Effect of sintering atmosphere on the microstructure of high carbon iron based powder metallurgy materials

-

摘要:

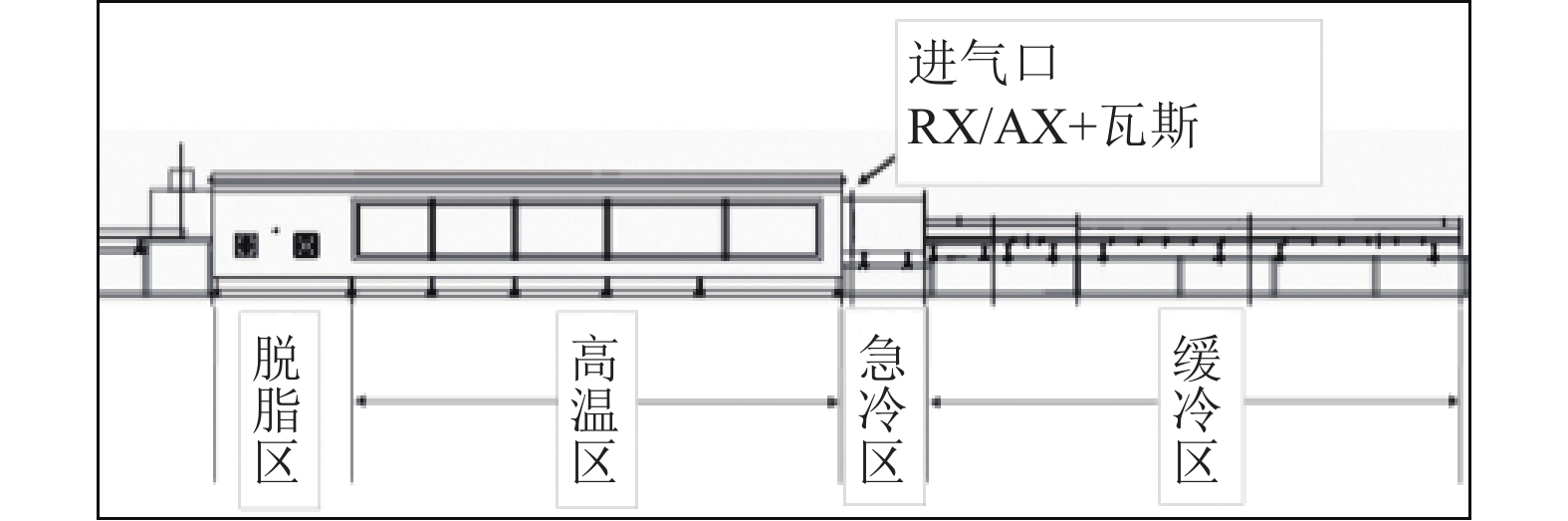

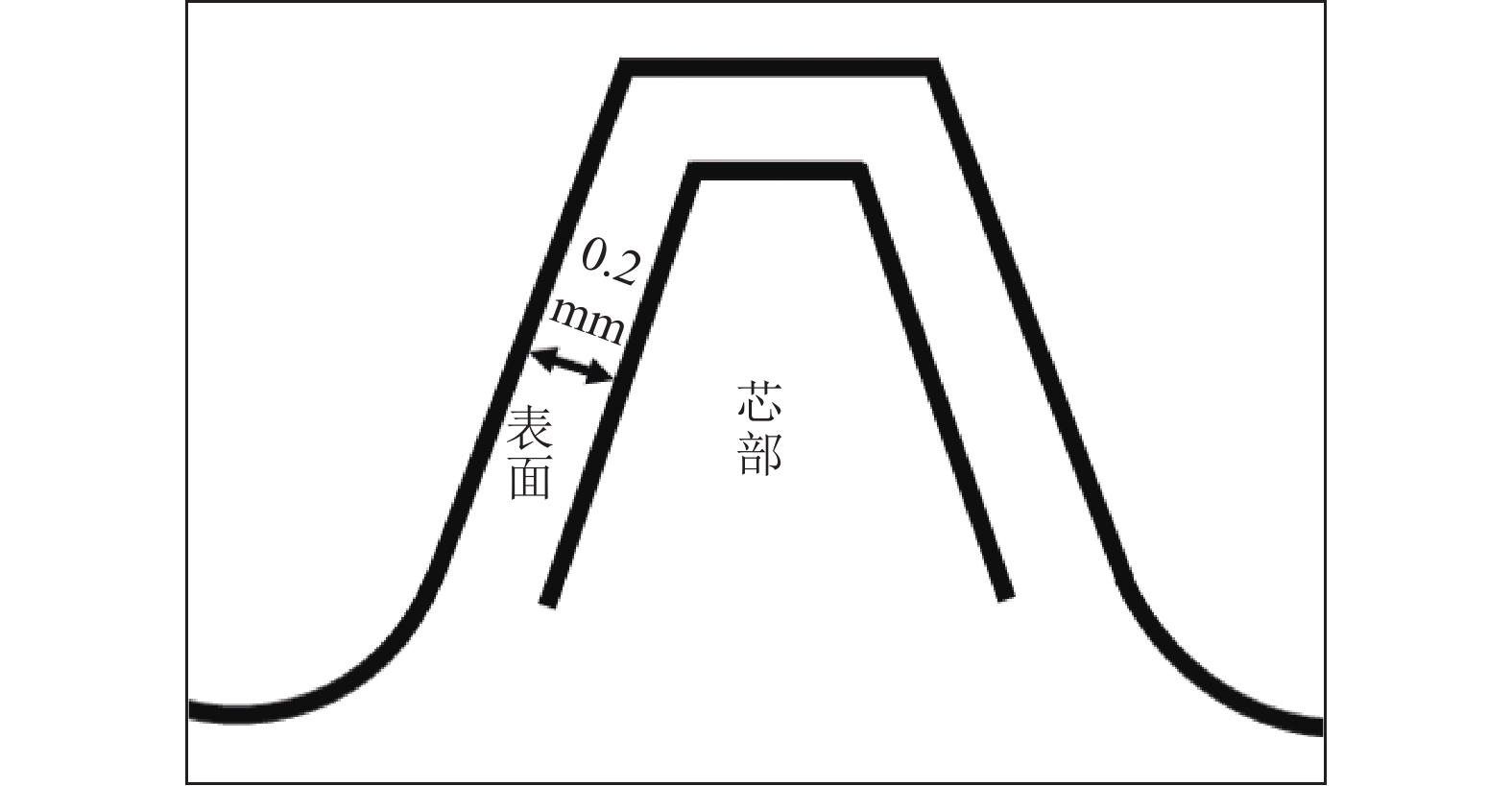

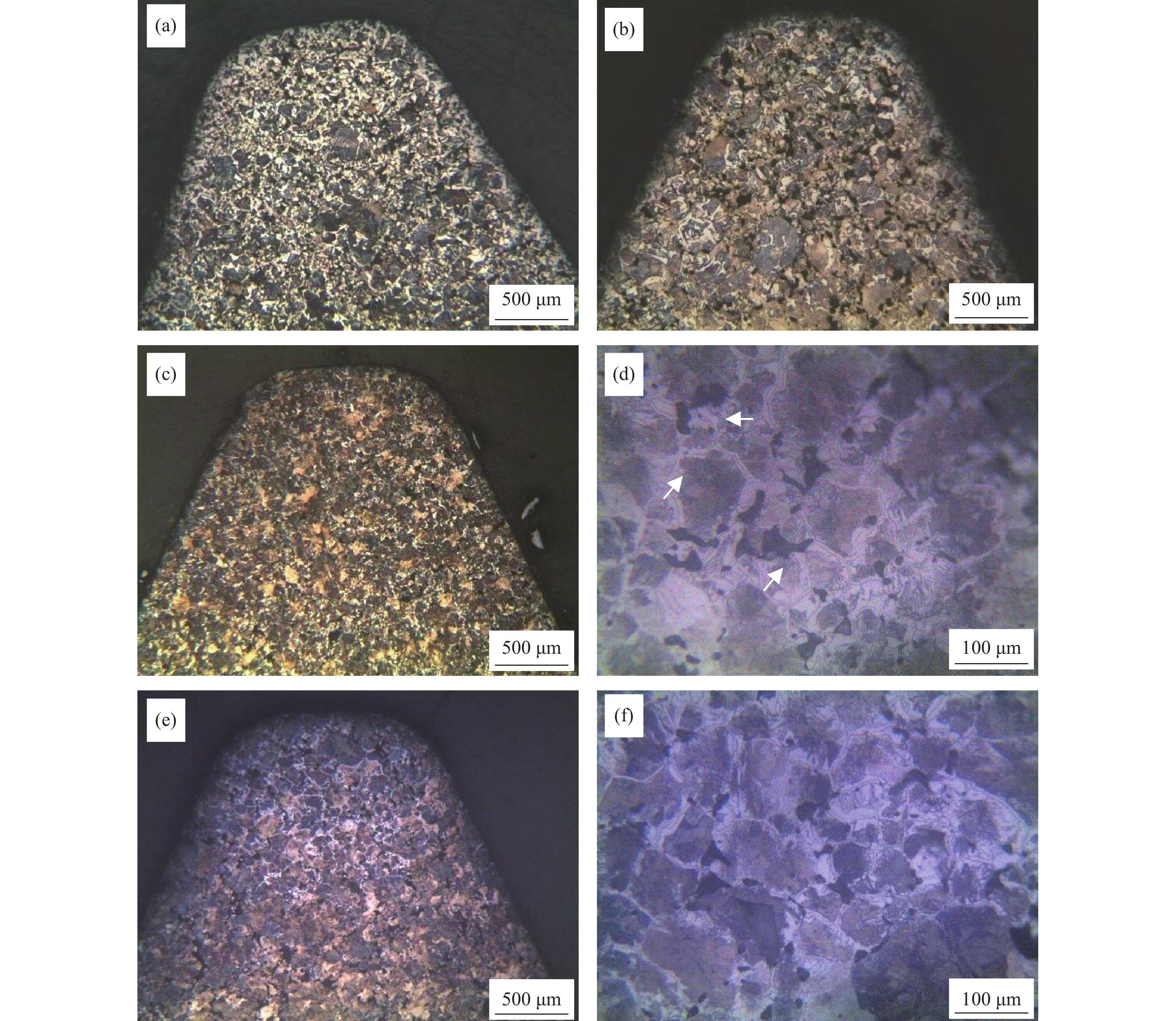

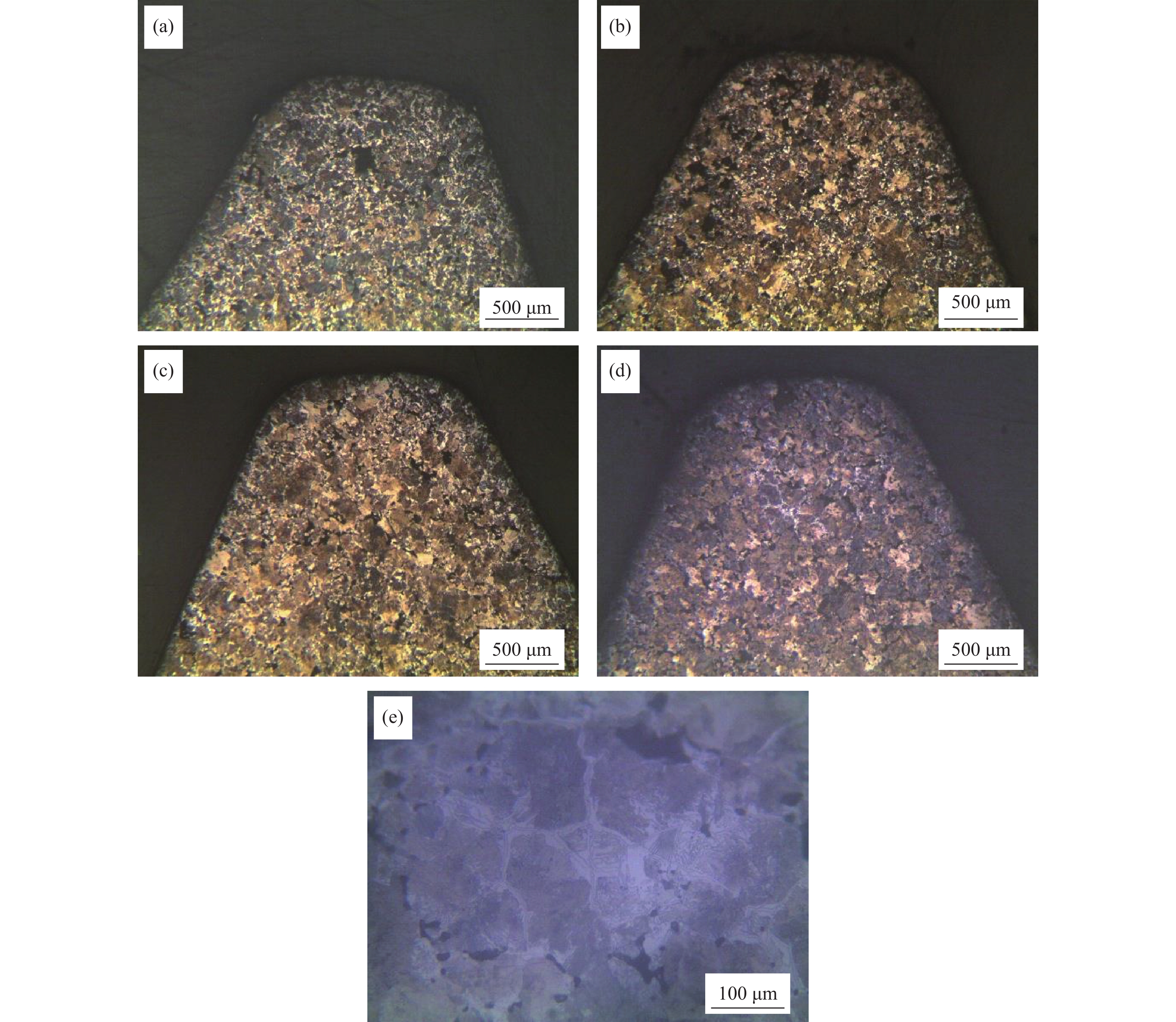

以Fe–Cu–0.8%C合金为原料,采用粉末冶金技术压制成形,研究不同烧结气氛(丙烷裂解和分解氨)条件对烧结产品显微组织的影响。结果表明:在丙烷裂解气氛中烧结,高碳产品表面会出现脱碳现象,产品表面硬度较芯部硬度低HV0.1 40,可通过添加不同流量的瓦斯进行碳补偿,但因补偿不均匀性,产品局部会出现网状渗碳体,影响产品的性能;在分解氨气氛中烧结,产品表面无明显脱碳情况,通过补偿5~10 L·h−1瓦斯即可获得最优的显微组织,而且试样表面与芯部的硬度基本一致。

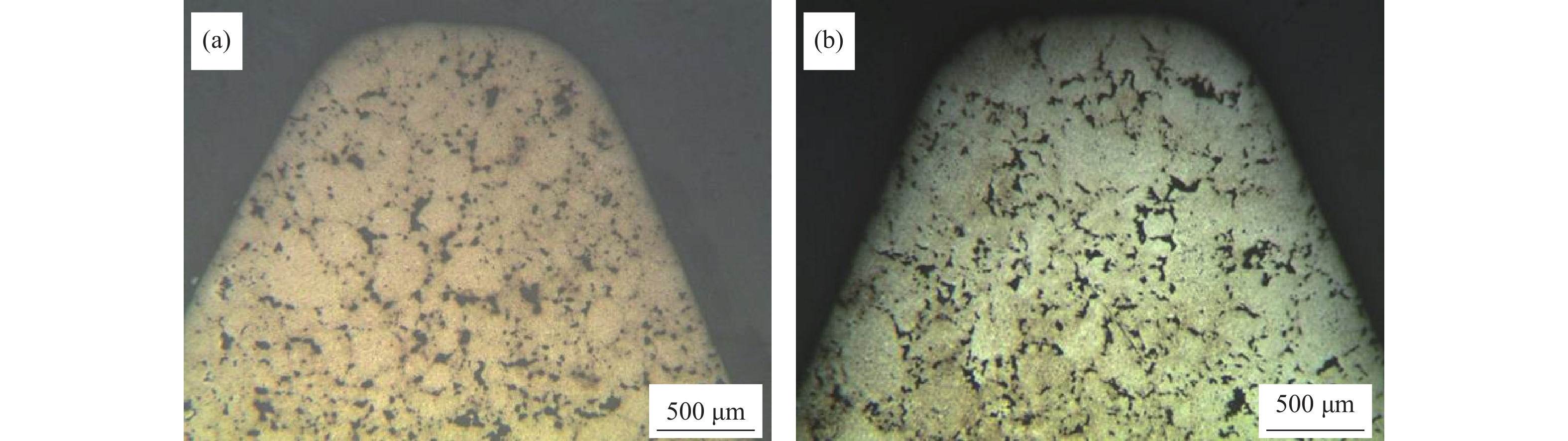

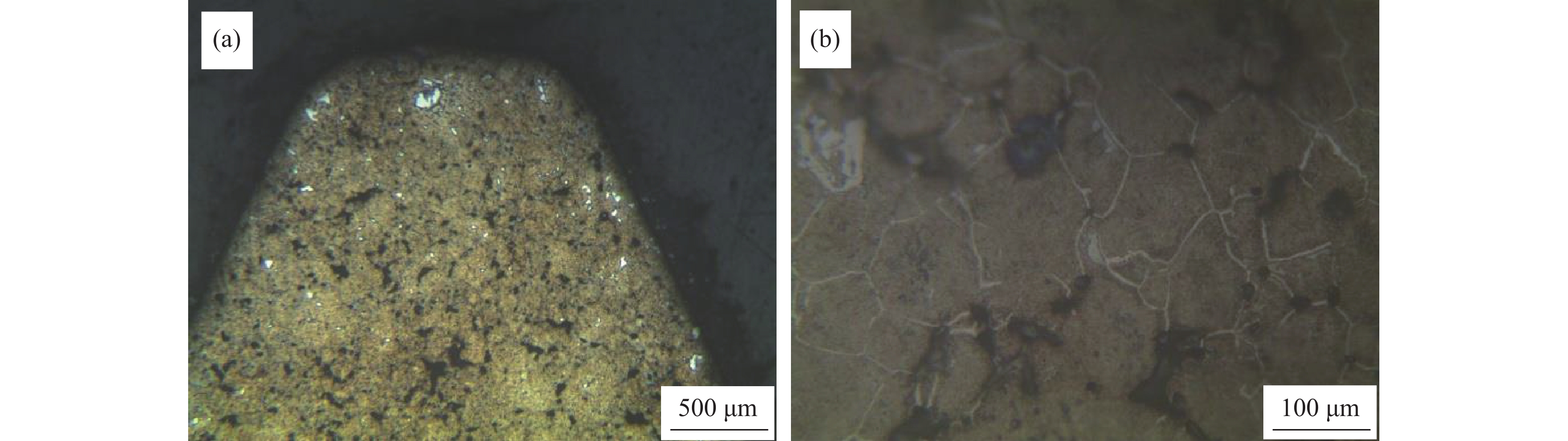

Abstract:The influence of sintering atmosphere (propane cracking and ammonia decomposition) on the microstructure of the Fe–Cu–0.8%C alloy products sintered by powder metallurgy technology was studied. The results show that the decarburization are present on the surface of high-carbon products sintered in propane cracking atmosphere, and the product hardness on the surface is lower than that in the core by HV0.1 40. Carbon compensation can be carried out by adding gas flow, but the network cementite may appear in the part of products because of the uneven compensation, affecting the product performance. There is no obvious decarburization on the surface of the products sintered in decomposed ammonia atmosphere, the optimal microstructure can be obtained by compensating gas flow as 5~10 L·h−1, and the hardness on the surface and in the core of the products are basically the same.

-

-

表 1 实验原料化学成分(质量分数)

Table 1 Chemical composition of the experimental raw materials

% Cu C 润滑剂 Fe 1.75 0.79 0.60 余量 表 2 不同烧结气氛条件下烧结试样平均硬度

Table 2 Average hardness of the Fe–Cu–C alloy products sintered at different sintering atmosphere

试样编号 烧结气氛 瓦斯流量 / (L·h−1) 表面硬度,HV0.1 芯部硬度,HV0.1 1 丙烷裂解 0 213.4 256.1 2 丙烷裂解 50 235.2 268.4 3 丙烷裂解(无渗碳体) 100 264.6 271.0 4 丙烷裂解 150 287.7 305.4 5 分解氨 0 258.9 267.5 6 分解氨 5 267.4 270.3 7 分解氨 10 271.2 268.7 8 分解氨 15 296.8 269.4 -

[1] 胡号, 李雷, 许磊, 等. Cu‒Fe合金制备技术研究进展. 粉末冶金技术, 2019, 37(6): 468 Hu H, Li L, Xu L, et al. Research progress on the preparation technology of Cu‒Fe alloy. Powder Metall Technol, 2019, 37(6): 468

[2] 沈宝龙, 吴菊清. 粉末冶金发展现状及趋势. 上海有色金属, 1994, 15(2): 109 Shen B L, Wu J Q. Present status and the trendency of the development of powder metallurgy. Shanghai Nonferrous Met, 1994, 15(2): 109

[3] 黄伯云, 易健宏. 现代粉末冶金材料和技术发展现状(一). 上海金属, 2007, 29(3): 1 DOI: 10.3969/j.issn.1001-7208.2007.03.001 Huang B Y, Yi J H. Current development of modern powder metallurgy materials and technologies (I). Shanghai Met, 2007, 29(3): 1 DOI: 10.3969/j.issn.1001-7208.2007.03.001

[4] 冯士超, 王艳红, 丁瑞锋. 粉末冶金在钢铁企业的应用及发展前景. 粉末冶金技术, 2015, 33(4): 296 DOI: 10.3969/j.issn.1001-3784.2015.04.011 Feng S C, Wang Y H, Ding R F. Application and prospect of powder metallurgy in steel enterprises. Powder Metall Technol, 2015, 33(4): 296 DOI: 10.3969/j.issn.1001-3784.2015.04.011

[5] 孙芳芳, 马少波, 毕岗, 等. 烧结温度对粉末冶金低合金钢显微组织和力学性能的影响. 机械工程材料, 2017, 41(10): 48 DOI: 10.11973/jxgccl201710011 Sun F F, Ma S B, Bi G, et al. Influence of sintering temperature on microstructure and mechanical properties of powder metallurgy low-alloy steel. Mater Mech Eng, 2017, 41(10): 48 DOI: 10.11973/jxgccl201710011

[6] Leo N T, Kuang Y H, Li Y Y. Warm compaction forming of a binder-treated Fe-base material. J Iron Steel Res Int, 2007, 14(5): 77 DOI: 10.1016/S1006-706X(08)60055-2

[7] 王盘鑫. 粉末冶金学. 北京: 冶金工业出版社, 1997 Wang Z X. Powder Metallurgy. Beijing: Metallurgical Industry Press, 1997

[8] 谭兆强, 王辉, UlfEngström. 粉末冶金钢烧结过程控制和分析. 粉末冶金工业, 2016, 26(6): 62 Tan Z Q, Wang H, UlfEngström. Control and analysis of powder metallurgy steel sintering process. Powder Metall Ind, 2016, 26(6): 62

[9] 韩凤麟. 粉末冶金烧结炉与烧结气氛气体控制. 粉末冶金工业, 2013, 23(1): 1 DOI: 10.3969/j.issn.1006-6543.2013.01.001 Han F L. Powder metallurgy sintering furnaces and protective gas atmospheres control. Powder Metall Ind, 2013, 23(1): 1 DOI: 10.3969/j.issn.1006-6543.2013.01.001

[10] 周华明. N2‒H2系氮基烧结气氛的研究. 粉末冶金技术, 1998, 16(4): 277 Zhou H M. Research of N2‒H2 (nitrogen-based) sintering atmospheres. Powder Metall Technol, 1998, 16(4): 277

[11] 柯美元, 吴裕农. 烧结气氛对不锈钢粉末烧结性能的影响. 顺德职业技术学院学报, 2007, 5(3): 27 DOI: 10.3969/j.issn.1672-6138.2007.03.008 Ke M Y, Wu Y N. Effects of sintering atmosphere on sintered properties of stainless steel powders. J Shunde Polytech, 2007, 5(3): 27 DOI: 10.3969/j.issn.1672-6138.2007.03.008

[12] 于洋. 烧结钢烧结过程中的气氛控制及其对性能的影响(1). 粉末冶金技术, 2002, 20(4): 239 DOI: 10.3321/j.issn:1001-3784.2002.04.010 Yu Y. Atmosphere control during sintering and its influence on the properties of PM steels (1). Powder Metall Technol, 2002, 20(4): 239 DOI: 10.3321/j.issn:1001-3784.2002.04.010

[13] 于洋. 烧结钢生产过程中的尺寸变化及其控制(1). 粉末冶金技术, 2003, 21(1): 46 DOI: 10.3321/j.issn:1001-3784.2003.01.008 Yu Y. Dimensional change and its control during the production of PM steels (1). Powder Metall Technol, 2003, 21(1): 46 DOI: 10.3321/j.issn:1001-3784.2003.01.008

[14] 张陈增, 陈存广, 李沛, 等. 粉末冶金铜铁合金的组织与性能. 粉末冶金技术, 2022, 40(2): 139 Zhang C Z, Chen C G, Li P, et al. Microstructure and properties of Cu‒Fe alloys prepared by powder metallurgy. Powder Metall Technol, 2022, 40(2): 139

[15] 杨芳, 隋延力, 郭志猛, 等. 铁粉表面硫化处理制备高密度Fe‒Cu‒C合金. 工程科学学报, 2017, 39(2): 232 Yang F, Sui Y L, Guo Z M, et al. Sulfurizing treatments on the surface of iron powder for preparing high density Fe‒Cu‒C alloys. Chin J Eng, 2017, 39(2): 232

[16] 胡明, 杨英杰, 李普明, 等. 锰源粉末对Fe‒Mn‒C烧结钢组织和力学性能的影响. 粉末冶金技术, 2020, 38(6): 403 Hu M, Yang Y J, Li P M, et al. Effect of manganese source powders on microstructure and mechanical properties of Fe‒Mn‒C sintered steel. Powder Metall Technol, 2020, 38(6): 403

[17] 夏立芳. 金属热处理工艺学. 哈尔滨: 哈尔滨工业大学出版社, 2012 Xia L F. Heat Treatment Technology of Metals. Harbin: Harbin Institute of Technology Press, 2012

下载:

下载: