Effect of heat treatment on microstructure evolution and mechanical properties of P/M Ni-based superalloy at diffusion bonding interface

-

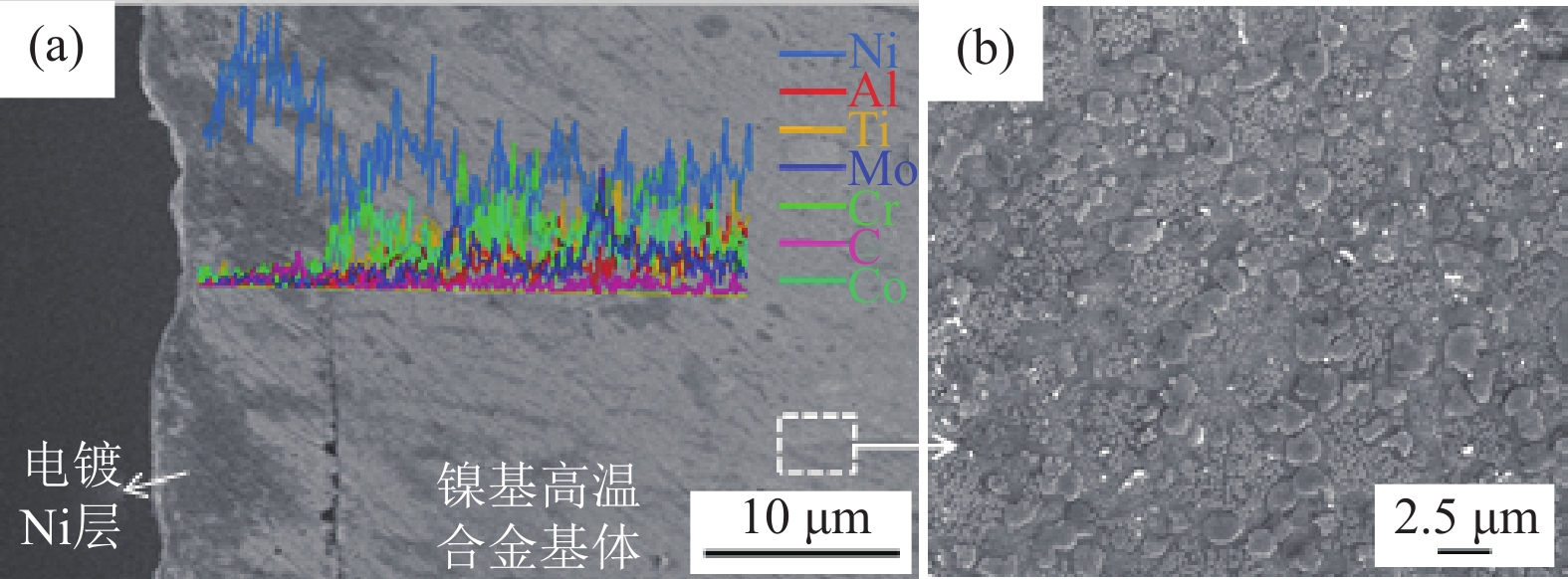

摘要: 采用金相显微镜、扫描电子显微镜、电子显微探针及高温拉伸测试的方法,研究了热处理对一种镍基粉末高温合金扩散连接界面组织演变及性能的影响。结果表明,在镍基粉末高温合金扩散连接时,基体中的Cr、Mo、Co、W、Al和Ti元素向界面扩散,导致界面处出现明显的连接影响区。Ni元素由电镀层向基体扩散,与Al和Ti元素发生反应,生成粗大γ'相,并呈“簇状”条带分布。经亚固溶处理和过固溶处理后,Cr、Mo、Co、W、Al、Ti和Ni元素进一步扩散,改变了连接影响区和γ'相“簇状”条带的宽度。650 ℃拉伸测试结果表明,扩散连接界面断裂面同时包含界面和基体,断口中存在大量韧窝及少量解离面,表现出韧性–解理的复合断裂模式。经亚固溶+时效处理后,界面强度显著提高,但界面塑性减低;经过固溶+时效处理后,界面强度有所下降,且界面塑性进一步降低。Abstract: Effect of the heat treatment on the microstructure evolution and mechanical properties of the a P/M Ni-based superalloy in the diffusion bonding interface was studied by the optical microscope (OM), scanning electron microscope (SEM), electron probe microanalysis (EPMA), and elevated temperature tensile test. The results show that Cr, Mo, Co, W, Al, and Ti elements diffuse from the alloy matrix to the interface, which leads to the appearance of the obvious bond-affected zone. Ni element diffuses from the electrodeposited coating to the matrix, and reacts with Al and Ti to form the coarse γ' phases. The coarse γ' phases are distributed as a cluster band in the interface. The width of the bond-affected zone and the cluster band are changed by the further diffusion of Cr, Mo, Co, W, Al, and Ti elements after the sub solution treatment and super solution treatment. The tensile test at 650 ℃ shows that the fracture location of diffusion bonding interface includes both the interface and the matrix. A large number of dimples and a small amount of dissociation surface in the fracture surface are found, showing a ductile-cleavage mixed fracture mode. The interfacial strength increases significantly, but the interfacial plasticity decreases after the sub solid solution and aging treatment. The interfacial strength decreases and the interfacial plasticity further decreases after the super solid solution and aging treatment.

-

图 5 经过不同热处理工艺后镍基粉末高温合金扩散连接界面扫描电子显微形貌:(a)和(d)DB0;(b)和(e)DB3;(c)和(f)DB5;(g)图5(d)A点能谱分析

Figure 5. SEM images of PM Ni-based superalloys in the diffusion bonding interface treated by the different heat treatments: (a) and (d) DB0; (b) and (e) DB3; (c) and (f) DB5; (g) EDS analysis of point A in Fig. 5(d)

表 1 镍基粉末高温合金的主要化学成分(质量分数)

Table 1. Chemical composition of the PM Ni-based superalloys

% Cr Co W Mo Ta Nb Al Ti C Zr Ni 11.0~

13.219.0~

22.03.5~

6.03.5~

6.02.4~

4.00.6~

1.13.0~

4.53.0~

4.50.054 0.042 余量 表 2 试样编号及热处理制度

Table 2. Sample designation and heat treatment regime

试样编号 热处理制度 DB0 未进行热处理 DB1 时效处理:760 ℃/8 h/炉冷 DB2 亚固溶处理:1135 ℃/2 h/空冷 DB3 亚固溶+时效处理:1135 ℃/2 h/空冷+

760 ℃/8 h/炉冷DB4 过固溶处理:1170 ℃/2 h/空冷 DB5 过固溶+时效处理:1170 ℃/2 h/空冷+

760 ℃/8 h/炉冷 -

[1] Zou J W, Wang W X. Development and application of P/M superalloy. J Aeron Mater, 2006, 26(3): 244 doi: 10.3969/j.issn.1005-5053.2006.03.051邹金文, 汪武祥. 粉末高温合金研究进展与应用. 航空材料学报, 2006, 26(3): 244 doi: 10.3969/j.issn.1005-5053.2006.03.051 [2] Fu H, Wang M Y, Ji Z, et al. Effect of thermal deformation on prior particle boundary of FGH96 superalloy. Powder Metall Technol, 2018, 36(3): 201傅豪, 王梦雅, 纪箴, 等. 热变形对FGH96高温合金原始颗粒边界的影响. 粉末冶金技术, 2018, 36(3): 201 [3] Xu W Y, Li Z, Liu Y F, et al. Influence of temperature on the oxidation behaviors of the nickel-based superalloy powders. Powder Metall Technol, 2020, 38(3): 192许文勇, 李周, 刘玉峰, 等. 温度对镍基高温合金粉末氧化行为的影响. 粉末冶金技术, 2020, 38(3): 192 [4] Zhong Z Y, Zhang Y W, Liu J T, et al. Effects of aging heat treatment on the microstructure and properties of a new type nickel-based PM superalloy. Powder Metall Ind, 2020, 30(3): 14钟治勇, 张义文, 刘建涛, 等. 时效处理对一种新型粉末高温合金组织和性能的影响. 粉末冶金工业, 2020, 30(3): 14 [5] Preuss M, Pang J W L, Withers P J, et al. Inertia welding nickel-based superalloy: Part I. metallurgical characterization. Metall Mater Trans A, 2002, 33: 3215 doi: 10.1007/s11661-002-0307-y [6] Senkov O N, Mahaffey D W, Semiatin S L. A comparison of the inertia friction welding behavior of similar and dissimilar Ni-based superalloys. Metall Mater Trans A, 2018, 49: 5428 doi: 10.1007/s11661-018-4853-3 [7] Li H Y, Huang Z W, Bray S, et al. High temperature fatigue of friction welded joints in dissimilar nickel based superalloys. Mater Sci Technol, 2007, 23: 1408 doi: 10.1179/174328407X243933 [8] Gale W F, Butts D A. Transient liquid phase bonding. Sci Technol Weld Joining, 2004, 9: 283 doi: 10.1179/136217104225021724 [9] Yuan L, Xiong J T, Peng Y, et al. Microstructure and mechanical properties in the solid-state diffusion bonding joints of Ni3Al based superalloy. Mater Sci Eng A, 2020, 772: 138670 doi: 10.1016/j.msea.2019.138670 [10] Zhang G, Chandel R S, Seow H P. Solid state diffusion bonding of Inconel 718. Sci Technol Weld Joining, 2001, 6: 235 doi: 10.1179/136217101101538820 [11] Xiong J T, Yuan L, Zhu Y, et al. Diffusion bonding of nickel-based superalloy GH4099 with pure nickel interlayer. J Mater Sci, 2019, 54: 6552 doi: 10.1007/s10853-018-03274-x [12] Chamanfar A, Jahazi M, Cormier J. A review on inertia and linear friction welding of Ni-based superalloys. Metall Mater Trans A, 2015, 46: 1639 doi: 10.1007/s11661-015-2752-4 [13] Zhu F H, Chen C J, Li X F, et al. Role of thermal cycle in joining Ti–6Al–4V and Ti2AlNb-based alloys through diffusion bonding and post heat treatment. Mater Charact, 2019, 156: 109830 doi: 10.1016/j.matchar.2019.109830 [14] Duarte L I, Ramos A S, Vieir M F, et al. Solid-state diffusion bonding of gamma-TiAl alloys using Ti/Al thin films as interlayers. Intermetallics, 2006, 14: 1151 doi: 10.1016/j.intermet.2005.12.011 [15] Fu X S, Wang X C, Wang Q, et al. Effect of surface self-nanocrystallization on diffusion bonding between a titanium alloy and a TiAl-based alloy. J Mater Eng Perform, 2018, 27: 5551 doi: 10.1007/s11665-018-3638-6 [16] Zhang C, Li M Q, Li H. Diffusion behavior at void tip and its contributions to void shrinkage during solid state bonding. J Mater Sci Technol, 2018, 34: 1449 doi: 10.1016/j.jmst.2017.12.001 [17] Elrefaey A, Tillmann W. Solid state diffusion bonding of titanium to steel using a copper base alloy as interlayer. J Mater Proc Technol, 2009, 209: 2746 doi: 10.1016/j.jmatprotec.2008.06.014 [18] Cui Z Q, Qin Y C. Metallurgy and Heat Treatment. 2nd Ed. Beijing: China Machine Press, 2011崔忠圻, 覃耀春. 金属学与热处理. 2版. 北京: 机械工业出版社, 2011 -

下载:

下载: