Springer, 1982: 1013 -

下载:

下载: